JP5208927B2 - 高速デジタル印刷装置 - Google Patents

高速デジタル印刷装置 Download PDFInfo

- Publication number

- JP5208927B2 JP5208927B2 JP2009513179A JP2009513179A JP5208927B2 JP 5208927 B2 JP5208927 B2 JP 5208927B2 JP 2009513179 A JP2009513179 A JP 2009513179A JP 2009513179 A JP2009513179 A JP 2009513179A JP 5208927 B2 JP5208927 B2 JP 5208927B2

- Authority

- JP

- Japan

- Prior art keywords

- image

- ink

- intermediate transfer

- image forming

- speed digital

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000007639 printing Methods 0.000 claims description 24

- 238000003384 imaging method Methods 0.000 claims description 15

- 230000007246 mechanism Effects 0.000 claims description 12

- 239000007788 liquid Substances 0.000 claims description 10

- 229920001971 elastomer Polymers 0.000 claims 1

- 239000000806 elastomer Substances 0.000 claims 1

- 239000000976 ink Substances 0.000 description 76

- 239000002245 particle Substances 0.000 description 46

- 239000002904 solvent Substances 0.000 description 36

- 238000000034 method Methods 0.000 description 16

- 239000000049 pigment Substances 0.000 description 11

- 239000003086 colorant Substances 0.000 description 9

- 238000005516 engineering process Methods 0.000 description 9

- 239000012141 concentrate Substances 0.000 description 8

- 230000008569 process Effects 0.000 description 8

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- 238000004140 cleaning Methods 0.000 description 5

- 238000005194 fractionation Methods 0.000 description 5

- 239000000356 contaminant Substances 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 238000000926 separation method Methods 0.000 description 4

- 230000008901 benefit Effects 0.000 description 3

- 239000000084 colloidal system Substances 0.000 description 3

- 239000006260 foam Substances 0.000 description 3

- 229920000642 polymer Polymers 0.000 description 3

- 238000007711 solidification Methods 0.000 description 3

- 230000008023 solidification Effects 0.000 description 3

- 239000003795 chemical substances by application Substances 0.000 description 2

- 239000000701 coagulant Substances 0.000 description 2

- 238000004581 coalescence Methods 0.000 description 2

- 238000001704 evaporation Methods 0.000 description 2

- 230000008020 evaporation Effects 0.000 description 2

- 238000001914 filtration Methods 0.000 description 2

- 238000007641 inkjet printing Methods 0.000 description 2

- 239000010410 layer Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 239000003960 organic solvent Substances 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 239000011148 porous material Substances 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 230000001681 protective effect Effects 0.000 description 2

- 239000006228 supernatant Substances 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 description 1

- 239000005997 Calcium carbide Substances 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000004927 clay Substances 0.000 description 1

- 238000005345 coagulation Methods 0.000 description 1

- 230000015271 coagulation Effects 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000006731 degradation reaction Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000010556 emulsion polymerization method Methods 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 238000005469 granulation Methods 0.000 description 1

- 230000003179 granulation Effects 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 239000002480 mineral oil Substances 0.000 description 1

- 235000010446 mineral oil Nutrition 0.000 description 1

- 238000007645 offset printing Methods 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 239000011241 protective layer Substances 0.000 description 1

- 238000000746 purification Methods 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 238000001694 spray drying Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- CLZWAWBPWVRRGI-UHFFFAOYSA-N tert-butyl 2-[2-[2-[2-[bis[2-[(2-methylpropan-2-yl)oxy]-2-oxoethyl]amino]-5-bromophenoxy]ethoxy]-4-methyl-n-[2-[(2-methylpropan-2-yl)oxy]-2-oxoethyl]anilino]acetate Chemical compound CC1=CC=C(N(CC(=O)OC(C)(C)C)CC(=O)OC(C)(C)C)C(OCCOC=2C(=CC=C(Br)C=2)N(CC(=O)OC(C)(C)C)CC(=O)OC(C)(C)C)=C1 CLZWAWBPWVRRGI-UHFFFAOYSA-N 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000010792 warming Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/0057—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material where an intermediate transfer member receives the ink before transferring it on the printing material

Landscapes

- Ink Jet (AREA)

- Ink Jet Recording Methods And Recording Media Thereof (AREA)

Description

Claims (4)

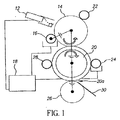

- 高速デジタル印刷装置であって、

画像形成部材と、

前記画像形成部材の上に画像の形状でインクを噴射することのできるインクジェットヘッドと、

前記画像形成部材の上のそのような画像の形状のインクを分画して、そこから液体を除去するためのメカニズムと、

そのような画像の形状のインクを前記画像形成部材から転写する先となる中間転写部材と、

前記中間転写部材とともに挟持部を形成し、液体が除去された画像の形状のインクを受像体に転写する転写部材と、

を備え、

前記画像形成部材の上のそのような画像の形状のインクを分画するための前記メカニズムは、前記画像形成部材と前記中間転写部材との間にかかる電気的バイアスを有し、

さらに、前記中間転写部材の上のそのような画像の形状のインクを分画して、そこから液体を除去するための第二のメカニズムを備えることを特徴とする高速デジタル印刷装置。 - 請求項1に記載の高速デジタル印刷装置であって、

前記画像形成部材の上のそのような画像の形状のインクを分画するための前記メカニズムは、電気的にバイアス可能なスカイビング部材であることを特徴とする高速デジタル印刷装置。 - 請求項1に記載の高速デジタル印刷装置であって、

前記中間転写部材はエラストマブランケットを備えることを特徴とする高速デジタル印刷装置。 - 請求項1に記載の高速デジタル印刷装置であって、

さらに、複数のモジュールを備え、各モジュールは画像形成部材と、前記画像形成部材の上に画像の形状でインクを噴射することのできるインクジェットヘッドと、前記画像形成部材の上のそのような画像の形状のインクを分画してそこから液体を除去するためのメカニズムと、そのような画像の形状のインクを前記画像形成部材から転写する先となる中間転写部材と、前記中間転写部材とともに挟持部を形成し、液体の除去された画像の形状のインクを、前記残りの複数のモジュールからの画像の形状のインクと見当合わせして受像体の上に転写するための転写部材と、を備えることを特徴とする高速デジタル印刷装置。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/445,712 | 2006-06-02 | ||

| US11/445,712 US7819518B2 (en) | 2006-06-02 | 2006-06-02 | Digital printing apparatus for producing prints at high speed |

| PCT/US2007/012252 WO2007142828A2 (en) | 2006-06-02 | 2007-05-23 | High speed digital printing apparatus |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2009538757A JP2009538757A (ja) | 2009-11-12 |

| JP2009538757A5 JP2009538757A5 (ja) | 2011-07-14 |

| JP5208927B2 true JP5208927B2 (ja) | 2013-06-12 |

Family

ID=38789583

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009513179A Expired - Fee Related JP5208927B2 (ja) | 2006-06-02 | 2007-05-23 | 高速デジタル印刷装置 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7819518B2 (ja) |

| EP (1) | EP2026970A2 (ja) |

| JP (1) | JP5208927B2 (ja) |

| WO (1) | WO2007142828A2 (ja) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7823996B2 (en) * | 2006-06-02 | 2010-11-02 | Eastman Kodak Company | Concentrating a liquid ink jet ink to transfer to a receiver member |

| JP2013121717A (ja) * | 2011-11-08 | 2013-06-20 | Canon Inc | 画像記録方法 |

| US8602535B2 (en) | 2012-03-28 | 2013-12-10 | Eastman Kodak Company | Digital drop patterning device and method |

| US8936353B2 (en) | 2012-03-28 | 2015-01-20 | Eastman Kodak Company | Digital drop patterning device and method |

| US8936354B2 (en) | 2012-03-28 | 2015-01-20 | Eastman Kodak Company | Digital drop patterning device and method |

| US8939551B2 (en) | 2012-03-28 | 2015-01-27 | Eastman Kodak Company | Digital drop patterning device and method |

| US20140015879A1 (en) * | 2012-07-12 | 2014-01-16 | Michael Alan Marcus | Intermediate member for large-particle inkjet development |

| CN104823115A (zh) * | 2012-11-23 | 2015-08-05 | 惠普深蓝有限责任公司 | 墨转移元件 |

| US9067449B2 (en) * | 2013-06-13 | 2015-06-30 | Canon Kabushiki Kaisha | Image recording method by serially transferring intermediate images |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3223927B2 (ja) * | 1991-08-23 | 2001-10-29 | セイコーエプソン株式会社 | 転写式記録装置 |

| JPH05261904A (ja) * | 1992-03-19 | 1993-10-12 | Seiko Epson Corp | 転写型インクジェットプリンタ |

| JPH06126945A (ja) * | 1992-10-16 | 1994-05-10 | Seiko Epson Corp | 転写型インクジェットプリンタ |

| SG46523A1 (en) | 1992-03-19 | 1998-02-20 | Seiko Epson Corp | Transfer type ink jet printer |

| JPH05318714A (ja) * | 1992-05-25 | 1993-12-03 | Seiko Epson Corp | インクジェット記録装置 |

| JP3178174B2 (ja) * | 1992-08-04 | 2001-06-18 | セイコーエプソン株式会社 | インクジェット記録用インク組成物 |

| US6389242B1 (en) * | 2000-09-15 | 2002-05-14 | Toshiba Tec Kabushiki Kaisha | Image forming apparatus and image forming method |

| US6719423B2 (en) * | 2001-10-09 | 2004-04-13 | Nexpress Solutions Llc | Ink jet process including removal of excess liquid from an intermediate member |

| US20030146963A1 (en) * | 2002-10-31 | 2003-08-07 | John Murray | Micro-diffusion ink and ink jet printing process |

-

2006

- 2006-06-02 US US11/445,712 patent/US7819518B2/en not_active Expired - Fee Related

-

2007

- 2007-05-23 JP JP2009513179A patent/JP5208927B2/ja not_active Expired - Fee Related

- 2007-05-23 EP EP07795209A patent/EP2026970A2/en not_active Withdrawn

- 2007-05-23 WO PCT/US2007/012252 patent/WO2007142828A2/en active Application Filing

Also Published As

| Publication number | Publication date |

|---|---|

| EP2026970A2 (en) | 2009-02-25 |

| WO2007142828A3 (en) | 2008-05-02 |

| US7819518B2 (en) | 2010-10-26 |

| JP2009538757A (ja) | 2009-11-12 |

| WO2007142828A2 (en) | 2007-12-13 |

| US20070279472A1 (en) | 2007-12-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5208927B2 (ja) | 高速デジタル印刷装置 | |

| US7677716B2 (en) | Latent inkjet printing, to avoid drying and liquid-loading problems, and provide sharper imaging | |

| JP5063687B2 (ja) | インクジェット印刷 | |

| JP2009538754A (ja) | インクジェット画像の製造 | |

| CN103481689A (zh) | 用于实施数字平版胶印印刷技术的系统和方法 | |

| US9014598B2 (en) | Oil vapor condensate drainage using oleophilic channels | |

| US6385405B1 (en) | Method and apparatus for combining xerographic and ink jet printing | |

| US20140331876A1 (en) | In-line integrated raised printing | |

| US9639050B2 (en) | Electrophotographic patterning of an image definition material | |

| JP3105388B2 (ja) | 印刷方法及び該方法を実施するための印刷機 | |

| US9551934B2 (en) | Imaging system with electrophotographic patterning of an image definition material and methods therefor | |

| WO2001092968A3 (de) | Einrichtung und verfahren zum reinigen und zum regenerieren eines bildträgers beim elektrografischen drucken oder kopieren unter verwendung flüssiger farbmittel | |

| US11628665B2 (en) | Digital ink application module and methods thereof | |

| US8758970B2 (en) | Deinking a print | |

| JP6929236B2 (ja) | 耐汚染性の画像形成部材洗浄デバイスおよび方法 | |

| JP3133030B2 (ja) | 強誘電性記録部材からの自己固定印刷のための方法および手段 | |

| US20130127149A1 (en) | Deinkable print | |

| US9096055B2 (en) | Systems and methods for ink-based digital printing | |

| US8801170B2 (en) | Producing a deinkable print | |

| US20130129393A1 (en) | Producing a deinkable print | |

| Garg | Identification and Characterization of Printing Processes on the Basis of Print Edge Analysis | |

| JPH01301279A (ja) | 容器の多色印刷方法 | |

| JPH11291604A (ja) | 印刷装置及び印刷方法 | |

| Wolf | Indigo's Ultrastream 2000: Has Offset-Like Quality Finally Been Achieved? | |

| JP2006264210A (ja) | 不揮発性液体現像剤を用いたデジタル印刷装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100519 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100519 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110518 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120508 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120801 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120925 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121129 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130129 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130220 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20160301 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |