JP2016166322A - 複合材の歪能力を向上させるための高分子ナノ粒子 - Google Patents

複合材の歪能力を向上させるための高分子ナノ粒子 Download PDFInfo

- Publication number

- JP2016166322A JP2016166322A JP2015162396A JP2015162396A JP2016166322A JP 2016166322 A JP2016166322 A JP 2016166322A JP 2015162396 A JP2015162396 A JP 2015162396A JP 2015162396 A JP2015162396 A JP 2015162396A JP 2016166322 A JP2016166322 A JP 2016166322A

- Authority

- JP

- Japan

- Prior art keywords

- resin

- nanoparticles

- polymer nanoparticles

- strain

- polymer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000002105 nanoparticle Substances 0.000 title claims abstract description 251

- 229920000642 polymer Polymers 0.000 title claims abstract description 150

- 239000002131 composite material Substances 0.000 title claims abstract description 142

- 229920005989 resin Polymers 0.000 claims abstract description 266

- 239000011347 resin Substances 0.000 claims abstract description 266

- 239000000203 mixture Substances 0.000 claims abstract description 132

- 238000000034 method Methods 0.000 claims abstract description 40

- 239000000463 material Substances 0.000 claims description 13

- 239000002245 particle Substances 0.000 claims description 13

- 239000011148 porous material Substances 0.000 claims description 10

- 239000012815 thermoplastic material Substances 0.000 claims description 6

- 229920002635 polyurethane Polymers 0.000 claims description 5

- 239000004814 polyurethane Substances 0.000 claims description 5

- 229920001187 thermosetting polymer Polymers 0.000 claims description 5

- 229920000728 polyester Polymers 0.000 claims description 4

- 239000000853 adhesive Substances 0.000 claims description 3

- 230000001070 adhesive effect Effects 0.000 claims description 3

- 238000000576 coating method Methods 0.000 claims description 3

- 239000007787 solid Substances 0.000 claims description 3

- 238000012546 transfer Methods 0.000 claims description 3

- XQUPVDVFXZDTLT-UHFFFAOYSA-N 1-[4-[[4-(2,5-dioxopyrrol-1-yl)phenyl]methyl]phenyl]pyrrole-2,5-dione Chemical compound O=C1C=CC(=O)N1C(C=C1)=CC=C1CC1=CC=C(N2C(C=CC2=O)=O)C=C1 XQUPVDVFXZDTLT-UHFFFAOYSA-N 0.000 claims description 2

- CMLFRMDBDNHMRA-UHFFFAOYSA-N 2h-1,2-benzoxazine Chemical compound C1=CC=C2C=CNOC2=C1 CMLFRMDBDNHMRA-UHFFFAOYSA-N 0.000 claims description 2

- 239000004593 Epoxy Substances 0.000 claims description 2

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 claims description 2

- 239000004952 Polyamide Substances 0.000 claims description 2

- 239000004695 Polyether sulfone Substances 0.000 claims description 2

- 239000004697 Polyetherimide Substances 0.000 claims description 2

- 239000004642 Polyimide Substances 0.000 claims description 2

- 229920000491 Polyphenylsulfone Polymers 0.000 claims description 2

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 claims description 2

- 239000011248 coating agent Substances 0.000 claims description 2

- 229920001940 conductive polymer Polymers 0.000 claims description 2

- 239000004643 cyanate ester Substances 0.000 claims description 2

- NBVXSUQYWXRMNV-UHFFFAOYSA-N fluoromethane Chemical compound FC NBVXSUQYWXRMNV-UHFFFAOYSA-N 0.000 claims description 2

- 239000004033 plastic Substances 0.000 claims description 2

- 229920003023 plastic Polymers 0.000 claims description 2

- 229920003192 poly(bis maleimide) Polymers 0.000 claims description 2

- 229920002492 poly(sulfone) Polymers 0.000 claims description 2

- 229920002647 polyamide Polymers 0.000 claims description 2

- 229920006260 polyaryletherketone Polymers 0.000 claims description 2

- 239000004417 polycarbonate Substances 0.000 claims description 2

- 229920000515 polycarbonate Polymers 0.000 claims description 2

- 229920006393 polyether sulfone Polymers 0.000 claims description 2

- 229920001601 polyetherimide Polymers 0.000 claims description 2

- 229920001721 polyimide Polymers 0.000 claims description 2

- 229920000098 polyolefin Polymers 0.000 claims description 2

- 238000001746 injection moulding Methods 0.000 claims 1

- 230000006872 improvement Effects 0.000 abstract description 3

- 238000010348 incorporation Methods 0.000 abstract 1

- 239000000835 fiber Substances 0.000 description 70

- 230000003014 reinforcing effect Effects 0.000 description 51

- 239000011159 matrix material Substances 0.000 description 15

- 238000004519 manufacturing process Methods 0.000 description 12

- 239000012783 reinforcing fiber Substances 0.000 description 11

- 238000002347 injection Methods 0.000 description 9

- 239000007924 injection Substances 0.000 description 9

- 230000008569 process Effects 0.000 description 9

- 238000010586 diagram Methods 0.000 description 8

- 239000004744 fabric Substances 0.000 description 7

- 238000012423 maintenance Methods 0.000 description 6

- 229920001169 thermoplastic Polymers 0.000 description 5

- -1 coatings Substances 0.000 description 4

- 239000011521 glass Substances 0.000 description 4

- 238000002156 mixing Methods 0.000 description 4

- 230000000694 effects Effects 0.000 description 3

- 239000011229 interlayer Substances 0.000 description 3

- 239000004416 thermosoftening plastic Substances 0.000 description 3

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 2

- 239000004696 Poly ether ether ketone Substances 0.000 description 2

- 229910052799 carbon Inorganic materials 0.000 description 2

- 238000004090 dissolution Methods 0.000 description 2

- 238000005470 impregnation Methods 0.000 description 2

- 230000010354 integration Effects 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 229920001652 poly(etherketoneketone) Polymers 0.000 description 2

- 229920002530 polyetherether ketone Polymers 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 125000006850 spacer group Chemical group 0.000 description 2

- 229920005992 thermoplastic resin Polymers 0.000 description 2

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 description 1

- 229920000181 Ethylene propylene rubber Polymers 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 239000004734 Polyphenylene sulfide Substances 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 239000005407 aluminoborosilicate glass Substances 0.000 description 1

- 239000005354 aluminosilicate glass Substances 0.000 description 1

- 238000013475 authorization Methods 0.000 description 1

- CJPQIRJHIZUAQP-MRXNPFEDSA-N benalaxyl-M Chemical compound CC=1C=CC=C(C)C=1N([C@H](C)C(=O)OC)C(=O)CC1=CC=CC=C1 CJPQIRJHIZUAQP-MRXNPFEDSA-N 0.000 description 1

- 229910052796 boron Inorganic materials 0.000 description 1

- 239000005388 borosilicate glass Substances 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- RTZKZFJDLAIYFH-UHFFFAOYSA-N ether Substances CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 1

- 238000009472 formulation Methods 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- 230000002706 hydrostatic effect Effects 0.000 description 1

- 238000001802 infusion Methods 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000002991 molded plastic Substances 0.000 description 1

- 239000005304 optical glass Substances 0.000 description 1

- 230000000737 periodic effect Effects 0.000 description 1

- 230000035699 permeability Effects 0.000 description 1

- 239000012071 phase Substances 0.000 description 1

- 229920001643 poly(ether ketone) Polymers 0.000 description 1

- 229920000767 polyaniline Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 229920000069 polyphenylene sulfide Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 1

- 229910010271 silicon carbide Inorganic materials 0.000 description 1

- 235000012239 silicon dioxide Nutrition 0.000 description 1

- 239000000779 smoke Substances 0.000 description 1

- 239000007790 solid phase Substances 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 230000003075 superhydrophobic effect Effects 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 238000005382 thermal cycling Methods 0.000 description 1

- 230000001988 toxicity Effects 0.000 description 1

- 231100000419 toxicity Toxicity 0.000 description 1

- 238000001721 transfer moulding Methods 0.000 description 1

- 239000003039 volatile agent Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/04—Reinforcing macromolecular compounds with loose or coherent fibrous material

- C08J5/10—Reinforcing macromolecular compounds with loose or coherent fibrous material characterised by the additives used in the polymer mixture

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/005—Reinforced macromolecular compounds with nanosized materials, e.g. nanoparticles, nanofibres, nanotubes, nanowires, nanorods or nanolayered materials

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/24—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs

- C08J5/241—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using inorganic fibres

- C08J5/243—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using inorganic fibres using carbon fibres

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/24—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs

- C08J5/241—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using inorganic fibres

- C08J5/244—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using inorganic fibres using glass fibres

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/24—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs

- C08J5/249—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs characterised by the additives used in the prepolymer mixture

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2300/00—Characterised by the use of unspecified polymers

- C08J2300/22—Thermoplastic resins

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2300/00—Characterised by the use of unspecified polymers

- C08J2300/24—Thermosetting resins

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2400/00—Characterised by the use of unspecified polymers

- C08J2400/22—Thermoplastic resins

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2400/00—Characterised by the use of unspecified polymers

- C08J2400/24—Thermosetting resins

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Manufacturing & Machinery (AREA)

- Inorganic Chemistry (AREA)

- Nanotechnology (AREA)

- Reinforced Plastic Materials (AREA)

- Compositions Of Macromolecular Compounds (AREA)

Abstract

Description

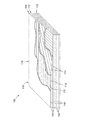

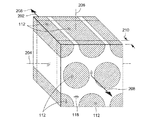

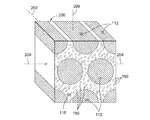

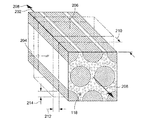

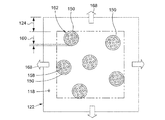

102 複合材レイアップ

104 複合材プライ

106 層間領域

108 一方向プライ

110 繊維トウ

112 強化フィラメント

114 樹脂混合物

116 組成物

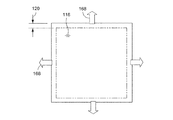

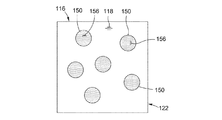

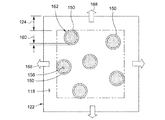

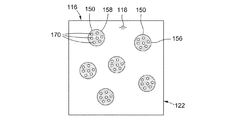

118 樹脂

120 強化フィラメント

122 樹脂混合物

124 樹脂混合物ひずみ

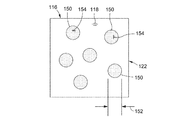

150 高分子ナノ粒子

152 粒子断面幅

154 ポリマー骨格

156 自由体積の大きい高分子ナノ粒子

158 多孔性高分子ナノ粒子

160 ナノ粒子ひずみ

162 拡張

168 2軸引張

170 ポア

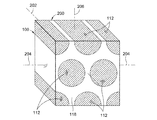

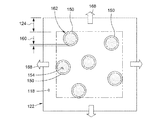

200 高分子ナノ粒子

202 第1の方向

204 第2の方向

206 第3の方向

208 単軸引張負荷

210 引張ひずみ

212、214 圧縮ひずみ

300、400 方法

Claims (15)

- 樹脂(118)、

複数の高分子ナノ粒子(150)、

前記樹脂と前記高分子ナノ粒子とを含む樹脂混合物(122)を含む組成物であって、

前記高分子ナノ粒子(150)の少なくとも幾つかが、

前記高分子ナノ粒子(150)のポリマー骨格の性質、

前記樹脂(118)の自由体積よりも大きいナノ粒子自由体積、及び

前記樹脂(118)の空隙率よりも高いナノ粒子空隙率

のうちの少なくとも1つに起因して、前記樹脂(118)よりも高い歪能力を有する、組成物。 - 前記高分子ナノ粒子(150)が概して球状である、請求項1に記載の組成物。

- 前記樹脂(118)は、硬化されると、前記高分子ナノ粒子(150)を含まない樹脂(118)の歪能力よりも高い、少なくとも1つの方向に沿った歪能力を有する、請求項1又は2に記載の組成物。

- 前記高分子ナノ粒子(150)の少なくとも幾つかが、ナノ粒子の全体積の50パーセントよりも多くを占める単一の細孔(170)によって提供されるナノ粒子空隙率を有する、請求項1から3の何れか一項に記載の組成物。

- 前記高分子ナノ粒子(150)の少なくとも幾つかがナノ粒子自由体積を有し、前記高分子ナノ粒子の体積の95パーセントまでが、非連結の固体であり、これにより、前記高分子ナノ粒子の自由体積膨張が可能となる、請求項1から4の何れか一項に記載の組成物。

- 前記高分子ナノ粒子(150)が、10〜200ナノメートルの粒子断面幅を有する、請求項1から5の何れか一項に記載の組成物。

- 前記高分子ナノ粒子(150)は、体積比で前記樹脂混合物(122)の10パーセント以上を構成し、前記高分子ナノ粒子(150)は、体積比で前記樹脂(118)混合物の75パーセントまでを構成する、請求項1から6の何れか一項に記載の組成物。

- 前記樹脂混合物(122)は、複合材構造体のコーティング、接着剤、射出成形用プラスチック、樹脂混合物のうちの少なくとも1つに含まれる、請求項1から7の何れか一項に記載の組成物。

- 前記樹脂(118)及び/又は前記高分子ナノ粒子(150)は、

熱可塑性材料、アクリル、フルオロカーボン、ポリアミド、ポリオレフィン、ポリエステル、ポリカーボネート、ポリウレタン、ポリアリールエーテルケトン、ポリエーテルイミド、ポリエーテルスルホン、ポリスルホン、及びポリフェニルスルホン、

熱硬化性材料、ポリウレタン、フェノール、ポリイミド、スルホン化ポリマー、導電性ポリマー、ベンゾオキサジン、ビスマレイミド、シアン酸エステル、ポリエステル、エポキシ、及びシルセスキオキサン

のうちの少なくとも1つで構成される、請求項1から8の何れか一項に記載の組成物。 - 前記高分子ナノ粒子(150)の少なくとも幾つかが、熱可塑性材料で形成され、且つ少なくとも部分的に前記樹脂(118)に可溶であり、

前記樹脂混合物(122)が、硬化されると、前記高分子ナノ粒子(150)を含まない硬化された樹脂(118)の靱性に対して増大した靱性を有する、請求項1から9の何れか一項に記載の組成物。 - 前記高分子ナノ粒子(150)が、

前記樹脂(118)と前記高分子ナノ粒子との間で負荷を伝達可能であるか、

少なくとも部分的に前記樹脂(118)に可溶であるかの何れかである、シース内に含有される、請求項1から10の何れか一項に記載の組成物。 - 複合材構造体に印加される負荷に抵抗する方法であって、

複数の高分子ナノ粒子(150)を含む樹脂(118)を有する複合材構造体に負荷を印加するステップであって、前記高分子ナノ粒子(150)の少なくとも幾つかが、

前記高分子ナノ粒子(150)のポリマー骨格の性質、

前記樹脂(118)の自由体積よりも大きいナノ粒子自由体積、及び

前記樹脂(118)よりも高い空隙率であるナノ粒子空隙率

の少なくとも1つに起因して、前記樹脂(118)よりも高い歪能力を有する、ステップと、

前記高分子ナノ粒子を含まない樹脂(118)の体積歪能力よりも高い前記樹脂(118)の体積歪能力を用いて、前記負荷に抵抗するステップと

を含む方法。 - 前記負荷を印加するステップ及び前記負荷に抵抗するステップが、

前記複合材構造体の第1の軸に沿って前記負荷を印加すること、及び

前記高分子ナノ粒子(150)を含まない複合材構造体の歪能力よりも高い、硬化された前記樹脂(118)の前記第1の軸に沿った歪能力を用いて、前記負荷に抵抗すること

を含む、請求項12に記載の方法。 - 前記負荷を印加するステップ及び前記負荷に抵抗するステップが、

前記第1の軸に沿って引張負荷を印加すること、及び

前記高分子ナノ粒子(150)を含まない複合材構造体の引張歪よりも大きい、前記第1の軸に沿った引張歪を用いて、前記負荷に抵抗することを含む、請求項12又は13に記載の方法。 - 前記複合材構造体が前記第1の軸に直角方向の第2の軸を有し、前記負荷に抵抗するステップが更に、

前記高分子ナノ粒子(150)を含まない複合材構造体の圧縮歪よりも大きい、前記第2の軸に沿った圧縮歪を用いて、前記負荷に抵抗することを含む、請求項14に記載の方法。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14/493,369 US10662302B2 (en) | 2014-09-23 | 2014-09-23 | Polymer nanoparticles for improved distortion capability in composites |

| US14/493,369 | 2014-09-23 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2016166322A true JP2016166322A (ja) | 2016-09-15 |

| JP2016166322A5 JP2016166322A5 (ja) | 2019-10-10 |

| JP7240079B2 JP7240079B2 (ja) | 2023-03-15 |

Family

ID=54325304

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015162396A Active JP7240079B2 (ja) | 2014-09-23 | 2015-08-20 | 複合材の変形能力を向上させるための高分子ナノ粒子 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US10662302B2 (ja) |

| EP (2) | EP3000839B1 (ja) |

| JP (1) | JP7240079B2 (ja) |

| ES (1) | ES2742692T3 (ja) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009119467A1 (ja) * | 2008-03-25 | 2009-10-01 | 東レ株式会社 | エポキシ樹脂組成物、繊維強化複合材料、およびその製造方法 |

| JP2010126702A (ja) * | 2008-12-01 | 2010-06-10 | Toray Ind Inc | エポキシ樹脂組成物、繊維強化複合材料およびそれらの製造方法 |

| JP2010242083A (ja) * | 2009-03-31 | 2010-10-28 | General Electric Co <Ge> | 硬化複合材組成物 |

| JP2011157491A (ja) * | 2010-02-02 | 2011-08-18 | Toray Ind Inc | トウプリプレグ用エポキシ樹脂組成物およびトウプリプレグ |

| JP2012528236A (ja) * | 2009-05-28 | 2012-11-12 | サイテク・テクノロジー・コーポレーシヨン | 粒子強化繊維強化重合体複合材料 |

| WO2014050264A1 (ja) * | 2012-09-28 | 2014-04-03 | 東レ株式会社 | プリプレグおよび炭素繊維強化複合材料 |

Family Cites Families (74)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1358276A (en) | 1972-06-27 | 1974-07-03 | British Railways Board | Composites of carbon fibres and synthetic plastics materials |

| US3860565A (en) | 1973-10-01 | 1975-01-14 | Minnesota Mining & Mfg | Encapsulated isocyanurate catalyst |

| US4306040A (en) | 1980-11-03 | 1981-12-15 | Monsanto Company | Multiphase core//shell polymers |

| US4629759A (en) | 1985-10-28 | 1986-12-16 | General Electric Company | Flame retardant polyetherimide-polycarbonate blends |

| US4701475A (en) | 1986-06-25 | 1987-10-20 | The Dow Chemical Company | Polyurethanes reinforced with rigid rod micro fillers |

| EP0274899B1 (en) | 1986-12-25 | 1994-02-09 | Toray Industries, Inc. | Highly tough composite materials |

| EP0378854A1 (en) | 1989-01-19 | 1990-07-25 | General Electric Company | Expanded fiber composite structure and process for making said structure |

| US4954195A (en) | 1989-02-13 | 1990-09-04 | Lockheed Corporation | Production of thermoset composites containing thermoplastic fillers |

| EP0392348A3 (en) | 1989-04-14 | 1991-12-27 | Cytec Technology Corp. | Toughened thermosetting structural materials |

| JPH03284988A (ja) | 1990-03-31 | 1991-12-16 | Toppan Printing Co Ltd | 可逆的記録媒体 |

| JPH0771804B2 (ja) | 1990-10-12 | 1995-08-02 | 株式会社神戸製鋼所 | 炭素繊維プリプレグ及び炭素繊維強化樹脂 |

| US5618857A (en) * | 1993-06-24 | 1997-04-08 | Loctite Corporation | Impregnation sealant composition of superior high temperature resistance, and method of making same |

| TW305860B (ja) | 1994-03-15 | 1997-05-21 | Toray Industries | |

| JP3296995B2 (ja) | 1997-06-12 | 2002-07-02 | イビデン株式会社 | 層間樹脂絶縁剤調製用の原料組成物および層間樹脂絶縁剤の調製方法 |

| US6096669A (en) | 1997-10-28 | 2000-08-01 | Gkn Westland Aerospace Inc. | Unidirectional fiber-random mat preform |

| JPH11269393A (ja) | 1998-01-22 | 1999-10-05 | Nippon Shokubai Co Ltd | 熱硬化性樹脂組成物 |

| CN1155531C (zh) | 1998-03-03 | 2004-06-30 | Ppg工业俄亥俄公司 | 无机颗粒涂覆的玻璃纤维束以及包括它的产品 |

| JP4204716B2 (ja) | 1999-10-15 | 2009-01-07 | 株式会社クラレ | 自立性多孔性繊維集積体およびその製造方法 |

| US7037865B1 (en) | 2000-08-08 | 2006-05-02 | Moldite, Inc. | Composite materials |

| TW572912B (en) | 2000-10-25 | 2004-01-21 | Rohm & Haas | Processes for preparing impact modifier powders |

| US6503856B1 (en) | 2000-12-05 | 2003-01-07 | Hexcel Corporation | Carbon fiber sheet materials and methods of making and using the same |

| US6740185B2 (en) | 2001-02-06 | 2004-05-25 | General Electric Company | Method of preparing preforms for RTM molding processes |

| US6518330B2 (en) | 2001-02-13 | 2003-02-11 | Board Of Trustees Of University Of Illinois | Multifunctional autonomically healing composite material |

| US6531340B2 (en) | 2001-02-23 | 2003-03-11 | Micron Technology, Inc. | Low temperature die attaching material for BOC packages |

| US6855652B2 (en) * | 2001-08-24 | 2005-02-15 | L&L Products, Inc. | Structurally reinforced panels |

| CN100429257C (zh) | 2001-11-02 | 2008-10-29 | 三洋化成工业株式会社 | 复合树脂粒子 |

| JP3927795B2 (ja) | 2001-11-29 | 2007-06-13 | 三菱レイヨン株式会社 | 炭素繊維束とその繊維織物 |

| AU2003217548A1 (en) | 2002-02-19 | 2003-09-09 | Photon-X, Inc. | Athermal polymer nanocomposites |

| EP1371684A1 (en) | 2002-06-14 | 2003-12-17 | Rohm And Haas Company | Improved plastic composition |

| WO2004110930A1 (ja) | 2003-06-12 | 2004-12-23 | Matsushita Electric Industrial Co., Ltd. | ナノ粒子含有複合多孔体およびその製造方法 |

| US7041740B2 (en) | 2003-09-26 | 2006-05-09 | Hexcel Corporation | Heat-settable resins |

| US7212284B2 (en) | 2004-05-12 | 2007-05-01 | General Electric Company | Method for forming nanoparticle films and application thereof |

| DE102005000683A1 (de) | 2004-08-21 | 2006-03-09 | Saertex Wagener Gmbh & Co. Kg | Verfahren zur Herstellung eines Faserverbundwerkstoffes zur Herstellung von Faserverbundbauteilen |

| US8399094B2 (en) | 2004-09-01 | 2013-03-19 | Ppg Industries Ohio, Inc. | Multilayer laminated articles including polyurethane and/or poly(ureaurethane) layers and methods of making the same |

| US7435693B2 (en) | 2005-01-07 | 2008-10-14 | The Boeing Company | Toughened, non-crimped unidirectional fabric apparatus and method of making same |

| US7356231B2 (en) | 2005-02-28 | 2008-04-08 | 3M Innovative Properties Company | Composite polymer fibers |

| CN103012820B (zh) * | 2005-05-09 | 2016-06-08 | Cytec技术有限公司 | 用于复合材料的树脂可溶的热塑性遮盖物 |

| US7655295B2 (en) | 2005-06-14 | 2010-02-02 | Siemens Energy, Inc. | Mix of grafted and non-grafted particles in a resin |

| US7678847B2 (en) | 2005-07-22 | 2010-03-16 | Appleton Papers Inc. | Encapsulated structural adhesive |

| KR101167733B1 (ko) | 2005-11-16 | 2012-07-23 | 삼성전기주식회사 | 캡핑 리간드가 표면에 결합되어 있는 나노입자용 분산제, 이를 이용한 나노입자의 분산방법 및 이를 포함하는 나노입자 박막 |

| AU2006326140B2 (en) | 2005-12-15 | 2012-08-02 | Huntsman Advanced Materials Licensing (Switzerland) Gmbh | Multiphase acrylic adhesives |

| US7569625B2 (en) | 2006-06-02 | 2009-08-04 | The Board Of Trustees Of The University Of Illinois | Self-healing elastomer system |

| US20080176987A1 (en) | 2007-01-22 | 2008-07-24 | Trevet Fred W | System and methods for modified resin and composite material |

| US20090004460A1 (en) | 2007-06-28 | 2009-01-01 | U.S.A. As Represented By The Administrator Of The National Aeronautics And Space Administration | Nanoparticle-Containing Thermoplastic Composites and Methods of Preparing Same |

| GB0717507D0 (en) | 2007-09-07 | 2007-10-17 | Cytec Tech Corp | Composite materials and their use |

| US20090130376A1 (en) | 2007-11-20 | 2009-05-21 | The Boeing Company | Unidirectional fiber material and fabrication method |

| US9518163B2 (en) | 2008-05-26 | 2016-12-13 | Semmes, Inc. | Reinforced polymer foams, articles and coatings prepared therefrom and methods of making the same |

| US8288453B2 (en) | 2008-06-26 | 2012-10-16 | Ccp Composites Us | Process to disperse organic microparticles/nanoparticles into non-aqueous resin medium |

| JP5243181B2 (ja) | 2008-10-20 | 2013-07-24 | スリーエム イノベイティブ プロパティズ カンパニー | 導電性高分子複合体及び導電性高分子材料を用いた熱電素子 |

| JP5422235B2 (ja) | 2009-03-19 | 2014-02-19 | 株式会社東芝 | エポキシ樹脂組成物、エポキシ樹脂硬化物、エポキシ樹脂系導電性組成物およびエポキシ樹脂系導電性硬化物 |

| GB0905362D0 (en) * | 2009-03-30 | 2009-05-13 | 3M Innovative Properties Co | Fire resistant epoxy resin based core filler material developing low exothermic heat |

| US20100273382A1 (en) | 2009-04-28 | 2010-10-28 | Malay Nandi | Acoustic and fire retardant foam coating composition for fibrous mat |

| US20100280151A1 (en) | 2009-05-04 | 2010-11-04 | Toray Industries, Inc. | Toughened fiber reinforced polymer composite with core-shell particles |

| EP2253677B1 (en) | 2009-05-19 | 2017-01-25 | Rohm and Haas Company | Opacifying pigment particle |

| US7897703B2 (en) | 2009-05-20 | 2011-03-01 | Hexcel Corporation | Epoxy resin and 4,4′-diaminobenzanilide powder |

| US8268926B2 (en) | 2009-05-28 | 2012-09-18 | Cytec Technology Corp. | Particle-toughened polymer compositions |

| US20110021360A1 (en) | 2009-07-22 | 2011-01-27 | Al-Ghamdi Ahmed Abdullah S | Superconductive nanocomposite |

| CN101623266B (zh) | 2009-07-24 | 2012-08-08 | 中国科学院上海硅酸盐研究所 | 磷酸钙/嵌段共聚物复合多孔纳米球及其制备方法 |

| JP5823393B2 (ja) | 2009-08-03 | 2015-11-25 | アプライド ナノストラクチャード ソリューションズ リミテッド ライアビリティー カンパニーApplied Nanostructuredsolutions, Llc | 複合繊維へのナノ粒子の組み込み |

| BR122015030054B1 (pt) | 2009-12-17 | 2019-05-28 | Marel Meat Processing B.V. | Sistema e método para processar uma carcaça ou parte de carcaça de um animal de abate suíno, bovino, ovino ou caprino |

| KR101800921B1 (ko) | 2010-09-17 | 2017-11-23 | 쓰리엠 이노베이티브 프로퍼티즈 컴파니 | 섬유 강화되고 나노입자 로딩된 열경화성 중합체 복합 와이어 및 케이블, 및 방법 |

| KR101951058B1 (ko) * | 2011-03-30 | 2019-02-21 | 도레이 카부시키가이샤 | 프리프레그, 섬유 강화 복합 재료 및 섬유 강화 복합 재료의 제조 방법 |

| CN104204040A (zh) * | 2011-10-24 | 2014-12-10 | 3M创新有限公司 | 包含双马来酰亚胺组合物的纳米二氧化硅 |

| JP5785112B2 (ja) | 2012-02-15 | 2015-09-24 | Jx日鉱日石エネルギー株式会社 | 繊維強化複合材料 |

| KR101326523B1 (ko) | 2012-02-23 | 2013-11-07 | 현대자동차주식회사 | 탄소나노튜브가 코팅된 상전이 물질을 함유하는 마이크로 캡슐과 탄소섬유를 함유한 전자파차폐용 고분자 복합재 및 그 제조방법 |

| US20140023862A1 (en) | 2012-07-23 | 2014-01-23 | Ryan W. Johnson | Process for forming an agglomerated particle cloud network coated fiber bundle |

| CA2880548A1 (en) * | 2012-08-03 | 2014-02-06 | Ocv Intellectual Capital, Llc | Improved fiberglass reinforced composites |

| KR20140037646A (ko) | 2012-09-19 | 2014-03-27 | 삼성전기주식회사 | 절연용 에폭시 수지 조성물, 절연 필름, 프리프레그 및 인쇄회로기판 |

| US9611396B2 (en) | 2012-11-09 | 2017-04-04 | AnCatt | Conducting polymer nanoparticle composites |

| NL2009777C2 (en) * | 2012-11-09 | 2014-05-12 | Ut Internat Ventures Holding B V | Polymer foam comprising a polymer and nanoparticles, and nanoparticles for the manufacture of such foam. |

| GB201222934D0 (en) | 2012-12-19 | 2013-01-30 | Cytec Ind Inc | Particle toughening for improving fracture toughness |

| US9309114B2 (en) * | 2013-01-14 | 2016-04-12 | Xerox Corporation | Porous nanoparticles produced by solvent-free emulsification |

| WO2015080098A1 (ja) * | 2013-11-27 | 2015-06-04 | 東レ株式会社 | 半導体用樹脂組成物および半導体用樹脂フィルムならびにこれらを用いた半導体装置 |

| WO2015097283A1 (en) | 2013-12-24 | 2015-07-02 | Hexcel Composites Limited | Improvements to matrix additives |

-

2014

- 2014-09-23 US US14/493,369 patent/US10662302B2/en active Active

-

2015

- 2015-08-20 JP JP2015162396A patent/JP7240079B2/ja active Active

- 2015-09-23 EP EP15186480.8A patent/EP3000839B1/en active Active

- 2015-09-23 ES ES15186480T patent/ES2742692T3/es active Active

- 2015-09-23 EP EP19175062.9A patent/EP3546504B1/en active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009119467A1 (ja) * | 2008-03-25 | 2009-10-01 | 東レ株式会社 | エポキシ樹脂組成物、繊維強化複合材料、およびその製造方法 |

| JP2010126702A (ja) * | 2008-12-01 | 2010-06-10 | Toray Ind Inc | エポキシ樹脂組成物、繊維強化複合材料およびそれらの製造方法 |

| JP2010242083A (ja) * | 2009-03-31 | 2010-10-28 | General Electric Co <Ge> | 硬化複合材組成物 |

| JP2012528236A (ja) * | 2009-05-28 | 2012-11-12 | サイテク・テクノロジー・コーポレーシヨン | 粒子強化繊維強化重合体複合材料 |

| JP2011157491A (ja) * | 2010-02-02 | 2011-08-18 | Toray Ind Inc | トウプリプレグ用エポキシ樹脂組成物およびトウプリプレグ |

| WO2014050264A1 (ja) * | 2012-09-28 | 2014-04-03 | 東レ株式会社 | プリプレグおよび炭素繊維強化複合材料 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP7240079B2 (ja) | 2023-03-15 |

| US10662302B2 (en) | 2020-05-26 |

| US20160185928A1 (en) | 2016-06-30 |

| EP3000839A1 (en) | 2016-03-30 |

| EP3546504B1 (en) | 2021-07-28 |

| EP3000839B1 (en) | 2019-05-22 |

| EP3546504A1 (en) | 2019-10-02 |

| ES2742692T3 (es) | 2020-02-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10995187B2 (en) | Composite structure having nanoparticles for performance enhancement | |

| US9862828B2 (en) | Polymer nanoparticle additions for resin modification | |

| US10059080B2 (en) | Method for the production of a fiber composite component, and semifinished textile product therefor | |

| CN107921718A (zh) | 模制件中的改善或与模制件有关的改善 | |

| US10465051B2 (en) | Composition having mechanical property gradients at locations of polymer nanoparticles | |

| JP6655328B2 (ja) | 樹脂の寸法安定性を改善するためのナノ粒子 | |

| JP7240079B2 (ja) | 複合材の変形能力を向上させるための高分子ナノ粒子 | |

| JP2010059300A (ja) | 炭素繊維強化複合材料およびその製造方法 | |

| JP2016166322A5 (ja) | ||

| AU2023256360A1 (en) | Resin molded body and method for manufacturing same | |

| KR20250007546A (ko) | 섬유 강화 수지 성형체 및 그 제조 방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20180724 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20190523 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190528 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20190828 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20200121 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20200417 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20200901 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20210104 |

|

| C60 | Trial request (containing other claim documents, opposition documents) |

Free format text: JAPANESE INTERMEDIATE CODE: C60 Effective date: 20210104 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20210112 |

|

| C21 | Notice of transfer of a case for reconsideration by examiners before appeal proceedings |

Free format text: JAPANESE INTERMEDIATE CODE: C21 Effective date: 20210119 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20210402 |

|

| C211 | Notice of termination of reconsideration by examiners before appeal proceedings |

Free format text: JAPANESE INTERMEDIATE CODE: C211 Effective date: 20210406 |

|

| C22 | Notice of designation (change) of administrative judge |

Free format text: JAPANESE INTERMEDIATE CODE: C22 Effective date: 20220712 |

|

| C13 | Notice of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: C13 Effective date: 20220823 |

|

| C28A | Non-patent document cited |

Free format text: JAPANESE INTERMEDIATE CODE: C2838 Effective date: 20220823 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20221124 |

|

| C22 | Notice of designation (change) of administrative judge |

Free format text: JAPANESE INTERMEDIATE CODE: C22 Effective date: 20221220 |

|

| C23 | Notice of termination of proceedings |

Free format text: JAPANESE INTERMEDIATE CODE: C23 Effective date: 20230110 |

|

| C03 | Trial/appeal decision taken |

Free format text: JAPANESE INTERMEDIATE CODE: C03 Effective date: 20230207 |

|

| C30A | Notification sent |

Free format text: JAPANESE INTERMEDIATE CODE: C3012 Effective date: 20230207 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20230303 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7240079 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |