JP4181069B2 - プラズマ処理装置 - Google Patents

プラズマ処理装置 Download PDFInfo

- Publication number

- JP4181069B2 JP4181069B2 JP2004052807A JP2004052807A JP4181069B2 JP 4181069 B2 JP4181069 B2 JP 4181069B2 JP 2004052807 A JP2004052807 A JP 2004052807A JP 2004052807 A JP2004052807 A JP 2004052807A JP 4181069 B2 JP4181069 B2 JP 4181069B2

- Authority

- JP

- Japan

- Prior art keywords

- plasma

- coating

- processing apparatus

- film

- plasma processing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Landscapes

- Coating By Spraying Or Casting (AREA)

- Drying Of Semiconductors (AREA)

Description

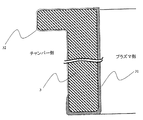

以下、本発明のプラズマ処理装置について、図示の実施の形態により詳細に説明する。

100…処理室、101…アンテナ、105…ハウジング、102…磁場形成手段、S…静電吸着電極、W…半導体ウエハ、103…真空排気系、104…排気調整手段、106…高電圧電源、107…バイアス電源、108…マッチング回路、109…音調ユニット、121…アンテナ電源、122…マッチング回路

Claims (3)

- 処理室の内側に配置された試料台上に載置された試料を、前記処理室内に生成したプラズマを用いて処理するプラズマ処理装置において、

前記処理室内に着脱可能に取り付けられた部材を備え、

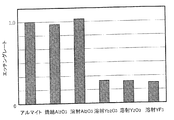

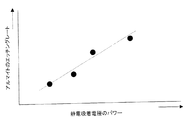

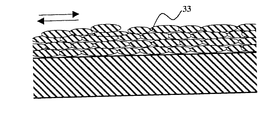

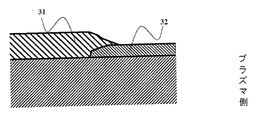

前記部材は、前記プラズマと接する側の表面に被覆された耐プラズマ性の高い材料またはこれらの混合材から構成された第1の被膜と前記処理室内に取り付けられる面を被覆する第2の被膜であって前記第1の被膜の耐プラズマ性の高い材料またはこれらの混合材よりも強度の高い材料からなる第2の被膜とを有し、前記第1および第2の被膜同士の境界部では、前記第1の被膜が前記第2の被膜の上面を覆うように被覆されるとともに、それぞれ被膜がそれぞれの境界に向かうにつれてその厚さが薄くされたプラズマ処理装置。 - 請求項1に記載のプラズマ処理装置であって、

前記第1の被膜は、Y 2 O 3 、Yb 2 O 3 またはYF 3 を主成分とした材料あるいはこれらの混合材から構成されたことを特徴とするプラズマ処理装置。 - 請求項1または2に記載のプラズマ処理装置であって、

前記Y2O3、Yb2O3またはYF3を主成分とした材料あるいはこれらの混合材から構成された被膜が溶射されて被覆され、該被膜の表面がフッ素樹脂、SiO2、ポリイミドまたはシリコーンを用いた封孔処理が施されたことを特徴とするプラズマ処理装置。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004052807A JP4181069B2 (ja) | 2004-02-27 | 2004-02-27 | プラズマ処理装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004052807A JP4181069B2 (ja) | 2004-02-27 | 2004-02-27 | プラズマ処理装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2005243987A JP2005243987A (ja) | 2005-09-08 |

| JP2005243987A5 JP2005243987A5 (ja) | 2005-11-17 |

| JP4181069B2 true JP4181069B2 (ja) | 2008-11-12 |

Family

ID=35025389

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004052807A Expired - Lifetime JP4181069B2 (ja) | 2004-02-27 | 2004-02-27 | プラズマ処理装置 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4181069B2 (ja) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007115973A (ja) * | 2005-10-21 | 2007-05-10 | Shin Etsu Chem Co Ltd | 耐食性部材 |

| JP2007243020A (ja) * | 2006-03-10 | 2007-09-20 | Hitachi High-Technologies Corp | プラズマ処理装置 |

| JP4905697B2 (ja) * | 2006-04-20 | 2012-03-28 | 信越化学工業株式会社 | 導電性耐プラズマ部材 |

| JP4887910B2 (ja) * | 2006-05-30 | 2012-02-29 | パナソニック株式会社 | プラズマ処理装置 |

| JP5071856B2 (ja) * | 2007-03-12 | 2012-11-14 | 日本碍子株式会社 | 酸化イットリウム材料及び半導体製造装置用部材 |

| JP5551353B2 (ja) * | 2008-10-30 | 2014-07-16 | 株式会社日本セラテック | 耐食性部材 |

| JP5782293B2 (ja) * | 2011-05-10 | 2015-09-24 | 東京エレクトロン株式会社 | プラズマ生成用電極およびプラズマ処理装置 |

| US9123651B2 (en) * | 2013-03-27 | 2015-09-01 | Lam Research Corporation | Dense oxide coated component of a plasma processing chamber and method of manufacture thereof |

| JP6156850B2 (ja) * | 2014-12-25 | 2017-07-05 | 東京エレクトロン株式会社 | プラズマ処理装置及びプラズマ処理装置の部材の交換判断方法 |

| CN108463345B (zh) * | 2015-11-16 | 2021-04-09 | 阔斯泰公司 | 耐腐蚀组件和制造方法 |

| KR102384436B1 (ko) * | 2016-11-16 | 2022-04-12 | 쿠어스 테크, 인코포레이티드 | 내부식성 부품 및 제조 방법 |

-

2004

- 2004-02-27 JP JP2004052807A patent/JP4181069B2/ja not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| JP2005243987A (ja) | 2005-09-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI795981B (zh) | 稀土氧化物系抗電漿腐蝕薄膜塗層 | |

| US9460898B2 (en) | Plasma generation chamber with smooth plasma resistant coating | |

| CN109256326B (zh) | 等离子体处理装置用部件及其喷镀方法 | |

| CN103794445B (zh) | 用于等离子体处理腔室的静电夹盘组件及制造方法 | |

| US20150311043A1 (en) | Chamber component with fluorinated thin film coating | |

| US20130162142A1 (en) | Plasma processing apparatus and method | |

| US20080236744A1 (en) | Plasma etching equipment | |

| KR101828862B1 (ko) | 플라즈마 처리 장치 및 샤워 헤드 | |

| US20080314321A1 (en) | Plasma processing apparatus | |

| US20170260616A1 (en) | Plasma resistant coating with tailorable coefficient of thermal expansion | |

| JP4181069B2 (ja) | プラズマ処理装置 | |

| US8715782B2 (en) | Surface processing method | |

| JP4856978B2 (ja) | プラズマエッチング装置及び処理室の内壁の形成方法 | |

| CN104241183A (zh) | 静电吸盘的制造方法,静电吸盘及等离子体处理装置 | |

| JP4098259B2 (ja) | プラズマ処理装置 | |

| CN104241181A (zh) | 静电吸盘的制造方法,静电吸盘及等离子体处理装置 | |

| US20050199183A1 (en) | Plasma processing apparatus | |

| KR102229990B1 (ko) | 플라즈마 처리 장치용 부재 및 플라즈마 처리 장치 | |

| JP2008098660A (ja) | プラズマ処理装置 | |

| KR100819530B1 (ko) | 플라즈마 에칭장치 및 플라즈마 처리실 내 부재의 형성방법 | |

| TW202217908A (zh) | 用於氫與氨電漿應用的具有保護性陶瓷塗層的處理套件 | |

| JP2006222240A (ja) | プラズマ処理装置 | |

| JP2007324186A (ja) | プラズマ処理装置 | |

| WO2023086165A1 (en) | Coated part for capacitively coupled chamber |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050930 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050930 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20070919 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20071002 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20071203 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080311 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080509 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20080826 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20080828 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4181069 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110905 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120905 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130905 Year of fee payment: 5 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| EXPY | Cancellation because of completion of term |