JP5592257B2 - 作動弁の故障を検出するための装置および方法 - Google Patents

作動弁の故障を検出するための装置および方法 Download PDFInfo

- Publication number

- JP5592257B2 JP5592257B2 JP2010515574A JP2010515574A JP5592257B2 JP 5592257 B2 JP5592257 B2 JP 5592257B2 JP 2010515574 A JP2010515574 A JP 2010515574A JP 2010515574 A JP2010515574 A JP 2010515574A JP 5592257 B2 JP5592257 B2 JP 5592257B2

- Authority

- JP

- Japan

- Prior art keywords

- ball

- torque

- drive shaft

- valve

- fuel circuit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000000034 method Methods 0.000 title claims description 9

- 239000000446 fuel Substances 0.000 claims description 73

- 238000001514 detection method Methods 0.000 claims description 19

- 238000012423 maintenance Methods 0.000 claims description 15

- 238000013459 approach Methods 0.000 claims description 4

- 230000009471 action Effects 0.000 claims description 3

- 230000008859 change Effects 0.000 claims description 3

- 238000002405 diagnostic procedure Methods 0.000 claims 1

- 230000002093 peripheral effect Effects 0.000 description 8

- 239000002828 fuel tank Substances 0.000 description 6

- 238000012544 monitoring process Methods 0.000 description 6

- 230000005856 abnormality Effects 0.000 description 5

- 239000003638 chemical reducing agent Substances 0.000 description 5

- 230000002950 deficient Effects 0.000 description 5

- 230000033001 locomotion Effects 0.000 description 5

- 230000009467 reduction Effects 0.000 description 3

- 230000005355 Hall effect Effects 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 230000006870 function Effects 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 230000008439 repair process Effects 0.000 description 2

- 230000004044 response Effects 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 230000001627 detrimental effect Effects 0.000 description 1

- 239000013536 elastomeric material Substances 0.000 description 1

- 230000008014 freezing Effects 0.000 description 1

- 238000007710 freezing Methods 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 238000012806 monitoring device Methods 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 230000000737 periodic effect Effects 0.000 description 1

- 230000011664 signaling Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

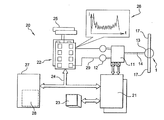

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K37/00—Special means in or on valves or other cut-off apparatus for indicating or recording operation thereof, or for enabling an alarm to be given

- F16K37/0025—Electrical or magnetic means

- F16K37/0041—Electrical or magnetic means for measuring valve parameters

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K31/00—Actuating devices; Operating means; Releasing devices

- F16K31/02—Actuating devices; Operating means; Releasing devices electric; magnetic

- F16K31/04—Actuating devices; Operating means; Releasing devices electric; magnetic using a motor

- F16K31/041—Actuating devices; Operating means; Releasing devices electric; magnetic using a motor for rotating valves

- F16K31/042—Actuating devices; Operating means; Releasing devices electric; magnetic using a motor for rotating valves with electric means, e.g. for controlling the motor or a clutch between the valve and the motor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K31/00—Actuating devices; Operating means; Releasing devices

- F16K31/02—Actuating devices; Operating means; Releasing devices electric; magnetic

- F16K31/04—Actuating devices; Operating means; Releasing devices electric; magnetic using a motor

- F16K31/041—Actuating devices; Operating means; Releasing devices electric; magnetic using a motor for rotating valves

- F16K31/043—Actuating devices; Operating means; Releasing devices electric; magnetic using a motor for rotating valves characterised by mechanical means between the motor and the valve, e.g. lost motion means reducing backlash, clutches, brakes or return means

- F16K31/045—Actuating devices; Operating means; Releasing devices electric; magnetic using a motor for rotating valves characterised by mechanical means between the motor and the valve, e.g. lost motion means reducing backlash, clutches, brakes or return means with torque limiters

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8158—With indicator, register, recorder, alarm or inspection means

- Y10T137/8225—Position or extent of motion indicator

- Y10T137/8242—Electrical

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Indication Of The Valve Opening Or Closing Status (AREA)

- Electrically Driven Valve-Operating Means (AREA)

- Taps Or Cocks (AREA)

- Electrical Control Of Air Or Fuel Supplied To Internal-Combustion Engine (AREA)

- Preventing Unauthorised Actuation Of Valves (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0705053A FR2918731B1 (fr) | 2007-07-12 | 2007-07-12 | Dispositif et procede de detection de panne dans une vanne motorisee |

| FR0705053 | 2007-07-12 | ||

| PCT/FR2008/051276 WO2009016299A2 (fr) | 2007-07-12 | 2008-07-08 | Dispositif et procédé de détection de panne dans une vanne motorisée |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010533270A JP2010533270A (ja) | 2010-10-21 |

| JP2010533270A5 JP2010533270A5 (enExample) | 2014-04-24 |

| JP5592257B2 true JP5592257B2 (ja) | 2014-09-17 |

Family

ID=38969764

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010515574A Expired - Fee Related JP5592257B2 (ja) | 2007-07-12 | 2008-07-08 | 作動弁の故障を検出するための装置および方法 |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US8807161B2 (enExample) |

| EP (1) | EP2171328A2 (enExample) |

| JP (1) | JP5592257B2 (enExample) |

| CN (1) | CN101784827B (enExample) |

| BR (1) | BRPI0814682A2 (enExample) |

| CA (1) | CA2693093C (enExample) |

| FR (1) | FR2918731B1 (enExample) |

| RU (1) | RU2471106C2 (enExample) |

| WO (1) | WO2009016299A2 (enExample) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2962406B1 (fr) | 2010-07-06 | 2013-05-31 | Airbus Operations Sas | Aeronef comprenant une vanne de carburant et un actionneur de commande fixe a la vanne |

| GB2488369B (en) * | 2011-02-28 | 2018-05-09 | Perkins Engines Co Ltd | Monitoring operation of a DC motor valve assembly |

| JP5945149B2 (ja) * | 2012-04-18 | 2016-07-05 | アズビル株式会社 | フィールド機器 |

| US9933088B2 (en) * | 2015-06-10 | 2018-04-03 | Woodward, Inc. | Rotary actuated valve with position indicator |

| CN108138660B (zh) * | 2015-09-25 | 2020-12-18 | 日产自动车株式会社 | 阀控制装置 |

| JP6265195B2 (ja) * | 2015-10-01 | 2018-01-24 | トヨタ自動車株式会社 | 内燃機関の制御装置 |

| US10041420B2 (en) | 2016-08-31 | 2018-08-07 | Borgwarner Inc. | Valve assembly and valve system including same |

| GB2570505A (en) * | 2018-01-29 | 2019-07-31 | Airbus Operations Ltd | Valve apparatus |

| CN113544424A (zh) * | 2019-03-18 | 2021-10-22 | 贝利莫控股公司 | 用于操作控制阀的方法 |

| EP3890459A1 (en) * | 2020-04-03 | 2021-10-06 | Hamilton Sundstrand Corporation | Microswitch based position sensor with harness relief for motorized valve |

| EP3904725A1 (en) * | 2020-05-01 | 2021-11-03 | Illinois Tool Works, Inc. | Gear train for a valve actuator |

| EP3940271B1 (en) * | 2020-07-17 | 2025-02-26 | Goodrich Corporation | Valve assembly with a position sensor assembly |

| CN111998121A (zh) * | 2020-07-28 | 2020-11-27 | 中广核核电运营有限公司 | 用于喷淋阀的检修定位装置及其检修定位方法 |

| US12181074B2 (en) * | 2020-11-20 | 2024-12-31 | Badger Meter, Inc. | Valve providing supplemental feedback during operation |

| CN113503997B (zh) * | 2021-09-02 | 2023-05-26 | 常州亿米基电站辅机有限公司 | 一种用于电动执行器的转矩检测设备 |

| CN115112361B (zh) * | 2022-06-27 | 2023-08-08 | 扬州恒春电子有限公司 | 一种用于检测闸阀阀杆与阀板脱落的方法及装置 |

| CN119467761A (zh) * | 2025-01-06 | 2025-02-18 | 大众阀门集团能源股份有限公司 | 一种介质颗粒防堵球阀 |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3705594A (en) * | 1971-07-01 | 1972-12-12 | North American Mfg Co The | Safety shutoff valve structure and method |

| US4542649A (en) * | 1983-07-19 | 1985-09-24 | Charbonneau And Godfrey Associates | Motor operated valve analysis and testing system |

| JPH01121733A (ja) | 1987-11-05 | 1989-05-15 | Nippon Beeles- Kk | 調節弁の診断装置 |

| US4856327A (en) * | 1988-01-19 | 1989-08-15 | General Physics Corporation | Method and apparatus for monitoring and measuring dynamic loads in thrust inducing systems |

| US5009101A (en) * | 1988-01-19 | 1991-04-23 | Westinghouse Electric Corporation | Method and apparatus for monitoring and measuring dynamic loads in thrust inducing systems |

| DE4107860A1 (de) * | 1991-03-12 | 1992-09-17 | Knebel & Roettger Fa | Verfahren zur erfassung der relativen oeffnungsstellung des elektrisch betaetigbaren kalt- und warmwasserventiles einer sanitaeren mischbatterie |

| US5178361A (en) * | 1992-07-02 | 1993-01-12 | The United States Of America As Represented By The Secretary Of The Army | Ball valve control |

| JPH07194186A (ja) | 1993-12-28 | 1995-07-28 | Nippon Steel Corp | モータ及びその駆動対象の異常診断装置 |

| JPH07280705A (ja) | 1994-04-14 | 1995-10-27 | Toshiba Corp | 弁のオンライン診断装置 |

| DE19504243A1 (de) * | 1994-06-10 | 1995-12-14 | Philips Patentverwaltung | Vorrichtung zum Verstellen eines Stellgliedes |

| US6220566B1 (en) * | 1996-02-16 | 2001-04-24 | Mueller Industries, Inc. | Incrementally positionable ball valve |

| JP2000065246A (ja) * | 1998-08-24 | 2000-03-03 | Toa Valve Co Ltd | 電動弁の異常診断装置 |

| US20030193310A1 (en) | 2002-04-12 | 2003-10-16 | Ford Motor Company | Diagnostic method for an electric motor using torque estimates |

| DK1398550T3 (da) * | 2002-09-11 | 2006-10-02 | Voest Alpine Ind Anlagen | Spærreanordning til spærring og/eller tætning af en rörledning |

| RU2235934C2 (ru) * | 2002-09-13 | 2004-09-10 | ООО "Промтехкомплект" | Автоматизированный электропривод для запорной арматуры |

| EP1558936A4 (en) * | 2002-09-20 | 2008-11-19 | Technotrans America Inc | CURRENT CONTROL FOR TUBES |

| US20050067600A1 (en) * | 2003-09-30 | 2005-03-31 | Wilfert Russell D. | Valve having an actuator that integrates mechanical hard stops |

| JP4367620B2 (ja) | 2003-12-22 | 2009-11-18 | 株式会社デンソー | モータ駆動システムの異常診断装置 |

| RU2273784C1 (ru) * | 2005-04-13 | 2006-04-10 | Закрытое акционерное общество "ЭЛЛИС" | Устройство управления запорно-регулирующим органом трубопроводной арматуры и способ настройки его ограничителя максимального крутящего момента |

-

2007

- 2007-07-12 FR FR0705053A patent/FR2918731B1/fr not_active Expired - Fee Related

-

2008

- 2008-07-08 EP EP08826848A patent/EP2171328A2/fr not_active Withdrawn

- 2008-07-08 JP JP2010515574A patent/JP5592257B2/ja not_active Expired - Fee Related

- 2008-07-08 US US12/668,607 patent/US8807161B2/en active Active

- 2008-07-08 BR BRPI0814682 patent/BRPI0814682A2/pt not_active IP Right Cessation

- 2008-07-08 WO PCT/FR2008/051276 patent/WO2009016299A2/fr not_active Ceased

- 2008-07-08 CN CN2008801043098A patent/CN101784827B/zh not_active Expired - Fee Related

- 2008-07-08 CA CA 2693093 patent/CA2693093C/fr not_active Expired - Fee Related

- 2008-07-08 RU RU2010104862/06A patent/RU2471106C2/ru not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| CA2693093A1 (fr) | 2009-02-05 |

| CN101784827B (zh) | 2012-06-20 |

| US8807161B2 (en) | 2014-08-19 |

| EP2171328A2 (fr) | 2010-04-07 |

| RU2010104862A (ru) | 2011-08-20 |

| US20110042593A1 (en) | 2011-02-24 |

| FR2918731A1 (fr) | 2009-01-16 |

| FR2918731B1 (fr) | 2012-07-20 |

| RU2471106C2 (ru) | 2012-12-27 |

| JP2010533270A (ja) | 2010-10-21 |

| WO2009016299A2 (fr) | 2009-02-05 |

| CN101784827A (zh) | 2010-07-21 |

| CA2693093C (fr) | 2013-10-01 |

| BRPI0814682A2 (pt) | 2015-01-20 |

| WO2009016299A3 (fr) | 2009-06-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5592257B2 (ja) | 作動弁の故障を検出するための装置および方法 | |

| JP2010533270A5 (enExample) | ||

| CN1140858C (zh) | 验证安全设备工作性能的方法和设备 | |

| KR101428203B1 (ko) | 차량용 액티브 에어플랩 장치 및 고장 진단 방법 | |

| NO337580B1 (no) | Nødisolasjonsventil med feilindikator | |

| US11174965B2 (en) | Detecting maintenance statuses of valves | |

| JP2002130531A (ja) | 弁装置における異常診断及び劣化予測方法並びに装置 | |

| KR20190012325A (ko) | 자가진단 기능을 기반으로 하여 안전 기능을 강화한 지능형 콘트롤 밸브 및 이를 이용한 콘트롤 밸브 관리 시스템 | |

| CN108351640B (zh) | 阀门监视 | |

| US20150142340A1 (en) | Device and system for predicting failures of actuated valves | |

| BRPI1103826A2 (pt) | mÉtodo e aparelho monitoramento da operaÇço de equipamento localizado em nÍvel subaquÁtico | |

| JPH0771206A (ja) | 蒸気タービン・システムにおける弁の性能を評価する診断システムおよび方法 | |

| JP6285523B2 (ja) | バルブ用電動アクチュエータと緊急遮断弁・緊急開放弁並びにバルブ用電動アクチュエータの異常診断方法 | |

| WO2011110856A2 (en) | An electric subsea valve actuating device | |

| KR101467744B1 (ko) | 발전소 밸브 테스트 블록장치 및 방법 | |

| US20230193809A1 (en) | Cooling system and method | |

| JP2017053490A5 (enExample) | ||

| US6764059B2 (en) | Valve isolation system | |

| US8413499B2 (en) | Partial stroke testing | |

| JP5203922B2 (ja) | 遮断弁故障検知方法及びガスメータ | |

| US20240151184A1 (en) | Method of determining an operating condition of a valve of an aircraft system | |

| EP4217633B1 (en) | Valve system and method | |

| Li et al. | A review of recent valve health monitoring and diagnosis methods | |

| CN118729046A (zh) | 阀维护辅助装置及辅助方法 | |

| CN120968765A (zh) | 一种可在线检修汽轮机遮断保护装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110629 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130111 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20130409 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20130409 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20131016 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20131127 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20131204 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20140210 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20140218 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20140307 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20140715 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140731 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5592257 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |