JP5063687B2 - インクジェット印刷 - Google Patents

インクジェット印刷 Download PDFInfo

- Publication number

- JP5063687B2 JP5063687B2 JP2009513173A JP2009513173A JP5063687B2 JP 5063687 B2 JP5063687 B2 JP 5063687B2 JP 2009513173 A JP2009513173 A JP 2009513173A JP 2009513173 A JP2009513173 A JP 2009513173A JP 5063687 B2 JP5063687 B2 JP 5063687B2

- Authority

- JP

- Japan

- Prior art keywords

- ink

- printing

- cells

- image

- marking

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000007641 inkjet printing Methods 0.000 title description 14

- 238000007639 printing Methods 0.000 claims description 50

- 238000012546 transfer Methods 0.000 claims description 23

- 239000000049 pigment Substances 0.000 claims description 20

- 239000002245 particle Substances 0.000 claims description 18

- 230000007246 mechanism Effects 0.000 claims description 6

- 239000000976 ink Substances 0.000 description 102

- 210000004027 cell Anatomy 0.000 description 59

- 239000000543 intermediate Substances 0.000 description 34

- 238000000034 method Methods 0.000 description 32

- 239000007788 liquid Substances 0.000 description 27

- 230000008569 process Effects 0.000 description 23

- 238000003384 imaging method Methods 0.000 description 20

- 238000007774 anilox coating Methods 0.000 description 13

- 239000002904 solvent Substances 0.000 description 13

- 238000000926 separation method Methods 0.000 description 7

- 229910000831 Steel Inorganic materials 0.000 description 6

- 238000005516 engineering process Methods 0.000 description 6

- 238000007646 gravure printing Methods 0.000 description 6

- 239000010959 steel Substances 0.000 description 6

- 238000004140 cleaning Methods 0.000 description 5

- 239000003086 colorant Substances 0.000 description 5

- 229920000642 polymer Polymers 0.000 description 5

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 5

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 4

- 239000000919 ceramic Substances 0.000 description 4

- 239000000975 dye Substances 0.000 description 4

- 239000012530 fluid Substances 0.000 description 4

- 238000007645 offset printing Methods 0.000 description 4

- 239000000758 substrate Substances 0.000 description 4

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 3

- 238000013459 approach Methods 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 3

- 238000001035 drying Methods 0.000 description 3

- 230000005684 electric field Effects 0.000 description 3

- 238000005194 fractionation Methods 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- 150000001298 alcohols Chemical class 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 210000002421 cell wall Anatomy 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 239000000701 coagulant Substances 0.000 description 2

- 230000003750 conditioning effect Effects 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- 238000000151 deposition Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000001704 evaporation Methods 0.000 description 2

- 238000005562 fading Methods 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 238000013518 transcription Methods 0.000 description 2

- 230000035897 transcription Effects 0.000 description 2

- CNPVJWYWYZMPDS-UHFFFAOYSA-N 2-methyldecane Chemical compound CCCCCCCCC(C)C CNPVJWYWYZMPDS-UHFFFAOYSA-N 0.000 description 1

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 1

- 241000876833 Emberizinae Species 0.000 description 1

- -1 Isopar L Chemical class 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- 101710149792 Triosephosphate isomerase, chloroplastic Proteins 0.000 description 1

- 101710195516 Triosephosphate isomerase, glycosomal Proteins 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical group [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 230000000740 bleeding effect Effects 0.000 description 1

- 238000010960 commercial process Methods 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 238000004132 cross linking Methods 0.000 description 1

- 230000002950 deficient Effects 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 230000001627 detrimental effect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 229920001971 elastomer Polymers 0.000 description 1

- 239000000806 elastomer Substances 0.000 description 1

- 230000005686 electrostatic field Effects 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 239000012634 fragment Substances 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- 238000001802 infusion Methods 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000002480 mineral oil Substances 0.000 description 1

- 235000010446 mineral oil Nutrition 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 231100000653 occupational exposure banding Toxicity 0.000 description 1

- 239000011236 particulate material Substances 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 229920005596 polymer binder Polymers 0.000 description 1

- 239000002491 polymer binding agent Substances 0.000 description 1

- 239000002861 polymer material Substances 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 229920002545 silicone oil Polymers 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 235000012424 soybean oil Nutrition 0.000 description 1

- 239000003549 soybean oil Substances 0.000 description 1

- 230000007723 transport mechanism Effects 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/0057—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material where an intermediate transfer member receives the ink before transferring it on the printing material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

Landscapes

- Ink Jet (AREA)

- Rotary Presses (AREA)

- Inks, Pencil-Leads, Or Crayons (AREA)

Description

を一様にコーティングするよう、グラビアインクの粘性は、約50乃至1,000センチポアズの範囲である(低剪断条件下で測定)。

10,10’ 印刷装置

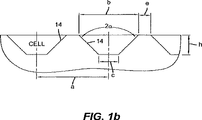

12,12’ テクスチャ加工されたイメージング部材(TIM)

14,14’ セル

16a−16d イメージングユニット

18 インクジェットデバイス

20 インキングユニット

21 導電ローラー

22 中間部材

24 調整ユニット

26 除去ユニット

28 転写域

30 クリーニングユニット

40a−40d イメージングユニット

42 インキングユニット

44 ローラー

46 インクジェットユニット

48 中間部材

50 調整ユニット

52 除去ユニット

54 転写域

56 クリーニングユニット

60 液体

62 顔料インク

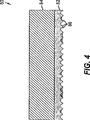

80 アニロックスローラー

82 セラミック層

84 スチール基材

86 セル

L ロジック及び制御デバイス

R,R’ レシーバ部材

V 電源

Claims (3)

- 非マーキングインク及びマーキングインクを使用する印刷装置であって、

印刷部材であって、当該印刷部材の表面に位置づけられ、前記表面に対して深さを有する、実質的に同等の寸法を有する一連のセルを含む、印刷部材と、

非マーキングインクの液滴を所望のネガティブ潜像パターンにおいて前記印刷部材の前記セルへと選択的に放出するインクジェットデバイスと、

前記印刷部材の、空である又は部分的に充填されたセルが満たされるように、帯電性の顔料粒子を有するマーキングインクを適用するインキングユニットと、

前記セル内の前記インク中のおける、前記帯電性の顔料粒子を有する前記マーキングインクが、前記表面の近くに配置されるように電気バイアスを印加することによって、前記セル内の前記インクを分別する電気バイアス印加装置と、前記表面の近くの前記インクの一部をレシーバへと転写する中間部材と、を含む転写機構と、

を有する印刷装置。 - 前記印刷部材は、前記セルを有するローラーであり、該セルは、密接につめられた構造において該ローラーの円周表面全体に実質的にわたって位置決めされる、

請求項1記載の印刷装置。 - 構造は、六角形、菱形、矩形、及び楕円形を有する構造の群から選択される、

請求項2記載の印刷装置。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/445,714 | 2006-06-02 | ||

| US11/445,714 US7789504B2 (en) | 2006-06-02 | 2006-06-02 | Ink jet printing using a combination of non-marking and marking inks |

| PCT/US2007/012085 WO2007142807A2 (en) | 2006-06-02 | 2007-05-21 | Ink jet printing |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2009538755A JP2009538755A (ja) | 2009-11-12 |

| JP2009538755A5 JP2009538755A5 (ja) | 2011-06-30 |

| JP5063687B2 true JP5063687B2 (ja) | 2012-10-31 |

Family

ID=38649960

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009513173A Expired - Fee Related JP5063687B2 (ja) | 2006-06-02 | 2007-05-21 | インクジェット印刷 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7789504B2 (ja) |

| EP (1) | EP2024181A2 (ja) |

| JP (1) | JP5063687B2 (ja) |

| WO (1) | WO2007142807A2 (ja) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5539703B2 (ja) * | 2009-11-26 | 2014-07-02 | 株式会社ミマキエンジニアリング | 印刷方法及び印刷システム |

| JP2013121717A (ja) * | 2011-11-08 | 2013-06-20 | Canon Inc | 画像記録方法 |

| US8936353B2 (en) | 2012-03-28 | 2015-01-20 | Eastman Kodak Company | Digital drop patterning device and method |

| US8939551B2 (en) | 2012-03-28 | 2015-01-27 | Eastman Kodak Company | Digital drop patterning device and method |

| US8936354B2 (en) | 2012-03-28 | 2015-01-20 | Eastman Kodak Company | Digital drop patterning device and method |

| US8602535B2 (en) | 2012-03-28 | 2013-12-10 | Eastman Kodak Company | Digital drop patterning device and method |

| FR2990153B1 (fr) * | 2012-05-07 | 2014-12-26 | Mgi France | Dispositif de controle de depot de matiere(s) pour systeme d’impression offset et procede de mise en oeuvre du dispositif |

| US9354557B2 (en) * | 2013-06-12 | 2016-05-31 | Canon Kabushiki Kaisha | Intermediate transfer member and image recording method |

| US9327498B1 (en) * | 2015-03-04 | 2016-05-03 | Xerox Corporation | System and method for applying electromagnetic ink to a non-electromagnetic ink image |

| US20170182829A1 (en) * | 2015-12-28 | 2017-06-29 | Energy Sciences Inc. | Electron beam curing of polymeric inks |

| US11472195B2 (en) | 2018-03-14 | 2022-10-18 | Hewlett-Packard Development Company, L.P. | Redundancy print modes |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5539440A (en) * | 1992-03-30 | 1996-07-23 | Kabushiki Kaisha Toshiba | Image forming apparatus having colorant holding regions and a colorant repelling region |

| US6109746A (en) * | 1998-05-26 | 2000-08-29 | Eastman Kodak Company | Delivering mixed inks to an intermediate transfer roller |

| US6481840B1 (en) * | 1999-08-25 | 2002-11-19 | Xerox Corporation | Automatic document feed of phase change inks |

| US6529220B1 (en) | 1999-09-06 | 2003-03-04 | Fuji Photo Film Co., Ltd. | Method and apparatus for forming image with image recording liquid and dummy liquid |

| US6682189B2 (en) | 2001-10-09 | 2004-01-27 | Nexpress Solutions Llc | Ink jet imaging via coagulation on an intermediate member |

| US6719423B2 (en) | 2001-10-09 | 2004-04-13 | Nexpress Solutions Llc | Ink jet process including removal of excess liquid from an intermediate member |

| US6932469B2 (en) * | 2001-10-09 | 2005-08-23 | Eastman Kodak Company | Imaging using a coagulable ink on an intermediate member |

| US6663215B2 (en) | 2001-10-25 | 2003-12-16 | Hewlett-Packard Company, L.P. | Printhead service station |

| JP4002859B2 (ja) * | 2002-12-27 | 2007-11-07 | 株式会社イソワ | インク除去回収装置および該装置を備えた印刷機、並びにインクの供給/回収方法 |

-

2006

- 2006-06-02 US US11/445,714 patent/US7789504B2/en not_active Expired - Fee Related

-

2007

- 2007-05-21 JP JP2009513173A patent/JP5063687B2/ja not_active Expired - Fee Related

- 2007-05-21 WO PCT/US2007/012085 patent/WO2007142807A2/en active Application Filing

- 2007-05-21 EP EP07795117A patent/EP2024181A2/en not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| WO2007142807A3 (en) | 2008-02-14 |

| EP2024181A2 (en) | 2009-02-18 |

| US7789504B2 (en) | 2010-09-07 |

| JP2009538755A (ja) | 2009-11-12 |

| US20070279473A1 (en) | 2007-12-06 |

| WO2007142807A2 (en) | 2007-12-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5063687B2 (ja) | インクジェット印刷 | |

| EP2024180B1 (en) | Producing an ink jet image | |

| US7959278B2 (en) | Method and apparatus for ink jet printing on patterned substrate | |

| US6761446B2 (en) | Ink jet process including removal of excess liquid from an intermediate member | |

| US6354701B2 (en) | Apparatus and method for printing | |

| EP0294172A2 (en) | Acoustic ink printer | |

| US20080192105A1 (en) | Digital printing apparatus fittable in a flexographic printing system | |

| US20070279472A1 (en) | Digital printing apparatus for producing prints at high speed | |

| EP2670597B1 (en) | Printers, methods, and apparatus to form an image on a print substrate | |

| US6385405B1 (en) | Method and apparatus for combining xerographic and ink jet printing | |

| US7585035B2 (en) | Marking device and method for golf ball | |

| US5821956A (en) | Method to improve solid ink output resolution | |

| JP2007253621A (ja) | 印刷版および印刷機の印刷装置 | |

| US11628665B2 (en) | Digital ink application module and methods thereof | |

| JPH05318714A (ja) | インクジェット記録装置 | |

| US7396107B2 (en) | Ink jet printing with low coverage second pass | |

| EP3765295A1 (en) | Image formation with image-receiving holder and image formation medium | |

| Harper | An Investigation into the relationship between contrast and resolution of a printing system using the RIT contrast resolution test target | |

| JP2004042584A (ja) | 無版転写印刷法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100511 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100511 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110506 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110802 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20111101 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20111109 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111130 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120731 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120807 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150817 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |