JP4047331B2 - 再資源化方法およびシステム、コンテナ - Google Patents

再資源化方法およびシステム、コンテナ Download PDFInfo

- Publication number

- JP4047331B2 JP4047331B2 JP2004524102A JP2004524102A JP4047331B2 JP 4047331 B2 JP4047331 B2 JP 4047331B2 JP 2004524102 A JP2004524102 A JP 2004524102A JP 2004524102 A JP2004524102 A JP 2004524102A JP 4047331 B2 JP4047331 B2 JP 4047331B2

- Authority

- JP

- Japan

- Prior art keywords

- container

- gas

- product

- temperature

- recycling method

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims description 85

- 238000004064 recycling Methods 0.000 title claims description 39

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 74

- 239000007789 gas Substances 0.000 claims description 70

- 230000008569 process Effects 0.000 claims description 45

- 239000012298 atmosphere Substances 0.000 claims description 44

- 229910052799 carbon Inorganic materials 0.000 claims description 40

- 238000012545 processing Methods 0.000 claims description 36

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 20

- 229920000642 polymer Polymers 0.000 claims description 19

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 claims description 18

- 239000000460 chlorine Substances 0.000 claims description 18

- 229910052801 chlorine Inorganic materials 0.000 claims description 18

- 238000010438 heat treatment Methods 0.000 claims description 18

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 13

- 239000001301 oxygen Substances 0.000 claims description 13

- 229910052760 oxygen Inorganic materials 0.000 claims description 13

- 239000000126 substance Substances 0.000 claims description 9

- 239000012530 fluid Substances 0.000 claims description 8

- 238000011068 loading method Methods 0.000 claims description 8

- 239000011261 inert gas Substances 0.000 claims description 6

- 238000009835 boiling Methods 0.000 claims description 4

- 230000008016 vaporization Effects 0.000 claims description 3

- 230000007704 transition Effects 0.000 claims description 2

- 238000010000 carbonizing Methods 0.000 claims 1

- 230000001939 inductive effect Effects 0.000 claims 1

- 238000007789 sealing Methods 0.000 claims 1

- 238000006467 substitution reaction Methods 0.000 claims 1

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 84

- 229910052757 nitrogen Inorganic materials 0.000 description 40

- 239000002699 waste material Substances 0.000 description 32

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 18

- 229910021393 carbon nanotube Inorganic materials 0.000 description 18

- 239000002041 carbon nanotube Substances 0.000 description 18

- 238000004519 manufacturing process Methods 0.000 description 17

- 238000001816 cooling Methods 0.000 description 13

- 239000003575 carbonaceous material Substances 0.000 description 12

- 150000001875 compounds Chemical class 0.000 description 11

- MWUXSHHQAYIFBG-UHFFFAOYSA-N nitrogen oxide Inorganic materials O=[N] MWUXSHHQAYIFBG-UHFFFAOYSA-N 0.000 description 11

- 150000002013 dioxins Chemical class 0.000 description 10

- 239000001569 carbon dioxide Substances 0.000 description 9

- 229910002092 carbon dioxide Inorganic materials 0.000 description 9

- 230000008901 benefit Effects 0.000 description 8

- 229910052751 metal Inorganic materials 0.000 description 8

- 239000002184 metal Substances 0.000 description 8

- 230000004913 activation Effects 0.000 description 5

- 230000000694 effects Effects 0.000 description 5

- 238000010924 continuous production Methods 0.000 description 4

- 229910001873 dinitrogen Inorganic materials 0.000 description 4

- 239000007788 liquid Substances 0.000 description 4

- 231100000331 toxic Toxicity 0.000 description 4

- 230000002588 toxic effect Effects 0.000 description 4

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 3

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 3

- 238000002485 combustion reaction Methods 0.000 description 3

- 239000000428 dust Substances 0.000 description 3

- 229910001385 heavy metal Inorganic materials 0.000 description 3

- 238000002347 injection Methods 0.000 description 3

- 239000007924 injection Substances 0.000 description 3

- 238000009434 installation Methods 0.000 description 3

- 230000003472 neutralizing effect Effects 0.000 description 3

- 230000009467 reduction Effects 0.000 description 3

- XTQHKBHJIVJGKJ-UHFFFAOYSA-N sulfur monoxide Chemical class S=O XTQHKBHJIVJGKJ-UHFFFAOYSA-N 0.000 description 3

- 229910052815 sulfur oxide Inorganic materials 0.000 description 3

- KVGZZAHHUNAVKZ-UHFFFAOYSA-N 1,4-Dioxin Chemical compound O1C=COC=C1 KVGZZAHHUNAVKZ-UHFFFAOYSA-N 0.000 description 2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 2

- 230000003213 activating effect Effects 0.000 description 2

- 239000003570 air Substances 0.000 description 2

- 238000001241 arc-discharge method Methods 0.000 description 2

- 238000003763 carbonization Methods 0.000 description 2

- 239000000110 cooling liquid Substances 0.000 description 2

- 238000011033 desalting Methods 0.000 description 2

- 238000007599 discharging Methods 0.000 description 2

- 238000010891 electric arc Methods 0.000 description 2

- 230000007613 environmental effect Effects 0.000 description 2

- 238000003912 environmental pollution Methods 0.000 description 2

- 239000000284 extract Substances 0.000 description 2

- 230000006698 induction Effects 0.000 description 2

- 229910052742 iron Inorganic materials 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 239000012299 nitrogen atmosphere Substances 0.000 description 2

- 230000003647 oxidation Effects 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 239000003208 petroleum Substances 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 230000001681 protective effect Effects 0.000 description 2

- 239000000523 sample Substances 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 239000002689 soil Substances 0.000 description 2

- 238000009834 vaporization Methods 0.000 description 2

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 2

- 229920002554 vinyl polymer Polymers 0.000 description 2

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- VEXZGXHMUGYJMC-UHFFFAOYSA-M Chloride anion Chemical compound [Cl-] VEXZGXHMUGYJMC-UHFFFAOYSA-M 0.000 description 1

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 1

- 239000002154 agricultural waste Substances 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- FFBHFFJDDLITSX-UHFFFAOYSA-N benzyl N-[2-hydroxy-4-(3-oxomorpholin-4-yl)phenyl]carbamate Chemical compound OC1=C(NC(=O)OCC2=CC=CC=C2)C=CC(=C1)N1CCOCC1=O FFBHFFJDDLITSX-UHFFFAOYSA-N 0.000 description 1

- AXCZMVOFGPJBDE-UHFFFAOYSA-L calcium dihydroxide Chemical compound [OH-].[OH-].[Ca+2] AXCZMVOFGPJBDE-UHFFFAOYSA-L 0.000 description 1

- 239000000920 calcium hydroxide Substances 0.000 description 1

- 235000011116 calcium hydroxide Nutrition 0.000 description 1

- 229910001861 calcium hydroxide Inorganic materials 0.000 description 1

- 230000003197 catalytic effect Effects 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 238000010612 desalination reaction Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- TXKMVPPZCYKFAC-UHFFFAOYSA-N disulfur monoxide Inorganic materials O=S=S TXKMVPPZCYKFAC-UHFFFAOYSA-N 0.000 description 1

- 229920001971 elastomer Polymers 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 239000000295 fuel oil Substances 0.000 description 1

- 239000001307 helium Substances 0.000 description 1

- 229910052734 helium Inorganic materials 0.000 description 1

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 239000002440 industrial waste Substances 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 229910052746 lanthanum Inorganic materials 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 239000002906 medical waste Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012544 monitoring process Methods 0.000 description 1

- 239000002048 multi walled nanotube Substances 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 239000005022 packaging material Substances 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 231100000614 poison Toxicity 0.000 description 1

- 238000000197 pyrolysis Methods 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 239000010802 sludge Chemical class 0.000 description 1

- 239000011780 sodium chloride Substances 0.000 description 1

- 235000011121 sodium hydroxide Nutrition 0.000 description 1

- 239000004071 soot Substances 0.000 description 1

- 239000013076 target substance Substances 0.000 description 1

- 230000008646 thermal stress Effects 0.000 description 1

- 239000003440 toxic substance Substances 0.000 description 1

- 231100000419 toxicity Toxicity 0.000 description 1

- 230000001988 toxicity Effects 0.000 description 1

- 229910052727 yttrium Inorganic materials 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10G—CRACKING HYDROCARBON OILS; PRODUCTION OF LIQUID HYDROCARBON MIXTURES, e.g. BY DESTRUCTIVE HYDROGENATION, OLIGOMERISATION, POLYMERISATION; RECOVERY OF HYDROCARBON OILS FROM OIL-SHALE, OIL-SAND, OR GASES; REFINING MIXTURES MAINLY CONSISTING OF HYDROCARBONS; REFORMING OF NAPHTHA; MINERAL WAXES

- C10G1/00—Production of liquid hydrocarbon mixtures from oil-shale, oil-sand, or non-melting solid carbonaceous or similar materials, e.g. wood, coal

- C10G1/10—Production of liquid hydrocarbon mixtures from oil-shale, oil-sand, or non-melting solid carbonaceous or similar materials, e.g. wood, coal from rubber or rubber waste

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B09—DISPOSAL OF SOLID WASTE; RECLAMATION OF CONTAMINATED SOIL

- B09B—DISPOSAL OF SOLID WASTE NOT OTHERWISE PROVIDED FOR

- B09B3/00—Destroying solid waste or transforming solid waste into something useful or harmless

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y30/00—Nanotechnology for materials or surface science, e.g. nanocomposites

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y40/00—Manufacture or treatment of nanostructures

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B32/00—Carbon; Compounds thereof

- C01B32/15—Nano-sized carbon materials

- C01B32/158—Carbon nanotubes

- C01B32/16—Preparation

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B32/00—Carbon; Compounds thereof

- C01B32/30—Active carbon

- C01B32/312—Preparation

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B47/00—Destructive distillation of solid carbonaceous materials with indirect heating, e.g. by external combustion

- C10B47/28—Other processes

- C10B47/32—Other processes in ovens with mechanical conveying means

- C10B47/46—Other processes in ovens with mechanical conveying means with trucks, containers, or trays

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B53/00—Destructive distillation, specially adapted for particular solid raw materials or solid raw materials in special form

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B53/00—Destructive distillation, specially adapted for particular solid raw materials or solid raw materials in special form

- C10B53/07—Destructive distillation, specially adapted for particular solid raw materials or solid raw materials in special form of solid raw materials consisting of synthetic polymeric materials, e.g. tyres

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/10—Process efficiency

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/141—Feedstock

- Y02P20/143—Feedstock the feedstock being recycled material, e.g. plastics

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/20—Waste processing or separation

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Organic Chemistry (AREA)

- Materials Engineering (AREA)

- Nanotechnology (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Crystallography & Structural Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Wood Science & Technology (AREA)

- Combustion & Propulsion (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Life Sciences & Earth Sciences (AREA)

- Environmental & Geological Engineering (AREA)

- Composite Materials (AREA)

- Processing Of Solid Wastes (AREA)

- Carbon And Carbon Compounds (AREA)

- Separation, Recovery Or Treatment Of Waste Materials Containing Plastics (AREA)

- Coke Industry (AREA)

- Treatment Of Sludge (AREA)

- Supplying Of Containers To The Packaging Station (AREA)

Description

12 水タンク

13 クーリングタワー

14 圧縮機

15 ボンベ

16 窒素輸送装置

17 冷却用液体窒素タンク

18 コンテナ

19 軌道

20 配管網

21 窒素管

22 酸素・水蒸気管

23 塩素・雑ガス管

24 雑ガス管

25 リサイクル窒素管

27 処理対象物

31 収得装置

33 不活性炭素

35 賦活処理装置

Claims (9)

- 内部に処理対象物が装填されたコンテナ内の雰囲気を無酸素雰囲気に置換する第1工程と、

コンテナ内無酸素雰囲気を維持しつつ、コンテナ内に組み込まれているヒータによりコンテナ内の処理対象物を所定温度まで加熱してその処理対象物から所期の気体を所定温度毎に遊離させ、遊離した気体たる第1生成物を、大気から隔離した状態を保ちつつコンテナ外の装置まで誘導し流体の状態で収得して処理対象物を炭化する第2工程と、

引き続きコンテナ内を所定の温度並びに無酸素雰囲気に維持した後、炭化した炭化物中の炭素が燃焼を開始する温度より低い温度までコンテナ内を冷まし、その後コンテナ内に残った物質である第2生成物を収得する第3工程と、

を有し、

当該第2工程の最初の段階で処理対象物を水の沸点以上摂氏150度以下の温度まで加熱して水分を気化させることを特徴とする再資源化方法。 - 請求の範囲第1項記載の再資源化方法において、

第2工程を複数の段階に分けて実施し、

第2工程の前記最初の段階以降の段階における処理対象物の加熱温度を、先行する段階における加熱温度より後続する段階における加熱温度の方が高くなるよう、かつその段階にて第1生成物として遊離させるべき気体の種類に応じて、設定し、

第1生成物の誘導経路及び誘導収得先を、第2工程のそれぞれの段階に対応して個別的に設定する再資源化方法。 - 請求の範囲第1項記載の再資源化方法において、

前記第2工程の前記最初の段階以降の工程として、第1生成物として水分を気化させた後、第1生成物として塩素を含む流体を収得する工程、並びに第1生成物として高分子ガス又は高分子ガスから生成された流体を収得する工程のうち、少なくともいずれかの工程を実施する再資源化方法。 - 請求の範囲第1項記載の再資源化方法において、

少なくとも、還元性気体又は不活性気体を送給する第1装置を第1管路を介しコンテナに接続した状態で、第1工程を実施し、

第1装置を第1管路を介してコンテナに接続しかつ上記コンテナ外の装置たる第2装置を第2管路を介しコンテナに接続した状態で、第2工程を実施し、

前工程から後工程への移行のためコンテナと第1又は第2装置との間の管路接続を断つ必要があるときは、必要に応じてコンテナを密閉状態とする再資源化方法。 - 請求の範囲第4項に記載の再資源化方法において、

前工程から後工程へと各コンテナを順繰りに移動させることによって流れ作業的に複数のコンテナを同時処理できるよう、工程毎に異なる実施場所を定め、各実施場所で実施される工程の実施に必要とされる管路をその実施場所まで延伸しておく再資源化方法。 - 請求の範囲第4項記載の再資源化方法において、

ヒータ内臓のコンテナを移動させずに少なくとも第1及び第2工程を実施できるよう、第1及び第2工程の実施に必要とされる管路全てをその場所まで延伸しておく再資源化方法。 - 内部に処理対象物が装填されたコンテナ内の雰囲気を無酸素雰囲気に置換する置換手段と、

コンテナ内無酸素雰囲気を維持しつつ、コンテナ内に組み込まれているヒータによりコンテナ内の処理対象物を所定温度まで加熱してその処理対象物から所期の気体を遊離させ、遊離した気体たる第1生成物を、大気から隔離した状態を保ちつつコンテナ外の装置まで誘導し流体の状態で収得する第1生成物収得手段と、

引き続きコンテナ内を所定の温度並びに無酸素雰囲気に維持した後、炭素が燃焼を開始する温度より低い温度までコンテナ内を冷まし、その後コンテナ内に残った物質である第2生成物を収得する第2生成物収得手段とを有し、

前記第1生成物収得手段には、処理対象物を水の沸点以上摂氏150度以下の温度まで加熱して水分を気化させる酸素・水蒸気管が設けられていることを特徴とする再資源化システム。 - 請求の範囲第7項に記載の再資源化システムにおいて、

前記置換手段は、少なくとも、還元性気体又は不活性気体を送給する第1装置を第1管路を介しコンテナに接続して前記コンテナ内の雰囲気を無酸素雰囲気に置換する手段であり、

前記第1生成物取得手段は、前記第1装置を前記第1管路を介してコンテナに接続し、かつ、前記コンテナ外の装置たる第2装置を第2管路を介しコンテナに接続した状態で、第2装置により前記第1生成物を収得する手段であり、

前記コンテナと前記第1装置または前記第2装置との間の管路接続を断つときは、前記コンテナを密閉状態とする再資源化システム。 - 再資源化方法を実施する際に使用されるコンテナであって、

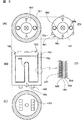

処理対象物装填及び第2生成物収得のための有蓋開口部、第1管路が接続される注入口並びに第2管路が接続される排出口が形成されたコンテナ本体と、

コンテナ本体を移動させるために使用される搬送補助構造と、

コンテナ本体内の処理対象物を加熱するためコンテナ本体に組み込まれたヒータとを備え、

前記コンテナ本体には、処理対象物を水の沸点以上摂氏150度以下の温度まで加熱して水分を気化させる酸素・水蒸気管が設けられていることを特徴とするコンテナ。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002217136 | 2002-07-25 | ||

| JP2002217136 | 2002-07-25 | ||

| PCT/JP2003/008028 WO2004011165A1 (ja) | 2002-07-25 | 2003-06-25 | 再資源化方法およびシステム、コンテナ |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JPWO2004011165A1 JPWO2004011165A1 (ja) | 2005-11-24 |

| JP4047331B2 true JP4047331B2 (ja) | 2008-02-13 |

Family

ID=31184596

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004524102A Expired - Lifetime JP4047331B2 (ja) | 2002-07-25 | 2003-06-25 | 再資源化方法およびシステム、コンテナ |

Country Status (12)

| Country | Link |

|---|---|

| US (1) | US7604791B2 (ja) |

| EP (1) | EP1522355B9 (ja) |

| JP (1) | JP4047331B2 (ja) |

| KR (1) | KR100572241B1 (ja) |

| CN (1) | CN1253255C (ja) |

| AT (1) | ATE535321T1 (ja) |

| AU (1) | AU2003243971A1 (ja) |

| ES (1) | ES2378148T3 (ja) |

| HK (1) | HK1071866A1 (ja) |

| MY (1) | MY144391A (ja) |

| TW (1) | TWI230101B (ja) |

| WO (1) | WO2004011165A1 (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2016155086A (ja) * | 2015-02-25 | 2016-09-01 | 農業生産法人株式会社 アグリジャパン | 再資源化設備 |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100652474B1 (ko) | 2004-12-31 | 2006-12-01 | 한국전기연구원 | 폐타이어 재활용 장치 및 재활용 방법 |

| US20110052102A1 (en) * | 2005-09-19 | 2011-03-03 | Sven Stiers | Drain connector for substance processing receptacle |

| US7614607B2 (en) * | 2005-09-19 | 2009-11-10 | Atmi Packaging N.V. | Drain connector for substance processing receptacle |

| JP2007111603A (ja) * | 2005-10-19 | 2007-05-10 | Toshiba Corp | 廃棄物熱分解処理システムおよび方法 |

| EP2014729A1 (en) | 2007-07-09 | 2009-01-14 | Sicpa Holding S.A. | Vanadium-drier intaglio ink |

| ITTO20070923A1 (it) * | 2007-12-20 | 2009-06-21 | Torino Politecnico | Procedimento di riciclo di materiali plastici di scarto con produzione di nanotubi di carbonio. |

| JP5778771B2 (ja) * | 2011-07-19 | 2015-09-16 | 株式会社ワンワールド | 有機物の炭化処理装置及び炭化処理方法 |

| KR101176765B1 (ko) * | 2012-03-05 | 2012-08-28 | 유성종 | 폐기물 열처리 장치 |

| TW201341075A (zh) * | 2012-04-12 | 2013-10-16 | Gianhon Environmental Technology Co Ltd | 有機固體廢棄物快速資源化處理方法與設備 |

| WO2014008371A2 (en) * | 2012-07-03 | 2014-01-09 | Plasmaten, Llc | Systems and methods of converting organic material into useful products |

| US9502723B2 (en) | 2013-11-22 | 2016-11-22 | Hamilton Sundstrand Corporation | Method of operating a fuel cell in confined space |

| CN109266365B (zh) * | 2018-09-05 | 2021-12-31 | 任慷平 | 成分分离式炭素化系统 |

| JP2023541114A (ja) | 2020-09-14 | 2023-09-28 | エコラボ ユーエスエー インコーポレイティド | プラスチック由来の合成原料のための低温流動性添加剤 |

| WO2023064375A1 (en) | 2021-10-14 | 2023-04-20 | Ecolab Usa Inc. | Antifouling agents for plastic-derived synthetic feedstocks |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5319176A (en) * | 1991-01-24 | 1994-06-07 | Ritchie G. Studer | Plasma arc decomposition of hazardous wastes into vitrified solids and non-hazardous gasses |

| US6172275B1 (en) * | 1991-12-20 | 2001-01-09 | Kabushiki Kaisha Toshiba | Method and apparatus for pyrolytically decomposing waste plastic |

| US5591312A (en) * | 1992-10-09 | 1997-01-07 | William Marsh Rice University | Process for making fullerene fibers |

| JP2651994B2 (ja) * | 1993-09-28 | 1997-09-10 | 株式会社會田金型製作所 | 廃タイヤから活性炭を製造する装置 |

| US5673635A (en) * | 1995-06-12 | 1997-10-07 | L.E. Maxwitat | Process for the recycling of organic wastes |

| GB2303859A (en) * | 1995-07-31 | 1997-03-05 | Combined Recycling & Power Ltd | Tyre pyrolysis method and apparatus |

| JP3405870B2 (ja) * | 1995-10-30 | 2003-05-12 | 株式会社デポ・ジャパン | 有機物炭化処理装置及び有機物炭化処理車両 |

| JPH101679A (ja) * | 1996-06-18 | 1998-01-06 | Masami Shibazuka | 有機廃棄物の炭化方法および炭化装置 |

| JP3946292B2 (ja) * | 1996-10-25 | 2007-07-18 | 株式会社ツシマ総業 | 炭素素材の製造装置 |

| JP3670469B2 (ja) | 1997-11-26 | 2005-07-13 | 株式会社東芝 | ポリ塩化ビニル含有廃プラスチック処理装置 |

| TW394749B (en) * | 1998-03-05 | 2000-06-21 | Deng Jian Lang | Method of manufacturing active carbon by using carbon black |

| JP2000319661A (ja) * | 1999-05-07 | 2000-11-21 | Sohachi Kosugi | 木と塩化ビニールの炭化方法及び装置 |

| US6244198B1 (en) * | 1999-11-30 | 2001-06-12 | Bcde Group Waste Management Ltd., Oy | Method and equipment for pyrolytic treatment of organic material |

-

2003

- 2003-06-25 AT AT03736245T patent/ATE535321T1/de active

- 2003-06-25 WO PCT/JP2003/008028 patent/WO2004011165A1/ja active IP Right Grant

- 2003-06-25 ES ES03736245T patent/ES2378148T3/es not_active Expired - Lifetime

- 2003-06-25 US US10/483,853 patent/US7604791B2/en not_active Expired - Fee Related

- 2003-06-25 EP EP03736245A patent/EP1522355B9/en not_active Expired - Lifetime

- 2003-06-25 KR KR1020047007588A patent/KR100572241B1/ko not_active IP Right Cessation

- 2003-06-25 AU AU2003243971A patent/AU2003243971A1/en not_active Abandoned

- 2003-06-25 JP JP2004524102A patent/JP4047331B2/ja not_active Expired - Lifetime

- 2003-06-25 CN CNB03801355XA patent/CN1253255C/zh not_active Expired - Fee Related

- 2003-07-14 TW TW092119119A patent/TWI230101B/zh not_active IP Right Cessation

- 2003-07-24 MY MYPI20032795A patent/MY144391A/en unknown

-

2005

- 2005-06-02 HK HK05104668A patent/HK1071866A1/xx not_active IP Right Cessation

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2016155086A (ja) * | 2015-02-25 | 2016-09-01 | 農業生産法人株式会社 アグリジャパン | 再資源化設備 |

Also Published As

| Publication number | Publication date |

|---|---|

| US7604791B2 (en) | 2009-10-20 |

| EP1522355A1 (en) | 2005-04-13 |

| AU2003243971A1 (en) | 2004-02-16 |

| KR20040055809A (ko) | 2004-06-26 |

| CN1253255C (zh) | 2006-04-26 |

| EP1522355B9 (en) | 2012-02-29 |

| JPWO2004011165A1 (ja) | 2005-11-24 |

| EP1522355A4 (en) | 2005-12-07 |

| US20040235655A1 (en) | 2004-11-25 |

| KR100572241B1 (ko) | 2006-04-24 |

| TWI230101B (en) | 2005-04-01 |

| WO2004011165A1 (ja) | 2004-02-05 |

| TW200402335A (en) | 2004-02-16 |

| EP1522355B1 (en) | 2011-11-30 |

| MY144391A (en) | 2011-09-15 |

| CN1578706A (zh) | 2005-02-09 |

| ES2378148T3 (es) | 2012-04-09 |

| ATE535321T1 (de) | 2011-12-15 |

| HK1071866A1 (en) | 2005-08-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4047331B2 (ja) | 再資源化方法およびシステム、コンテナ | |

| US9599337B2 (en) | Method for treating solid waste based on a gradient composed of two distinct thermal sources | |

| JP2008272534A (ja) | Psa方式の窒素ガス発生装置を利用する有機ハロゲン化合物を含む廃棄物の加熱処理方法及び加熱処理装置 | |

| US20090121798A1 (en) | High power microwave waste management | |

| CN1251776C (zh) | 用于处理含烃物料的方法 | |

| KR101200478B1 (ko) | 건슬러지 탄화처리장치 | |

| US20130199091A1 (en) | Process and system for converting waste material to fuel or synthetic gas feedstock | |

| JPH10130007A (ja) | 炭素素材の製造方法及びその装置 | |

| JP5395062B2 (ja) | 廃棄物を予備加熱して廃棄物を焼却する方法及びプラント | |

| KR20230018566A (ko) | 폐기물 처리시스템 및 그 공정 | |

| JP4160065B2 (ja) | 土壌の処理装置 | |

| KR101377425B1 (ko) | 폐 알루미늄 병뚜껑으로부터 알루미늄을 회수하기 위한 사전처리 장치 및 방법 | |

| KR101300203B1 (ko) | 방사성 폐기물 탄화장치 | |

| KR100582561B1 (ko) | 폐기물 탄소화처리장치 | |

| KR20220042858A (ko) | 열분해 기반의 친환경 폐기물 처리 장비 | |

| JP2002121560A (ja) | 炭化方法および装置 | |

| JP2005058820A (ja) | 放電エネルギによる物質の無残渣処理方法およびその装置 | |

| JPH1176978A (ja) | 廃ゴム金属複合材の処理方法 | |

| JP2015108457A (ja) | 連続式処理装置 | |

| BR102018004299A2 (pt) | Tecnologia de plasma frio para tratamento térmico de resíduos sólidos industriais e resíduos do serviço de saúde por oxidação espontãnea a partir de dispositivos de indução eletromagnética | |

| EA004393B1 (ru) | Способ переработки резиновых отходов и устройство для осуществления способа | |

| JP2009191243A (ja) | 回分式油状物回収装置 | |

| ITMO20010035A1 (it) | Impianto per la trasformazione di prodotti contenenti materiale organico, particolarmente pneumatici, guarnizioni fuori uso o simili |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070320 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070521 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070731 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20071001 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20071030 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20071121 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101130 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4047331 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111130 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121130 Year of fee payment: 5 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121130 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131130 Year of fee payment: 6 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |