JP5268626B2 - Plasma processing equipment - Google Patents

Plasma processing equipment Download PDFInfo

- Publication number

- JP5268626B2 JP5268626B2 JP2008331822A JP2008331822A JP5268626B2 JP 5268626 B2 JP5268626 B2 JP 5268626B2 JP 2008331822 A JP2008331822 A JP 2008331822A JP 2008331822 A JP2008331822 A JP 2008331822A JP 5268626 B2 JP5268626 B2 JP 5268626B2

- Authority

- JP

- Japan

- Prior art keywords

- sample

- gas

- processed

- diameter

- gas supply

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000002347 injection Methods 0.000 claims description 9

- 239000007924 injection Substances 0.000 claims description 9

- 238000004381 surface treatment Methods 0.000 claims description 4

- 239000011148 porous material Substances 0.000 claims description 2

- 239000007789 gas Substances 0.000 description 171

- 238000005530 etching Methods 0.000 description 17

- 238000009826 distribution Methods 0.000 description 12

- 238000000034 method Methods 0.000 description 10

- 230000002093 peripheral effect Effects 0.000 description 10

- 239000000203 mixture Substances 0.000 description 8

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 6

- 239000006185 dispersion Substances 0.000 description 6

- 229910052710 silicon Inorganic materials 0.000 description 6

- 239000010703 silicon Substances 0.000 description 6

- 230000000694 effects Effects 0.000 description 5

- 239000004065 semiconductor Substances 0.000 description 5

- 238000001179 sorption measurement Methods 0.000 description 4

- 239000000463 material Substances 0.000 description 3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- 239000007795 chemical reaction product Substances 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 230000002950 deficient Effects 0.000 description 2

- 238000001312 dry etching Methods 0.000 description 2

- 150000002500 ions Chemical class 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000005457 optimization Methods 0.000 description 2

- 239000000047 product Substances 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 229910052814 silicon oxide Inorganic materials 0.000 description 2

- BOTDANWDWHJENH-UHFFFAOYSA-N Tetraethyl orthosilicate Chemical compound CCO[Si](OCC)(OCC)OCC BOTDANWDWHJENH-UHFFFAOYSA-N 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- NBVXSUQYWXRMNV-UHFFFAOYSA-N fluoromethane Chemical compound FC NBVXSUQYWXRMNV-UHFFFAOYSA-N 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 238000001459 lithography Methods 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 238000001020 plasma etching Methods 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/306—Chemical or electrical treatment, e.g. electrolytic etching

- H01L21/3065—Plasma etching; Reactive-ion etching

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67017—Apparatus for fluid treatment

- H01L21/67063—Apparatus for fluid treatment for etching

- H01L21/67069—Apparatus for fluid treatment for etching for drying etching

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32009—Arrangements for generation of plasma specially adapted for examination or treatment of objects, e.g. plasma sources

- H01J37/32082—Radio frequency generated discharge

- H01J37/32091—Radio frequency generated discharge the radio frequency energy being capacitively coupled to the plasma

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32431—Constructional details of the reactor

- H01J37/3244—Gas supply means

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- General Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Drying Of Semiconductors (AREA)

- Cleaning Or Drying Semiconductors (AREA)

- Plasma Technology (AREA)

Description

本発明は、半導体デバイスを製造するプラズマ処理装置にかかり、特に、レジスト材料等で形成されたマスクパタン形状どおりにシリコンやシリコン酸化膜等の半導体材料をエッチングするドライエッチング技術に関する。 The present invention relates to a plasma processing apparatus for manufacturing a semiconductor device, and more particularly to a dry etching technique for etching a semiconductor material such as silicon or a silicon oxide film according to a mask pattern shape formed of a resist material or the like.

ドライエッチングは、真空排気手段を有する真空容器内に原料ガスを導入し、該原料ガスを電磁波によりプラズマ化して被加工試料にさらし、被加工試料表面のマスク部以外をエッチングすることで所望の形状を得る半導体微細加工方法である。被加工試料面内での加工均一性にはプラズマの分布,被加工試料面内の温度分布,供給ガスの組成および流量分布等が影響する。 In dry etching, a raw material gas is introduced into a vacuum vessel having a vacuum exhaust means, the raw material gas is converted into plasma by electromagnetic waves, exposed to a sample to be processed, and a portion other than the mask portion on the surface of the sample to be processed is etched. Is a semiconductor microfabrication method. The processing uniformity within the surface of the sample to be processed is influenced by the plasma distribution, the temperature distribution within the surface of the sample to be processed, the composition of the supply gas, the flow rate distribution, and the like.

特に平行平板型のプラズマ装置では、被加工試料の対面に配置されるシャワープレートから原料ガスが供給され、かつ被加工試料とシャワープレート間の距離も比較的短いことからシャワープレートから供給されるガス供給分布が、加工速度や加工形状等に影響する。 In particular, in a parallel plate type plasma apparatus, the source gas is supplied from a shower plate arranged on the opposite side of the sample to be processed, and the distance between the sample to be processed and the shower plate is relatively short, so the gas supplied from the shower plate Supply distribution affects the processing speed, processing shape, and the like.

この特性を活用して、シャワープレートの中心部と周辺部で独立にガス組成や流量を制御することで加工形状等の被加工面内均一性を向上させているプラズマ処理装置が、例えば、特許文献1により提案されている。

A plasma processing apparatus that uses this characteristic to improve the in-plane uniformity of the processed shape, for example, by controlling the gas composition and flow rate independently at the center and the peripheral part of the shower plate is, for example, a patent Proposed by

図7に従来のシャワープレートを示す。 FIG. 7 shows a conventional shower plate.

通常、シャワープレートガス供給面5上には複数のガス噴出し孔2を全て均等に配置し、かつ基本的に微細孔1個当たりから噴出するガスの組成や流量は同様であり被加工試料の単位面積あたりのガス供給状態が均等になるよう設計されている。

Usually, all of the plurality of

また、被加工試料面内の中心部と周辺部で大まかにガスの供給量を制御し、反応生成物等の影響を相殺して加工形状の均一化を実現している。 In addition, the gas supply amount is roughly controlled at the center and the periphery in the sample surface to be processed, and the influence of reaction products and the like is offset to achieve uniform processing shape.

特許文献1に示されるガス供給分布構造においては、中心領域と周辺領域の2領域間では孔1個当たりから噴出するガス組成や流量は異なるが、それぞれの領域内の孔では同様な組成および流量のガスが噴出する構造となっている。

In the gas supply distribution structure shown in

シャワープレートに形成されるガス供給孔は、基本的に均等に配置されているため、被加工試料の外周部でガスの供給量が中心付近に比べ相対的に少なくなる傾向にある。 Since the gas supply holes formed in the shower plate are basically arranged uniformly, the gas supply amount tends to be relatively small at the outer peripheral portion of the sample to be processed compared to the vicinity of the center.

特に、狭ギャップ型の装置では、シャワープレートと被加工試料間の距離が短いため、このガス供給量の不均一に伴う被加工試料外周部での形状不均一が問題となる場合がある。 In particular, in the narrow gap type apparatus, since the distance between the shower plate and the sample to be processed is short, there is a case where the shape non-uniformity in the outer peripheral portion of the sample to be processed due to the nonuniformity of the gas supply amount becomes a problem.

図3に、ウエハ(被加工試料)直径をD(300mm),ウエハからシャワープレートまでの距離をLとした時、アスペクト比(D/L)と相対ガス分子到達量との関係を示す。これは、シャワープレートの各ガス噴出し孔から均等に噴出したガス分子が等方拡散した場合を仮定し、また、ウエハに対面するガス噴出し孔がウエハ直径と同一径でかつ単位面積あたりの孔数が均一な場合を仮定して、対面するウエハに到達するガス分子の相対量を一次元で計算した結果である。 FIG. 3 shows the relationship between the aspect ratio (D / L) and the amount of relative gas molecules when the diameter of the wafer (sample to be processed) is D (300 mm) and the distance from the wafer to the shower plate is L. This is based on the assumption that gas molecules ejected uniformly from each gas ejection hole of the shower plate diffuse isotropically, and the gas ejection holes facing the wafer have the same diameter as the wafer diameter and per unit area. This is a result of one-dimensional calculation of the relative amount of gas molecules that reach the facing wafer, assuming that the number of holes is uniform.

図3に示すように、ウエハ面に到達するガス分子の相対量はアスペクト比が大きくなるとウエハ外周部で不足気味となることが分かる。つまり、アスペクト比1以上、即ちウエハ直径がφ300mmの場合、ウエハとシャワープレートの距離が300mm以下の場合からウエハ端部でのガス供給量の相対的な不足が生じることが判った。実質的には、アスペクト比が2以上となると、供給量の差を許容できなくなることが判った。 As shown in FIG. 3, it can be seen that the relative amount of gas molecules reaching the wafer surface becomes deficient at the outer periphery of the wafer as the aspect ratio increases. That is, it was found that when the aspect ratio is 1 or more, that is, the wafer diameter is 300 mm, a relative shortage of the gas supply amount at the wafer edge occurs when the distance between the wafer and the shower plate is 300 mm or less. In practice, it has been found that when the aspect ratio is 2 or more, the difference in supply amount cannot be allowed.

図3で示した課題の解決方法として、シャワープレートに形成するガス噴出し孔の領域を被加工試料直径に対して拡大する方法が考えられる。 As a method for solving the problem shown in FIG. 3, a method of enlarging the region of the gas ejection hole formed in the shower plate with respect to the diameter of the sample to be processed can be considered.

図4に、ガス噴出し領域径と相対ガス分子到達量との関係を示す。 FIG. 4 shows the relationship between the gas ejection region diameter and the relative gas molecule arrival amount.

これは、ウエハ直径を300mm、シャワープレートには均等にガス噴出し孔が配置されており、ウエハとシャワープレート間の距離Lを24mm(アスペクト比D/L=12.5)とした場合について計算した結果である。 This is calculated when the wafer diameter is 300 mm, the gas ejection holes are evenly arranged in the shower plate, and the distance L between the wafer and the shower plate is 24 mm (aspect ratio D / L = 12.5). It is the result.

図4に示すように、ガス噴出し孔領域の径を拡大する方法において、十分なガス供給均一性を得るためには、実質的に、ウエハ直径Dの約1.5倍以上、つまり、ガス噴出し孔領域径をφ450mm以上とする必要があることが判った。 As shown in FIG. 4, in the method of enlarging the diameter of the gas ejection hole region, in order to obtain sufficient gas supply uniformity, the wafer diameter D is substantially 1.5 times or more, that is, the gas. It was found that the diameter of the ejection hole area should be φ450 mm or more.

つまり、ガス噴出し領域径の拡大では、シャワープレートの大型化に伴う装置の大型化を招くと共に、シャワープレートは一般的に消耗部品として定期的に交換される部品であるため、大型化による消耗品コストの増大が問題となり、現実的な解決策とはならない。 In other words, the expansion of the gas ejection area diameter leads to an increase in the size of the apparatus accompanying an increase in the size of the shower plate, and since the shower plate is generally a part that is regularly replaced as a consumable part, the exhaustion due to the increase in size is required. Increasing product costs is a problem and is not a realistic solution.

本発明の目的は、被加工試料の外周部で生じるシャワープレートからのガス供給不足を解決し、被加工試料での加工精度の面内均一性を向上させるプラズマ処理装置を提供することにある。 An object of the present invention is to provide a plasma processing apparatus that solves the shortage of gas supply from a shower plate that occurs at the outer peripheral portion of a sample to be processed, and improves in-plane uniformity of processing accuracy on the sample to be processed.

特に、シャワープレート直径の拡大を最小限に抑制し、被加工試料面内へのガス供給均一性を改善することで加工特性の被加工試料面内均一性の向上と消耗品コストの低減を両立するプラズマ処理装置を提供することにある。 In particular, the expansion of the shower plate diameter is minimized, and the uniformity of gas supply into the sample surface to be processed is improved to improve the uniformity of the processing sample surface within the sample and reduce the cost of consumables. An object of the present invention is to provide a plasma processing apparatus.

上記課題を解決するために、本発明のプラズマ処理装置は、真空容器と、前記真空容器内に設けられ被加工試料を載置する試料台と、前記試料台に対向し前記被加工試料直径よりも大きな直径のガス供給面を有するガス供給手段とを有し、前記被加工試料の表面処理を行うプラズマ処理装置において、前記ガス供給手段のガス供給面の前記被加工試料に面する領域には複数の同一直径のガス噴出し孔が配置されており、前記ガス噴出し孔は、前記被加工試料直径よりも内側である内側領域内においてその孔数密度が全体で均等に配置され、前記被加工試料直径の1倍から1.1倍の範囲であって前記内側領域に隣接した外側領域内において前記内側領域内における前記ガス噴出し孔の孔数密度の1.5倍から4倍の範囲内の孔数密度で配置されたことを特徴とする。

In order to solve the above-described problems, a plasma processing apparatus of the present invention includes a vacuum vessel, a sample stage provided in the vacuum vessel on which a sample to be processed is placed, and a diameter of the sample to be processed facing the sample table. And a gas supply means having a gas supply surface having a large diameter, and in a plasma processing apparatus for performing a surface treatment of the sample to be processed, a region of the gas supply surface of the gas supply means facing the sample to be processed is provided. A plurality of gas ejection holes having the same diameter are arranged, and the gas ejection holes are uniformly arranged throughout the inside area, which is inside the workpiece sample diameter, and the gas ejection holes are arranged uniformly. A range of 1 to 1.1 times the diameter of the processed sample and a range of 1.5 to 4 times the number density of the gas ejection holes in the inner region in the outer region adjacent to the inner region. Arranged with the pore number density in It is characterized in.

また、真空容器と、前記真空容器内に設けられ被加工試料を載置する試料台と、前記試料台に対向し前記被加工試料直径よりも大きな直径のガス供給面を有するガス供給手段とを有し、前記被加工試料の表面処理を行うプラズマ処理装置において、前記ガス供給手段のガス供給面の前記被加工試料に面する領域には複数の同一直径のガス噴出し孔が配置されており、前記被加工試料直径の1倍から1.1倍の範囲内に前記被加工試料直径よりも内側にあるガス噴出し孔直径の1.1倍から1.5倍の範囲内の直径の値で複数の前記ガス噴出し孔を配置した特徴とする。

A vacuum vessel; a sample stage provided in the vacuum vessel on which a sample to be processed is placed; and a gas supply unit having a gas supply surface facing the sample table and having a diameter larger than the diameter of the sample to be processed. And a plasma processing apparatus for performing a surface treatment of the sample to be processed, wherein a plurality of gas ejection holes having the same diameter are arranged in a region of the gas supply surface of the gas supply means facing the sample to be processed. The value of the diameter within the range of 1.1 to 1.5 times the diameter of the gas ejection hole inside the sample diameter within the range of 1 to 1.1 times the sample diameter. And a plurality of the gas ejection holes are arranged.

本発明によれば、装置の大型化や交換部品であるシャワープレートの大型化を伴わずに被加工試料全面で均等なガス供給分布が得られ、被加工試料の加工速度および加工形状の均一化が達成できる。 According to the present invention, a uniform gas supply distribution can be obtained over the entire surface of the sample without increasing the size of the apparatus and the size of the shower plate as a replacement part, and the processing speed and shape of the sample to be processed are made uniform. Can be achieved.

以下、本発明の実施の形態を用いて説明する。 Hereinafter, description will be made using embodiments of the present invention.

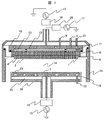

本発明の第一の実施例を図1及び図2を用いて説明する。 A first embodiment of the present invention will be described with reference to FIGS.

図1は、本発明の一実施例になるプラズマ処理装置の断面図を示す。プラズマ処理装置は、真空容器24内に被加工試料7を載置する静電吸着機能付の電極15(試料台)と試料台に対向して設けられたシャワープレート1(ガス供給手段)を有している。また、プレート8および分散プレート11を組み込んだ導体製のアンテナ12に放電用高周波電源13から200MHzの高周波電力を供給し、シャワープレート1から供給したガスを放電空間14でプラズマ化する。また被加工試料7には静電吸着機能付の電極15を介して、高周波電源16から4MHzの高周波電圧が印加されており、被加工試料7表面にプラズマからイオンを加速して入射する構造となっている。また、アンテナ12には、放電用の200MHzの高周波電力に重畳して独立に高周波電源17から4MHzの高周波電圧が印加されており、シャワープレート1表面にプラズマから入射するイオンのエネルギーをプラズマ生成および被加工試料のバイアス状態とは独立に制御している。また、アンテナ12および静電吸着機能付の電極15は、絶縁性の液体冷却循環機能21および22によりそれぞれ独立に温度制御されている。

FIG. 1 is a sectional view of a plasma processing apparatus according to an embodiment of the present invention. The plasma processing apparatus has an electrode 15 (sample stage) with an electrostatic adsorption function for placing the sample 7 to be processed in a

シャワープレート1はシリコンで形成されている。シャワープレートの上段には、シャワープレートと同様な位置でかつシャワープレート1に形成されているガス噴出し孔2より若干大きい孔が形成されたプレート8が配置されている。さらにその上段にはガス供給部9からのガスを分散させるガス分散層10を形成する分散プレート11が配置されている。ガス供給部9は、被加工試料7の内側領域用と外側領域用にそれぞれ独立にもうけられており、流量およびガス組成を被加工試料7の内外で独立に制御できる構造となっている。また該内側領域と外側領域は、それぞれのガス噴出し孔2の形成領域面積がほぼ等しくなる位置を境界としている。なお、本実施例では、内側領域と外側領域の2つの領域に分けた装置で説明するが、領域を分けなくても良いし、3つ以上に分けても良い。

The

図1では、直径300mmのシリコンウエハを被加工試料とした装置構成であり、シャワープレート1に形成されるガス噴出し孔の中心は、φ314mmの範囲内に形成されている。この314mmの内、内側のφ200mm領域が内側領域、それより外側が外側領域となっている。ガス分散層10も内外で独立しており、それぞれの領域で均一にガスが分散する構造となっている。

FIG. 1 shows an apparatus configuration in which a silicon wafer having a diameter of 300 mm is used as a sample to be processed, and the center of the gas ejection hole formed in the

図2は、シャワープレート1の表面図で、ガス噴出し孔2の配置を示している。ガス噴出し孔2の直径は0.5mm、シャワープレート1のガス噴出し孔2が形成されている領域の厚さは10mmである。シャワープレートガス供給面5上に形成されるガス噴出し孔2の直径は全て等しい。シャワープレート中心3から等しい間隔(10mmピッチ)で同心円状にガス噴出し孔が形成されている。また各円周上のガス噴出し孔の数は、中心から外周付近までは、円周にほぼ比例する数の孔が形成されている。よって中心から外周付近までは、シャワープレートの単位面積当たりのガス噴出し孔数がほぼ等しい配置となっている。シャワープレートガス供給面5の直径は被加工試料7の直径よりも大きくしている。

FIG. 2 is a surface view of the

図2の構成では、外側領域の外周部の総ガス噴出し孔数は内側領域の約2倍となっている。よって、外側領域に内側領域の約2倍の流量を流すことで、内側および外側領域両方のガス噴出し孔1個当たりから噴出するガス流量は等しくなる。 In the configuration of FIG. 2, the total number of gas ejection holes in the outer peripheral portion of the outer region is about twice that of the inner region. Therefore, by flowing a flow rate about twice that of the inner region through the outer region, the gas flow rate ejected from one gas ejection hole in both the inner and outer regions becomes equal.

以上の構成から、被加工試料7の内側および外側のそれぞれでは各ガス噴出し孔2から噴出するガスは、流量およびガス組成がほぼ等しく、被加工試料7表面に供給されるガス状態(流量および組成)分布はガス噴出し孔の密度で決まる構成となっている。なお、本実施例では、ガス噴出し孔1個当たりから噴出するガス流量を等しくした装置で説明するが、例えば、反応生成物起因によるデポ分布を補正する目的で、例えば、酸素流量を内側領域と外側領域で変える場合もあり、必ずしも、ガス噴出し孔1個当たりから噴出するガス流量を等しくする必要はない。

From the above configuration, the gas ejected from each

本実施例では、対向する被加工試料7の端部に相当する位置、つまり、ガス噴出し孔の最外周二周分の位置の円周上の単位長さに対する孔数密度を他の円周上の孔数密度に比べ約二倍としている。その他の位置に形成されたガス噴出し孔同士のピッチが10mmであるのに対し、最外周二周分の位置にあるガス噴出し孔同士のピッチは7mmとなっている。 In this embodiment, the hole number density with respect to the unit length on the circumference at the position corresponding to the end of the facing sample 7 to be processed, that is, the position corresponding to the two outermost circumferences of the gas ejection holes, is set to other circumferences. It is about twice the number density of holes above. While the pitch between the gas ejection holes formed at other positions is 10 mm, the pitch between the gas ejection holes at the position of the two outermost circumferences is 7 mm.

この結果、被加工試料端部に位置するガス噴出し孔の孔数密度は他の領域に比べ約2.85倍(円周方向の密度(2倍)×径方向の密度(10mm/7mm))多くなっている。 As a result, the number density of the gas ejection holes located at the end of the sample to be processed is about 2.85 times that of other regions (circumferential density (2 times) x radial density (10 mm / 7 mm). ) It is increasing.

即ち、被加工試料7の内側領域では、ガス噴出し孔2が均等に等しい密度で配置されているため均一なガス供給が行われるが、外側領域では、被加工試料7の端部に位置するガス噴出し孔密度が高いため他の領域より多いガスが被加工試料端部に供給されることになる。 That is, in the inner region of the sample 7 to be processed, the gas ejection holes 2 are arranged at an equal density, so that uniform gas supply is performed. However, in the outer region, the gas sample is located at the end of the sample 7 to be processed. Since the gas ejection hole density is high, more gas than other regions is supplied to the end of the sample to be processed.

図5に、本発明のシャワープレートと従来のシャワープレートにおけるウエハ端部での相対ガス分子到達量の計算結果を示す。 FIG. 5 shows the calculation results of the amount of relative gas molecules reached at the wafer edge in the shower plate of the present invention and the conventional shower plate.

図5では、ウエハ直径Dがφ300mm、ウエハとシャワープレート間の距離Lが24mm(アスペクト比D/L=12.5)とした。 In FIG. 5, the wafer diameter D is 300 mm, and the distance L between the wafer and the shower plate is 24 mm (aspect ratio D / L = 12.5).

図5に示すように、本発明のシャワープレートでは、ウエハ端部付近でのガス供給量不足が補われウエハ全面で均等なガス供給ができることが確認できる。一方、従来のシャワープレートでは、ウエハ端部付近でガス供給量が中心部に比べ相対的に少なくなっている。これは、シャワープレートから供給されたガスがウエハ周辺から排気され際、円周長の長いウエハ端部では、中心部に比べ排気速度が速くなることが原因と考えられる。また、中心領域では、外周部から噴出したガスも等方拡散により到達するが、ガス噴出し孔の最外周に位置する領域は、それより外側からのガス供給がないことが原因と考えられる。 As shown in FIG. 5, in the shower plate of the present invention, it can be confirmed that the shortage of gas supply near the edge of the wafer is compensated and the gas can be supplied uniformly over the entire surface of the wafer. On the other hand, in the conventional shower plate, the gas supply amount is relatively smaller in the vicinity of the wafer edge than in the central portion. This is considered to be due to the fact that when the gas supplied from the shower plate is exhausted from the periphery of the wafer, the exhaust speed is higher at the end of the wafer with a long circumferential length than at the center. Further, in the central region, the gas ejected from the outer peripheral portion also arrives by isotropic diffusion, but the region located at the outermost periphery of the gas ejection hole is considered to be caused by the absence of gas supply from the outside.

これにより、本発明のシャワープレートを用いれば、均等なガス供給が可能となり、エッチング特性の均一化に有効であることが判る。 Thus, it can be seen that the use of the shower plate of the present invention enables an even gas supply and is effective in making the etching characteristics uniform.

特に、狭ギャップの対向電極構造で、エッチング特性がガスの圧力よりも供給されるガス流量に大きく依存するエッチングメカニズム(フロロカーボン系ガスによるシリコン酸化膜エッチング等)では、エッチング速度やエッチング形状のウエハ面内での差を抑制できる。 In particular, an etching mechanism (such as silicon oxide film etching with a fluorocarbon-based gas) whose etching characteristics greatly depend on the gas flow rate supplied rather than the gas pressure in a counter electrode structure with a narrow gap, has an etching rate and an etched shape on the wafer surface. The difference in the inside can be suppressed.

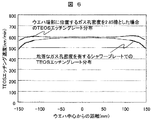

図6に、本発明のシャワープレートと従来のシャワープレートにおける、TEOS膜のエッチングレート分布を示す。 FIG. 6 shows the etching rate distribution of the TEOS film in the shower plate of the present invention and the conventional shower plate.

本発明のシャワープレートを用いた場合は、内側領域及び外側領域の全てのガス噴出し孔一個当たりから噴出するガス供給量を等しくするため、ガス噴出し孔数比(約2倍)に従って、外側領域のガス流量を内側領域に比べ約2倍の流量(内側流量はAr=500sccm,C4F8=15sccm,O2=15sccm,外側流量はAr=1000sccm,C4F8=30sccm,O2=30sccm)とした。 In the case of using the shower plate of the present invention, in order to equalize the gas supply amount ejected from all the gas ejection holes in the inner region and the outer region, the outer side according to the gas ejection hole number ratio (about twice) The gas flow rate in the region is about twice that in the inner region (the inner flow rate is Ar = 500 sccm, C 4 F 8 = 15 sccm, O 2 = 15 sccm, the outer flow rate is Ar = 1000 sccm, C 4 F 8 = 30 sccm, O 2 = 30 sccm).

一方、従来のシャワープレートを用いた場合は、内側領域と外側領域でほぼガス噴出し孔数が等しいため、同様なガス流量を供給(内側及び外側流量はAr/C4F8/O2の混合ガスで、Ar=500sccm,C4F8=15sccm,O2=15sccm)している。 On the other hand, when the conventional shower plate is used, since the number of gas ejection holes is almost equal in the inner region and the outer region, the same gas flow rate is supplied (the inner and outer flow rates are Ar / C 4 F 8 / O 2 . The mixed gas is Ar = 500 sccm, C 4 F 8 = 15 sccm, O 2 = 15 sccm).

図6に示すように、従来のシャワープレートを用いた場合では、ウエハ端部のエッチング速度が低下しており、エッチングレート均一性が8%程度であったが、本発明のシャワープレートを用いた場合は、ウエハ中心領域のエッチング速度には影響を与えず、ウエハ端部のエッチング速度は増加しており、エッチングレート均一性は3%程度と改善されていた。 As shown in FIG. 6, in the case of using the conventional shower plate, the etching rate at the wafer edge was reduced and the etching rate uniformity was about 8%, but the shower plate of the present invention was used. In this case, the etching rate in the wafer central region was not affected, the etching rate at the wafer edge was increased, and the etching rate uniformity was improved to about 3%.

本発明は、エッチング特性に合わせてガス噴出し孔密度を変えることで、加工対象やプロセス条件にとって最適なガス供給分布を選択することが可能である。 In the present invention, it is possible to select an optimum gas supply distribution for a processing object and process conditions by changing the gas ejection hole density according to the etching characteristics.

次に、本発明において、ガス噴出し孔の孔数密度の最適化と孔数密度を増加させる領域の最適化について説明する。 Next, in the present invention, optimization of the hole density of the gas ejection holes and optimization of the region where the hole density is increased will be described.

図8に、シャワープレートのφ280付近にガス噴出し孔密度を増加させた場合のウエハ表面での相対ガス分子到達量の計算結果を示す。 FIG. 8 shows the calculation result of the relative gas molecule arrival amount on the wafer surface when the gas ejection hole density is increased in the vicinity of φ280 of the shower plate.

図9に、シャワープレートのφ290付近にガス噴出し孔密度を増加させた場合のウエハ表面での相対ガス分子到達量の計算結果を示す。 FIG. 9 shows a calculation result of the amount of relative gas molecules reached on the wafer surface when the gas injection hole density is increased in the vicinity of φ290 of the shower plate.

図10に、シャワープレートのφ300付近にガス噴出し孔密度を増加させた場合のウエハ表面での相対ガス分子到達量の計算結果を示す。 FIG. 10 shows the calculation result of the relative gas molecule arrival amount on the wafer surface when the gas injection hole density is increased in the vicinity of φ300 of the shower plate.

図11に、シャワープレートのφ320付近にガス噴出し孔密度を増加させた場合のウエハ表面での相対ガス分子到達量の計算結果を示す。 FIG. 11 shows the calculation result of the relative gas molecule arrival amount on the wafer surface when the gas injection hole density is increased in the vicinity of φ320 of the shower plate.

図12に、シャワープレートのφ330付近にガス噴出し孔密度を増加させた場合のウエハ表面での相対ガス分子到達量の計算結果を示す。 FIG. 12 shows the calculation result of the relative gas molecule arrival amount on the wafer surface when the gas injection hole density is increased in the vicinity of φ330 of the shower plate.

図13に、シャワープレートのφ340付近にガス噴出し孔密度を増加させた場合のウエハ表面での相対ガス分子到達量の計算結果を示す。 FIG. 13 shows the calculation result of the relative gas molecule arrival amount on the wafer surface when the gas injection hole density is increased in the vicinity of φ340 of the shower plate.

図14に、シャワープレートのφ360付近にガス噴出し孔密度を増加させた場合のウエハ表面での相対ガス分子到達量の計算結果を示す。 FIG. 14 shows the calculation result of the amount of relative gas molecules reached on the wafer surface when the gas injection hole density is increased in the vicinity of φ360 of the shower plate.

図8,図9に示すように、ウエハ直径よりも内側の領域で、ガス噴出し孔密度を増加させウエハ端部のガス供給量を増加させると、内側のガス供給量が増加するものの、若干、改善されることが判った。 As shown in FIG. 8 and FIG. 9, when the gas injection hole density is increased in the region inside the wafer diameter and the gas supply amount at the wafer edge is increased, the inner gas supply amount increases, , Found to be improved.

一方、図10〜図14に示すように、ウエハ直径またはそれよりも外側の領域で、ガス噴出し孔密度を増加させウエハ端部のガス供給量を増加させると、ウエハ領域内で均一なガス供給分布を得られることが判った。 On the other hand, as shown in FIGS. 10 to 14, when the gas ejection hole density is increased and the gas supply amount at the edge of the wafer is increased in the wafer diameter or an area outside the wafer diameter, a uniform gas is produced in the wafer area. It was found that a supply distribution could be obtained.

しかし、図13,図14に示すように、φ340mm以上の領域に追加する場合には、その追加位置のガス噴出し孔密度の必要増加倍数が4倍以上となるため、ガス供給量も増加させる必要がある。よって、ガス消費量の増加や装置の排気能力に余分な負担をかけることになる。 However, as shown in FIGS. 13 and 14, when adding to a region of φ340 mm or more, the required increase multiple of the gas ejection hole density at the additional position is four times or more, so the gas supply amount is also increased. There is a need. Therefore, an extra burden is imposed on the increase in gas consumption and the exhaust capacity of the apparatus.

このことから、図10〜図12に示すように、φ300からφ330mm程度、即ち、ウエハ直径の1倍から1.1倍程度の範囲でのガス噴出し孔数密度増加が望ましい。 Therefore, as shown in FIGS. 10 to 12, it is desirable to increase the gas ejection hole number density in the range of about φ300 to φ330 mm, that is, about 1 to 1.1 times the wafer diameter.

また、ガス噴出し孔密度の増加は、加工対象やプロセス条件により変わるが、1.5倍から4倍の範囲で増加させると、エッチング特性の均一性を最適化すると共に、ガスの消費量を抑えることができる。 In addition, the increase in gas ejection hole density varies depending on the object to be processed and the process conditions, but increasing it in the range of 1.5 to 4 times optimizes the uniformity of etching characteristics and reduces gas consumption. Can be suppressed.

本発明の第2の実施例を図15を用いて説明する。 A second embodiment of the present invention will be described with reference to FIG.

図15は、本発明の実施例2となるシャワープレート1の表面図である。

FIG. 15 is a surface view of the

本実施例では、対向するウエハ端部に相当する位置のガス噴出し孔27を、他の部分に位置する孔径に対して1.3倍(中心部の孔径を0.5mmとすると外周部の孔径は0.65mm)とし、孔数密度は均等とした。実施例1では、同一径のガス噴出し孔4の孔数密度でウエハ端部へのガス供給量を調整したが、実施例2では、孔径で調整することとした。

In this embodiment, the

シャワープレートのガス噴出し孔をガスが通過する際のコンダクタンスは孔径の3〜4乗に比例して増加する(分子流の場合は3乗、粘性流の場合は4乗)。実際には、分子流と粘性流の中間的な値(中間流は3.5乗)になる。 The conductance when gas passes through the gas ejection holes of the shower plate increases in proportion to the third to fourth power of the hole diameter (third power for molecular flow and fourth power for viscous flow). Actually, it is an intermediate value between the molecular flow and the viscous flow (the intermediate flow is the power of 3.5).

よって、同じ孔数密度でも孔径を拡大することで孔数密度を増加させたのと同様の効果が得られる。 Therefore, the same effect as increasing the hole number density by expanding the hole diameter can be obtained even with the same hole number density.

実施例2では、孔数密度は等しく外周部の孔径を他の領域の1.3倍とすることで、外周部のガス供給量を約2.85倍に向上することができる。 In Example 2, the hole number density is equal, and the hole diameter in the outer peripheral portion is 1.3 times that in other regions, so that the gas supply amount in the outer peripheral portion can be improved to about 2.85 times.

実施例1と同様に孔径の拡大量は加工対象やプロセス条件により変えることができる。ガス噴出し孔密度を1.5倍から4倍の範囲に増加、即ち、ガス供給量を1.5倍から4倍に増加させるためには、孔径を1.1倍(1.5の(1/3.5)乗=1.123)から1.5倍(4の(1/3.5)乗=1.486)の範囲とすることで、エッチング特性の均一性を最適化することができる。 As in the first embodiment, the amount of expansion of the hole diameter can be changed depending on the object to be processed and the process conditions. In order to increase the gas injection hole density from 1.5 times to 4 times, that is, to increase the gas supply amount from 1.5 times to 4 times, the hole diameter is increased by a factor of 1.1 (1.5 ( The uniformity of the etching characteristics is optimized by setting the range from 1 / 3.5) power = 1.123) to 1.5 times (4 (1 / 3.5) power = 1.486). Can do.

また、ガス噴出し孔径を拡大する領域は、実施例1同様にウエハ直径の1倍から1.1倍程度の範囲が好適となる。 Further, the region in which the gas ejection hole diameter is enlarged is preferably in the range of about 1 to 1.1 times the wafer diameter as in the first embodiment.

本発明は、半導体装置の製造装置、特にリソグラフィー技術によって描かれたパタンをマスクに半導体材料のエッチング処理を行うプラズマエッチング装置に関する。本発明により、被加工試料であるシリコンウエハ端部での加工特性,特に加工速度の均一性および加工形状の均一性を向上させることが可能となる。以上の本発明の効果により、シリコンウエハ端部での良品取得率が高まり、エッチング装置の歩留まり向上が図れる。 The present invention relates to a semiconductor device manufacturing apparatus, and more particularly to a plasma etching apparatus that performs an etching process of a semiconductor material using a pattern drawn by a lithography technique as a mask. According to the present invention, it is possible to improve the processing characteristics, particularly the processing speed uniformity and the processing shape uniformity at the edge of the silicon wafer that is the sample to be processed. Due to the effects of the present invention described above, the non-defective product acquisition rate at the edge of the silicon wafer is increased, and the yield of the etching apparatus can be improved.

1 シャワープレート

2 ガス噴出し孔

3 シャワープレート中心

4,27 シャワープレート外周部位置のガス噴出し孔

5 シャワープレートガス供給面

6 シャワープレート固定用ネジ孔部

7 被加工試料

8 プレート

9 ガス供給部

10 ガス分散層

11 分散プレート

12 アンテナ

13 放電用高周波電源

14 放電空間

15 静電吸着機能付の電極

16,17 高周波電源

18,19,20 自動整合器

21,22 絶縁性の液体冷却循環機能

23 シリコン製フォーカスリング

24 真空容器

25 絶縁材

26 アース板

DESCRIPTION OF

Claims (4)

前記ガス供給手段のガス供給面の前記被加工試料に対向する領域には複数の同一直径のガス噴出し孔が配置されており、

前記ガス噴出し孔は、前記被加工試料直径よりも内側である内側領域内においてその孔数密度が全体で均等に配置され、前記被加工試料直径の1倍から1.1倍の範囲であって前記内側領域に隣接した外側領域内において前記内側領域内における前記ガス噴出し孔の孔数密度の1.5倍から4倍の範囲内の孔数密度で配置されたことを特徴とするプラズマ処理装置。

A vacuum vessel, a sample stage provided in the vacuum vessel on which a sample to be processed is placed, and a gas supply unit having a gas supply surface facing the sample table and having a diameter larger than the diameter of the sample to be processed In the plasma processing apparatus for performing the surface treatment of the sample to be processed,

A plurality of gas ejection holes of the same diameter are arranged in a region facing the sample to be processed on the gas supply surface of the gas supply means,

The gas injection holes, the evenly spaced throughout its pore density in the inner region is an inner than the sample to be processed diameter, met 1.1 times the range of 1 times the sample to be processed in diameter The plasma is arranged in the outer region adjacent to the inner region at a hole density in the range of 1.5 to 4 times the hole density of the gas ejection holes in the inner region. Processing equipment.

前記ガス供給手段のガス供給面の前記被加工試料に面する領域には複数の同一直径のガス噴出し孔が配置されており、

前記ガス噴出し孔は、前記被加工試料直径の1倍から1.1倍の範囲の外側領域内において、前記被加工試料直径よりも内側であって前記外側領域に隣接した内側領域内にける同じ値にされたガス噴出し孔直径の1.1倍から1.5倍の範囲内の直径の値で複数配置されたことを特徴とするプラズマ処理装置。

A vacuum vessel, a sample stage provided in the vacuum vessel on which a sample to be processed is placed, and a gas supply unit having a gas supply surface facing the sample table and having a diameter larger than the diameter of the sample to be processed In the plasma processing apparatus for performing the surface treatment of the sample to be processed,

A plurality of gas ejection holes having the same diameter are arranged in a region facing the sample to be processed on the gas supply surface of the gas supply means,

The gas ejection hole is formed in an inner region adjacent to the outer region and inside the workpiece sample diameter in an outer region in a range of 1 to 1.1 times the workpiece sample diameter. A plasma processing apparatus, wherein a plurality of gas ejection holes having the same value and a diameter within a range of 1.1 to 1.5 times the diameter of the gas ejection hole are arranged .

前記ガス供給面と前記試料台の前記試料が載置される面との間の距離が24mmにされたことを特徴とするプラズマ処理装置。

The plasma processing apparatus according to claim 1 or 2,

The plasma processing apparatus characterized by distance between the surface of the sample of the sample stage and the gas supply surface is placed is a 24 mm.

前記被加工試料直径をD、前記被加工試料から前記ガス供給面までの距離をLとした時、アスペクト比(D/L)が2以上であることを特徴とするプラズマ処理装置。 The plasma processing apparatus according to any one of claims 1 to 3,

A plasma processing apparatus, wherein an aspect ratio (D / L) is 2 or more, where D is a diameter of the sample to be processed and L is a distance from the sample to be processed to the gas supply surface.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008331822A JP5268626B2 (en) | 2008-12-26 | 2008-12-26 | Plasma processing equipment |

| KR1020090006817A KR101039087B1 (en) | 2008-12-26 | 2009-01-29 | Plasma processing apparatus |

| US12/392,237 US20100163187A1 (en) | 2008-12-26 | 2009-02-25 | Plasma processing apparatus |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008331822A JP5268626B2 (en) | 2008-12-26 | 2008-12-26 | Plasma processing equipment |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010153680A JP2010153680A (en) | 2010-07-08 |

| JP2010153680A5 JP2010153680A5 (en) | 2012-02-16 |

| JP5268626B2 true JP5268626B2 (en) | 2013-08-21 |

Family

ID=42283459

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008331822A Expired - Fee Related JP5268626B2 (en) | 2008-12-26 | 2008-12-26 | Plasma processing equipment |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US20100163187A1 (en) |

| JP (1) | JP5268626B2 (en) |

| KR (1) | KR101039087B1 (en) |

Families Citing this family (196)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20130023129A1 (en) | 2011-07-20 | 2013-01-24 | Asm America, Inc. | Pressure transmitter for a semiconductor processing environment |

| JP5792563B2 (en) | 2011-08-31 | 2015-10-14 | 東京エレクトロン株式会社 | Plasma etching method and plasma etching apparatus |

| JP2014082354A (en) * | 2012-10-17 | 2014-05-08 | Hitachi High-Technologies Corp | Plasma processing apparatus |

| US20160376700A1 (en) | 2013-02-01 | 2016-12-29 | Asm Ip Holding B.V. | System for treatment of deposition reactor |

| KR101530949B1 (en) * | 2013-11-15 | 2015-06-25 | 하나머티리얼즈(주) | Cooling plate for plasma chamber |

| US10941490B2 (en) | 2014-10-07 | 2021-03-09 | Asm Ip Holding B.V. | Multiple temperature range susceptor, assembly, reactor and system including the susceptor, and methods of using the same |

| US10276355B2 (en) | 2015-03-12 | 2019-04-30 | Asm Ip Holding B.V. | Multi-zone reactor, system including the reactor, and method of using the same |

| CN104681402B (en) * | 2015-03-16 | 2018-03-16 | 京东方科技集团股份有限公司 | Substrate heating equipment and substrate heating method |

| US10378107B2 (en) * | 2015-05-22 | 2019-08-13 | Lam Research Corporation | Low volume showerhead with faceplate holes for improved flow uniformity |

| US11139308B2 (en) | 2015-12-29 | 2021-10-05 | Asm Ip Holding B.V. | Atomic layer deposition of III-V compounds to form V-NAND devices |

| US10529554B2 (en) | 2016-02-19 | 2020-01-07 | Asm Ip Holding B.V. | Method for forming silicon nitride film selectively on sidewalls or flat surfaces of trenches |

| JP2017162901A (en) * | 2016-03-08 | 2017-09-14 | 株式会社ディスコ | Wafer dividing method |

| US11453943B2 (en) | 2016-05-25 | 2022-09-27 | Asm Ip Holding B.V. | Method for forming carbon-containing silicon/metal oxide or nitride film by ALD using silicon precursor and hydrocarbon precursor |

| US10612137B2 (en) | 2016-07-08 | 2020-04-07 | Asm Ip Holdings B.V. | Organic reactants for atomic layer deposition |

| US9859151B1 (en) | 2016-07-08 | 2018-01-02 | Asm Ip Holding B.V. | Selective film deposition method to form air gaps |

| US9812320B1 (en) | 2016-07-28 | 2017-11-07 | Asm Ip Holding B.V. | Method and apparatus for filling a gap |

| US9887082B1 (en) | 2016-07-28 | 2018-02-06 | Asm Ip Holding B.V. | Method and apparatus for filling a gap |

| US11532757B2 (en) | 2016-10-27 | 2022-12-20 | Asm Ip Holding B.V. | Deposition of charge trapping layers |

| US10714350B2 (en) | 2016-11-01 | 2020-07-14 | ASM IP Holdings, B.V. | Methods for forming a transition metal niobium nitride film on a substrate by atomic layer deposition and related semiconductor device structures |

| KR102546317B1 (en) | 2016-11-15 | 2023-06-21 | 에이에스엠 아이피 홀딩 비.브이. | Gas supply unit and substrate processing apparatus including the same |

| US11447861B2 (en) | 2016-12-15 | 2022-09-20 | Asm Ip Holding B.V. | Sequential infiltration synthesis apparatus and a method of forming a patterned structure |

| US11581186B2 (en) | 2016-12-15 | 2023-02-14 | Asm Ip Holding B.V. | Sequential infiltration synthesis apparatus |

| US11390950B2 (en) | 2017-01-10 | 2022-07-19 | Asm Ip Holding B.V. | Reactor system and method to reduce residue buildup during a film deposition process |

| US10468261B2 (en) | 2017-02-15 | 2019-11-05 | Asm Ip Holding B.V. | Methods for forming a metallic film on a substrate by cyclical deposition and related semiconductor device structures |

| US10770286B2 (en) | 2017-05-08 | 2020-09-08 | Asm Ip Holdings B.V. | Methods for selectively forming a silicon nitride film on a substrate and related semiconductor device structures |

| US12040200B2 (en) | 2017-06-20 | 2024-07-16 | Asm Ip Holding B.V. | Semiconductor processing apparatus and methods for calibrating a semiconductor processing apparatus |

| US11306395B2 (en) | 2017-06-28 | 2022-04-19 | Asm Ip Holding B.V. | Methods for depositing a transition metal nitride film on a substrate by atomic layer deposition and related deposition apparatus |

| KR20190009245A (en) | 2017-07-18 | 2019-01-28 | 에이에스엠 아이피 홀딩 비.브이. | Methods for forming a semiconductor device structure and related semiconductor device structures |

| US10590535B2 (en) | 2017-07-26 | 2020-03-17 | Asm Ip Holdings B.V. | Chemical treatment, deposition and/or infiltration apparatus and method for using the same |

| US10692741B2 (en) | 2017-08-08 | 2020-06-23 | Asm Ip Holdings B.V. | Radiation shield |

| US10770336B2 (en) | 2017-08-08 | 2020-09-08 | Asm Ip Holding B.V. | Substrate lift mechanism and reactor including same |

| US11769682B2 (en) | 2017-08-09 | 2023-09-26 | Asm Ip Holding B.V. | Storage apparatus for storing cassettes for substrates and processing apparatus equipped therewith |

| US11830730B2 (en) | 2017-08-29 | 2023-11-28 | Asm Ip Holding B.V. | Layer forming method and apparatus |

| US11295980B2 (en) | 2017-08-30 | 2022-04-05 | Asm Ip Holding B.V. | Methods for depositing a molybdenum metal film over a dielectric surface of a substrate by a cyclical deposition process and related semiconductor device structures |

| US10658205B2 (en) | 2017-09-28 | 2020-05-19 | Asm Ip Holdings B.V. | Chemical dispensing apparatus and methods for dispensing a chemical to a reaction chamber |

| US10403504B2 (en) | 2017-10-05 | 2019-09-03 | Asm Ip Holding B.V. | Method for selectively depositing a metallic film on a substrate |

| US10923344B2 (en) | 2017-10-30 | 2021-02-16 | Asm Ip Holding B.V. | Methods for forming a semiconductor structure and related semiconductor structures |

| JP7214724B2 (en) | 2017-11-27 | 2023-01-30 | エーエスエム アイピー ホールディング ビー.ブイ. | Storage device for storing wafer cassettes used in batch furnaces |

| WO2019103610A1 (en) | 2017-11-27 | 2019-05-31 | Asm Ip Holding B.V. | Apparatus including a clean mini environment |

| US10872771B2 (en) | 2018-01-16 | 2020-12-22 | Asm Ip Holding B. V. | Method for depositing a material film on a substrate within a reaction chamber by a cyclical deposition process and related device structures |

| TWI799494B (en) | 2018-01-19 | 2023-04-21 | 荷蘭商Asm 智慧財產控股公司 | Deposition method |

| CN111630203A (en) | 2018-01-19 | 2020-09-04 | Asm Ip私人控股有限公司 | Method for depositing gap filling layer by plasma auxiliary deposition |

| US11081345B2 (en) | 2018-02-06 | 2021-08-03 | Asm Ip Holding B.V. | Method of post-deposition treatment for silicon oxide film |

| JP7124098B2 (en) | 2018-02-14 | 2022-08-23 | エーエスエム・アイピー・ホールディング・ベー・フェー | Method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process |

| US10896820B2 (en) | 2018-02-14 | 2021-01-19 | Asm Ip Holding B.V. | Method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process |

| KR102636427B1 (en) | 2018-02-20 | 2024-02-13 | 에이에스엠 아이피 홀딩 비.브이. | Substrate processing method and apparatus |

| US10975470B2 (en) | 2018-02-23 | 2021-04-13 | Asm Ip Holding B.V. | Apparatus for detecting or monitoring for a chemical precursor in a high temperature environment |

| US11473195B2 (en) | 2018-03-01 | 2022-10-18 | Asm Ip Holding B.V. | Semiconductor processing apparatus and a method for processing a substrate |

| KR102646467B1 (en) | 2018-03-27 | 2024-03-11 | 에이에스엠 아이피 홀딩 비.브이. | Method of forming an electrode on a substrate and a semiconductor device structure including an electrode |

| US12025484B2 (en) | 2018-05-08 | 2024-07-02 | Asm Ip Holding B.V. | Thin film forming method |

| US20190348261A1 (en) * | 2018-05-09 | 2019-11-14 | Asm Ip Holding B.V. | Apparatus for use with hydrogen radicals and method of using same |

| KR102596988B1 (en) | 2018-05-28 | 2023-10-31 | 에이에스엠 아이피 홀딩 비.브이. | Method of processing a substrate and a device manufactured by the same |

| US11718913B2 (en) | 2018-06-04 | 2023-08-08 | Asm Ip Holding B.V. | Gas distribution system and reactor system including same |

| US10797133B2 (en) | 2018-06-21 | 2020-10-06 | Asm Ip Holding B.V. | Method for depositing a phosphorus doped silicon arsenide film and related semiconductor device structures |

| KR102568797B1 (en) | 2018-06-21 | 2023-08-21 | 에이에스엠 아이피 홀딩 비.브이. | Substrate processing system |

| WO2020003000A1 (en) | 2018-06-27 | 2020-01-02 | Asm Ip Holding B.V. | Cyclic deposition methods for forming metal-containing material and films and structures including the metal-containing material |

| TW202409324A (en) | 2018-06-27 | 2024-03-01 | 荷蘭商Asm Ip私人控股有限公司 | Cyclic deposition processes for forming metal-containing material |

| US10755922B2 (en) | 2018-07-03 | 2020-08-25 | Asm Ip Holding B.V. | Method for depositing silicon-free carbon-containing film as gap-fill layer by pulse plasma-assisted deposition |

| US10388513B1 (en) | 2018-07-03 | 2019-08-20 | Asm Ip Holding B.V. | Method for depositing silicon-free carbon-containing film as gap-fill layer by pulse plasma-assisted deposition |

| US11430674B2 (en) | 2018-08-22 | 2022-08-30 | Asm Ip Holding B.V. | Sensor array, apparatus for dispensing a vapor phase reactant to a reaction chamber and related methods |

| US11024523B2 (en) | 2018-09-11 | 2021-06-01 | Asm Ip Holding B.V. | Substrate processing apparatus and method |

| KR102707956B1 (en) | 2018-09-11 | 2024-09-19 | 에이에스엠 아이피 홀딩 비.브이. | Method for deposition of a thin film |

| TWI844567B (en) | 2018-10-01 | 2024-06-11 | 荷蘭商Asm Ip私人控股有限公司 | Substrate retaining apparatus, system including the apparatus, and method of using same |

| KR102592699B1 (en) | 2018-10-08 | 2023-10-23 | 에이에스엠 아이피 홀딩 비.브이. | Substrate support unit and apparatuses for depositing thin film and processing the substrate including the same |

| KR102546322B1 (en) | 2018-10-19 | 2023-06-21 | 에이에스엠 아이피 홀딩 비.브이. | Substrate processing apparatus and substrate processing method |

| US11087997B2 (en) | 2018-10-31 | 2021-08-10 | Asm Ip Holding B.V. | Substrate processing apparatus for processing substrates |

| KR20200051105A (en) | 2018-11-02 | 2020-05-13 | 에이에스엠 아이피 홀딩 비.브이. | Substrate support unit and substrate processing apparatus including the same |

| US11572620B2 (en) | 2018-11-06 | 2023-02-07 | Asm Ip Holding B.V. | Methods for selectively depositing an amorphous silicon film on a substrate |

| US10818758B2 (en) | 2018-11-16 | 2020-10-27 | Asm Ip Holding B.V. | Methods for forming a metal silicate film on a substrate in a reaction chamber and related semiconductor device structures |

| US12040199B2 (en) | 2018-11-28 | 2024-07-16 | Asm Ip Holding B.V. | Substrate processing apparatus for processing substrates |

| KR102636428B1 (en) | 2018-12-04 | 2024-02-13 | 에이에스엠 아이피 홀딩 비.브이. | A method for cleaning a substrate processing apparatus |

| US11158513B2 (en) | 2018-12-13 | 2021-10-26 | Asm Ip Holding B.V. | Methods for forming a rhenium-containing film on a substrate by a cyclical deposition process and related semiconductor device structures |

| JP7504584B2 (en) | 2018-12-14 | 2024-06-24 | エーエスエム・アイピー・ホールディング・ベー・フェー | Method and system for forming device structures using selective deposition of gallium nitride - Patents.com |

| TWI819180B (en) | 2019-01-17 | 2023-10-21 | 荷蘭商Asm 智慧財產控股公司 | Methods of forming a transition metal containing film on a substrate by a cyclical deposition process |

| KR20200102357A (en) | 2019-02-20 | 2020-08-31 | 에이에스엠 아이피 홀딩 비.브이. | Apparatus and methods for plug fill deposition in 3-d nand applications |

| JP2020136678A (en) | 2019-02-20 | 2020-08-31 | エーエスエム・アイピー・ホールディング・ベー・フェー | Method for filing concave part formed inside front surface of base material, and device |

| TWI845607B (en) | 2019-02-20 | 2024-06-21 | 荷蘭商Asm Ip私人控股有限公司 | Cyclical deposition method and apparatus for filling a recess formed within a substrate surface |

| TWI842826B (en) | 2019-02-22 | 2024-05-21 | 荷蘭商Asm Ip私人控股有限公司 | Substrate processing apparatus and method for processing substrate |

| US11742198B2 (en) | 2019-03-08 | 2023-08-29 | Asm Ip Holding B.V. | Structure including SiOCN layer and method of forming same |

| KR20200108242A (en) | 2019-03-08 | 2020-09-17 | 에이에스엠 아이피 홀딩 비.브이. | Method for Selective Deposition of Silicon Nitride Layer and Structure Including Selectively-Deposited Silicon Nitride Layer |

| KR20200116033A (en) | 2019-03-28 | 2020-10-08 | 에이에스엠 아이피 홀딩 비.브이. | Door opener and substrate processing apparatus provided therewith |

| KR20200116855A (en) | 2019-04-01 | 2020-10-13 | 에이에스엠 아이피 홀딩 비.브이. | Method of manufacturing semiconductor device |

| KR20200123380A (en) | 2019-04-19 | 2020-10-29 | 에이에스엠 아이피 홀딩 비.브이. | Layer forming method and apparatus |

| KR20200125453A (en) | 2019-04-24 | 2020-11-04 | 에이에스엠 아이피 홀딩 비.브이. | Gas-phase reactor system and method of using same |

| KR20200130121A (en) | 2019-05-07 | 2020-11-18 | 에이에스엠 아이피 홀딩 비.브이. | Chemical source vessel with dip tube |

| KR20200130652A (en) | 2019-05-10 | 2020-11-19 | 에이에스엠 아이피 홀딩 비.브이. | Method of depositing material onto a surface and structure formed according to the method |

| JP2020188254A (en) | 2019-05-16 | 2020-11-19 | エーエスエム アイピー ホールディング ビー.ブイ. | Wafer boat handling device, vertical batch furnace, and method |

| JP2020188255A (en) | 2019-05-16 | 2020-11-19 | エーエスエム アイピー ホールディング ビー.ブイ. | Wafer boat handling device, vertical batch furnace, and method |

| USD975665S1 (en) | 2019-05-17 | 2023-01-17 | Asm Ip Holding B.V. | Susceptor shaft |

| USD947913S1 (en) | 2019-05-17 | 2022-04-05 | Asm Ip Holding B.V. | Susceptor shaft |

| KR20200141003A (en) | 2019-06-06 | 2020-12-17 | 에이에스엠 아이피 홀딩 비.브이. | Gas-phase reactor system including a gas detector |

| KR20200143254A (en) | 2019-06-11 | 2020-12-23 | 에이에스엠 아이피 홀딩 비.브이. | Method of forming an electronic structure using an reforming gas, system for performing the method, and structure formed using the method |

| KR20210005515A (en) | 2019-07-03 | 2021-01-14 | 에이에스엠 아이피 홀딩 비.브이. | Temperature control assembly for substrate processing apparatus and method of using same |

| JP7499079B2 (en) | 2019-07-09 | 2024-06-13 | エーエスエム・アイピー・ホールディング・ベー・フェー | Plasma device using coaxial waveguide and substrate processing method |

| CN112216646A (en) | 2019-07-10 | 2021-01-12 | Asm Ip私人控股有限公司 | Substrate supporting assembly and substrate processing device comprising same |

| KR20210010307A (en) | 2019-07-16 | 2021-01-27 | 에이에스엠 아이피 홀딩 비.브이. | Substrate processing apparatus |

| KR20210010820A (en) | 2019-07-17 | 2021-01-28 | 에이에스엠 아이피 홀딩 비.브이. | Methods of forming silicon germanium structures |

| KR20210010816A (en) | 2019-07-17 | 2021-01-28 | 에이에스엠 아이피 홀딩 비.브이. | Radical assist ignition plasma system and method |

| US11643724B2 (en) | 2019-07-18 | 2023-05-09 | Asm Ip Holding B.V. | Method of forming structures using a neutral beam |

| KR20210010817A (en) | 2019-07-19 | 2021-01-28 | 에이에스엠 아이피 홀딩 비.브이. | Method of Forming Topology-Controlled Amorphous Carbon Polymer Film |

| CN112309843A (en) | 2019-07-29 | 2021-02-02 | Asm Ip私人控股有限公司 | Selective deposition method for achieving high dopant doping |

| CN112309899A (en) | 2019-07-30 | 2021-02-02 | Asm Ip私人控股有限公司 | Substrate processing apparatus |

| CN112309900A (en) | 2019-07-30 | 2021-02-02 | Asm Ip私人控股有限公司 | Substrate processing apparatus |

| US11587815B2 (en) | 2019-07-31 | 2023-02-21 | Asm Ip Holding B.V. | Vertical batch furnace assembly |

| US11587814B2 (en) | 2019-07-31 | 2023-02-21 | Asm Ip Holding B.V. | Vertical batch furnace assembly |

| US11227782B2 (en) | 2019-07-31 | 2022-01-18 | Asm Ip Holding B.V. | Vertical batch furnace assembly |

| CN118422165A (en) | 2019-08-05 | 2024-08-02 | Asm Ip私人控股有限公司 | Liquid level sensor for chemical source container |

| USD965044S1 (en) | 2019-08-19 | 2022-09-27 | Asm Ip Holding B.V. | Susceptor shaft |

| USD965524S1 (en) | 2019-08-19 | 2022-10-04 | Asm Ip Holding B.V. | Susceptor support |

| JP2021031769A (en) | 2019-08-21 | 2021-03-01 | エーエスエム アイピー ホールディング ビー.ブイ. | Production apparatus of mixed gas of film deposition raw material and film deposition apparatus |

| KR20210024423A (en) | 2019-08-22 | 2021-03-05 | 에이에스엠 아이피 홀딩 비.브이. | Method for forming a structure with a hole |

| USD979506S1 (en) | 2019-08-22 | 2023-02-28 | Asm Ip Holding B.V. | Insulator |

| US11286558B2 (en) | 2019-08-23 | 2022-03-29 | Asm Ip Holding B.V. | Methods for depositing a molybdenum nitride film on a surface of a substrate by a cyclical deposition process and related semiconductor device structures including a molybdenum nitride film |

| US11859284B2 (en) * | 2019-08-23 | 2024-01-02 | Taiwan Semiconductor Manufacturing Company Ltd. | Shower head structure and plasma processing apparatus using the same |

| KR20210024420A (en) | 2019-08-23 | 2021-03-05 | 에이에스엠 아이피 홀딩 비.브이. | Method for depositing silicon oxide film having improved quality by peald using bis(diethylamino)silane |

| KR20210029090A (en) | 2019-09-04 | 2021-03-15 | 에이에스엠 아이피 홀딩 비.브이. | Methods for selective deposition using a sacrificial capping layer |

| KR20210029663A (en) | 2019-09-05 | 2021-03-16 | 에이에스엠 아이피 홀딩 비.브이. | Substrate processing apparatus |

| US11562901B2 (en) | 2019-09-25 | 2023-01-24 | Asm Ip Holding B.V. | Substrate processing method |

| CN112593212B (en) | 2019-10-02 | 2023-12-22 | Asm Ip私人控股有限公司 | Method for forming topologically selective silicon oxide film by cyclic plasma enhanced deposition process |

| KR20210042810A (en) | 2019-10-08 | 2021-04-20 | 에이에스엠 아이피 홀딩 비.브이. | Reactor system including a gas distribution assembly for use with activated species and method of using same |

| TWI846953B (en) | 2019-10-08 | 2024-07-01 | 荷蘭商Asm Ip私人控股有限公司 | Substrate processing device |

| KR20210043460A (en) | 2019-10-10 | 2021-04-21 | 에이에스엠 아이피 홀딩 비.브이. | Method of forming a photoresist underlayer and structure including same |

| US12009241B2 (en) | 2019-10-14 | 2024-06-11 | Asm Ip Holding B.V. | Vertical batch furnace assembly with detector to detect cassette |

| TWI834919B (en) | 2019-10-16 | 2024-03-11 | 荷蘭商Asm Ip私人控股有限公司 | Method of topology-selective film formation of silicon oxide |

| US11637014B2 (en) | 2019-10-17 | 2023-04-25 | Asm Ip Holding B.V. | Methods for selective deposition of doped semiconductor material |

| KR20210047808A (en) | 2019-10-21 | 2021-04-30 | 에이에스엠 아이피 홀딩 비.브이. | Apparatus and methods for selectively etching films |

| KR20210050453A (en) | 2019-10-25 | 2021-05-07 | 에이에스엠 아이피 홀딩 비.브이. | Methods for filling a gap feature on a substrate surface and related semiconductor structures |

| US11646205B2 (en) | 2019-10-29 | 2023-05-09 | Asm Ip Holding B.V. | Methods of selectively forming n-type doped material on a surface, systems for selectively forming n-type doped material, and structures formed using same |

| KR20210054983A (en) | 2019-11-05 | 2021-05-14 | 에이에스엠 아이피 홀딩 비.브이. | Structures with doped semiconductor layers and methods and systems for forming same |

| US11501968B2 (en) | 2019-11-15 | 2022-11-15 | Asm Ip Holding B.V. | Method for providing a semiconductor device with silicon filled gaps |

| KR20210062561A (en) | 2019-11-20 | 2021-05-31 | 에이에스엠 아이피 홀딩 비.브이. | Method of depositing carbon-containing material on a surface of a substrate, structure formed using the method, and system for forming the structure |

| CN112951697A (en) | 2019-11-26 | 2021-06-11 | Asm Ip私人控股有限公司 | Substrate processing apparatus |

| KR20210065848A (en) | 2019-11-26 | 2021-06-04 | 에이에스엠 아이피 홀딩 비.브이. | Methods for selectivley forming a target film on a substrate comprising a first dielectric surface and a second metallic surface |

| CN112885693A (en) | 2019-11-29 | 2021-06-01 | Asm Ip私人控股有限公司 | Substrate processing apparatus |

| CN112885692A (en) | 2019-11-29 | 2021-06-01 | Asm Ip私人控股有限公司 | Substrate processing apparatus |

| JP7527928B2 (en) | 2019-12-02 | 2024-08-05 | エーエスエム・アイピー・ホールディング・ベー・フェー | Substrate processing apparatus and substrate processing method |

| KR20210070898A (en) | 2019-12-04 | 2021-06-15 | 에이에스엠 아이피 홀딩 비.브이. | Substrate processing apparatus |

| TW202125596A (en) | 2019-12-17 | 2021-07-01 | 荷蘭商Asm Ip私人控股有限公司 | Method of forming vanadium nitride layer and structure including the vanadium nitride layer |

| US11527403B2 (en) | 2019-12-19 | 2022-12-13 | Asm Ip Holding B.V. | Methods for filling a gap feature on a substrate surface and related semiconductor structures |

| TW202140135A (en) | 2020-01-06 | 2021-11-01 | 荷蘭商Asm Ip私人控股有限公司 | Gas supply assembly and valve plate assembly |

| KR20210089079A (en) | 2020-01-06 | 2021-07-15 | 에이에스엠 아이피 홀딩 비.브이. | Channeled lift pin |

| US11993847B2 (en) | 2020-01-08 | 2024-05-28 | Asm Ip Holding B.V. | Injector |

| KR102675856B1 (en) | 2020-01-20 | 2024-06-17 | 에이에스엠 아이피 홀딩 비.브이. | Method of forming thin film and method of modifying surface of thin film |

| TW202130846A (en) | 2020-02-03 | 2021-08-16 | 荷蘭商Asm Ip私人控股有限公司 | Method of forming structures including a vanadium or indium layer |

| TW202146882A (en) | 2020-02-04 | 2021-12-16 | 荷蘭商Asm Ip私人控股有限公司 | Method of verifying an article, apparatus for verifying an article, and system for verifying a reaction chamber |

| US11776846B2 (en) | 2020-02-07 | 2023-10-03 | Asm Ip Holding B.V. | Methods for depositing gap filling fluids and related systems and devices |

| US11781243B2 (en) | 2020-02-17 | 2023-10-10 | Asm Ip Holding B.V. | Method for depositing low temperature phosphorous-doped silicon |

| TW202203344A (en) | 2020-02-28 | 2022-01-16 | 荷蘭商Asm Ip控股公司 | System dedicated for parts cleaning |

| KR20210116249A (en) | 2020-03-11 | 2021-09-27 | 에이에스엠 아이피 홀딩 비.브이. | lockout tagout assembly and system and method of using same |

| KR20210116240A (en) | 2020-03-11 | 2021-09-27 | 에이에스엠 아이피 홀딩 비.브이. | Substrate handling device with adjustable joints |

| CN113394086A (en) | 2020-03-12 | 2021-09-14 | Asm Ip私人控股有限公司 | Method for producing a layer structure having a target topological profile |

| KR20210124042A (en) | 2020-04-02 | 2021-10-14 | 에이에스엠 아이피 홀딩 비.브이. | Thin film forming method |

| TW202146689A (en) | 2020-04-03 | 2021-12-16 | 荷蘭商Asm Ip控股公司 | Method for forming barrier layer and method for manufacturing semiconductor device |

| TW202145344A (en) | 2020-04-08 | 2021-12-01 | 荷蘭商Asm Ip私人控股有限公司 | Apparatus and methods for selectively etching silcon oxide films |

| KR20210127620A (en) | 2020-04-13 | 2021-10-22 | 에이에스엠 아이피 홀딩 비.브이. | method of forming a nitrogen-containing carbon film and system for performing the method |

| KR20210128343A (en) | 2020-04-15 | 2021-10-26 | 에이에스엠 아이피 홀딩 비.브이. | Method of forming chromium nitride layer and structure including the chromium nitride layer |

| US11821078B2 (en) | 2020-04-15 | 2023-11-21 | Asm Ip Holding B.V. | Method for forming precoat film and method for forming silicon-containing film |

| US11996289B2 (en) | 2020-04-16 | 2024-05-28 | Asm Ip Holding B.V. | Methods of forming structures including silicon germanium and silicon layers, devices formed using the methods, and systems for performing the methods |

| JP2021172884A (en) | 2020-04-24 | 2021-11-01 | エーエスエム・アイピー・ホールディング・ベー・フェー | Method of forming vanadium nitride-containing layer and structure comprising vanadium nitride-containing layer |

| KR20210132600A (en) | 2020-04-24 | 2021-11-04 | 에이에스엠 아이피 홀딩 비.브이. | Methods and systems for depositing a layer comprising vanadium, nitrogen, and a further element |

| TW202146831A (en) | 2020-04-24 | 2021-12-16 | 荷蘭商Asm Ip私人控股有限公司 | Vertical batch furnace assembly, and method for cooling vertical batch furnace |

| KR20210134226A (en) | 2020-04-29 | 2021-11-09 | 에이에스엠 아이피 홀딩 비.브이. | Solid source precursor vessel |

| KR20210134869A (en) | 2020-05-01 | 2021-11-11 | 에이에스엠 아이피 홀딩 비.브이. | Fast FOUP swapping with a FOUP handler |

| TW202147543A (en) | 2020-05-04 | 2021-12-16 | 荷蘭商Asm Ip私人控股有限公司 | Semiconductor processing system |

| KR20210141379A (en) | 2020-05-13 | 2021-11-23 | 에이에스엠 아이피 홀딩 비.브이. | Laser alignment fixture for a reactor system |

| TW202146699A (en) | 2020-05-15 | 2021-12-16 | 荷蘭商Asm Ip私人控股有限公司 | Method of forming a silicon germanium layer, semiconductor structure, semiconductor device, method of forming a deposition layer, and deposition system |

| KR20210143653A (en) | 2020-05-19 | 2021-11-29 | 에이에스엠 아이피 홀딩 비.브이. | Substrate processing apparatus |

| KR20210145078A (en) | 2020-05-21 | 2021-12-01 | 에이에스엠 아이피 홀딩 비.브이. | Structures including multiple carbon layers and methods of forming and using same |

| KR102702526B1 (en) | 2020-05-22 | 2024-09-03 | 에이에스엠 아이피 홀딩 비.브이. | Apparatus for depositing thin films using hydrogen peroxide |

| TW202201602A (en) | 2020-05-29 | 2022-01-01 | 荷蘭商Asm Ip私人控股有限公司 | Substrate processing device |

| TW202212620A (en) | 2020-06-02 | 2022-04-01 | 荷蘭商Asm Ip私人控股有限公司 | Apparatus for processing substrate, method of forming film, and method of controlling apparatus for processing substrate |

| TW202218133A (en) | 2020-06-24 | 2022-05-01 | 荷蘭商Asm Ip私人控股有限公司 | Method for forming a layer provided with silicon |

| TW202217953A (en) | 2020-06-30 | 2022-05-01 | 荷蘭商Asm Ip私人控股有限公司 | Substrate processing method |

| KR102707957B1 (en) | 2020-07-08 | 2024-09-19 | 에이에스엠 아이피 홀딩 비.브이. | Method for processing a substrate |

| TW202219628A (en) | 2020-07-17 | 2022-05-16 | 荷蘭商Asm Ip私人控股有限公司 | Structures and methods for use in photolithography |

| TW202204662A (en) | 2020-07-20 | 2022-02-01 | 荷蘭商Asm Ip私人控股有限公司 | Method and system for depositing molybdenum layers |

| US12040177B2 (en) | 2020-08-18 | 2024-07-16 | Asm Ip Holding B.V. | Methods for forming a laminate film by cyclical plasma-enhanced deposition processes |

| KR20220027026A (en) | 2020-08-26 | 2022-03-07 | 에이에스엠 아이피 홀딩 비.브이. | Method and system for forming metal silicon oxide and metal silicon oxynitride |

| TW202229601A (en) | 2020-08-27 | 2022-08-01 | 荷蘭商Asm Ip私人控股有限公司 | Method of forming patterned structures, method of manipulating mechanical property, device structure, and substrate processing system |

| USD990534S1 (en) | 2020-09-11 | 2023-06-27 | Asm Ip Holding B.V. | Weighted lift pin |

| USD1012873S1 (en) * | 2020-09-24 | 2024-01-30 | Asm Ip Holding B.V. | Electrode for semiconductor processing apparatus |

| US12009224B2 (en) | 2020-09-29 | 2024-06-11 | Asm Ip Holding B.V. | Apparatus and method for etching metal nitrides |

| KR20220045900A (en) | 2020-10-06 | 2022-04-13 | 에이에스엠 아이피 홀딩 비.브이. | Deposition method and an apparatus for depositing a silicon-containing material |

| CN114293174A (en) | 2020-10-07 | 2022-04-08 | Asm Ip私人控股有限公司 | Gas supply unit and substrate processing apparatus including the same |

| TW202229613A (en) | 2020-10-14 | 2022-08-01 | 荷蘭商Asm Ip私人控股有限公司 | Method of depositing material on stepped structure |

| KR20220053482A (en) | 2020-10-22 | 2022-04-29 | 에이에스엠 아이피 홀딩 비.브이. | Method of depositing vanadium metal, structure, device and a deposition assembly |

| TW202223136A (en) | 2020-10-28 | 2022-06-16 | 荷蘭商Asm Ip私人控股有限公司 | Method for forming layer on substrate, and semiconductor processing system |

| TW202235649A (en) | 2020-11-24 | 2022-09-16 | 荷蘭商Asm Ip私人控股有限公司 | Methods for filling a gap and related systems and devices |

| TW202235675A (en) | 2020-11-30 | 2022-09-16 | 荷蘭商Asm Ip私人控股有限公司 | Injector, and substrate processing apparatus |

| US11946137B2 (en) | 2020-12-16 | 2024-04-02 | Asm Ip Holding B.V. | Runout and wobble measurement fixtures |

| TW202231903A (en) | 2020-12-22 | 2022-08-16 | 荷蘭商Asm Ip私人控股有限公司 | Transition metal deposition method, transition metal layer, and deposition assembly for depositing transition metal on substrate |

| USD1023959S1 (en) | 2021-05-11 | 2024-04-23 | Asm Ip Holding B.V. | Electrode for substrate processing apparatus |

| USD981973S1 (en) | 2021-05-11 | 2023-03-28 | Asm Ip Holding B.V. | Reactor wall for substrate processing apparatus |

| USD980814S1 (en) | 2021-05-11 | 2023-03-14 | Asm Ip Holding B.V. | Gas distributor for substrate processing apparatus |

| USD980813S1 (en) | 2021-05-11 | 2023-03-14 | Asm Ip Holding B.V. | Gas flow control plate for substrate processing apparatus |

| USD990441S1 (en) | 2021-09-07 | 2023-06-27 | Asm Ip Holding B.V. | Gas flow control plate |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5000113A (en) * | 1986-12-19 | 1991-03-19 | Applied Materials, Inc. | Thermal CVD/PECVD reactor and use for thermal chemical vapor deposition of silicon dioxide and in-situ multi-step planarized process |

| US4872947A (en) * | 1986-12-19 | 1989-10-10 | Applied Materials, Inc. | CVD of silicon oxide using TEOS decomposition and in-situ planarization process |

| US4892753A (en) * | 1986-12-19 | 1990-01-09 | Applied Materials, Inc. | Process for PECVD of silicon oxide using TEOS decomposition |

| US5871811A (en) * | 1986-12-19 | 1999-02-16 | Applied Materials, Inc. | Method for protecting against deposition on a selected region of a substrate |

| US6079356A (en) * | 1997-12-02 | 2000-06-27 | Applied Materials, Inc. | Reactor optimized for chemical vapor deposition of titanium |

| US6106625A (en) * | 1997-12-02 | 2000-08-22 | Applied Materials, Inc. | Reactor useful for chemical vapor deposition of titanium nitride |

| US6050506A (en) * | 1998-02-13 | 2000-04-18 | Applied Materials, Inc. | Pattern of apertures in a showerhead for chemical vapor deposition |

| KR20020080014A (en) * | 2001-04-10 | 2002-10-23 | 주식회사 에이티씨 | plasma processing apparatus |

| JP4502639B2 (en) * | 2003-06-19 | 2010-07-14 | 財団法人国際科学振興財団 | Shower plate, plasma processing apparatus, and product manufacturing method |

| US20050284573A1 (en) * | 2004-06-24 | 2005-12-29 | Egley Fred D | Bare aluminum baffles for resist stripping chambers |

| JP4550507B2 (en) * | 2004-07-26 | 2010-09-22 | 株式会社日立ハイテクノロジーズ | Plasma processing equipment |

| JP2007042951A (en) * | 2005-08-04 | 2007-02-15 | Tokyo Electron Ltd | Plasma processing device |

| JP2008235611A (en) * | 2007-03-21 | 2008-10-02 | Tohoku Univ | Plasma processing equipment and method for processing plasma |

-

2008

- 2008-12-26 JP JP2008331822A patent/JP5268626B2/en not_active Expired - Fee Related

-

2009

- 2009-01-29 KR KR1020090006817A patent/KR101039087B1/en not_active IP Right Cessation

- 2009-02-25 US US12/392,237 patent/US20100163187A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| KR20100076848A (en) | 2010-07-06 |

| US20100163187A1 (en) | 2010-07-01 |

| JP2010153680A (en) | 2010-07-08 |

| KR101039087B1 (en) | 2011-06-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5268626B2 (en) | Plasma processing equipment | |

| US11482418B2 (en) | Substrate processing method and apparatus | |

| JP5371466B2 (en) | Plasma processing method | |

| TWI670783B (en) | Methods and systems to enhance process uniformity | |

| JP5457037B2 (en) | Inert gas injection into the edge of the substrate | |

| US20090218317A1 (en) | Method to control uniformity using tri-zone showerhead | |

| US7832354B2 (en) | Cathode liner with wafer edge gas injection in a plasma reactor chamber | |

| US20090057269A1 (en) | Method of processing a workpiece in a plasma reactor with independent wafer edge process gas injection | |

| TWI430395B (en) | Cathode liner with wafer edge gas injection in a plasma reactor chamber | |

| US20110203735A1 (en) | Gas injection system for etching profile control | |

| JP6050944B2 (en) | Plasma etching method and plasma processing apparatus | |

| US11309165B2 (en) | Gas showerhead, manufacturing method, and plasma apparatus including the gas showerhead | |

| CN111095498B (en) | Mounting table, substrate processing apparatus, and edge ring | |

| KR20120094980A (en) | Plazma treatment apparatus | |

| JP2014082354A (en) | Plasma processing apparatus | |

| JP2007067037A (en) | Vacuum processing device | |

| JP2002217171A (en) | Etching equipment | |

| JP3913244B2 (en) | Substrate processing method | |

| JP2018121051A (en) | Plasma processing device | |

| JP2000294538A (en) | Vacuum treatment apparatus | |

| WO2015016980A1 (en) | Gas diffuser hole design for improving edge uniformity | |

| JP2006120872A (en) | Gaseous diffusion plate | |

| KR101197020B1 (en) | Substrate processing apparatus for uniform plasma discharge and method of adjusting strength of plasma discharge | |

| JP2006344701A (en) | Etching device and etching method | |

| JP4642358B2 (en) | Wafer mounting electrode |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111222 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20111222 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111222 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120913 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120925 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121121 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20121218 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130215 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130409 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130507 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |