JP2015159212A - カーボンを含むシリコン膜の形成方法、及び、形成装置 - Google Patents

カーボンを含むシリコン膜の形成方法、及び、形成装置 Download PDFInfo

- Publication number

- JP2015159212A JP2015159212A JP2014033686A JP2014033686A JP2015159212A JP 2015159212 A JP2015159212 A JP 2015159212A JP 2014033686 A JP2014033686 A JP 2014033686A JP 2014033686 A JP2014033686 A JP 2014033686A JP 2015159212 A JP2015159212 A JP 2015159212A

- Authority

- JP

- Japan

- Prior art keywords

- silicon

- chlorine

- reaction chamber

- adsorbate

- forming

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/32—Carbides

- C23C16/325—Silicon carbide

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45523—Pulsed gas flow or change of composition over time

- C23C16/45525—Atomic layer deposition [ALD]

- C23C16/45527—Atomic layer deposition [ALD] characterized by the ALD cycle, e.g. different flows or temperatures during half-reactions, unusual pulsing sequence, use of precursor mixtures or auxiliary reactants or activations

- C23C16/45531—Atomic layer deposition [ALD] characterized by the ALD cycle, e.g. different flows or temperatures during half-reactions, unusual pulsing sequence, use of precursor mixtures or auxiliary reactants or activations specially adapted for making ternary or higher compositions

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45523—Pulsed gas flow or change of composition over time

- C23C16/45525—Atomic layer deposition [ALD]

- C23C16/45527—Atomic layer deposition [ALD] characterized by the ALD cycle, e.g. different flows or temperatures during half-reactions, unusual pulsing sequence, use of precursor mixtures or auxiliary reactants or activations

- C23C16/45536—Use of plasma, radiation or electromagnetic fields

- C23C16/4554—Plasma being used non-continuously in between ALD reactions

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45523—Pulsed gas flow or change of composition over time

- C23C16/45525—Atomic layer deposition [ALD]

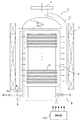

- C23C16/45544—Atomic layer deposition [ALD] characterized by the apparatus

- C23C16/45546—Atomic layer deposition [ALD] characterized by the apparatus specially adapted for a substrate stack in the ALD reactor

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/52—Controlling or regulating the coating process

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02365—Forming inorganic semiconducting materials on a substrate

- H01L21/02518—Deposited layers

- H01L21/02521—Materials

- H01L21/02524—Group 14 semiconducting materials

- H01L21/02529—Silicon carbide

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02365—Forming inorganic semiconducting materials on a substrate

- H01L21/02612—Formation types

- H01L21/02617—Deposition types

- H01L21/0262—Reduction or decomposition of gaseous compounds, e.g. CVD

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02365—Forming inorganic semiconducting materials on a substrate

- H01L21/02518—Deposited layers

- H01L21/0257—Doping during depositing

- H01L21/02573—Conductivity type

- H01L21/02579—P-type

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Computer Hardware Design (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Inorganic Chemistry (AREA)

- Electromagnetism (AREA)

- Plasma & Fusion (AREA)

- Chemical Vapour Deposition (AREA)

- Formation Of Insulating Films (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014033686A JP2015159212A (ja) | 2014-02-25 | 2014-02-25 | カーボンを含むシリコン膜の形成方法、及び、形成装置 |

| TW104105218A TWI602944B (zh) | 2014-02-25 | 2015-02-16 | 含碳之矽膜之形成方法 |

| KR1020150025765A KR20150100557A (ko) | 2014-02-25 | 2015-02-24 | 카본을 포함하는 실리콘막의 형성 방법, 및 형성 장치 |

| US14/629,666 US9490122B2 (en) | 2014-02-25 | 2015-02-24 | Method and apparatus of forming carbon-containing silicon film |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014033686A JP2015159212A (ja) | 2014-02-25 | 2014-02-25 | カーボンを含むシリコン膜の形成方法、及び、形成装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2015159212A true JP2015159212A (ja) | 2015-09-03 |

| JP2015159212A5 JP2015159212A5 (enExample) | 2016-10-20 |

Family

ID=53882893

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014033686A Pending JP2015159212A (ja) | 2014-02-25 | 2014-02-25 | カーボンを含むシリコン膜の形成方法、及び、形成装置 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US9490122B2 (enExample) |

| JP (1) | JP2015159212A (enExample) |

| KR (1) | KR20150100557A (enExample) |

| TW (1) | TWI602944B (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2017183490A (ja) * | 2016-03-30 | 2017-10-05 | 株式会社日立国際電気 | 半導体装置の製造方法、基板処理装置およびプログラム |

| JP2017179431A (ja) * | 2016-03-29 | 2017-10-05 | 一般財団法人ファインセラミックスセンター | 蒸着処理装置 |

| JP2024520783A (ja) * | 2021-06-11 | 2024-05-24 | ジュスン エンジニアリング カンパニー リミテッド | パワー半導体素子の製造方法 |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6999616B2 (ja) * | 2019-08-07 | 2022-01-18 | 株式会社Kokusai Electric | 半導体装置の製造方法、基板処理方法、基板処理装置およびプログラム |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH01119015A (ja) * | 1987-10-31 | 1989-05-11 | Nippon Soken Inc | 炭化ケイ素半導体膜およびその製造方法 |

| US20120177841A1 (en) * | 2010-09-24 | 2012-07-12 | Applied Materials, Inc. | Low Temperature Silicon Carbide Deposition Process |

| US20140051260A1 (en) * | 2012-08-14 | 2014-02-20 | Hitachi Kokusai Electric Inc. | Method of manufacturing semiconductor device, substrate processing apparatus, and recording medium |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH086180B2 (ja) | 1991-07-30 | 1996-01-24 | 科学技術庁金属材料技術研究所長 | 結晶性SiC膜の製造法 |

| US6117233A (en) | 1995-02-07 | 2000-09-12 | Max-Planck-Gesellschaft Zur Forderung De | Formation of single-crystal thin SiC films |

| TW527429B (en) * | 1999-10-15 | 2003-04-11 | Asm Inc | Deposition of transition metal carbides |

| JP2008123213A (ja) | 2006-11-10 | 2008-05-29 | Canon Inc | 画像出力装置及び文書処理方法 |

| US7888248B2 (en) | 2007-07-13 | 2011-02-15 | Northrop Grumman Systems Corporation | Method of producing large area SiC substrates |

| US8012859B1 (en) | 2010-03-31 | 2011-09-06 | Tokyo Electron Limited | Atomic layer deposition of silicon and silicon-containing films |

| US20120000490A1 (en) * | 2010-07-01 | 2012-01-05 | Applied Materials, Inc. | Methods for enhanced processing chamber cleaning |

-

2014

- 2014-02-25 JP JP2014033686A patent/JP2015159212A/ja active Pending

-

2015

- 2015-02-16 TW TW104105218A patent/TWI602944B/zh not_active IP Right Cessation

- 2015-02-24 US US14/629,666 patent/US9490122B2/en not_active Expired - Fee Related

- 2015-02-24 KR KR1020150025765A patent/KR20150100557A/ko not_active Ceased

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH01119015A (ja) * | 1987-10-31 | 1989-05-11 | Nippon Soken Inc | 炭化ケイ素半導体膜およびその製造方法 |

| US20120177841A1 (en) * | 2010-09-24 | 2012-07-12 | Applied Materials, Inc. | Low Temperature Silicon Carbide Deposition Process |

| US20140051260A1 (en) * | 2012-08-14 | 2014-02-20 | Hitachi Kokusai Electric Inc. | Method of manufacturing semiconductor device, substrate processing apparatus, and recording medium |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2017179431A (ja) * | 2016-03-29 | 2017-10-05 | 一般財団法人ファインセラミックスセンター | 蒸着処理装置 |

| JP2017183490A (ja) * | 2016-03-30 | 2017-10-05 | 株式会社日立国際電気 | 半導体装置の製造方法、基板処理装置およびプログラム |

| JP2024520783A (ja) * | 2021-06-11 | 2024-05-24 | ジュスン エンジニアリング カンパニー リミテッド | パワー半導体素子の製造方法 |

| JP7741205B2 (ja) | 2021-06-11 | 2025-09-17 | ジュスン エンジニアリング カンパニー リミテッド | パワー半導体素子の製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20150100557A (ko) | 2015-09-02 |

| TW201546313A (zh) | 2015-12-16 |

| US20150243496A1 (en) | 2015-08-27 |

| TWI602944B (zh) | 2017-10-21 |

| US9490122B2 (en) | 2016-11-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6017396B2 (ja) | 薄膜形成方法および薄膜形成装置 | |

| JP4607637B2 (ja) | シリコン窒化膜の形成方法、シリコン窒化膜の形成装置及びプログラム | |

| JP6703496B2 (ja) | 基板処理装置、半導体装置の製造方法およびプログラム | |

| JP4456533B2 (ja) | シリコン酸化膜の形成方法、シリコン酸化膜の形成装置及びプログラム | |

| JP4974815B2 (ja) | 薄膜形成装置の洗浄方法、薄膜形成方法及び薄膜形成装置 | |

| JP6656103B2 (ja) | 窒化膜の成膜方法および成膜装置 | |

| JP2018022716A (ja) | 窒化膜の形成方法および形成装置 | |

| JP2007019145A (ja) | シリコン酸窒化膜の形成方法、シリコン酸窒化膜の形成装置及びプログラム | |

| US20170162386A1 (en) | Method of manufacturing semiconductor device | |

| KR102760116B1 (ko) | 처리 장치 및 처리 방법 | |

| CN111066122B (zh) | 基板处理装置、半导体装置的制造方法以及存储介质 | |

| JP5247781B2 (ja) | シリコン窒化膜の形成方法、シリコン窒化膜の形成装置及びプログラム | |

| JP2014207426A (ja) | 積層型半導体素子の製造方法、積層型半導体素子、及び、その製造装置 | |

| JP2015159212A (ja) | カーボンを含むシリコン膜の形成方法、及び、形成装置 | |

| JP2015192063A (ja) | アモルファスシリコン膜形成装置の洗浄方法、アモルファスシリコン膜の形成方法およびアモルファスシリコン膜形成装置 | |

| JP6349234B2 (ja) | シリコン酸化膜の形成方法、及び、シリコン酸化膜の形成装置 | |

| JP2016178224A (ja) | シリコン窒化膜の形成方法、および、シリコン窒化膜の形成装置 | |

| JP5571233B2 (ja) | 薄膜形成装置の洗浄方法、薄膜形成方法及び薄膜形成装置 | |

| CN103681307B (zh) | 层叠膜的形成方法及其形成装置 | |

| KR20140005090A (ko) | 실리콘 산화막의 형성 방법 및 그 형성 장치 | |

| JP5658118B2 (ja) | シリコン酸化膜の形成方法およびその形成装置 | |

| JP6340332B2 (ja) | 薄膜形成方法、および、薄膜形成装置 | |

| JP2024120206A (ja) | 基板処理方法、半導体装置の製造方法、基板処理装置、およびプログラム | |

| JP2015162554A (ja) | シリコン窒化膜の形成装置、及び、シリコン窒化膜の形成方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160901 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160901 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20170518 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20170523 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170718 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20171107 |