JP3979092B2 - 処理液体の塗布方法および光学用レンズ加工装置 - Google Patents

処理液体の塗布方法および光学用レンズ加工装置 Download PDFInfo

- Publication number

- JP3979092B2 JP3979092B2 JP2002001624A JP2002001624A JP3979092B2 JP 3979092 B2 JP3979092 B2 JP 3979092B2 JP 2002001624 A JP2002001624 A JP 2002001624A JP 2002001624 A JP2002001624 A JP 2002001624A JP 3979092 B2 JP3979092 B2 JP 3979092B2

- Authority

- JP

- Japan

- Prior art keywords

- optical lens

- treatment liquid

- lens

- plastic

- processing apparatus

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000007788 liquid Substances 0.000 title claims description 83

- 238000000034 method Methods 0.000 title claims description 58

- 230000003287 optical effect Effects 0.000 title claims description 49

- 239000002994 raw material Substances 0.000 claims description 28

- 238000000576 coating method Methods 0.000 claims description 10

- 239000011248 coating agent Substances 0.000 claims description 5

- 239000000049 pigment Substances 0.000 claims description 4

- 239000007921 spray Substances 0.000 description 28

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 10

- 239000011521 glass Substances 0.000 description 10

- 238000010586 diagram Methods 0.000 description 6

- 239000000463 material Substances 0.000 description 6

- 229920001296 polysiloxane Polymers 0.000 description 6

- 238000001723 curing Methods 0.000 description 5

- 230000007547 defect Effects 0.000 description 5

- 238000006243 chemical reaction Methods 0.000 description 4

- 239000000975 dye Substances 0.000 description 4

- 238000007654 immersion Methods 0.000 description 4

- 238000007598 dipping method Methods 0.000 description 3

- 238000004043 dyeing Methods 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000002904 solvent Substances 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 238000000889 atomisation Methods 0.000 description 2

- 239000003054 catalyst Substances 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- 238000007599 discharging Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000009499 grossing Methods 0.000 description 2

- 238000006460 hydrolysis reaction Methods 0.000 description 2

- 239000003999 initiator Substances 0.000 description 2

- 239000003595 mist Substances 0.000 description 2

- 239000003086 colorant Substances 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000013007 heat curing Methods 0.000 description 1

- 238000003384 imaging method Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 238000004528 spin coating Methods 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 239000004094 surface-active agent Substances 0.000 description 1

- 238000002834 transmittance Methods 0.000 description 1

- 238000001771 vacuum deposition Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

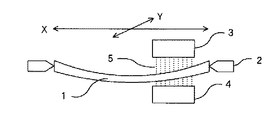

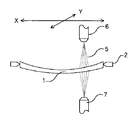

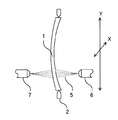

Images

Landscapes

- Ink Jet (AREA)

- Surface Treatment Of Optical Elements (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002001624A JP3979092B2 (ja) | 2002-01-08 | 2002-01-08 | 処理液体の塗布方法および光学用レンズ加工装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002001624A JP3979092B2 (ja) | 2002-01-08 | 2002-01-08 | 処理液体の塗布方法および光学用レンズ加工装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2003200102A JP2003200102A (ja) | 2003-07-15 |

| JP2003200102A5 JP2003200102A5 (enExample) | 2005-08-04 |

| JP3979092B2 true JP3979092B2 (ja) | 2007-09-19 |

Family

ID=27641703

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002001624A Expired - Fee Related JP3979092B2 (ja) | 2002-01-08 | 2002-01-08 | 処理液体の塗布方法および光学用レンズ加工装置 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3979092B2 (enExample) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011237761A (ja) * | 2010-04-15 | 2011-11-24 | Seiko Epson Corp | レンズの製造方法 |

| KR101673602B1 (ko) * | 2010-06-11 | 2016-11-16 | 엘지이노텍 주식회사 | 나노 스프레이 코팅 공정 및 이를 이용한 나노 스프레이 코팅된 디스플레이 장치용 부재 |

| JP5382028B2 (ja) * | 2011-02-21 | 2014-01-08 | 豊田合成株式会社 | 加飾印刷方法 |

| JP5814568B2 (ja) * | 2011-03-10 | 2015-11-17 | イーエイチエス レンズ フィリピン インク | カラーレンズの製造方法 |

| JP5814576B2 (ja) * | 2011-03-24 | 2015-11-17 | イーエイチエス レンズ フィリピン インク | 処理層形成方法 |

| US20180264515A1 (en) * | 2015-02-10 | 2018-09-20 | The Trustees Of The Selectacoat Pension Scheme | Methods and apparatus for producing coated articles |

-

2002

- 2002-01-08 JP JP2002001624A patent/JP3979092B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2003200102A (ja) | 2003-07-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| AU2008211023B2 (en) | Method of Producing Coated Lenses | |

| TW594037B (en) | Spreading method, spreading device, optical member and optical device | |

| KR100615934B1 (ko) | 마이크로 렌즈의 제조 방법 및 마이크로 렌즈, 광학 장치,광전송 장치, 레이저 프린터용 헤드, 레이저 프린터 | |

| US7404982B2 (en) | Color filter forming method | |

| JP3979092B2 (ja) | 処理液体の塗布方法および光学用レンズ加工装置 | |

| JP2001327908A (ja) | 液体の塗布方法、平滑処理方法およびこれを用いた光学部材の製造方法並びに光学部材加工装置 | |

| JP2020052323A (ja) | 眼鏡レンズの製造方法 | |

| JP2003200102A5 (enExample) | ||

| JP2006030634A (ja) | マイクロレンズの製造方法 | |

| JPH11142608A (ja) | 光学素子とその製造方法 | |

| JPH0999494A (ja) | 着色眼鏡レンズの製造方法 | |

| JP2000255069A (ja) | インクジェット記録ヘッドおよびその製造方法 | |

| WO2000067051A1 (fr) | Lentille en plastic et son procede de traitement | |

| KR102145423B1 (ko) | 잉크젯을 사용한 콘택트 렌즈 제조 방법 | |

| KR100908270B1 (ko) | 디스플레이용 투명소재 코팅장치 및 그 방법 | |

| US20240094561A1 (en) | Inkjet Colorization and Imaging System for Eyewear Lenses | |

| JPS63122560A (ja) | インクジエツト記録ヘツドの表面処理方法 | |

| JP2006264109A (ja) | プラスチックレンズの製造方法 | |

| JP2006264108A (ja) | プラスチックレンズの製造方法 | |

| US20240077649A1 (en) | Optical lens structure having at least one micro thin film | |

| JP4061810B2 (ja) | カラーフィルター用中間品の作製方法、カラーフィルターの作製方法 | |

| JP2000108359A (ja) | インクジェット記録ヘッドの製造方法 | |

| JP2001281434A (ja) | カラーフィルターの製造方法及びカラーフィルター | |

| JPH1120037A (ja) | 薄膜形成装置、薄膜形成方法及びそれを用いる複合レンズの製造方法 | |

| US20230176258A1 (en) | Polarized lens and method for providing a polarized lens |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20041227 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20041227 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20061214 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070109 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070226 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070320 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20070402 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070508 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20070605 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20070618 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100706 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110706 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110706 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120706 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120706 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130706 Year of fee payment: 6 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |