JP3771972B2 - 摩擦攪拌接合法 - Google Patents

摩擦攪拌接合法 Download PDFInfo

- Publication number

- JP3771972B2 JP3771972B2 JP22978696A JP22978696A JP3771972B2 JP 3771972 B2 JP3771972 B2 JP 3771972B2 JP 22978696 A JP22978696 A JP 22978696A JP 22978696 A JP22978696 A JP 22978696A JP 3771972 B2 JP3771972 B2 JP 3771972B2

- Authority

- JP

- Japan

- Prior art keywords

- probe

- joining

- support

- joining member

- friction stir

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000000034 method Methods 0.000 title claims description 24

- 238000003756 stirring Methods 0.000 title claims description 18

- 238000003466 welding Methods 0.000 title claims description 17

- 239000000523 sample Substances 0.000 claims description 63

- 239000000463 material Substances 0.000 description 7

- 238000003780 insertion Methods 0.000 description 3

- 230000037431 insertion Effects 0.000 description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 229910000677 High-carbon steel Inorganic materials 0.000 description 1

- 229910000997 High-speed steel Inorganic materials 0.000 description 1

- 229910001315 Tool steel Inorganic materials 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

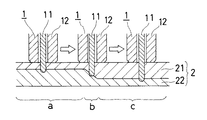

- 238000010586 diagram Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/12—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding

- B23K20/122—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding

- B23K20/1245—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding characterised by the apparatus

- B23K20/1255—Tools therefor, e.g. characterised by the shape of the probe

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Pressure Welding/Diffusion-Bonding (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP22978696A JP3771972B2 (ja) | 1996-08-30 | 1996-08-30 | 摩擦攪拌接合法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP22978696A JP3771972B2 (ja) | 1996-08-30 | 1996-08-30 | 摩擦攪拌接合法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JPH1071478A JPH1071478A (ja) | 1998-03-17 |

| JPH1071478A5 JPH1071478A5 (enExample) | 2004-09-09 |

| JP3771972B2 true JP3771972B2 (ja) | 2006-05-10 |

Family

ID=16897658

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP22978696A Expired - Fee Related JP3771972B2 (ja) | 1996-08-30 | 1996-08-30 | 摩擦攪拌接合法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3771972B2 (enExample) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6247633B1 (en) * | 1999-03-02 | 2001-06-19 | Ford Global Technologies, Inc. | Fabricating low distortion lap weld construction |

| JP4827359B2 (ja) * | 2000-05-08 | 2011-11-30 | ブリガム ヤング ユニバーシティ | 高耐摩耗性工具を使用する摩擦撹拌接合 |

| US6352193B1 (en) | 2000-08-01 | 2002-03-05 | General Electric Company | Apparatus for joining electrically conductive materials |

| JP3864684B2 (ja) * | 2000-09-04 | 2007-01-10 | 日本軽金属株式会社 | 接合方法 |

| JP4754904B2 (ja) * | 2005-08-24 | 2011-08-24 | 住友軽金属工業株式会社 | アルミ接合製品及びその製造方法 |

| FR2900082B1 (fr) * | 2006-04-20 | 2008-07-18 | Eads Europ Aeronautic Defence | Procede de soudage par friction malaxage |

| JP4453682B2 (ja) * | 2006-06-14 | 2010-04-21 | 日本軽金属株式会社 | 接合方法および接合ツール |

| JP5115719B2 (ja) * | 2008-04-09 | 2013-01-09 | トヨタ自動車株式会社 | 摩擦攪拌接合方法および密閉容器 |

| JP2009274117A (ja) * | 2008-05-15 | 2009-11-26 | Nippon Light Metal Co Ltd | 中空部を有する部材の摩擦攪拌接合方法 |

| JP4740289B2 (ja) * | 2008-06-23 | 2011-08-03 | 川崎重工業株式会社 | 摩擦撹拌接合装置 |

| JP5022502B2 (ja) * | 2011-02-07 | 2012-09-12 | 川崎重工業株式会社 | 摩擦撹拌接合装置 |

| JP6577696B2 (ja) * | 2014-01-28 | 2019-09-18 | 日本軽金属株式会社 | 内部に流路を設けない複合板の製造方法 |

| EP3059028A1 (de) * | 2015-02-20 | 2016-08-24 | Siemens Aktiengesellschaft | Gussteil mit einem metallischen Funktionsbereich |

| CN105880826B (zh) * | 2016-04-11 | 2017-12-15 | 江西理工大学 | 一种避免底部缺陷、提高接头性能的厚板搅拌摩擦焊接方法 |

| RU186699U1 (ru) * | 2018-05-22 | 2019-01-29 | Федеральное государственное автономное образовательное учреждение высшего образования "Дальневосточный федеральный университет" (ДВФУ) | Инструмент для сварки трением с перемешиванием |

| RU192077U1 (ru) * | 2019-05-17 | 2019-09-03 | Федеральное государственное автономное образовательное учреждение высшего образования "Дальневосточный федеральный университет" (ДВФУ) | Инструмент для сварки трением с перемешиванием |

| EP4620607A1 (en) | 2023-06-05 | 2025-09-24 | Yamazaki Mazak Corporation | Friction stir welding method, automobile component manufacturing method, machine tool, and program |

-

1996

- 1996-08-30 JP JP22978696A patent/JP3771972B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JPH1071478A (ja) | 1998-03-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3771972B2 (ja) | 摩擦攪拌接合法 | |

| US6053391A (en) | Friction stir welding tool | |

| KR100492836B1 (ko) | 마찰교반용접을위한용접루우트폐쇄방법 | |

| CN103097072B (zh) | 用于摩擦搅拌焊接的方法和设备 | |

| JP4388140B2 (ja) | 摩擦溶接接合を形成する固着部材 | |

| JPH1071477A (ja) | 摩擦スター溶接工具および方法 | |

| JP6052232B2 (ja) | 接合方法 | |

| EP1132167A3 (en) | Friction stir welding | |

| US20040118900A1 (en) | Precessing rivet and method for friction stir riveting | |

| JP2000042759A (ja) | 摩擦撹拌接合法 | |

| JP3986604B2 (ja) | 金属材の接合方法 | |

| JP3295376B2 (ja) | 摩擦撹拌接合法 | |

| JP4732571B2 (ja) | 摩擦撹拌接合用接合工具及び摩擦撹拌接合法 | |

| WO2020208844A1 (ja) | 接合方法 | |

| JPH11333572A (ja) | 摩擦撹拌接合法 | |

| JP2001121274A (ja) | 摩擦攪拌接合装置及び接合方法 | |

| JP3452044B2 (ja) | 摩擦攪拌ツールおよびこれを用いた接合方法ならびに鋳物表面の微細空隙除去方法 | |

| JP4543204B2 (ja) | 摩擦攪拌接合方法 | |

| JP4008593B2 (ja) | 摩擦撹拌接合法及び摩擦撹拌接合装置 | |

| JP2000225476A (ja) | 金属製ワーク同士の摩擦撹拌接合方法 | |

| JP3867546B2 (ja) | 摩擦攪拌接合用ツールと摩擦攪拌接合装置及び摩擦攪拌接合方法 | |

| JP2004034139A (ja) | 突合せ継手の製造方法、突合せ継手、摩擦撹拌接合法及び摩擦撹拌接合装置 | |

| JP6740960B2 (ja) | 接合方法 | |

| JP2005081427A (ja) | 接合方法 | |

| WO2021053839A1 (ja) | 摩擦攪拌接合方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20060207 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20060213 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: R3D02 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120217 Year of fee payment: 6 |

|

| LAPS | Cancellation because of no payment of annual fees |