JP4512737B2 - 超音波振動加工装置 - Google Patents

超音波振動加工装置 Download PDFInfo

- Publication number

- JP4512737B2 JP4512737B2 JP2005129743A JP2005129743A JP4512737B2 JP 4512737 B2 JP4512737 B2 JP 4512737B2 JP 2005129743 A JP2005129743 A JP 2005129743A JP 2005129743 A JP2005129743 A JP 2005129743A JP 4512737 B2 JP4512737 B2 JP 4512737B2

- Authority

- JP

- Japan

- Prior art keywords

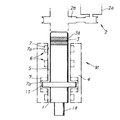

- spindle

- tool

- bearing body

- ultrasonic vibration

- machining

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Turning (AREA)

- Machine Tool Units (AREA)

- Grinding And Polishing Of Tertiary Curved Surfaces And Surfaces With Complex Shapes (AREA)

- Polishing Bodies And Polishing Tools (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005129743A JP4512737B2 (ja) | 2005-04-27 | 2005-04-27 | 超音波振動加工装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005129743A JP4512737B2 (ja) | 2005-04-27 | 2005-04-27 | 超音波振動加工装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006305661A JP2006305661A (ja) | 2006-11-09 |

| JP2006305661A5 JP2006305661A5 (enExample) | 2008-06-19 |

| JP4512737B2 true JP4512737B2 (ja) | 2010-07-28 |

Family

ID=37473148

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005129743A Expired - Fee Related JP4512737B2 (ja) | 2005-04-27 | 2005-04-27 | 超音波振動加工装置 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4512737B2 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102873594A (zh) * | 2012-09-27 | 2013-01-16 | 厦门大学 | 一种高度可调的倾角式超声振动加工装置 |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4943303B2 (ja) * | 2007-11-14 | 2012-05-30 | Juki株式会社 | 部品保持装置及び部品配置装置 |

| JP5285381B2 (ja) * | 2008-10-06 | 2013-09-11 | 三菱重工業株式会社 | 超砥粒工具 |

| JP5745754B2 (ja) * | 2009-07-30 | 2015-07-08 | 株式会社岡本工作機械製作所 | クレードル式傘歯車創成装置を用いて傘歯車を製造する方法 |

| KR20110105222A (ko) * | 2010-03-18 | 2011-09-26 | 삼성에스디아이 주식회사 | 연료 전지용 커넥터 및 이를 구비하는 연료전지시스템 |

| CN108015597B (zh) * | 2017-12-19 | 2019-05-31 | 长春理工大学 | 一种小型自取能超声振动电主轴 |

| CN111390658A (zh) * | 2020-04-30 | 2020-07-10 | 岭南师范学院 | 微流道电泳辅助微细超声加工装置及方法 |

| CN113102786B (zh) * | 2021-05-06 | 2022-07-05 | 广东工业大学 | 一种旋转超声加工主轴 |

| CN114833596A (zh) * | 2022-04-28 | 2022-08-02 | 深圳迈菲精密有限公司 | 一种超声波主轴 |

| CN115070517A (zh) * | 2022-07-26 | 2022-09-20 | 杭州和昇塑料制品有限公司 | 一种中空瓶的刮口处理结构及其处理方法 |

-

2005

- 2005-04-27 JP JP2005129743A patent/JP4512737B2/ja not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102873594A (zh) * | 2012-09-27 | 2013-01-16 | 厦门大学 | 一种高度可调的倾角式超声振动加工装置 |

| CN102873594B (zh) * | 2012-09-27 | 2014-08-06 | 厦门大学 | 一种高度可调的倾角式超声振动加工装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2006305661A (ja) | 2006-11-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Rahman et al. | Tool-based nanofinishing and micromachining | |

| CN113523968B (zh) | 石英半球谐振子激光和超声辅助磨削制造装备及其方法 | |

| Chen et al. | State-of-the-art review on vibration-assisted milling: principle, system design, and application | |

| Onikura et al. | Fabrication of micro carbide tools by ultrasonic vibration grinding | |

| Egashira et al. | Ultrasonic vibration drilling of microholes in glass | |

| Lin et al. | Development of a non-resonant 3D elliptical vibration cutting apparatus for diamond turning | |

| JPWO2008010414A1 (ja) | 切削用振動体、振動切削ユニット、加工装置、成形金型、及び光学素子 | |

| JP4512737B2 (ja) | 超音波振動加工装置 | |

| US7692360B2 (en) | Apparatus for ultrasonic vibration-assisted machining | |

| CN107378655A (zh) | 多维旋转超声展成加工机构及其加工方法 | |

| CN108972302A (zh) | 一种非谐振式振动辅助抛光装置及方法 | |

| Yadava et al. | Design of horn for rotary ultrasonic machining using the finite element method | |

| CN117601016A (zh) | 一种微细磨削工具及超微细孔加工方法 | |

| KR20110015155A (ko) | 초정밀 진동 절삭기구 장치 | |

| JPS62140701A (ja) | 重畳振動切削方法 | |

| KR100417643B1 (ko) | 초음파 진동공구를 이용한 금형 다듬질 자동화장치 | |

| Wu et al. | A new centerless grinding technique without employing a regulating wheel | |

| Kuriyagawa et al. | Development of micro ultrasonic abrasive machining system (1st report, studies in micro ultrasonic abrasive machining) | |

| JP2005001042A (ja) | 切削加工方法および切削加工装置 | |

| Ostasevicius et al. | Development of actuators for ultrasonically assisted grinding of hard brittle materials | |

| JP2002301601A (ja) | 加工装置および加工方法 | |

| JP2006326705A (ja) | 切削工具 | |

| JPH11333702A (ja) | 球面創成加工装置及び球面創成加工方法 | |

| JPS58196934A (ja) | セラミツクスの精密振動切削法 | |

| JP4893177B2 (ja) | 切削用振動体、振動切削ユニット、及び加工装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080422 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080422 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20081023 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20081023 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20081219 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090803 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091002 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20091130 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100330 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100330 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130521 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |