JP5081624B2 - 溶接装置 - Google Patents

溶接装置 Download PDFInfo

- Publication number

- JP5081624B2 JP5081624B2 JP2007536006A JP2007536006A JP5081624B2 JP 5081624 B2 JP5081624 B2 JP 5081624B2 JP 2007536006 A JP2007536006 A JP 2007536006A JP 2007536006 A JP2007536006 A JP 2007536006A JP 5081624 B2 JP5081624 B2 JP 5081624B2

- Authority

- JP

- Japan

- Prior art keywords

- welding

- head

- welding method

- position change

- control means

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000003466 welding Methods 0.000 title claims description 357

- 238000000034 method Methods 0.000 claims abstract description 112

- 230000008859 change Effects 0.000 claims abstract description 66

- 230000008569 process Effects 0.000 claims abstract description 7

- 238000001514 detection method Methods 0.000 claims description 37

- 230000005855 radiation Effects 0.000 claims description 5

- 238000003754 machining Methods 0.000 claims description 3

- 230000001419 dependent effect Effects 0.000 claims description 2

- 238000003825 pressing Methods 0.000 claims description 2

- 239000007789 gas Substances 0.000 claims 1

- 238000010348 incorporation Methods 0.000 claims 1

- 239000011261 inert gas Substances 0.000 claims 1

- 238000000926 separation method Methods 0.000 abstract description 12

- 238000004381 surface treatment Methods 0.000 abstract description 12

- 230000009471 action Effects 0.000 description 8

- 230000015572 biosynthetic process Effects 0.000 description 8

- 230000001133 acceleration Effects 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 230000000630 rising effect Effects 0.000 description 4

- 230000006978 adaptation Effects 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 241001093575 Alma Species 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000010985 leather Substances 0.000 description 1

- 239000011344 liquid material Substances 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 1

- 229910052753 mercury Inorganic materials 0.000 description 1

- 230000000750 progressive effect Effects 0.000 description 1

- 230000011218 segmentation Effects 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K37/00—Auxiliary devices or processes, not specially adapted to a procedure covered by only one of the preceding main groups

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/10—Other electric circuits therefor; Protective circuits; Remote controls

- B23K9/1087—Arc welding using remote control

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/095—Monitoring or automatic control of welding parameters

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Plasma & Fusion (AREA)

- Optics & Photonics (AREA)

- Arc Welding In General (AREA)

- Butt Welding And Welding Of Specific Article (AREA)

Description

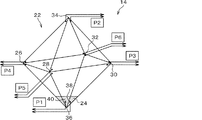

検知手段であるセンサー(16)は作業ヘッド(4)の並進位置又は並進位置変更を検知する。

空間内の三次元的基準点が労働者によって或いは制御手段18によって選択できる。

制御手段は選択された基準位置又は検知手段によって検知された溶接ヘッド(4)の位置或いは位置変更の少なくとも一つに依存して溶接法の特性量を所定値として組み込む。

4....溶接ヘッド

6....エネルギー源

8....溶接ワイア

14、16...センサー

18...制御ユニット

20...制御装置

22...ハウジング

24...正8面体

26、28、30、32、34、36...先端

38、40...接点

42...球

44、46、48、50...板

56...操作装置

58...表示装置

60...床薄板

62...垂直側面薄板

64...垂直側面薄板

66...垂直側面薄板

68...上薄板

Claims (25)

- 加工すべき工作物に作用する作業ヘッドとして溶接すべき工作物に溶接エネルギーを与える溶接ヘッドを備えて、溶接方法を実施する手動案内された溶接装置において、溶接方法の少なくとも一つの特性量が検知された位置及び位置変更又はそのいずれか一方に依存して影響を受けるように、空間内の基準点或いは加工すべき、即ち溶接すべき工作物又は少なくともその一つに対して作業ヘッド(4)の並進位置又は並進位置変更を検知するセンサー(16)を包含する検知手段を備えて、

検知手段によって検知された作業ヘッド(4)の位置及び位置変更又はそのいずれか一方に依存して溶接方法の少なくとも一つの特性量を自動的にオープンループ制御する制御手段(18)を備えて、

溶接方法の少なくとも一つの特性量が検知手段によって検知された溶接ヘッド(4)の位置及び位置変更又はそのいずれか一方に依存して溶接エネルギー源(6)をオープンループ制御できるように、制御手段(18)は溶接ヘッド(4)に溶接エネルギーを供給する溶接エネルギー源(6)を始動するためにこの溶接エネルギー源と接続されていることを特徴とする溶接装置。 - 検知手段は作業ヘッド(4)の回転位置又は回転位置変更を検知する少なくとも一つのセンサー(14)を有することを特徴とする請求項1に記載の溶接装置。

- 溶接方法はビーム溶接法であることを特徴とする請求項1或いは2に記載の溶接装置。

- 溶接方法はガス溶接法であることを特徴とする請求項1或いは2に記載の溶接装置。

- 溶接方法はアーク溶接法であることを特徴とする請求項1或いは2に記載の溶接装置。

- 溶接方法は不活性ガスアーク溶接法であることを特徴とする請求項5に記載の溶接装置。

- 溶接方法はボルト溶接法であることを特徴とする請求項1或いは2に記載の溶接装置。

- 溶接方法はレーザー放射溶接法であることを特徴とする請求項1或いは2に記載の溶接装置。

- 検知手段によって検知された溶接ヘッド(4)の位置及び位置変更又はそのいずれか一方に依存して影響を受ける溶接方法の特性量は、溶接電流及び溶接電圧又はそれらのいずれか一方の振幅と、信号形態、即ちパルス形態と、パルス周波数と、パルス変調とのすべて又はそれらの少なくとも一つを包含することを特徴とする請求項3、6或いは7に記載の溶接装置。

- 検知手段によって検知された溶接ヘッド(4)の位置及び位置変更又はそのいずれか一方に依存して影響を受ける溶接方法の特性量は、溶接すべき工作物の一つに溶接ヘッドの少なくとも一つの溶接電極の押圧力を包含することを特徴とする請求項9に記載の溶接装置。

- 検知手段によって検知された溶接ヘッド(4)の位置及び位置変更又はそのいずれか一方に依存して影響を受ける溶接法の特性量は、溶接ヘッド(4)に案内された溶接電線(8)の供給速度を包含することを特徴とする請求項10に記載の溶接装置。

- 溶接装置は溶接バーナーであることを特徴とする請求項1或いは2に記載の溶接装置。

- 検知手段は、作業ヘッド(4)に配置されている一つのセンサー(14、16)を包含することを特徴とする請求項1乃至12のいずれか一項に記載の溶接装置。

- 検知手段は、作業ヘッド(4)に一体化されている一つのセンサー(14、16)を包含することを特徴とすることを特徴とする請求項1乃至12のいずれか一項に記載の溶接装置。

- 検知手段は、溶接装置(2)を利用する労働者の身体に取付けできる少なくとも一つのセンサーを包含することを特徴とする請求項1乃至12のいずれか一項に記載の溶接装置。

- 取付け場所は身体の手或いは腕であることを特徴とする請求項15に記載の溶接装置。

- 空間内の基準点が労働者によって及び制御手段(18)によって又はそれらのいずれか一方によって選択できることを特徴とする請求項1乃至16のいずれか一項に記載の溶接装置。

- 制御手段は選択された基準位置又は検知手段によって検知された溶接ヘッド(4)の位置或いは位置変更の少なくとも一つに依存して溶接方法の特性量に所定値を組み込むことを特徴とする請求項1乃至17のいずれか一項に記載の溶接装置。

- 制御手段は溶接方法の特性量を加工作用中に自動的にオープンループ又はクローズループ制御することを特徴とする請求項1乃至17のいずれか一項に記載の溶接装置。

- 制御手段によって検知手段の出力信号に依存して選定された装置の作動モードを表示する表示装置(58)を備えることを特徴とする請求項1乃至19のいずれか一項に記載の溶接装置。

- 装置の作動モードを手により選定する操作装置(56)を備えることを特徴とする請求項1乃至20のいずれか一項に記載の溶接装置。

- 制御手段は、溶接方法が中断しないで実施できるように単数或いは複数の特性量に影響を与えることを特徴とする請求項1乃至21のいずれか一項に記載の溶接装置。

- 制御手段は単数或いは複数の特性量に時間連続的に影響を与えることを特徴とする請求項1乃至22のいずれか一項に記載の溶接装置。

- 制御手段は単数或いは複数の特性量に時間不連続的に影響を与えることを特徴とする請求項1乃至21のいずれか一項に記載の溶接装置。

- 検知手段は三次元的空間における作業ヘッド(4)の立体的位置及び立体的位置変更又はそれらのいずれか一方を検出することを特徴とする請求項1乃至24のいずれか一項に記載の溶接装置。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102004049957 | 2004-10-13 | ||

| DE102004049957.8 | 2004-10-13 | ||

| PCT/EP2005/001060 WO2006042572A1 (de) | 2004-10-13 | 2005-02-03 | Vorrichtung zur ausführung eines füge-, trenn- oder oberflächenbehanlungsverfahrens, insbesondere eines schweissverfahrens |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008515646A JP2008515646A (ja) | 2008-05-15 |

| JP2008515646A5 JP2008515646A5 (ja) | 2012-04-12 |

| JP5081624B2 true JP5081624B2 (ja) | 2012-11-28 |

Family

ID=34960190

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007536006A Active JP5081624B2 (ja) | 2004-10-13 | 2005-02-03 | 溶接装置 |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US20070187378A1 (ja) |

| EP (1) | EP1812200B2 (ja) |

| JP (1) | JP5081624B2 (ja) |

| KR (2) | KR101166320B1 (ja) |

| CN (1) | CN100528463C (ja) |

| AT (1) | ATE431218T1 (ja) |

| DE (1) | DE502005007293D1 (ja) |

| DK (1) | DK1812200T3 (ja) |

| ES (1) | ES2327136T3 (ja) |

| PL (1) | PL1812200T3 (ja) |

| WO (1) | WO2006042572A1 (ja) |

Families Citing this family (84)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9104195B2 (en) | 2006-12-20 | 2015-08-11 | Lincoln Global, Inc. | Welding job sequencer |

| WO2009146359A1 (en) * | 2008-05-28 | 2009-12-03 | Illinois Tool Works Inc. | Welding training system |

| EP2454031A4 (en) * | 2009-07-17 | 2014-08-20 | Diversitech Equipment And Sales 1984 Ltd | EXTRACTOR SYSTEM WITH AUTOMATIC DUSTER POSITIONING |

| DE202009018923U1 (de) | 2009-09-08 | 2014-06-26 | Ewm Hightec Welding Gmbh | Vorrichtung zum Ermitteln einer Schweiß- oder Lötgeschwindigkeit |

| EP2292363B1 (de) | 2009-09-08 | 2017-01-04 | Ewm Ag | Verfahren und Vorrichtung zum Ermitteln einer Schweiß- oder Lötgeschwindigkeit |

| KR101108933B1 (ko) * | 2009-10-13 | 2012-01-31 | 웰텍 주식회사 | 지능형 로봇장치를 이용한 강관 내면 자동용접장치 및 이를 이용한 자동용접방법 |

| US20110220619A1 (en) * | 2010-03-10 | 2011-09-15 | Illinois Tool Works Inc. | Positional monitoring systems and methods for welding devices |

| CN101862889B (zh) * | 2010-05-13 | 2012-05-23 | 上海交通大学 | 电阻点焊中电极振幅的监测装置 |

| US9993891B2 (en) * | 2010-07-14 | 2018-06-12 | Illinois Tool Works Inc. | Welding parameter control via welder motion or position monitoring |

| DE102010042591B4 (de) * | 2010-10-18 | 2012-08-30 | Lorch Schweißtechnik GmbH | Schweißbrenner und Lichtbogenschweißanlage mit einem derartigen Schweißbrenner |

| FR2976833B1 (fr) | 2011-06-23 | 2013-07-26 | Air Liquide | Dispositif et procede de soudage a l'arc mettant en oeuvre un accelerometre triaxial |

| CN102909466B (zh) * | 2011-08-03 | 2015-10-21 | 奇昊汽车系统(苏州)有限公司 | 螺柱焊接定位装置 |

| US9101994B2 (en) | 2011-08-10 | 2015-08-11 | Illinois Tool Works Inc. | System and device for welding training |

| DE102011053799A1 (de) * | 2011-09-20 | 2013-03-21 | Dritte Patentportfolio Beteiligungsgesellschaft Mbh & Co.Kg | Verfahren zur Steuerung von wenigstens einer Steuergröße eines Werkzeugs sowie das Werkzeug |

| DE102011053798A1 (de) | 2011-09-20 | 2013-03-21 | Dritte Patentportfolio Beteiligungsgesellschaft Mbh & Co.Kg | Verfahren zur Bestimmung einer Lageänderung eines Werkzeuges sowie das Werkzeug und die Werkzeugsteuerung |

| GB2496686A (en) * | 2011-11-21 | 2013-05-22 | Uniarc Ltd | Remote control apparatus for a welding machine |

| US9573215B2 (en) | 2012-02-10 | 2017-02-21 | Illinois Tool Works Inc. | Sound-based weld travel speed sensing system and method |

| US9583014B2 (en) | 2012-11-09 | 2017-02-28 | Illinois Tool Works Inc. | System and device for welding training |

| US9368045B2 (en) | 2012-11-09 | 2016-06-14 | Illinois Tool Works Inc. | System and device for welding training |

| US9713852B2 (en) | 2013-03-15 | 2017-07-25 | Illinois Tool Works Inc. | Welding training systems and devices |

| US9583023B2 (en) | 2013-03-15 | 2017-02-28 | Illinois Tool Works Inc. | Welding torch for a welding training system |

| US9672757B2 (en) | 2013-03-15 | 2017-06-06 | Illinois Tool Works Inc. | Multi-mode software and method for a welding training system |

| US9728103B2 (en) | 2013-03-15 | 2017-08-08 | Illinois Tool Works Inc. | Data storage and analysis for a welding training system |

| US9666100B2 (en) | 2013-03-15 | 2017-05-30 | Illinois Tool Works Inc. | Calibration devices for a welding training system |

| US9511440B2 (en) * | 2013-05-15 | 2016-12-06 | Lincoln Global, Inc. | Methods and systems for multi-wire surfacing |

| US11090753B2 (en) * | 2013-06-21 | 2021-08-17 | Illinois Tool Works Inc. | System and method for determining weld travel speed |

| US10056010B2 (en) | 2013-12-03 | 2018-08-21 | Illinois Tool Works Inc. | Systems and methods for a weld training system |

| US10105782B2 (en) | 2014-01-07 | 2018-10-23 | Illinois Tool Works Inc. | Feedback from a welding torch of a welding system |

| US9757819B2 (en) | 2014-01-07 | 2017-09-12 | Illinois Tool Works Inc. | Calibration tool and method for a welding system |

| US10170019B2 (en) | 2014-01-07 | 2019-01-01 | Illinois Tool Works Inc. | Feedback from a welding torch of a welding system |

| US9589481B2 (en) | 2014-01-07 | 2017-03-07 | Illinois Tool Works Inc. | Welding software for detection and control of devices and for analysis of data |

| US9724788B2 (en) | 2014-01-07 | 2017-08-08 | Illinois Tool Works Inc. | Electrical assemblies for a welding system |

| US9751149B2 (en) | 2014-01-07 | 2017-09-05 | Illinois Tool Works Inc. | Welding stand for a welding system |

| US10335883B2 (en) * | 2014-06-05 | 2019-07-02 | Illinois Tool Works Inc. | Gravity-based weld travel speed sensing system and method |

| US9862049B2 (en) | 2014-06-27 | 2018-01-09 | Illinois Tool Works Inc. | System and method of welding system operator identification |

| US10665128B2 (en) | 2014-06-27 | 2020-05-26 | Illinois Tool Works Inc. | System and method of monitoring welding information |

| US9937578B2 (en) | 2014-06-27 | 2018-04-10 | Illinois Tool Works Inc. | System and method for remote welding training |

| US10307853B2 (en) | 2014-06-27 | 2019-06-04 | Illinois Tool Works Inc. | System and method for managing welding data |

| US11014183B2 (en) | 2014-08-07 | 2021-05-25 | Illinois Tool Works Inc. | System and method of marking a welding workpiece |

| US9724787B2 (en) | 2014-08-07 | 2017-08-08 | Illinois Tool Works Inc. | System and method of monitoring a welding environment |

| US9875665B2 (en) | 2014-08-18 | 2018-01-23 | Illinois Tool Works Inc. | Weld training system and method |

| US10201868B2 (en) | 2014-09-30 | 2019-02-12 | Illinois Tool Works Inc. | Systems and methods for gesture control of a welding system |

| US10987762B2 (en) | 2014-09-30 | 2021-04-27 | Illinois Tool Works Inc. | Armband based systems and methods for controlling welding equipment using gestures and like motions |

| US11247289B2 (en) | 2014-10-16 | 2022-02-15 | Illinois Tool Works Inc. | Remote power supply parameter adjustment |

| US10239147B2 (en) | 2014-10-16 | 2019-03-26 | Illinois Tool Works Inc. | Sensor-based power controls for a welding system |

| US10373304B2 (en) | 2014-11-05 | 2019-08-06 | Illinois Tool Works Inc. | System and method of arranging welding device markers |

| US10417934B2 (en) | 2014-11-05 | 2019-09-17 | Illinois Tool Works Inc. | System and method of reviewing weld data |

| US10210773B2 (en) | 2014-11-05 | 2019-02-19 | Illinois Tool Works Inc. | System and method for welding torch display |

| US10402959B2 (en) | 2014-11-05 | 2019-09-03 | Illinois Tool Works Inc. | System and method of active torch marker control |

| US10204406B2 (en) | 2014-11-05 | 2019-02-12 | Illinois Tool Works Inc. | System and method of controlling welding system camera exposure and marker illumination |

| US10490098B2 (en) | 2014-11-05 | 2019-11-26 | Illinois Tool Works Inc. | System and method of recording multi-run data |

| US20160175976A1 (en) * | 2014-12-18 | 2016-06-23 | Illinois Tool Works Inc. | Systems and methods for determining a weld torch location |

| US10076802B2 (en) * | 2014-12-19 | 2018-09-18 | Illinois Tool Works Inc. | Electric arc start systems and methods |

| US9975196B2 (en) | 2015-01-05 | 2018-05-22 | University Of Kentucky Research Foundation | Measurement of three-dimensional welding torch orientation for manual arc welding process |

| US10773329B2 (en) | 2015-01-20 | 2020-09-15 | Illinois Tool Works Inc. | Multiple input welding vision system |

| US10406638B2 (en) | 2015-02-27 | 2019-09-10 | Illinois Tool Works Inc. | Augmented vision system with active welder guidance |

| EP3265865B1 (en) | 2015-03-06 | 2024-07-10 | Illinois Tool Works Inc. | Sensor assisted head mounted displays for welding |

| WO2016144744A1 (en) | 2015-03-09 | 2016-09-15 | Illinois Tool Works Inc. | Methods and apparatus to provide visual information associated with welding operations |

| US9666160B2 (en) | 2015-03-26 | 2017-05-30 | Illinois Tool Works Inc. | Control of mediated reality welding system based on lighting conditions |

| US9977242B2 (en) | 2015-03-26 | 2018-05-22 | Illinois Tool Works Inc. | Control of mediated reality welding system based on lighting conditions |

| US10427239B2 (en) | 2015-04-02 | 2019-10-01 | Illinois Tool Works Inc. | Systems and methods for tracking weld training arc parameters |

| US10363632B2 (en) | 2015-06-24 | 2019-07-30 | Illinois Tool Works Inc. | Time of flight camera for welding machine vision |

| US10373517B2 (en) | 2015-08-12 | 2019-08-06 | Illinois Tool Works Inc. | Simulation stick welding electrode holder systems and methods |

| US10657839B2 (en) | 2015-08-12 | 2020-05-19 | Illinois Tool Works Inc. | Stick welding electrode holders with real-time feedback features |

| US10593230B2 (en) | 2015-08-12 | 2020-03-17 | Illinois Tool Works Inc. | Stick welding electrode holder systems and methods |

| US10438505B2 (en) | 2015-08-12 | 2019-10-08 | Illinois Tool Works | Welding training system interface |

| JP6821903B2 (ja) * | 2016-11-14 | 2021-01-27 | 株式会社ダイヘン | 溶接トーチ、および、溶接システム |

| JP2018114539A (ja) * | 2017-01-19 | 2018-07-26 | 株式会社ダイヘン | 溶接トーチ、および、溶接システム |

| JP6798334B2 (ja) * | 2017-02-08 | 2020-12-09 | 株式会社ダイヘン | 溶接トーチ、および、溶接システム |

| JP6911252B2 (ja) * | 2017-07-04 | 2021-07-28 | 株式会社ダイヘン | 溶接トーチ、および、溶接システム |

| JP7045243B2 (ja) * | 2018-04-03 | 2022-03-31 | 株式会社ダイヘン | コンピュータプログラム、溶接情報算出装置、溶接トーチ、溶接電源、溶接システム |

| WO2019202854A1 (ja) * | 2018-04-20 | 2019-10-24 | パナソニックIpマネジメント株式会社 | 溶接トーチ及びそれを用いたアーク溶接装置 |

| DE102018217670A1 (de) * | 2018-10-16 | 2020-04-16 | Robert Bosch Gmbh | Vorrichtung und Verfahren zum Betreiben einer Widerstandschweißvorrichtung |

| DE102018009536B4 (de) | 2018-12-07 | 2022-06-15 | Olaf Rautner | Elektrische Lichtbogenschweißanlage und Verfahren zum Betrieb einer elektrischen Lichtbogenschweißanlage |

| US11521512B2 (en) | 2019-02-19 | 2022-12-06 | Illinois Tool Works Inc. | Systems for simulating joining operations using mobile devices |

| US11450233B2 (en) | 2019-02-19 | 2022-09-20 | Illinois Tool Works Inc. | Systems for simulating joining operations using mobile devices |

| US11311958B1 (en) * | 2019-05-13 | 2022-04-26 | Airgas, Inc. | Digital welding and cutting efficiency analysis, process evaluation and response feedback system for process optimization |

| DE102019119341B4 (de) * | 2019-07-17 | 2023-10-26 | Alexander Binzel Schweisstechnik Gmbh & Co. Kg | Vorrichtung zum thermischen Fügen wenigstens eines Werkstücks mit einem Brenner und einer Absaugeinrichtung |

| US11776423B2 (en) | 2019-07-22 | 2023-10-03 | Illinois Tool Works Inc. | Connection boxes for gas tungsten arc welding training systems |

| US11288978B2 (en) | 2019-07-22 | 2022-03-29 | Illinois Tool Works Inc. | Gas tungsten arc welding training systems |

| US11721231B2 (en) | 2019-11-25 | 2023-08-08 | Illinois Tool Works Inc. | Weld training simulations using mobile devices, modular workpieces, and simulated welding equipment |

| US11322037B2 (en) | 2019-11-25 | 2022-05-03 | Illinois Tool Works Inc. | Weld training simulations using mobile devices, modular workpieces, and simulated welding equipment |

| DE102020102792B4 (de) | 2020-02-04 | 2023-01-26 | Alexander Binzel Schweisstechnik Gmbh & Co. Kg | Zuschaltung für Prozessversorgungsleitungen eines Schweiß- oder Schneidbrenners und Schlauchpaket mit einer Zusatzschaltung |

| EP4046737A1 (de) | 2021-02-18 | 2022-08-24 | FRONIUS INTERNATIONAL GmbH | Schweissvorrichtung und schweissverfahren zur durchführung eines schweissprozesses |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS4921355A (ja) * | 1972-06-20 | 1974-02-25 | ||

| GB2167990B (en) * | 1984-12-04 | 1989-02-01 | Nat Res Dev | Autonomously-controllable self-propelling working apparatus |

| DE3543681A1 (de) * | 1985-12-11 | 1987-06-19 | Jurca Marius Christian | Vorrichtung zur herstellung einer schweissnaht |

| US4931018A (en) * | 1987-12-21 | 1990-06-05 | Lenco, Inc. | Device for training welders |

| US5030812A (en) * | 1989-06-13 | 1991-07-09 | Nkk Corporation | Method for one-side root pass welding of a pipe joint |

| JP2921390B2 (ja) * | 1994-04-12 | 1999-07-19 | 日本鋼管株式会社 | 升目溶接ロボット |

| JP3418456B2 (ja) * | 1994-06-23 | 2003-06-23 | ファナック株式会社 | ロボット位置教示具及びロボット位置教示方法 |

| JPH0866772A (ja) * | 1994-08-30 | 1996-03-12 | Mitsui Eng & Shipbuild Co Ltd | 曲り板継ぎの自動溶接法 |

| US5811055A (en) * | 1996-02-06 | 1998-09-22 | Geiger; Michael B. | Torch mounted gas scavaging system for manual and robotic welding and cutting torches |

| US5837966A (en) * | 1997-07-23 | 1998-11-17 | Timmons, Jr.; John E. | Apparatus for weld head to pipe joint alignment for welding |

| IT1314478B1 (it) * | 2000-02-15 | 2002-12-18 | Cr Electronic S R L | Testa portautensili,in particolare per macchine di taglio al fascio di plasma |

| US6794608B2 (en) * | 2001-10-30 | 2004-09-21 | Tri Tool Inc. | Welding current control system and method |

| US6593540B1 (en) * | 2002-02-08 | 2003-07-15 | Honeywell International, Inc. | Hand held powder-fed laser fusion welding torch |

| JP2004223555A (ja) * | 2003-01-22 | 2004-08-12 | Souki Kk | アーク溶接機 |

| US20050092809A1 (en) * | 2003-10-29 | 2005-05-05 | Mazda Motor Corporation | Friction agitation welding apparatus |

| US20080053978A1 (en) * | 2006-08-29 | 2008-03-06 | Lincoln Global, Inc. | Welder with positional heat control and method of using same |

-

2005

- 2005-02-03 EP EP05701326.0A patent/EP1812200B2/de active Active

- 2005-02-03 AT AT05701326T patent/ATE431218T1/de active

- 2005-02-03 DE DE502005007293T patent/DE502005007293D1/de active Active

- 2005-02-03 PL PL05701326T patent/PL1812200T3/pl unknown

- 2005-02-03 KR KR1020117022559A patent/KR101166320B1/ko active IP Right Grant

- 2005-02-03 DK DK05701326T patent/DK1812200T3/da active

- 2005-02-03 WO PCT/EP2005/001060 patent/WO2006042572A1/de active Application Filing

- 2005-02-03 JP JP2007536006A patent/JP5081624B2/ja active Active

- 2005-02-03 CN CNB2005800349859A patent/CN100528463C/zh not_active Expired - Fee Related

- 2005-02-03 ES ES05701326T patent/ES2327136T3/es active Active

- 2005-02-03 KR KR1020077010871A patent/KR101145025B1/ko active IP Right Grant

-

2007

- 2007-04-13 US US11/783,947 patent/US20070187378A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008515646A (ja) | 2008-05-15 |

| DE502005007293D1 (de) | 2009-06-25 |

| EP1812200A1 (de) | 2007-08-01 |

| CN101068648A (zh) | 2007-11-07 |

| DK1812200T3 (da) | 2009-09-07 |

| US20070187378A1 (en) | 2007-08-16 |

| KR101166320B1 (ko) | 2012-07-18 |

| ES2327136T3 (es) | 2009-10-26 |

| KR20110113665A (ko) | 2011-10-17 |

| KR101145025B1 (ko) | 2012-05-17 |

| WO2006042572A1 (de) | 2006-04-27 |

| EP1812200B2 (de) | 2018-06-20 |

| ATE431218T1 (de) | 2009-05-15 |

| EP1812200B1 (de) | 2009-05-13 |

| CN100528463C (zh) | 2009-08-19 |

| PL1812200T3 (pl) | 2009-12-31 |

| KR20070085350A (ko) | 2007-08-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5081624B2 (ja) | 溶接装置 | |

| CN101274386B (zh) | 单面焊接装置及单面焊接方法 | |

| CN111971140B (zh) | 焊炬以及使用了该焊炬的电弧焊接装置 | |

| JP2009504410A (ja) | 揺動する電極による狭開先サブマージアーク溶接法 | |

| EP0066626A1 (en) | Rotating arc welding method | |

| US20070023408A1 (en) | Welding system and method | |

| CN104487197A (zh) | 自适应旋转电弧焊接方法和系统 | |

| EP0584643B1 (en) | Welding method and welding robot | |

| KR20030049325A (ko) | 아크용접장치와 그 제어방법 | |

| CA1250028A (en) | Gas-shielded arc welding apparatus | |

| AU2020315094A1 (en) | Device for thermally joining at least one workpiece, comprising a torch and an extraction unit | |

| JP4327508B2 (ja) | スポット溶接方法およびスポット溶接装置 | |

| JP4045713B2 (ja) | 自動機用溶接機 | |

| JP3793750B2 (ja) | 薄板の重ね接合用パルスプラズマ自動溶接方法及びその装置 | |

| MXPA96004219A (en) | Method for joining metal components with improved perception and control of the voltage of a | |

| KR100602200B1 (ko) | 하이브리드 용접 제어장치 | |

| KR100543316B1 (ko) | 레이저 비전센서를 이용한 에스에이더블유 협개선 자동 용접 시스템 | |

| US7138600B2 (en) | Automatic pulse plasma welding method and apparatus for forming lap joint between membrane sheets | |

| WO2001003875A1 (fr) | Procede de soudage et dispositif de soudage a ecartement serre | |

| JP2000271750A (ja) | アーク溶接装置 | |

| KR102250332B1 (ko) | 가변전극이 구비된 용접토치 | |

| US20240253161A1 (en) | Systems and methods to control laser application for handheld laser welding torches and laser welding equipment | |

| CN213945245U (zh) | 一种割炬枪自动定位的等离子切割机 | |

| WO2024163589A1 (en) | Systems and methods to control laser application for handheld laser welding torches and laser welding equipment | |

| JPS6233071A (ja) | ミグブレイズ溶接方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080130 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20080922 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20081215 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090120 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20090420 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090825 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091125 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100323 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100722 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20100726 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20100816 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20110318 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20111226 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20120104 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20120126 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20120131 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120227 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20120227 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120702 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120903 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150907 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 5081624 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |