JP4056587B2 - 摩擦撹拌接合による継手の形成方法 - Google Patents

摩擦撹拌接合による継手の形成方法 Download PDFInfo

- Publication number

- JP4056587B2 JP4056587B2 JP18111997A JP18111997A JP4056587B2 JP 4056587 B2 JP4056587 B2 JP 4056587B2 JP 18111997 A JP18111997 A JP 18111997A JP 18111997 A JP18111997 A JP 18111997A JP 4056587 B2 JP4056587 B2 JP 4056587B2

- Authority

- JP

- Japan

- Prior art keywords

- workpiece

- groove

- friction stir

- work

- probe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000003756 stirring Methods 0.000 title claims description 40

- 238000003466 welding Methods 0.000 title claims description 29

- 238000000034 method Methods 0.000 title claims description 24

- 239000000523 sample Substances 0.000 claims description 41

- 235000013372 meat Nutrition 0.000 claims description 14

- 239000000463 material Substances 0.000 claims description 8

- 229910052782 aluminium Inorganic materials 0.000 claims description 5

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 5

- 238000003780 insertion Methods 0.000 description 11

- 230000037431 insertion Effects 0.000 description 11

- 238000005304 joining Methods 0.000 description 9

- 230000000694 effects Effects 0.000 description 4

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 238000001125 extrusion Methods 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 238000013019 agitation Methods 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- -1 for example Chemical compound 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 239000007790 solid phase Substances 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

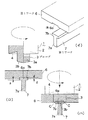

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/12—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding

- B23K20/122—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding

- B23K20/1245—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding characterised by the apparatus

- B23K20/1255—Tools therefor, e.g. characterised by the shape of the probe

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/12—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding

- B23K20/122—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding

- B23K20/1265—Non-butt welded joints, e.g. overlap-joints, T-joints or spot welds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K33/00—Specially-profiled edge portions of workpieces for making soldering or welding connections; Filling the seams formed thereby

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Pressure Welding/Diffusion-Bonding (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP18111997A JP4056587B2 (ja) | 1997-07-07 | 1997-07-07 | 摩擦撹拌接合による継手の形成方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP18111997A JP4056587B2 (ja) | 1997-07-07 | 1997-07-07 | 摩擦撹拌接合による継手の形成方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JPH1128581A JPH1128581A (ja) | 1999-02-02 |

| JPH1128581A5 JPH1128581A5 (enExample) | 2005-05-19 |

| JP4056587B2 true JP4056587B2 (ja) | 2008-03-05 |

Family

ID=16095192

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP18111997A Expired - Fee Related JP4056587B2 (ja) | 1997-07-07 | 1997-07-07 | 摩擦撹拌接合による継手の形成方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4056587B2 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10668559B2 (en) | 2015-08-26 | 2020-06-02 | Nippon Light Metal Company, Ltd. | Joining method, method of manufacturing liquid cooling jacket, and liquid cooling jacket |

| WO2024089372A1 (fr) * | 2022-10-28 | 2024-05-02 | Safran Nacelles | Procédé de soudage par friction malaxage et ensemble de soudage associé |

Families Citing this family (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3459210B2 (ja) | 1999-11-24 | 2003-10-20 | 株式会社日立製作所 | 摩擦攪拌接合方法 |

| JP3589930B2 (ja) | 2000-02-25 | 2004-11-17 | 株式会社日立製作所 | 摩擦攪拌接合方法 |

| US6352193B1 (en) | 2000-08-01 | 2002-03-05 | General Electric Company | Apparatus for joining electrically conductive materials |

| JP2002086281A (ja) | 2000-09-13 | 2002-03-26 | Hitachi Ltd | 摩擦攪拌接合方法 |

| JP3553012B2 (ja) * | 2000-11-17 | 2004-08-11 | 株式会社日立製作所 | 摩擦攪拌接合方法 |

| US6933057B2 (en) * | 2003-07-17 | 2005-08-23 | The Boeing Company | Friction stir welded assembly and method of forming a friction stir welded assembly |

| JP4509648B2 (ja) * | 2004-05-21 | 2010-07-21 | 住友軽金属工業株式会社 | 摩擦撹拌接合方法 |

| JP4814631B2 (ja) * | 2005-12-22 | 2011-11-16 | 富士重工業株式会社 | 摩擦攪拌接合方法 |

| JP5649271B2 (ja) * | 2008-08-12 | 2015-01-07 | 日立機材株式会社 | フリーアクセスフロア用パネル |

| JP2010043448A (ja) * | 2008-08-12 | 2010-02-25 | Hitachi Metals Techno Ltd | フリーアクセスフロア用パネル |

| JP5226439B2 (ja) * | 2008-09-11 | 2013-07-03 | 日立機材株式会社 | フリーアクセスフロア用パネル |

| JP2010065480A (ja) * | 2008-09-11 | 2010-03-25 | Hitachi Metals Techno Ltd | フリーアクセスフロア用パネル |

| JP2010084346A (ja) * | 2008-09-29 | 2010-04-15 | Hitachi Metals Techno Ltd | フリーアクセスフロア用パネル |

| JP5415738B2 (ja) * | 2008-10-23 | 2014-02-12 | 日立機材株式会社 | フリーアクセスフロア用パネル |

| JP2010101065A (ja) * | 2008-10-23 | 2010-05-06 | Hitachi Metals Techno Ltd | フリーアクセスフロア用パネル |

| JP5570000B2 (ja) * | 2008-10-23 | 2014-08-13 | 日立機材株式会社 | フリーアクセスフロア用パネル |

| US8561877B2 (en) * | 2011-10-27 | 2013-10-22 | GM Global Technology Operations LLC | Structural integrity welded assembly |

| FR2995237B1 (fr) | 2012-09-07 | 2015-05-01 | Airbus Operations Sas | Systeme ameliore de soudage par friction malaxage comprenant un contre-appui mobile. |

| FR2995236B1 (fr) | 2012-09-07 | 2015-05-01 | Airbus Operations Sas | Procede et systeme ameliores de soudage par friction malaxage d'un raidisseur sur un panneau d'aeronef. |

| FR3032369B1 (fr) * | 2015-02-06 | 2017-08-11 | Latecoere | Procede de realisation de panneau a raidissement croise, en particulier pour architecture d'avion, et structure d'avion formee a partir d'un tel panneau |

| FR3049929B1 (fr) * | 2016-04-12 | 2019-09-06 | Dassault Aviation | Methode d'assemblage d'un raidisseur sur un panneau de structure d'aeronef, procede de montage d'un aeronef et panneau associes |

| JP2018051563A (ja) * | 2016-09-26 | 2018-04-05 | 日本軽金属株式会社 | 接合方法 |

| JP6766477B2 (ja) * | 2016-07-01 | 2020-10-14 | 日本軽金属株式会社 | 接合方法 |

| JP6799878B1 (ja) * | 2020-06-16 | 2020-12-16 | 松本工業株式会社 | 接合部材の製造方法 |

-

1997

- 1997-07-07 JP JP18111997A patent/JP4056587B2/ja not_active Expired - Fee Related

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10668559B2 (en) | 2015-08-26 | 2020-06-02 | Nippon Light Metal Company, Ltd. | Joining method, method of manufacturing liquid cooling jacket, and liquid cooling jacket |

| WO2024089372A1 (fr) * | 2022-10-28 | 2024-05-02 | Safran Nacelles | Procédé de soudage par friction malaxage et ensemble de soudage associé |

| FR3141359A1 (fr) * | 2022-10-28 | 2024-05-03 | Safran Nacelles | Procédé de soudage par friction malaxage et ensemble de soudage associé |

Also Published As

| Publication number | Publication date |

|---|---|

| JPH1128581A (ja) | 1999-02-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4056587B2 (ja) | 摩擦撹拌接合による継手の形成方法 | |

| JP4210148B2 (ja) | テーパー摩擦撹拌溶接工具 | |

| JP2001321965A (ja) | 摩擦撹拌接合によるすみ接合法 | |

| JP2004106037A (ja) | 金属材料の結合方法 | |

| JP3978257B2 (ja) | 摩擦撹拌接合によるワークの接合方法 | |

| JP3329281B2 (ja) | アルミニウム又はアルミニウム合金板材の接合方法 | |

| JP6052237B2 (ja) | 摩擦攪拌接合方法 | |

| US6557746B2 (en) | Friction stir bonding method | |

| JP3290608B2 (ja) | 摩擦攪拌接合方法 | |

| JP4732571B2 (ja) | 摩擦撹拌接合用接合工具及び摩擦撹拌接合法 | |

| JP3990770B2 (ja) | 摩擦撹拌接合用ツール及び同ツールを用いたt継手の形成方法 | |

| JP5050674B2 (ja) | 接合方法 | |

| JP4161581B2 (ja) | 摩擦撹拌接合方法 | |

| JP3947271B2 (ja) | 摩擦撹拌接合によるt継手の形成方法 | |

| JPH1158039A (ja) | 摩擦撹拌接合による重ね継手及びその形成方法 | |

| JP3935234B2 (ja) | 突き合わせ継手の製造方法 | |

| JP3452044B2 (ja) | 摩擦攪拌ツールおよびこれを用いた接合方法ならびに鋳物表面の微細空隙除去方法 | |

| JPH1110367A (ja) | 摩擦撹拌接合方法 | |

| JP2000233285A (ja) | 摩擦撹拌接合方法 | |

| JP2001162383A (ja) | 摩擦撹拌接合法 | |

| JP3482523B2 (ja) | 摩擦接合方法 | |

| JPH1133749A (ja) | 摩擦撹拌接合によるワークの接合方法 | |

| JP2004034139A (ja) | 突合せ継手の製造方法、突合せ継手、摩擦撹拌接合法及び摩擦撹拌接合装置 | |

| JP2000233284A (ja) | 摩擦撹拌接合方法 | |

| JP7465465B2 (ja) | 異種金属の接合方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20040705 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20040705 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A132 Effective date: 20060725 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060925 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070320 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070515 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20071120 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20071212 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101221 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101221 Year of fee payment: 3 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: R3D02 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101221 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131221 Year of fee payment: 6 |

|

| LAPS | Cancellation because of no payment of annual fees |