JP4903383B2 - 多孔質のプレート状の金属複合材の製造方法 - Google Patents

多孔質のプレート状の金属複合材の製造方法 Download PDFInfo

- Publication number

- JP4903383B2 JP4903383B2 JP2004547612A JP2004547612A JP4903383B2 JP 4903383 B2 JP4903383 B2 JP 4903383B2 JP 2004547612 A JP2004547612 A JP 2004547612A JP 2004547612 A JP2004547612 A JP 2004547612A JP 4903383 B2 JP4903383 B2 JP 4903383B2

- Authority

- JP

- Japan

- Prior art keywords

- metal

- fiber

- metal composite

- metal fiber

- fibers

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000002905 metal composite material Substances 0.000 title claims description 31

- 238000004519 manufacturing process Methods 0.000 title claims description 13

- 238000000034 method Methods 0.000 claims abstract description 47

- 239000000835 fiber Substances 0.000 claims description 73

- 239000002184 metal Substances 0.000 claims description 60

- 230000004927 fusion Effects 0.000 claims description 15

- 239000010409 thin film Substances 0.000 claims description 7

- 239000011261 inert gas Substances 0.000 claims description 4

- 239000002131 composite material Substances 0.000 abstract description 5

- 229920000914 Metallic fiber Polymers 0.000 abstract 1

- 238000010304 firing Methods 0.000 description 15

- 238000007499 fusion processing Methods 0.000 description 9

- 239000007789 gas Substances 0.000 description 6

- 239000000463 material Substances 0.000 description 6

- 239000003990 capacitor Substances 0.000 description 5

- 239000002657 fibrous material Substances 0.000 description 4

- 238000003466 welding Methods 0.000 description 4

- 239000011358 absorbing material Substances 0.000 description 3

- 239000013590 bulk material Substances 0.000 description 3

- 238000002485 combustion reaction Methods 0.000 description 3

- 238000010137 moulding (plastic) Methods 0.000 description 3

- 230000003647 oxidation Effects 0.000 description 3

- 238000007254 oxidation reaction Methods 0.000 description 3

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 2

- 238000005096 rolling process Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 239000006096 absorbing agent Substances 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 239000004566 building material Substances 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 238000007730 finishing process Methods 0.000 description 1

- 239000001307 helium Substances 0.000 description 1

- 229910052734 helium Inorganic materials 0.000 description 1

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 1

- 230000003116 impacting effect Effects 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 238000005272 metallurgy Methods 0.000 description 1

- 230000002028 premature Effects 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10K—SOUND-PRODUCING DEVICES; METHODS OR DEVICES FOR PROTECTING AGAINST, OR FOR DAMPING, NOISE OR OTHER ACOUSTIC WAVES IN GENERAL; ACOUSTICS NOT OTHERWISE PROVIDED FOR

- G10K11/00—Methods or devices for transmitting, conducting or directing sound in general; Methods or devices for protecting against, or for damping, noise or other acoustic waves in general

- G10K11/16—Methods or devices for protecting against, or for damping, noise or other acoustic waves in general

- G10K11/162—Selection of materials

- G10K11/168—Plural layers of different materials, e.g. sandwiches

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/002—Manufacture of articles essentially made from metallic fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K11/00—Resistance welding; Severing by resistance heating

- B23K11/002—Resistance welding; Severing by resistance heating specially adapted for particular articles or work

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

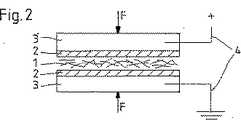

- B32B15/00—Layered products comprising a layer of metal

- B32B15/14—Layered products comprising a layer of metal next to a fibrous or filamentary layer

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23M—CASINGS, LININGS, WALLS OR DOORS SPECIALLY ADAPTED FOR COMBUSTION CHAMBERS, e.g. FIREBRIDGES; DEVICES FOR DEFLECTING AIR, FLAMES OR COMBUSTION PRODUCTS IN COMBUSTION CHAMBERS; SAFETY ARRANGEMENTS SPECIALLY ADAPTED FOR COMBUSTION APPARATUS; DETAILS OF COMBUSTION CHAMBERS, NOT OTHERWISE PROVIDED FOR

- F23M20/00—Details of combustion chambers, not otherwise provided for, e.g. means for storing heat from flames

- F23M20/005—Noise absorbing means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/002—Wall structures

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/10—Scrim [e.g., open net or mesh, gauze, loose or open weave or knit, etc.]

- Y10T442/102—Woven scrim

- Y10T442/109—Metal or metal-coated fiber-containing scrim

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/10—Scrim [e.g., open net or mesh, gauze, loose or open weave or knit, etc.]

- Y10T442/102—Woven scrim

- Y10T442/109—Metal or metal-coated fiber-containing scrim

- Y10T442/121—Including a nonwoven fabric which is not a scrim

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/10—Scrim [e.g., open net or mesh, gauze, loose or open weave or knit, etc.]

- Y10T442/102—Woven scrim

- Y10T442/159—Including a nonwoven fabric which is not a scrim

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/60—Nonwoven fabric [i.e., nonwoven strand or fiber material]

- Y10T442/654—Including a free metal or alloy constituent

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/60—Nonwoven fabric [i.e., nonwoven strand or fiber material]

- Y10T442/654—Including a free metal or alloy constituent

- Y10T442/655—Metal or metal-coated strand or fiber material

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Acoustics & Sound (AREA)

- Multimedia (AREA)

- Powder Metallurgy (AREA)

- Soundproofing, Sound Blocking, And Sound Damping (AREA)

- Laminated Bodies (AREA)

- Chemical Or Physical Treatment Of Fibers (AREA)

- Nonwoven Fabrics (AREA)

- Chemically Coating (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10250716A DE10250716C1 (de) | 2002-10-31 | 2002-10-31 | Verfahren zur Herstellung eines porösen, plattenförmigen Metallverbundes |

| DE10250716.3 | 2002-10-31 | ||

| PCT/EP2003/012045 WO2004039580A1 (de) | 2002-10-31 | 2003-10-30 | Verfahren zur herstellung eines porösen, plattenförmigen metallverbundes |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006504878A JP2006504878A (ja) | 2006-02-09 |

| JP2006504878A5 JP2006504878A5 (enExample) | 2011-11-10 |

| JP4903383B2 true JP4903383B2 (ja) | 2012-03-28 |

Family

ID=29594648

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004547612A Expired - Fee Related JP4903383B2 (ja) | 2002-10-31 | 2003-10-30 | 多孔質のプレート状の金属複合材の製造方法 |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US20060014451A1 (enExample) |

| EP (1) | EP1558443B2 (enExample) |

| JP (1) | JP4903383B2 (enExample) |

| CN (1) | CN1708397A (enExample) |

| AT (1) | ATE363381T1 (enExample) |

| AU (1) | AU2003283320A1 (enExample) |

| DE (2) | DE10250716C1 (enExample) |

| ES (1) | ES2285210T3 (enExample) |

| WO (1) | WO2004039580A1 (enExample) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10357693B4 (de) * | 2003-12-10 | 2010-04-15 | Melicon Gmbh | Verfahren zur Herstellung metallischer Gewebelaminate |

| EP1602803A1 (de) * | 2004-06-03 | 2005-12-07 | ABB Turbo Systems AG | Vorrichtung zum Reduzieren von Schwingungen eines Verbrennungsmotor und Abgasturbolader umfassenden Systems |

| DE102005028031A1 (de) * | 2005-06-17 | 2006-12-21 | Emitec Gesellschaft Für Emissionstechnologie Mbh | Wabenkörper-Herstellung mit einem metallischen Vlies |

| DE102006001833A1 (de) * | 2006-01-13 | 2007-07-19 | Emitec Gesellschaft Für Emissionstechnologie Mbh | Diskontinuierliches Verschweißen von metallischen Fasern |

| DE102009003363B4 (de) * | 2009-01-20 | 2013-01-10 | Webasto Ag | Heizgerät-Faserverdampfer |

| RU2011138927A (ru) * | 2009-02-25 | 2013-04-10 | Басф Се | Способ изготовления гибких металлических контактов |

| DE102010012416A1 (de) * | 2010-03-23 | 2011-09-29 | Dbw Holding Gmbh | Bauteil und Formteil sowie Herstellungsverfahren hierfür |

| GB2495735A (en) * | 2011-10-18 | 2013-04-24 | Bae Systems Plc | Transducer for acoustic communications |

| EP2985096B1 (de) | 2014-08-14 | 2016-11-02 | Melicon GmbH | Gasdiffusionselektrode |

| CN109226959B (zh) * | 2018-10-26 | 2020-08-25 | 同济大学 | 一种纤维增强金属基复合板材及其预处理方法 |

| CN112610984B (zh) * | 2020-12-14 | 2022-11-11 | 上海航天化工应用研究所 | 一种适用于高温高压的燃气隔离装置 |

| CN113245684A (zh) * | 2021-05-28 | 2021-08-13 | 中国石油化工股份有限公司 | 金属微纤材料及其定型方法、制备方法和应用 |

| DE102022209312A1 (de) * | 2022-09-07 | 2024-03-07 | Siemens Energy Global GmbH & Co. KG | Verfahren zur Herstellung eines Verbunds von Streckgittern, Stapel von Streckgittern und Portalmaschine |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2604517A (en) * | 1947-04-23 | 1952-07-22 | Everett D Mccurdy | Electrode and terminal assembly for electrolytic devices and methods of making same |

| US3384958A (en) * | 1965-06-30 | 1968-05-28 | Ibm | Method of brazing |

| US3505038A (en) † | 1964-08-24 | 1970-04-07 | Brunswick Corp | Metal fibril compacts |

| US3469297A (en) † | 1966-04-20 | 1969-09-30 | Brunswick Corp | Porous metal structure |

| US3437783A (en) * | 1966-07-26 | 1969-04-08 | Jerome H Lemelson | Matte structure and method of producing same |

| FR2585603B1 (fr) * | 1985-08-05 | 1990-09-14 | Asturienne France | Panneau sandwich, son procede de fabrication et appareil pour la mise en oeuvre de ce procede |

| JPS63266018A (ja) * | 1987-04-22 | 1988-11-02 | Nippon Seisen Kk | 金属繊維材料の為の熱処理炉 |

| DE3935120C2 (de) * | 1989-10-21 | 1997-03-13 | Reiner Prof Dr Ing Kopp | Verfahren zur Herstellung von Metallverbundplatten |

| ATE174681T1 (de) † | 1992-03-03 | 1999-01-15 | Bekaert Sa Nv | Poröse metallfiber-platte |

| BE1006452A3 (nl) † | 1992-12-18 | 1994-08-30 | Bekaert Sa Nv | Poreus gesinterd laminaat omvattende metaalvezels. |

| BE1007596A3 (nl) † | 1993-10-08 | 1995-08-16 | Bekaert Sa Nv | Poreuze metaalvezelplaat. |

| JPH08284279A (ja) * | 1995-04-13 | 1996-10-29 | Toyo Electric Mfg Co Ltd | アルミニウム繊維の吸音材製造方法 |

| JPH09143510A (ja) * | 1995-11-14 | 1997-06-03 | Kataoka Tokushu Kogyo Kk | 電池電極基板用金属繊維多孔体、電池電極板およびその製造方法 |

| FR2767088B1 (fr) * | 1997-08-06 | 1999-09-03 | Usinor | Tole de structure multicouche dite tole sandwich |

| FR2792394B1 (fr) * | 1999-04-16 | 2001-07-27 | Gaz De France | Procede pour realiser une surface d'accrochage de flammes |

| FR2793714B1 (fr) † | 1999-05-21 | 2001-07-13 | Renault | Procede et dispositif de formage de pieces metalliques par soudage |

| DE19924675A1 (de) * | 1999-05-29 | 2000-11-30 | Gkn Sinter Metals Filters Gmbh | Sintermetallurgisches Verfahren zur Herstellung eines Filterkörpers aus schmelzextrahierten Metallfasern |

| DE10045342C1 (de) * | 2000-09-14 | 2001-11-22 | Drafas Gmbh | Einrichtung zum Behandeln von Abgasen aus technischen Verbrennungsprozessen |

| US6465110B1 (en) * | 2000-10-10 | 2002-10-15 | Material Sciences Corporation | Metal felt laminate structures |

| DE20119367U1 (de) * | 2001-11-29 | 2002-04-11 | Cambridge University Technical Services Ltd., Cambridge | Sandwich-Verbundmaterial |

| US20040247927A1 (en) * | 2003-06-06 | 2004-12-09 | Kurz Douglas L. | Method of producing seamless, multi-layer, bonded, metallic, laminate strips or coils of arbitrarily long length |

-

2002

- 2002-10-31 DE DE10250716A patent/DE10250716C1/de not_active Expired - Fee Related

-

2003

- 2003-10-30 AT AT03775256T patent/ATE363381T1/de not_active IP Right Cessation

- 2003-10-30 ES ES03775256T patent/ES2285210T3/es not_active Expired - Lifetime

- 2003-10-30 EP EP03775256.5A patent/EP1558443B2/de not_active Expired - Lifetime

- 2003-10-30 JP JP2004547612A patent/JP4903383B2/ja not_active Expired - Fee Related

- 2003-10-30 AU AU2003283320A patent/AU2003283320A1/en not_active Abandoned

- 2003-10-30 CN CNA200380102197XA patent/CN1708397A/zh active Pending

- 2003-10-30 US US10/533,438 patent/US20060014451A1/en not_active Abandoned

- 2003-10-30 WO PCT/EP2003/012045 patent/WO2004039580A1/de not_active Ceased

- 2003-10-30 DE DE50307390T patent/DE50307390D1/de not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| DE50307390D1 (de) | 2007-07-12 |

| US20060014451A1 (en) | 2006-01-19 |

| AU2003283320A1 (en) | 2004-05-25 |

| CN1708397A (zh) | 2005-12-14 |

| ES2285210T3 (es) | 2007-11-16 |

| EP1558443B1 (de) | 2007-05-30 |

| ATE363381T1 (de) | 2007-06-15 |

| DE10250716C1 (de) | 2003-12-24 |

| EP1558443A1 (de) | 2005-08-03 |

| EP1558443B2 (de) | 2015-03-04 |

| WO2004039580A1 (de) | 2004-05-13 |

| JP2006504878A (ja) | 2006-02-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4903383B2 (ja) | 多孔質のプレート状の金属複合材の製造方法 | |

| US6085965A (en) | Pressure bonding and densification process for manufacturing low density core metal parts | |

| KR101370751B1 (ko) | 클래드 빌릿, 클래드 빌릿 제조 방법 및 클래드 파이프 또는 배관 제조 방법 | |

| EP1939403B1 (de) | Hybrid-Fanschaufel und Verfahren zu deren Herstellung | |

| CN107225241B (zh) | 使用3d打印制造绝热三维(3d)结构的方法 | |

| JP2009214540A (ja) | 金属−セラミックマトリックスハイブリッド複合構造の製造方法、複合構造の製造方法、および積層複合構造 | |

| US20210205883A1 (en) | Tuned multilayered material systems and methods for manufacturing | |

| US5972521A (en) | Expanded metal structure and method of making same | |

| JP4355774B2 (ja) | 発泡金属コア及び中実カバープレートからなる複合材料及び該複合材料よりなる構成部品、その使用方法ならびに製造方法 | |

| CN108326395A (zh) | 一种超塑成形/扩散连接三层空心构件制备方法 | |

| US20210205884A1 (en) | Tuned multilayered material systems and methods for manufacturing | |

| JP5764506B2 (ja) | セラミックス多孔体−金属断熱材及びその製造方法 | |

| KR20170085080A (ko) | 복합 재료를 제조하기 위한 방법 | |

| US5181647A (en) | Method and tooling for fabricating monolithic metal or metal matrix composite structures | |

| JP2006504878A5 (enExample) | ||

| RU2196747C2 (ru) | Способ получения композиционного изделия | |

| JP3259959B2 (ja) | 複合材とその製造方法 | |

| JP5862630B2 (ja) | 接合体の製造方法 | |

| US5174143A (en) | Surface densification of porous materials | |

| US4881314A (en) | Method of explosively forming a multilayered composite material | |

| CN118881820B (zh) | 一种脱硫用陶瓷复合管道及其制造工艺 | |

| JP2000085045A (ja) | 複合材料及びその製造方法並びに複合材料作製用部材 | |

| JP2004255394A (ja) | 中空金属集合材の接合方法、並びに衝撃吸収部材及びその製造方法 | |

| JP7477097B2 (ja) | 異材接合部材及びその製造方法 | |

| US20030012676A1 (en) | Formed membrane and method of making |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060915 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090619 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090630 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20090930 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100420 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20100720 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20100727 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101020 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110621 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20110921 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20111220 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120105 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4903383 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150113 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |