JP5551327B2 - 撚りケーブルおよびその製造方法 - Google Patents

撚りケーブルおよびその製造方法 Download PDFInfo

- Publication number

- JP5551327B2 JP5551327B2 JP2002512986A JP2002512986A JP5551327B2 JP 5551327 B2 JP5551327 B2 JP 5551327B2 JP 2002512986 A JP2002512986 A JP 2002512986A JP 2002512986 A JP2002512986 A JP 2002512986A JP 5551327 B2 JP5551327 B2 JP 5551327B2

- Authority

- JP

- Japan

- Prior art keywords

- twisted

- cable

- brittle

- wire

- tape

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000004519 manufacturing process Methods 0.000 title description 11

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 48

- 229910052782 aluminium Inorganic materials 0.000 claims description 47

- 239000000835 fiber Substances 0.000 claims description 44

- 239000011159 matrix material Substances 0.000 claims description 44

- 230000005540 biological transmission Effects 0.000 claims description 28

- 239000004020 conductor Substances 0.000 claims description 23

- 238000005452 bending Methods 0.000 claims description 20

- 239000002131 composite material Substances 0.000 claims description 16

- 229910018072 Al 2 O 3 Inorganic materials 0.000 claims description 13

- 239000002390 adhesive tape Substances 0.000 claims description 9

- 239000004820 Pressure-sensitive adhesive Substances 0.000 claims description 7

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 3

- 229910052799 carbon Inorganic materials 0.000 claims description 3

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 claims description 3

- 229910010271 silicon carbide Inorganic materials 0.000 claims description 3

- 239000010410 layer Substances 0.000 description 50

- 239000011230 binding agent Substances 0.000 description 20

- 229910052751 metal Inorganic materials 0.000 description 18

- 239000002184 metal Substances 0.000 description 18

- 239000000853 adhesive Substances 0.000 description 16

- 230000001070 adhesive effect Effects 0.000 description 16

- 239000000463 material Substances 0.000 description 14

- 229920002430 Fibre-reinforced plastic Polymers 0.000 description 13

- 239000011151 fibre-reinforced plastic Substances 0.000 description 13

- 238000012423 maintenance Methods 0.000 description 12

- 238000000034 method Methods 0.000 description 12

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 8

- 239000011888 foil Substances 0.000 description 7

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 6

- 229910052802 copper Inorganic materials 0.000 description 6

- 239000010949 copper Substances 0.000 description 6

- 229920001187 thermosetting polymer Polymers 0.000 description 6

- 238000004804 winding Methods 0.000 description 6

- 241001589086 Bellapiscis medius Species 0.000 description 5

- 229910045601 alloy Inorganic materials 0.000 description 5

- 239000000956 alloy Substances 0.000 description 5

- 229920003023 plastic Polymers 0.000 description 5

- 239000004033 plastic Substances 0.000 description 5

- 239000011347 resin Substances 0.000 description 5

- 229920005989 resin Polymers 0.000 description 5

- 239000003522 acrylic cement Substances 0.000 description 4

- 229910052742 iron Inorganic materials 0.000 description 4

- 239000011156 metal matrix composite Substances 0.000 description 4

- 229920000728 polyester Polymers 0.000 description 4

- 238000012546 transfer Methods 0.000 description 4

- 229910000838 Al alloy Inorganic materials 0.000 description 3

- 239000004593 Epoxy Substances 0.000 description 3

- 229910000831 Steel Inorganic materials 0.000 description 3

- 239000003795 chemical substances by application Substances 0.000 description 3

- 239000000155 melt Substances 0.000 description 3

- 230000035515 penetration Effects 0.000 description 3

- 229920013639 polyalphaolefin Polymers 0.000 description 3

- 239000013464 silicone adhesive Substances 0.000 description 3

- 239000010959 steel Substances 0.000 description 3

- PNEYBMLMFCGWSK-UHFFFAOYSA-N Alumina Chemical compound [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 2

- 229910000881 Cu alloy Inorganic materials 0.000 description 2

- 239000012790 adhesive layer Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 229920001577 copolymer Polymers 0.000 description 2

- 239000013078 crystal Substances 0.000 description 2

- 239000003733 fiber-reinforced composite Substances 0.000 description 2

- 239000002657 fibrous material Substances 0.000 description 2

- 150000002739 metals Chemical class 0.000 description 2

- 229910052758 niobium Inorganic materials 0.000 description 2

- 239000010955 niobium Substances 0.000 description 2

- GUCVJGMIXFAOAE-UHFFFAOYSA-N niobium atom Chemical compound [Nb] GUCVJGMIXFAOAE-UHFFFAOYSA-N 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 230000003014 reinforcing effect Effects 0.000 description 2

- 239000012783 reinforcing fiber Substances 0.000 description 2

- 238000010079 rubber tapping Methods 0.000 description 2

- 229920005992 thermoplastic resin Polymers 0.000 description 2

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 description 1

- -1 Coated Substances 0.000 description 1

- 239000004971 Cross linker Substances 0.000 description 1

- 244000043261 Hevea brasiliensis Species 0.000 description 1

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 239000002313 adhesive film Substances 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 229920001400 block copolymer Polymers 0.000 description 1

- 125000004432 carbon atom Chemical group C* 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 239000011247 coating layer Substances 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 238000001723 curing Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 230000005489 elastic deformation Effects 0.000 description 1

- 238000010292 electrical insulation Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 239000003365 glass fiber Substances 0.000 description 1

- 229920001519 homopolymer Polymers 0.000 description 1

- 239000012943 hotmelt Substances 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 238000000050 ionisation spectroscopy Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 239000002905 metal composite material Substances 0.000 description 1

- 238000005065 mining Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229910052750 molybdenum Inorganic materials 0.000 description 1

- 239000011733 molybdenum Substances 0.000 description 1

- 239000000178 monomer Substances 0.000 description 1

- 229920003052 natural elastomer Polymers 0.000 description 1

- 229920001194 natural rubber Polymers 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 239000011253 protective coating Substances 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 238000003847 radiation curing Methods 0.000 description 1

- 238000007665 sagging Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 229920001897 terpolymer Polymers 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B5/00—Non-insulated conductors or conductive bodies characterised by their form

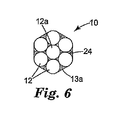

- H01B5/08—Several wires or the like stranded in the form of a rope

- H01B5/10—Several wires or the like stranded in the form of a rope stranded around a space, insulating material, or dissimilar conducting material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B5/00—Non-insulated conductors or conductive bodies characterised by their form

- H01B5/08—Several wires or the like stranded in the form of a rope

- H01B5/10—Several wires or the like stranded in the form of a rope stranded around a space, insulating material, or dissimilar conducting material

- H01B5/102—Several wires or the like stranded in the form of a rope stranded around a space, insulating material, or dissimilar conducting material stranded around a high tensile strength core

- H01B5/105—Several wires or the like stranded in the form of a rope stranded around a space, insulating material, or dissimilar conducting material stranded around a high tensile strength core composed of synthetic filaments, e.g. glass-fibres

Landscapes

- Non-Insulated Conductors (AREA)

- Ropes Or Cables (AREA)

- Manufacturing Of Electric Cables (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US09/616,784 US6559385B1 (en) | 2000-07-14 | 2000-07-14 | Stranded cable and method of making |

| US09/616,784 | 2000-07-14 | ||

| PCT/US2000/031992 WO2002007170A1 (en) | 2000-07-14 | 2000-11-21 | Stranded cable and method of making |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013019229A Division JP2013149621A (ja) | 2000-07-14 | 2013-02-04 | 撚りケーブルおよびその製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2004508660A JP2004508660A (ja) | 2004-03-18 |

| JP2004508660A5 JP2004508660A5 (cg-RX-API-DMAC7.html) | 2008-01-10 |

| JP5551327B2 true JP5551327B2 (ja) | 2014-07-16 |

Family

ID=24470925

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002512986A Expired - Fee Related JP5551327B2 (ja) | 2000-07-14 | 2000-11-21 | 撚りケーブルおよびその製造方法 |

| JP2013019229A Pending JP2013149621A (ja) | 2000-07-14 | 2013-02-04 | 撚りケーブルおよびその製造方法 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013019229A Pending JP2013149621A (ja) | 2000-07-14 | 2013-02-04 | 撚りケーブルおよびその製造方法 |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US6559385B1 (cg-RX-API-DMAC7.html) |

| EP (1) | EP1301930B1 (cg-RX-API-DMAC7.html) |

| JP (2) | JP5551327B2 (cg-RX-API-DMAC7.html) |

| KR (1) | KR100721885B1 (cg-RX-API-DMAC7.html) |

| CN (1) | CN1224982C (cg-RX-API-DMAC7.html) |

| AU (1) | AU2001219251A1 (cg-RX-API-DMAC7.html) |

| CA (1) | CA2413187C (cg-RX-API-DMAC7.html) |

| DE (1) | DE60032948T2 (cg-RX-API-DMAC7.html) |

| ES (1) | ES2278642T3 (cg-RX-API-DMAC7.html) |

| WO (1) | WO2002007170A1 (cg-RX-API-DMAC7.html) |

Families Citing this family (82)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE20018560U1 (de) * | 2000-10-30 | 2002-03-21 | CAMERON GmbH, 29227 Celle | Steuer- und Versorgungssystem |

| DE20115474U1 (de) * | 2001-09-19 | 2003-02-20 | Biester, Klaus, 29342 Wienhausen | Gleichspannungs-Wandlervorrichtung |

| US7615893B2 (en) * | 2000-05-11 | 2009-11-10 | Cameron International Corporation | Electric control and supply system |

| DE20115471U1 (de) | 2001-09-19 | 2003-02-20 | Biester, Klaus, 29342 Wienhausen | Universelles Energieversorgungssystem |

| DE20115473U1 (de) * | 2001-09-19 | 2003-02-20 | Biester, Klaus, 29342 Wienhausen | Universelles Energieversorgungssystem |

| US6723451B1 (en) | 2000-07-14 | 2004-04-20 | 3M Innovative Properties Company | Aluminum matrix composite wires, cables, and method |

| US7020271B2 (en) * | 2003-06-12 | 2006-03-28 | Barbara Isabel Hummel | Ring control device |

| DE20115475U1 (de) * | 2001-09-19 | 2003-02-20 | Biester, Klaus, 29342 Wienhausen | Gleichspannungs-Wandlervorrichtung |

| AU2003221761B2 (en) * | 2002-04-23 | 2008-11-06 | Ctc Cable Corporation | Aluminum conductor composite core reinforced cable and method of manufacture |

| US9093191B2 (en) | 2002-04-23 | 2015-07-28 | CTC Global Corp. | Fiber reinforced composite core for an aluminum conductor cable |

| JP2004212269A (ja) * | 2003-01-07 | 2004-07-29 | Ngk Spark Plug Co Ltd | 温度センサ |

| CN101601574B (zh) | 2003-04-29 | 2013-11-13 | 航空医学有限公司 | 具有照相机附装件的喉镜 |

| US7615127B2 (en) * | 2003-05-13 | 2009-11-10 | Alcan International, Ltd. | Process of producing overhead transmission conductor |

| AU2004284079B2 (en) * | 2003-10-22 | 2011-08-18 | Ctc Cable Corporation | Aluminum conductor composite core reinforced cable and method of manufacture |

| US7438971B2 (en) | 2003-10-22 | 2008-10-21 | Ctc Cable Corporation | Aluminum conductor composite core reinforced cable and method of manufacture |

| US7272284B1 (en) * | 2004-01-29 | 2007-09-18 | Honeywell International Inc. | Bundled cables and method of making the same |

| DE102004005033A1 (de) * | 2004-02-02 | 2005-08-18 | Alstom Technology Ltd | Verfahren zum Herstellen eines aus verröbelten Litzenleitern aufgebauten Leiterstabes sowie nach diesem Verfahren hergestellter Leiterstab |

| US20050181228A1 (en) * | 2004-02-13 | 2005-08-18 | 3M Innovative Properties Company | Metal-cladded metal matrix composite wire |

| US7131308B2 (en) * | 2004-02-13 | 2006-11-07 | 3M Innovative Properties Company | Method for making metal cladded metal matrix composite wire |

| US7093416B2 (en) * | 2004-06-17 | 2006-08-22 | 3M Innovative Properties Company | Cable and method of making the same |

| US20050279527A1 (en) * | 2004-06-17 | 2005-12-22 | Johnson Douglas E | Cable and method of making the same |

| US20050279526A1 (en) * | 2004-06-17 | 2005-12-22 | Johnson Douglas E | Cable and method of making the same |

| DE102004043020B3 (de) * | 2004-09-06 | 2006-04-27 | eupec Europäische Gesellschaft für Leistungshalbleiter mbH | Bonddraht und Bondverbindung |

| JP4804860B2 (ja) | 2004-10-27 | 2011-11-02 | 古河電気工業株式会社 | 複合撚線導体 |

| US8413723B2 (en) | 2006-01-12 | 2013-04-09 | Schlumberger Technology Corporation | Methods of using enhanced wellbore electrical cables |

| US7326854B2 (en) * | 2005-06-30 | 2008-02-05 | Schlumberger Technology Corporation | Cables with stranded wire strength members |

| US7462781B2 (en) * | 2005-06-30 | 2008-12-09 | Schlumberger Technology Corporation | Electrical cables with stranded wire strength members |

| US7511245B2 (en) * | 2005-09-12 | 2009-03-31 | Nelson Stud Welding, Inc. | Stud welding apparatus with composite cable |

| US7228627B1 (en) * | 2005-12-16 | 2007-06-12 | United States Alumoweld Co., Inc. | Method of manufacturing a high strength aluminum-clad steel strand core wire for ACSR power transmission cables |

| CA2635709C (en) * | 2005-12-30 | 2013-11-05 | 3M Innovative Properties Company | Ceramic oxide fibers |

| US7353602B2 (en) * | 2006-03-07 | 2008-04-08 | 3M Innovative Properties Company | Installation of spliced electrical transmission cables |

| US7390963B2 (en) * | 2006-06-08 | 2008-06-24 | 3M Innovative Properties Company | Metal/ceramic composite conductor and cable including same |

| US7921005B2 (en) * | 2006-12-28 | 2011-04-05 | 3M Innovative Properties Company | Method for selecting conductors of an overhead power transmission line |

| US7547843B2 (en) * | 2006-12-28 | 2009-06-16 | 3M Innovative Properties Company | Overhead electrical power transmission line |

| US7687710B2 (en) | 2006-12-28 | 2010-03-30 | 3M Innovative Properties Company | Overhead electrical power transmission line |

| DE102007014605A1 (de) * | 2007-03-23 | 2008-09-25 | Alexander Binzel Schweisstechnik Gmbh & Co. Kg | Schlauchpaket |

| US8697992B2 (en) * | 2008-02-01 | 2014-04-15 | Schlumberger Technology Corporation | Extended length cable assembly for a hydrocarbon well application |

| US8525033B2 (en) * | 2008-08-15 | 2013-09-03 | 3M Innovative Properties Company | Stranded composite cable and method of making and using |

| US20100059249A1 (en) * | 2008-09-09 | 2010-03-11 | Powers Wilber F | Enhanced Strength Conductor |

| FR2941812A1 (fr) | 2009-02-03 | 2010-08-06 | Nexans | Cable de transmission electrique a haute tension. |

| US11387014B2 (en) | 2009-04-17 | 2022-07-12 | Schlumberger Technology Corporation | Torque-balanced, gas-sealed wireline cables |

| US9412492B2 (en) | 2009-04-17 | 2016-08-09 | Schlumberger Technology Corporation | Torque-balanced, gas-sealed wireline cables |

| US12163394B2 (en) | 2009-04-17 | 2024-12-10 | Schlumberger Technology Corporation | Reduced torque wireline cable |

| CA2767809A1 (en) | 2009-07-16 | 2011-01-20 | 3M Innovative Properties Company | Submersible composite cable and methods |

| AU2010298356B2 (en) | 2009-09-22 | 2015-12-17 | Schlumberger Technology B.V. | Wireline cable for use with downhole tractor assemblies |

| EA021355B1 (ru) | 2009-11-11 | 2015-05-29 | Бореалис Аг | Кабель и способ его получения |

| US11078312B2 (en) | 2009-11-11 | 2021-08-03 | Borealis Ag | Crosslinkable polymer composition and cable with advantageous electrical properties |

| BR112012011290B1 (pt) * | 2009-11-11 | 2022-07-12 | Borealis Ag | Composição polimérica compreendendo uma poliolefina produzida em um processo de alta pressão, cabo de força e processos de produção |

| CN102597021B (zh) | 2009-11-11 | 2014-07-23 | 博瑞立斯有限公司 | 聚合物组合物和包括该聚合物组合物的电力电缆 |

| CN101707069B (zh) * | 2009-11-23 | 2011-07-20 | 常州市利多合金材料有限公司 | 绞合线 |

| CN102834876A (zh) * | 2010-02-01 | 2012-12-19 | 3M创新有限公司 | 绞合热塑性聚合物复合缆线及其制备和使用方法 |

| WO2011103036A1 (en) | 2010-02-18 | 2011-08-25 | 3M Innovative Properties Company | Compression connector and assembly for composite cables and methods for making and using same |

| US8901425B2 (en) * | 2010-10-15 | 2014-12-02 | Schlumberger Technology Corporatoon | Wireline cables not requiring seasoning |

| CN102398533A (zh) * | 2010-09-09 | 2012-04-04 | 北京盈电电气有限公司 | 一种防疲劳型预绞式保护条 |

| EP2617043B1 (en) | 2010-09-17 | 2018-12-19 | 3M Innovative Properties Company | Fiber-reinforced nanoparticle-loaded thermoset polymer composite wires and cables as well as processes for their production |

| US8454186B2 (en) | 2010-09-23 | 2013-06-04 | Willis Electric Co., Ltd. | Modular lighted tree with trunk electical connectors |

| ES2750266T3 (es) | 2010-11-03 | 2020-03-25 | Borealis Ag | Una composición de polímero y un cable de alimentación que comprende la composición de polímero |

| CN102074316B (zh) * | 2010-12-24 | 2012-07-11 | 领亚电子科技股份有限公司 | 一种电线电缆外被挤出同步包带方法及实施该方法的设备 |

| US9440272B1 (en) | 2011-02-07 | 2016-09-13 | Southwire Company, Llc | Method for producing aluminum rod and aluminum wire |

| EP3048615B1 (en) | 2011-04-12 | 2018-01-03 | Ticona LLC | Composite core for electrical transmission cables |

| PL2697800T3 (pl) | 2011-04-12 | 2017-07-31 | Southwire Company, Llc | Kable do transmisji elektrycznej z rdzeniami kompozytowymi |

| CN102602083B (zh) * | 2012-03-20 | 2014-10-22 | 浙江顺天复合材料有限公司 | 一种纤维增强复合材料芯及其制备方法 |

| CN103373246A (zh) * | 2012-04-13 | 2013-10-30 | 北京盈电电气有限公司 | 一种承力索用预绞式铠装接续线夹 |

| US9044056B2 (en) | 2012-05-08 | 2015-06-02 | Willis Electric Co., Ltd. | Modular tree with electrical connector |

| US8978239B2 (en) * | 2013-01-09 | 2015-03-17 | General Electric Company | Field coil winding assembly |

| JP6074336B2 (ja) * | 2013-08-06 | 2017-02-01 | 日新製鋼株式会社 | アルミニウム電線の接続構造 |

| CN103854795A (zh) * | 2013-09-10 | 2014-06-11 | 安徽华源电缆集团有限公司 | 一种船用耐火电力电缆 |

| US9140438B2 (en) | 2013-09-13 | 2015-09-22 | Willis Electric Co., Ltd. | Decorative lighting with reinforced wiring |

| US9157588B2 (en) | 2013-09-13 | 2015-10-13 | Willis Electric Co., Ltd | Decorative lighting with reinforced wiring |

| US11306881B2 (en) | 2013-09-13 | 2022-04-19 | Willis Electric Co., Ltd. | Tangle-resistant decorative lighting assembly |

| CA2946387A1 (en) | 2015-10-26 | 2017-04-26 | Willis Electric Co., Ltd. | Tangle-resistant decorative lighting assembly |

| US10315590B2 (en) * | 2016-06-14 | 2019-06-11 | Hitachi Metals, Ltd. | Cable and wire harness |

| CN105929507B (zh) * | 2016-06-29 | 2018-04-03 | 深圳长飞智连技术有限公司 | 一种具有粘接涂覆层的钢丝加强元件及其制造方法 |

| AU2017398629B2 (en) * | 2017-02-08 | 2022-04-07 | Prysmian S.P.A. | Cable or flexible pipe with improved tensile elements |

| US10388435B2 (en) | 2017-06-26 | 2019-08-20 | Panduit Corp. | Communications cable with improved electro-magnetic performance |

| US20200126686A1 (en) * | 2018-10-18 | 2020-04-23 | Saudi Arabian Oil Company | Power cable with non-conductive armor |

| CN110197745A (zh) * | 2019-03-28 | 2019-09-03 | 中复碳芯电缆科技有限公司 | 一种多股复合材料加强芯及其制备方法 |

| US12436347B2 (en) | 2019-06-28 | 2025-10-07 | Schlumberger Technology Corporation | Stranded fiber-optic cable |

| EP3798703A1 (en) * | 2019-09-26 | 2021-03-31 | Services Petroliers Schlumberger | Cable for downhole use |

| BR112022017374A2 (pt) * | 2020-03-13 | 2022-10-18 | Galactic Co Llc | Cabos de controle compósitos e tendões estabilizadores para aplicações em aeronave e método para a fabricação dos mesmos |

| CN112099161A (zh) * | 2020-08-13 | 2020-12-18 | 浙江东通光网物联科技有限公司 | 一种无需扎纱的光缆 |

| EP4352562A4 (en) | 2021-06-10 | 2025-04-16 | Services Pétroliers Schlumberger | ELECTRO-OPTIC METAL CABLES |

Family Cites Families (35)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2883314A (en) | 1955-03-24 | 1959-04-21 | Western Electric Co | Methods of making insulated conductors |

| US3294604A (en) | 1960-12-20 | 1966-12-27 | Anaconda Wire & Cable Co | Method of making electric cable having compressed insulation |

| US3631519A (en) * | 1970-12-21 | 1971-12-28 | Gen Electric | Stress graded cable termination |

| JPS58150913A (ja) * | 1982-03-03 | 1983-09-07 | Furukawa Electric Co Ltd:The | 光ケ−ブル |

| JPS6134167A (ja) | 1984-03-22 | 1986-02-18 | Agency Of Ind Science & Technol | Frm用プリフオ−ムワイヤ−,プリフオ−ムシ−トまたはテ−プの製造方法および該方法に用いられる超音波振動装置 |

| US4751269A (en) * | 1985-07-08 | 1988-06-14 | Minnesota Mining And Manufacturing Company | Crosslinked pressure-sensitive adhesive |

| JPS63195235A (ja) * | 1987-02-10 | 1988-08-12 | Sumitomo Chem Co Ltd | 繊維強化金属複合材料 |

| DE3710298A1 (de) * | 1987-03-28 | 1988-10-06 | Nicolay Gmbh | Der feuchtigkeit ausgesetztes kabel mit wenigstens einem lahnlitzenleiter |

| DE3822543C2 (de) | 1988-07-04 | 1995-05-24 | Rheydt Kabelwerk Ag | Verfahren zum Herstellen eines gefüllten Kabels |

| JPH02155129A (ja) | 1988-12-05 | 1990-06-14 | Fujikura Ltd | 繊維強化プラスチック線がい装ケーブルの製造方法 |

| CA1313237C (en) | 1989-05-05 | 1993-01-26 | Robert R. Pawluk | Armoured electric cable with integral tensile members |

| JPH03129606A (ja) | 1989-07-27 | 1991-06-03 | Hitachi Cable Ltd | 架空送電線 |

| JPH03101004A (ja) * | 1989-09-13 | 1991-04-25 | Furukawa Electric Co Ltd:The | 架空送電線 |

| JP3176390B2 (ja) | 1990-06-13 | 2001-06-18 | 宇部日東化成株式会社 | 強化プラスチック製鎧装ケーブルの製造方法 |

| JPH0465022A (ja) * | 1990-07-02 | 1992-03-02 | Sumitomo Electric Ind Ltd | 自動車用電線導体 |

| JPH04296316A (ja) | 1990-12-18 | 1992-10-20 | General Electric Co <Ge> | 耐熱性樹脂組成物、製品及び方法 |

| US5171942A (en) | 1991-02-28 | 1992-12-15 | Southwire Company | Oval shaped overhead conductor and method for making same |

| JPH04304333A (ja) * | 1991-03-25 | 1992-10-27 | Aluminum Co Of America <Alcoa> | アルミニウムまたはアルミニウム合金をマトリクスとする複合材料およびその強化材とマトリクスとの濡れおよび結合を向上させる方法 |

| JP3101004B2 (ja) | 1991-07-08 | 2000-10-23 | 株式会社リコー | 光走査装置 |

| TW222668B (cg-RX-API-DMAC7.html) * | 1992-03-19 | 1994-04-21 | Minnesota Mining & Mfg | |

| SE9201080D0 (sv) * | 1992-04-03 | 1992-04-03 | Asea Cerama Ab | Saett att framstaella fiberkompositer |

| JPH05290632A (ja) * | 1992-04-13 | 1993-11-05 | Furukawa Electric Co Ltd:The | Al架空電線 |

| JPH0583931U (ja) * | 1992-04-16 | 1993-11-12 | 古河電気工業株式会社 | 架空送電線 |

| US5243137A (en) | 1992-06-25 | 1993-09-07 | Southwire Company | Overhead transmission conductor |

| JP3182939B2 (ja) * | 1992-11-27 | 2001-07-03 | 住友電気工業株式会社 | 複合材の製造方法 |

| JPH06187851A (ja) * | 1992-12-18 | 1994-07-08 | Hitachi Cable Ltd | 架空送電線用繊維強化複合素線の製造方法及び製造装置 |

| JPH07335029A (ja) | 1994-06-03 | 1995-12-22 | Furukawa Electric Co Ltd:The | 架空送電線 |

| JP3129606B2 (ja) | 1994-08-17 | 2001-01-31 | 住友ベークライト株式会社 | 複合成形物 |

| US6245425B1 (en) | 1995-06-21 | 2001-06-12 | 3M Innovative Properties Company | Fiber reinforced aluminum matrix composite wire |

| US6022914A (en) * | 1995-11-27 | 2000-02-08 | 3M Innovative Properties Company | Pressure-sensitive adhesive composition and tapes |

| JPH09198922A (ja) * | 1996-01-22 | 1997-07-31 | Tokyo Electric Power Co Inc:The | 繊維強化複合電線及びその製造方法 |

| JPH1021758A (ja) | 1996-07-02 | 1998-01-23 | Hitachi Cable Ltd | テンションメンバー付電力ケーブル |

| JP3067649B2 (ja) * | 1996-07-04 | 2000-07-17 | 住友金属工業株式会社 | 高合金継目無鋼管の管圧延方法 |

| EP0834662B1 (en) * | 1996-10-03 | 2002-09-11 | Nippon Cable System Inc. | Inner cable for push-pull control cable |

| JPH10321048A (ja) * | 1997-05-16 | 1998-12-04 | Furukawa Electric Co Ltd:The | テンションメンバ、それを用いた軽量低弛度架空電線 |

-

2000

- 2000-07-14 US US09/616,784 patent/US6559385B1/en not_active Expired - Lifetime

- 2000-11-21 KR KR1020037000462A patent/KR100721885B1/ko not_active Expired - Fee Related

- 2000-11-21 CA CA2413187A patent/CA2413187C/en not_active Expired - Fee Related

- 2000-11-21 ES ES00982188T patent/ES2278642T3/es not_active Expired - Lifetime

- 2000-11-21 JP JP2002512986A patent/JP5551327B2/ja not_active Expired - Fee Related

- 2000-11-21 DE DE60032948T patent/DE60032948T2/de not_active Expired - Lifetime

- 2000-11-21 AU AU2001219251A patent/AU2001219251A1/en not_active Abandoned

- 2000-11-21 WO PCT/US2000/031992 patent/WO2002007170A1/en not_active Ceased

- 2000-11-21 EP EP00982188A patent/EP1301930B1/en not_active Expired - Lifetime

- 2000-11-21 CN CNB008197555A patent/CN1224982C/zh not_active Expired - Lifetime

-

2013

- 2013-02-04 JP JP2013019229A patent/JP2013149621A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| AU2001219251A1 (en) | 2002-01-30 |

| KR20030016398A (ko) | 2003-02-26 |

| CN1454386A (zh) | 2003-11-05 |

| JP2013149621A (ja) | 2013-08-01 |

| CA2413187C (en) | 2010-06-29 |

| KR100721885B1 (ko) | 2007-05-25 |

| CA2413187A1 (en) | 2002-01-24 |

| US6559385B1 (en) | 2003-05-06 |

| WO2002007170A1 (en) | 2002-01-24 |

| DE60032948D1 (de) | 2007-02-22 |

| ES2278642T3 (es) | 2007-08-16 |

| JP2004508660A (ja) | 2004-03-18 |

| EP1301930B1 (en) | 2007-01-10 |

| CN1224982C (zh) | 2005-10-26 |

| DE60032948T2 (de) | 2007-10-25 |

| EP1301930A1 (en) | 2003-04-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5551327B2 (ja) | 撚りケーブルおよびその製造方法 | |

| JP5568131B2 (ja) | 絶縁複合体電力ケーブル、並びにその作製及び使用方法 | |

| RU2372697C1 (ru) | Установка состыкованных кабелей электропередачи | |

| JP5628172B2 (ja) | 撚り複合体ケーブル並びにその製造及び使用の方法 | |

| KR101750131B1 (ko) | 복합 케이블을 위한 압축 커넥터 및 조립체와 이를 제조 및 사용하기 위한 방법 | |

| CN102834876A (zh) | 绞合热塑性聚合物复合缆线及其制备和使用方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20071113 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20071113 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20101130 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20110224 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20110303 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110530 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120214 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20120514 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20120521 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20121002 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130204 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20130212 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20130315 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130701 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130705 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140212 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140326 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140522 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5551327 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |