JP2018009822A - ゴムの耐摩耗性評価方法 - Google Patents

ゴムの耐摩耗性評価方法 Download PDFInfo

- Publication number

- JP2018009822A JP2018009822A JP2016137238A JP2016137238A JP2018009822A JP 2018009822 A JP2018009822 A JP 2018009822A JP 2016137238 A JP2016137238 A JP 2016137238A JP 2016137238 A JP2016137238 A JP 2016137238A JP 2018009822 A JP2018009822 A JP 2018009822A

- Authority

- JP

- Japan

- Prior art keywords

- test sample

- wear

- rubber

- test

- circumferential surface

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N19/00—Investigating materials by mechanical methods

- G01N19/02—Measuring coefficient of friction between materials

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N3/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N3/56—Investigating resistance to wear or abrasion

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N3/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N3/08—Investigating strength properties of solid materials by application of mechanical stress by applying steady tensile or compressive forces

- G01N3/14—Investigating strength properties of solid materials by application of mechanical stress by applying steady tensile or compressive forces generated by dead weight, e.g. pendulum; generated by springs tension

Landscapes

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Engineering & Computer Science (AREA)

- Automation & Control Theory (AREA)

- Investigating Strength Of Materials By Application Of Mechanical Stress (AREA)

Abstract

Description

2 ベース

3 保持部

4 回転体

4a 円周面

4b 回転軸

5 駆動モータ

6a 動力計

6b 温度センサ

6c カメラ

7 制御部

8 温調機構

9 投入機構

10 圧着機構

11 支柱

11a 保持アーム

12 ワイヤ

13 バランサー

14 支持軸

15 錘

16 スクレーパ

S(S1、S2、S3) 試験サンプル

Claims (5)

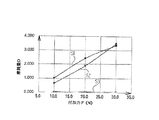

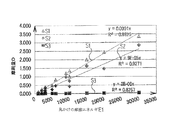

- ゴムの試験サンプルに対して、駆動モータにより回転する回転体の円周面に向かう付加力を付与することにより、前記試験サンプルを所定の定位置で前記円周面に圧着しつつ、前記試験サンプルを前記付加力とは反対方向への移動を常に許容した状態で保持して、前記試験サンプルの前記円周面との接触面を摩耗させる摩耗試験を行い、前記試験サンプルの摩耗量に加えて、前記摩耗試験中の前記駆動モータの回転駆動に要する電力および前記試験サンプルの温度の2項目うちの少なくとも1項目に基づいて、前記試験サンプルの耐摩耗性を評価することを特徴とするゴムの耐摩耗性評価方法。

- 前記摩耗量と前記付加力の大きさおよび前記円周面の周速に基づいて、前記試験サンプルの耐摩耗性を評価する請求項1に記載のゴムの耐摩耗性評価方法。

- 前記電力に基づいて、前記試験サンプルの前記円周面に対する摩擦力を算出し、この摩擦力の大きさに基づいて前記試験サンプルの耐摩耗性を評価する請求項1または請求項2に記載のゴムの耐摩耗性評価方法。

- 前記電力の変動に基づいて、前記試験サンプルに生じるスティック・スリップ現象の発生周期を算出し、この周期の大きさに基づいて前記試験サンプルの耐摩耗性を評価する請求項1〜3のいずれかに記載のゴムの耐摩耗性評価方法。

- 前記温度に基づいて、前記試験サンプルが摩耗する際の熱エネルギを算出し、この熱エネルギの大きさに基づいて前記試験サンプルの耐摩耗性を評価する請求項1〜4のいずれかに記載のゴムの耐摩耗性評価方法。

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016137238A JP6794684B2 (ja) | 2016-07-12 | 2016-07-12 | ゴムの耐摩耗性評価方法 |

| PCT/JP2017/007440 WO2018012023A1 (ja) | 2016-07-12 | 2017-02-27 | ゴムの耐摩耗性評価方法 |

| US16/316,027 US10989641B2 (en) | 2016-07-12 | 2017-02-27 | Rubber wear resistance evaluation method |

| DE112017003531.7T DE112017003531B4 (de) | 2016-07-12 | 2017-02-27 | Verfahren zur Bewertung von Kautschukabriebbeständigkeit |

| CN201780029998.XA CN109154547B (zh) | 2016-07-12 | 2017-02-27 | 橡胶的耐磨耗性评价方法 |

| AU2017296469A AU2017296469B2 (en) | 2016-07-12 | 2017-02-27 | Method for evaluating wear resistance of rubber |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016137238A JP6794684B2 (ja) | 2016-07-12 | 2016-07-12 | ゴムの耐摩耗性評価方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2018009822A true JP2018009822A (ja) | 2018-01-18 |

| JP6794684B2 JP6794684B2 (ja) | 2020-12-02 |

Family

ID=60952535

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016137238A Active JP6794684B2 (ja) | 2016-07-12 | 2016-07-12 | ゴムの耐摩耗性評価方法 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US10989641B2 (ja) |

| JP (1) | JP6794684B2 (ja) |

| CN (1) | CN109154547B (ja) |

| AU (1) | AU2017296469B2 (ja) |

| DE (1) | DE112017003531B4 (ja) |

| WO (1) | WO2018012023A1 (ja) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6743472B2 (ja) * | 2016-04-22 | 2020-08-19 | 横浜ゴム株式会社 | 衝撃試験方法および装置 |

| EP3489655B1 (en) * | 2016-07-21 | 2022-04-20 | Hitachi Metals, Ltd. | Abrasion test apparatus |

| CN110887650B (zh) * | 2019-11-29 | 2022-07-29 | 山东金麒麟股份有限公司 | 获取刹车片的耐高温范围的测试方法 |

| CN112304760B (zh) * | 2020-10-30 | 2022-12-16 | 广西玉柴机器股份有限公司 | 一种评估非金属垫片拉伸强度的方法 |

| CN112284954B (zh) * | 2020-11-02 | 2023-09-15 | 重庆交通职业学院 | 一种橡胶摩擦磨损实验台 |

| CN112362454B (zh) * | 2020-11-20 | 2022-10-04 | 中国石油天然气集团有限公司 | 一种钻具耐磨带实物性能检测评价装置和试验方法 |

| CN113405899B (zh) * | 2021-05-07 | 2023-11-03 | 安徽省江海橡塑制品有限责任公司 | 一种用于检测橡胶制品的装置 |

| CN113624587B (zh) * | 2021-07-30 | 2023-06-23 | 华电电力科学研究院有限公司 | 一种旋转式催化剂磨损强度检测装置及测试方法 |

| US12130225B2 (en) * | 2022-05-12 | 2024-10-29 | Gm Cruise Holdings Llc | Rotary seal testing apparatus |

| CN115326617B (zh) * | 2022-07-21 | 2025-07-18 | 长春汽车检测中心有限责任公司 | 一种汽车车身耐磨性试验装置 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61210926A (ja) * | 1985-03-15 | 1986-09-19 | Agency Of Ind Science & Technol | 多連式摩擦摩耗試験機 |

| JP2001242056A (ja) * | 2000-02-28 | 2001-09-07 | Bridgestone Corp | 摩耗試験装置および摩耗試験方法 |

| JP2004037286A (ja) * | 2002-07-04 | 2004-02-05 | Yokohama Rubber Co Ltd:The | 室内タイヤ耐久試験方法 |

| JP2013178163A (ja) * | 2012-02-28 | 2013-09-09 | Kayaba Ind Co Ltd | プラスチック材料の評価方法 |

| JP2016061597A (ja) * | 2014-09-16 | 2016-04-25 | 横浜ゴム株式会社 | 摩耗試験装置および方法 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1711866A (en) * | 1927-06-01 | 1929-05-07 | Grasselli Chemical Co | Method of and apparatus for testing materials |

| US2990713A (en) * | 1957-03-20 | 1961-07-04 | American Viscose Corp | Multi-purpose friction tester |

| US2929240A (en) * | 1957-05-16 | 1960-03-22 | Huber Corp J M | Apparatus for testing materials for wear resistance |

| BE655226A (ja) * | 1964-11-04 | 1965-05-04 | ||

| JPS4824784B1 (ja) * | 1970-10-09 | 1973-07-24 | ||

| JPS4824784U (ja) | 1971-07-27 | 1973-03-23 | ||

| US3899917A (en) * | 1973-12-06 | 1975-08-19 | Frederick N Kisbany | Laboratory wear resistance test machine for tires |

| US4995197A (en) * | 1990-01-29 | 1991-02-26 | Shieh Chiung Huei | Method of abrading |

| US5689058A (en) * | 1996-12-20 | 1997-11-18 | Cooper Industries, Inc. | Friction material evaluation apparatus |

| JP3320654B2 (ja) * | 1998-05-08 | 2002-09-03 | 株式会社ブリヂストン | ゴム摩耗度測定方法 |

| EP1637863A1 (en) * | 2004-09-20 | 2006-03-22 | PIRELLI PNEUMATICI S.p.A. | Method for calculating a friction-slippage curve for a tire |

| JP4963978B2 (ja) | 2007-01-30 | 2012-06-27 | 株式会社ブリヂストン | ゴム摩耗試験機、および、それを用いたタイヤトレッド用ゴムの摩耗試験方法 |

| CN201004038Y (zh) | 2007-02-05 | 2008-01-09 | 华南理工大学 | 一种橡胶磨耗测试设备 |

| US9581534B2 (en) * | 2010-07-09 | 2017-02-28 | Tribis Engineering, Inc. | Tribometer |

| JP6002462B2 (ja) * | 2012-06-15 | 2016-10-05 | 横浜ゴム株式会社 | コンベヤベルトの支持ローラ乗り越え抵抗力測定方法およびその装置 |

| CN203164071U (zh) * | 2013-03-18 | 2013-08-28 | 高铁检测仪器(东莞)有限公司 | 橡胶耐磨测试装置 |

| CN105628528A (zh) * | 2014-10-28 | 2016-06-01 | 南宁市生润科技有限公司 | 橡胶耐磨实验装置 |

-

2016

- 2016-07-12 JP JP2016137238A patent/JP6794684B2/ja active Active

-

2017

- 2017-02-27 CN CN201780029998.XA patent/CN109154547B/zh active Active

- 2017-02-27 AU AU2017296469A patent/AU2017296469B2/en not_active Ceased

- 2017-02-27 WO PCT/JP2017/007440 patent/WO2018012023A1/ja not_active Ceased

- 2017-02-27 US US16/316,027 patent/US10989641B2/en not_active Expired - Fee Related

- 2017-02-27 DE DE112017003531.7T patent/DE112017003531B4/de active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61210926A (ja) * | 1985-03-15 | 1986-09-19 | Agency Of Ind Science & Technol | 多連式摩擦摩耗試験機 |

| JP2001242056A (ja) * | 2000-02-28 | 2001-09-07 | Bridgestone Corp | 摩耗試験装置および摩耗試験方法 |

| JP2004037286A (ja) * | 2002-07-04 | 2004-02-05 | Yokohama Rubber Co Ltd:The | 室内タイヤ耐久試験方法 |

| JP2013178163A (ja) * | 2012-02-28 | 2013-09-09 | Kayaba Ind Co Ltd | プラスチック材料の評価方法 |

| JP2016061597A (ja) * | 2014-09-16 | 2016-04-25 | 横浜ゴム株式会社 | 摩耗試験装置および方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20190310175A1 (en) | 2019-10-10 |

| DE112017003531T5 (de) | 2019-03-28 |

| CN109154547B (zh) | 2021-11-12 |

| US10989641B2 (en) | 2021-04-27 |

| JP6794684B2 (ja) | 2020-12-02 |

| CN109154547A (zh) | 2019-01-04 |

| AU2017296469B2 (en) | 2020-08-20 |

| DE112017003531B4 (de) | 2024-12-12 |

| AU2017296469A1 (en) | 2019-02-21 |

| WO2018012023A1 (ja) | 2018-01-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2018009822A (ja) | ゴムの耐摩耗性評価方法 | |

| JP7018938B2 (ja) | ゴム摩耗を測定するための装置 | |

| US6494765B2 (en) | Method and apparatus for controlled polishing | |

| JP4527728B2 (ja) | 摩耗試験機および試験方法 | |

| AU2016253804B2 (en) | Abrasive wear test device and method | |

| JP6821981B2 (ja) | ゴムの摩耗試験装置 | |

| JP6531363B2 (ja) | 摩耗試験装置および方法 | |

| CN102782814A (zh) | 垫片状态化刮扫力矩模式化以达成恒定移除率 | |

| JP5534587B2 (ja) | ゴム試験機 | |

| JP4299692B2 (ja) | 摩擦試験装置 | |

| JP2001502807A (ja) | 潤滑油の機能有効性を検出する方法 | |

| JP2011047906A (ja) | 負荷試験装置 | |

| JP6844148B2 (ja) | 摩耗試験装置 | |

| JP2012202926A (ja) | 摩耗試験装置 | |

| JP3185975U (ja) | ボール試験機 | |

| JP4538007B2 (ja) | 摩擦計 | |

| JP2016133388A (ja) | 摩耗試験機 | |

| JP2016045133A (ja) | 摩擦特性測定装置および摩擦特性測定方法 | |

| TWI464378B (zh) | A component testing device containing a ball | |

| JP2016045134A (ja) | 摩擦特性測定装置および摩擦特性測定方法 | |

| JP2012108077A (ja) | 摩耗試験装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20190705 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20200602 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20200706 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20201013 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20201026 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6794684 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |