JP2015159204A - ceramic package - Google Patents

ceramic package Download PDFInfo

- Publication number

- JP2015159204A JP2015159204A JP2014033570A JP2014033570A JP2015159204A JP 2015159204 A JP2015159204 A JP 2015159204A JP 2014033570 A JP2014033570 A JP 2014033570A JP 2014033570 A JP2014033570 A JP 2014033570A JP 2015159204 A JP2015159204 A JP 2015159204A

- Authority

- JP

- Japan

- Prior art keywords

- package

- ceramic

- view

- plan

- rectangular

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/15—Details of package parts other than the semiconductor or other solid state devices to be connected

- H01L2924/161—Cap

- H01L2924/1615—Shape

- H01L2924/16195—Flat cap [not enclosing an internal cavity]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/15—Details of package parts other than the semiconductor or other solid state devices to be connected

- H01L2924/161—Cap

- H01L2924/163—Connection portion, e.g. seal

- H01L2924/16315—Shape

Landscapes

- Piezo-Electric Or Mechanical Vibrators, Or Delay Or Filter Circuits (AREA)

Abstract

Description

本発明は、全体が箱形状を呈するパッケージ本体と、該本体の表面に開口するキャビティなどの開口部とを備え、追って該開口部内に各種の素子を実装した後、上記開口部を金属製の蓋板で封止されるセラミックパッケージに関する。 The present invention comprises a package main body having a box shape as a whole and an opening such as a cavity opened on the surface of the main body, and after mounting various elements in the opening, the opening is made of metal. The present invention relates to a ceramic package sealed with a lid plate.

例えば、セラミックからなり、全体が箱形状を呈する絶縁基体の表面に開口する凹部内に電子部品を実装した後、該凹部の開口部を囲む矩形枠状の表面に予め形成した封止用メタライズ層の上に、ロウ材を介して金属蓋体をシーム溶接により正確且つ強固に接合して気密信頼性を高めて、上記凹部内に実装した電子部品を長期間にわたり正常に作動させるため、平面視が矩形枠状である上記封止用メタライズ層の各辺をそれらの長さ方向において凹状に反らせた電子部品収納用パッケージが提案されている(例えば、特許文献1参照)。 For example, a sealing metallization layer formed in advance on a rectangular frame-shaped surface surrounding an opening of the recess after mounting an electronic component in a recess made of ceramic and entirely open on the surface of an insulating substrate having a box shape In addition, the metal lid body is accurately and firmly joined by seam welding through the brazing material to improve the airtight reliability, and the electronic components mounted in the recesses operate normally over a long period of time. There has been proposed an electronic component storage package in which each side of the sealing metallization layer having a rectangular frame shape is bent in a concave shape in the length direction thereof (for example, see Patent Document 1).

しかし、前記電子部品収納用パッケージのように、セラミックからなる絶縁基体の表面上に形成された平面視が矩形枠状の封止用メタライズ層を、その各辺を長さ方向において凹状に反らせた場合、該メタライズ層の四隅付近が上方に盛り上がっている。そのため、該メタライズ層のロウ材を介して金属蓋体をシーム溶接により接合した際に、該ロウ材の一部が上記四隅付近において金属蓋体の外側面を回り込んだ後、該金属蓋体の上面に這い上がり易い、という不具合を招く場合があった。また、上記シーム溶接時における金属蓋体の加熱による膨張と、その後の冷却に伴う収縮とによる該金属蓋体の熱変形により、上記ロウ材を介して絶縁基体の表面付近のセラミックに応力が生じることよって、該セラミックにクラックなどの破損を招く場合もあった。更に、前記電子部品収納用パッケージのように、封止用メタライズ層の四隅付近が上方に盛り上がり、且つ各辺の長さ方向における中央部が凹んだ形態である場合、前記シーム溶接時に用いる一対のローラ電極を各隅部の上記メタライズ層上に正確にセットして下向きに押し付けにくい、という不具合もあった。 However, as in the case of the electronic component storage package, the metallization layer for sealing formed in a rectangular frame shape on the surface of the insulating base made of ceramic is warped concavely in the length direction on each side. In this case, the four corners of the metallized layer are raised upward. Therefore, when the metal lid is joined by seam welding through the brazing material of the metallized layer, the metal lid after the part of the brazing material wraps around the outer surface of the metal lid near the four corners. In some cases, it may cause a problem that it is easy to crawl on the top surface. In addition, stress is generated in the ceramic near the surface of the insulating substrate through the brazing material due to thermal deformation of the metal lid due to expansion of the metal lid during the seam welding and subsequent contraction due to cooling. As a result, the ceramic may be damaged such as cracks. Further, in the case where the vicinity of the four corners of the metallization layer for sealing is raised upward and the central part in the length direction of each side is recessed as in the electronic component storage package, a pair of used for the seam welding There was also a problem that it was difficult to accurately set the roller electrode on the metallized layer at each corner and press it downward.

本発明は、背景技術で説明した不具合などを解決し、セラミックからなるパッケージ本体の表面に形成した平面視が矩形枠状のメタライズ層の上に金属製の蓋板をロウ材を介して接合しても、該ロウ材の一部が前記蓋板の上面に這い上がりにくく、且つ上記蓋板の熱変形による応力を緩和して、パッケージ本体のセラミックに破損が生じにくいセラミックパッケージを提供する、ことを課題とする。 The present invention solves the problems described in the background art, and joins a metal cover plate over a metallized layer having a rectangular frame shape on a surface of a ceramic package body via a brazing material. However, it is possible to provide a ceramic package in which a part of the brazing material is unlikely to crawl up to the upper surface of the lid plate, and stress due to thermal deformation of the lid plate is relieved to prevent damage to the ceramic of the package body. Is an issue.

本発明は、前記課題を解決するため、セラミックからなるパッケージ本体の表面に開口するキャビティなどの開口部を囲む平面視が矩形枠状の前記表面において、該表面の四隅における外側領域に各隅部がパッケージ本体の裏面側に垂れ下がる垂れ下がり面部を形成する、ことに着想して成されたものである。

即ち、本発明のセラミックパッケージ(請求項1)は、セラミックからなり、平面視の外形が矩形状の表面および裏面と、該表面および裏面の各辺間に位置する四つの側面とを含むパッケージ本体と、該パッケージ本体の表面側に開口し且つ平面視が矩形状の開口部と、を備えたセラミックパッケージであって、上記矩形状を呈する表面の四つの隅部には、該隅部ごとを挟んで隣接する2つの辺状の表面ごとの最高位置を基準面として、かかる2つの基準面よりも上記パッケージ本体の裏面側に垂れ下がった垂れ下がり面部を設けてなり、該垂れ下がり面部は、平面視における上記パッケージ本体の隣接する2つの側面同士の交点と、上記開口部における隣接する2つの内面同士の交点とを通過する内外方向に沿った基準線上において、該基準線と交差する最外部と最内部との全長における該最外部の位置から少なくとも10%以上の位置までに設けられている、ことを特徴とする。

In order to solve the above-mentioned problems, the present invention has a rectangular frame-shaped surface surrounding an opening such as a cavity opened on the surface of a package body made of ceramic, and each corner is formed in an outer region at four corners of the surface. Is formed with the idea of forming a hanging surface portion that hangs down on the back side of the package body.

That is, the ceramic package of the present invention (Claim 1) is made of ceramic and includes a front surface and a back surface having a rectangular outer shape in plan view and four side surfaces located between the sides of the front surface and the back surface. And an opening having a rectangular shape in a plan view, and the four corners of the surface having the rectangular shape are provided with each of the corners. With the highest position of each of the two side surfaces adjacent to each other as a reference plane, a hanging surface portion hanging from the two reference surfaces to the back surface side of the package body is provided, and the hanging surface portion is in plan view On the reference line along the inner and outer direction passing through the intersection of two adjacent side surfaces of the package body and the intersection of two adjacent inner surfaces of the opening, the base It is provided on the outermost outside position to at least 10% or more positions in the entire length of the outermost and innermost intersecting the line, characterized in that.

これによれば、平面視が矩形(枠)状である前記表面の四つの隅部には、該隅部ごとを挟んで隣接する2つの辺状の表面ごとの最高位置を基準面として、当該2つの基準面よりも前記パッケージ本体の裏面側に垂れ下がった垂れ下がり面部を設けられ、該垂れ下がり面部は、平面視で上記パッケージ本体において隣接する二つの側面同士の交点側あるいは該二つの側面の延長線同士の交点側が最下部となっている。そのため、後述するように、上記表面上に予め被覆したメタライズ層および金属メッキ層の上方に、追って、ロウ材を介して金属製の蓋板を接合した際に、上記表面の四隅付近に位置する四つの垂れ下がり面部の真上には、上記ロウ材の溜まり領域が形成され、かかる溜まり領域を四隅付近に含む矩形枠状のロウ材層を介して上記蓋板が接合(ロウ付け、またはシーム溶接)される。

その結果、上記蓋板をその上面側からロウ材層側に向けて押しつつ上記接合をしても、該ロウ材の一部が上記蓋板の上面に這い上がりにくくすることができる。

しかも、上記接合時における上記蓋板の熱膨張および冷却収縮に伴って生じる応力を、該応力が最も作用し易いパッケージ本体の表面における四隅付近ごとに位置している前記垂れ下がり面部の真上のロウ材溜まり領域によって緩和することができる。そのため、上記応力を受けても、パッケージ本体の表面の四隅付近におけるセラミックにクラックなどの破損を確実に防止することができる。

従って、前記開口部内に実装した各種の素子を長期間にわたり正常に作動させ得る気密信頼性の高いセラミックパッケージを提供することが可能となる。

According to this, at the four corners of the surface having a rectangular (frame) shape in plan view, the highest position for each of the two side surfaces adjacent to each other with the corners interposed therebetween is used as the reference plane. A drooping surface portion that hangs down on the back surface side of the package body from two reference surfaces is provided, and the drooping surface portion is an intersection of two side surfaces adjacent to each other in the package body in a plan view or an extension line of the two side surfaces The intersection side of each other is the bottom. Therefore, as will be described later, when a metal lid plate is joined via a brazing material over the metallized layer and the metal plating layer previously coated on the surface, it is located near the four corners of the surface. The brazing material reservoir region is formed directly above the four hanging surface portions, and the lid plate is joined (brazed or seam welded) via a rectangular frame-shaped brazing material layer including the reservoir region in the vicinity of the four corners. )

As a result, even if the joining is performed while pushing the cover plate from the upper surface side toward the brazing material layer side, it is possible to prevent a part of the brazing material from climbing up to the upper surface of the cover plate.

In addition, the stress generated along with the thermal expansion and cooling contraction of the lid plate at the time of the bonding is reduced to a level just above the drooping surface portion located at each of the four corners on the surface of the package body where the stress is most likely to act. It can be relieved by the material accumulation area. Therefore, even if the stress is received, breakage such as cracks can be reliably prevented in the ceramic near the four corners of the surface of the package body.

Therefore, it is possible to provide a highly airtight and reliable ceramic package that can normally operate various elements mounted in the opening for a long period of time.

尚、前記セラミックは、例えば、アルミナなどの高温焼成セラミック、あるいはガラス−セラミックなどの低温焼成セラミックである。

また、開口部には、例えば、全体が直方体形状のキャビティ、あるいは凹曲面などからなる凹部が含まれ、前記キャビティの場合、その底面には、例えば、水晶振動子などの素子を実装するための一対以上(複数)の電極が形成されている。

更に、前記辺状の表面ごとの最高位置とは、各辺ごとの表面の表層における凹凸面のうち、最も上方に位置する凸面の頂部付近である。かかる基準面となる最高位置を得るには、前記辺状の表面ごとを側面視した際に、該表面を含む側面において、パッケージ本体の裏面を基準として、複数の凸部のうち、該裏面から最も離れた位置の凸部を含む平面を前記基準面とした。但し、上記側面視した際において、パッケージ本体の裏面が上向きに反っている場合には、側面視における裏面の両端を結ぶ仮想線を含む仮想平面を基準として、該仮想線から最も離れた位置の凸部を含む平面を前記基準面とした。

また、前記垂れ下がり面部は、平面視でパッケージ本体の隣接する二つの側面同士の交点側、あるいは該二つの側面の延長線同士の交点側が最下部となり、例えば、側面視が上向きの凸の緩くカーブした曲面、または単一の傾斜面を呈する。

更に、前記垂れ下がり面部は、平面視において、前記キャビティ側に位置する最内側の辺が隅側に凸または凹の曲線であるか、あるいは、隣接する2つの側面間と斜めに交差する傾斜した直線である。

The ceramic is, for example, a high-temperature fired ceramic such as alumina, or a low-temperature fired ceramic such as glass-ceramic.

In addition, the opening includes, for example, a rectangular parallelepiped cavity or a concave portion formed of a concave curved surface. In the case of the cavity, for example, a crystal resonator or the like is mounted on the bottom surface of the cavity. A pair or more (plural) of electrodes are formed.

Further, the highest position for each side-shaped surface is the vicinity of the top of the convex surface located at the uppermost position among the uneven surfaces on the surface layer of the surface for each side. In order to obtain the highest position serving as the reference surface, when the side surfaces are viewed from the side, the side surface including the surface has a back surface of the package main body as a reference, and the plurality of convex portions from the back surface. The plane including the convex portion at the most distant position was taken as the reference plane. However, when the back surface of the package body is warped upward when viewed from the side, the position of the furthest distance from the virtual line is based on the virtual plane including the virtual line connecting both ends of the back surface in the side view. A plane including the convex portion was used as the reference plane.

In addition, the sagging surface portion is the lowermost portion at the intersection of two adjacent side surfaces of the package body in plan view, or at the intersection of the extension lines of the two side surfaces, for example, a convex, gently curved curve with the side view upward It exhibits a curved surface or a single inclined surface.

Further, in the plan view, the sagging surface portion is a curved line in which the innermost side located on the cavity side is convex or concave toward the corner side, or an inclined straight line that obliquely intersects between two adjacent side surfaces. It is.

また、前記垂れ下がり面部は、前記基準線と交差する最外部と最内部との全長にて、望ましくは、該最外部の位置から20%以上内側の位置まで、より望ましくは、該最外部の位置から30%以上内側の位置までに設けられる。尚、最も内側の位置は、上記全長と同じ100%であるが、該100%の場合には、垂れ下がり面部と隣接する2つの辺状の表面との境界は、該2つの辺状の表面側ごとに分割された形態も含まれる。

更に、前記垂れ下がり部面は、例えば、前記パッケージ本体を構成する複数のグリーンシートを積層した後、熱圧着する際の押圧治具を工夫するか、あるいは多数個取り用のグリーンシート積層体に個片化用の分割溝を縦横方向に沿ってレーザ加工により形成する際に、縦横の分割溝同士が交差する位置付近の加工条件を、該交差部付近以外の位置における加工条件と相違させることで形成される。

また、前記内外方向とは、平面視したパッケージ本体において、前記四辺の側面を外側とし、且つ前記開口部の中央部を内側とする方向である。

更に、前記基準線、二つの交点、あるいは位置は、仮想の線または点である。

加えて、前記セラミックパッケージは、該パッケージを平面視で縦横ごとに隣接して併設した製品領域と、該製品領域の周囲に位置し且つ前記セラミックからなる耳部とを併有する多数個取りの形態として提供しても良い。

In addition, the sagging surface portion is the entire length between the outermost portion and the innermost portion intersecting the reference line, preferably 20% or more from the outermost position, more preferably the outermost position. To 30% or more inside position. The innermost position is 100%, which is the same as the total length. In the case of 100%, the boundary between the drooping surface portion and the two adjacent side surfaces is the side of the two side surfaces. The form divided for each is also included.

Further, the hanging part surface is formed by, for example, devising a pressing jig at the time of thermocompression bonding after laminating a plurality of green sheets constituting the package main body, or by separating a plurality of green sheet laminates for taking multiple pieces. When forming the dividing grooves for singulation by laser processing along the vertical and horizontal directions, the processing conditions near the positions where the vertical and horizontal divided grooves intersect with each other are made different from the processing conditions at positions other than the vicinity of the intersections. It is formed.

In addition, the inside / outside direction is a direction in which the side surfaces of the four sides are on the outside and the center of the opening is on the inside in the package body in plan view.

Furthermore, the reference line, two intersections, or positions are virtual lines or points.

In addition, the ceramic package has a multi-cavity configuration having both a product region in which the package is adjacent to each other in the vertical and horizontal directions in plan view and an ear portion that is located around the product region and is made of the ceramic. May be provided as

また、本発明には、前記パッケージ本体における矩形状の表面には、該表面の四隅に位置する前記垂れ下がり面部を含めて、メタライズ層および金属メッキ層が被覆されている、セラミックパッケージ(請求項2)も含まれる。

これによれば、四隅付近に位置する前記垂れ下がり面部を含めた矩形(枠)状の表面上に、メタライズ層および金属メッキ層が順次被覆されている。そのため、少なくとも表層側の金属メッキ層上にロウ材を介して、次述する金属製の蓋板を直に接合(ロウ付け、あるいは所謂ダイレクトシーム)できると共に、その際において、前述したロウ材の蓋板の上面への這い上がりや、上記接合時に生じる熱応力によるセラミックの破損をなくするか、確実に抑制することが可能となる。

尚、前記メタライズ層には、前記パッケージ本体が高温焼成セラミックである場合には、WまたはMoなどを主成分とする金属が用いられ、低温焼成セラミックである場合には、CuまたはAgなどを主成分とする金属が用いられる。

また、前記金属メッキ膜は、例えば、下層側のNiメッキ膜および上層側のAuメッキ膜からなる。

According to the present invention, there is also provided a ceramic package in which a rectangular surface of the package body is covered with a metallized layer and a metal plating layer including the hanging surface portions located at four corners of the surface. ) Is also included.

According to this, the metallized layer and the metal plating layer are sequentially coated on the rectangular (frame) -shaped surface including the sagging surface portion located near the four corners. Therefore, a metal lid plate described below can be directly joined (brazed or so-called direct seam) via a brazing material at least on the metal plating layer on the surface layer side. It is possible to eliminate or surely prevent the ceramic plate from being crushed to the upper surface of the cover plate and from the thermal stress generated during the joining.

In the metallized layer, when the package body is a high-temperature fired ceramic, a metal mainly composed of W or Mo is used. When the package body is a low-temperature fired ceramic, Cu or Ag is mainly used. The component metal is used.

The metal plating film is composed of, for example, a lower Ni plating film and an upper Au plating film.

更に、本発明には、前記金属メッキ層の上方には、ロウ材を介して金属製の蓋板が接合されている、セラミックパッケージ(請求項3)も含まれる。

これによれば、四隅付近ごとに位置する前記垂れ下がり面部を含めた矩形(枠)状の前記表面上において、順次被覆されメタライズ層および金属メッキ層の上に、四隅付近に溜まり領域を含むロウ材層を介して金属製の蓋板が接合されている。そのため、前述したロウ材の蓋板の上面への這い上がりや、上記接合時に生じる熱応力によるセラミックの破損をなくすか、確実に抑制することができる。従って、前記開口部内に実装した各種の素子を長期間にわたり正常に作動させる気密信頼性の高いセラミックパッケージを提供することができる。

尚、前記ロウ材には、例えば、Agロウ(Ag−15%Cu)が用いられる。

また、前記蓋板は、例えば、42アロイ(42%Ni−Fe)、コバール(Fe−29%Ni−17%Co)、194合金(Cu−2.3%Fe−0.03%P)、あるいはステンレス鋼からなる。

Furthermore, the present invention includes a ceramic package (Claim 3) in which a metal cover plate is joined above the metal plating layer via a brazing material.

According to this, on the rectangular (frame) -shaped surface including the sagging surface portion located near each of the four corners, the brazing material including a pool region in the vicinity of the four corners on the metallized layer and the metal plating layer that are sequentially coated. A metal lid plate is joined via the layers. Therefore, it is possible to eliminate or surely suppress the above-described creeping of the brazing material to the upper surface of the lid plate and the breakage of the ceramic due to the thermal stress generated during the joining. Accordingly, it is possible to provide a highly airtight and reliable ceramic package that normally operates various elements mounted in the opening for a long period of time.

For example, Ag brazing (Ag-15% Cu) is used for the brazing material.

The lid plate may be, for example, 42 alloy (42% Ni-Fe), Kovar (Fe-29% Ni-17% Co), 194 alloy (Cu-2.3% Fe-0.03% P), Or it consists of stainless steel.

以下において、本発明を実施するための形態について説明する。

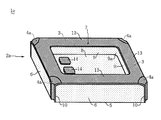

図1は、本発明による一形態のセラミックパッケージ(以下、単にパッケージと称する)1aを示す斜視図、図2は、該パッケージ1aの平面図である。

上記パッケージ1aは、図1,図2に示すように、セラミックからなり全体が箱形状を呈するパッケージ本体2aと、該パッケージ本体2aの表面3側の中央側に開口するキャビティ(開口部)7と、を備えている。

上記パッケージ本体2aは、例えば、アルミナなどの高温焼成セラミック、あるいはガラス−セラミックなどの低温焼成セラミックからなり、平面視の外形が長方形(矩形)状の表面3および裏面5と、これらの四辺間に位置する四つの側面6とを含んでいる。上記表面3は、平面視で全体が矩形枠状を呈し、その四隅付近に隣接する二つの側面6の延長線同士の交点側が最下位置となる平面視で扇形状の垂れ下がり面部4aを備えている。尚、上記裏面5は、平坦面である。

また、隣接する二つの前記側面6同士の間ごとには、垂直方向に沿って平面視が円弧形状の凹溝10が垂直方向に沿って形成されている。

Hereinafter, modes for carrying out the present invention will be described.

FIG. 1 is a perspective view showing a ceramic package (hereinafter simply referred to as a package) 1a according to an embodiment of the present invention, and FIG. 2 is a plan view of the package 1a.

As shown in FIGS. 1 and 2, the package 1a includes a

The

A

図1,図2に示すように、四隅付近の垂れ下がり面部4aを含む前記表面3のほぼ全面、および四隅の凹溝10の全面には、後述するメタライズ層(11)と下層側のメッキ層(12)とを介して、表層側のメッキ層13が被覆されている。

更に、前記キャビティ7は、平面視が長方形(矩形)状の底面8と、その四辺から表面3側に立設した内面9と、隣接する二つの該内面9間ごとの内隅に位置する曲面9aとからなる。上記底面8には、一対の電極14が形成されている。

上記電極14には、前記パッケージ本体2aが高温焼成セラミックである場合には、WまたはMoなどを主成分とする金属が用いられ、低温焼成セラミックである場合には、CuまたはAgなどを主成分とする金属が用いられると共に、その表面には、後述するメッキ層(12,13)が被覆されている。

尚、上記電極14は、キャビティ7の底面8とパッケージ本体2aの裏面5との間を貫通するビア導体(図示せず)を介して、上記裏面5に形成された複数の外部接続端子(図示せず)と個別に導通可能とされている。上記ビア導体および外部接続端子も、前記同様の金属からなり、このうち、外部接続端子の表面には前記同様のメッキ層が被覆されている。

As shown in FIG. 1 and FIG. 2, a metallized layer (11) and a lower plating layer (described later) are formed on almost the

Further, the

When the package

The

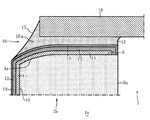

図2中の矢印Aで例示する前記パッケージ本体2aの四隅ごとには、図3(A)に示すように、平坦な表面3、隣接する二つの側面6、および凹溝10に囲まれ、平面視で全体が扇形状を呈し、側面視が上向きの凸の曲面からなる前記垂れ下がり面部4aが位置している。

かかる垂れ下がり面部4aは、図3(B)に示すように、その隅部を挟んで隣接する二つの辺状の表面3,3ごとの最高位置M1,M2を基準面とした際に、これらよりもパッケージ本体2aの前記裏面5側に垂れ下がっている。しかも、該垂れ下がり面部4aは、平面視で隣接する二つの側面6の延長線同士の交点Vと、前記キャビティ7において隣接する二つの内面9の延長線同士の交点Uとを通過する基準線L上において、該基準線Lと交差する最外部と最内部との全長W1に対し、前記最外部から該全長W1の少なくとも10%以上の範囲内の内側の位置Sまでの間に設けられている。即ち、基準線Lと交差する垂れ下がり面部4aの内外方向の長さW2は、上記全長W1の10%〜100%の範囲内にある。

尚、上記長さW2は、望ましくは、上記全長W1の20%〜90%、より望ましくは、上記全長W1の30%〜80%の範囲内である。

Each of the four corners of the

As shown in FIG. 3 (B), the sagging

The length W2 is desirably in the range of 20% to 90% of the full length W1, and more desirably in the range of 30% to 80% of the full length W1.

前記図2中のX−X線の矢視に沿った垂直断面図の図4、および該図4中の一点鎖線部分Yを拡大した図5に示すように、パッケージ本体2aの表面3、垂れ下がり面部4a、および凹溝10の上には、メタライズ層11、および金属メッキ12,13が順次被覆されている。上記メタライズ層11も、前記パッケージ本体2aが高温焼成セラミックである場合には、WまたはMoなどを主成分とする金属が用いられ、低温焼成セラミックである場合には、CuまたはAgなどを主成分とする金属が用いられ、例えば、約5〜40μmの厚みを有する。

また、下層(下地)側の金属メッキ層12は、例えば、厚みが約1〜10μmのNiメッキ膜からなり、表層側の金属メッキ層13は、例えば、厚みが約0.1〜1.2μmのAuメッキ膜からなる。

尚、前記メタライズ層11、および金属メッキ12,13は、パッケージ本体2aの裏面5側に沿っても位置しており、かかる部分は、例えば、本パッケージ1aを図示しないマザーボードの表面に搭載する際の接合に利用される。

As shown in FIG. 4 which is a vertical sectional view taken along the line X--X in FIG. 2 and FIG. 5 in which the one-dot chain line portion Y in FIG. 4 is enlarged, the

Moreover, the

The metallized

前記のようなパッケージ1aは、例えば、以下のようにして製造された。

平面視で縦横に複数のパッケージ領域を併有する多数個取り用のグリーンシートを複数枚用意し、これらの一部のグリーンシートにおけるパッケージ領域ごとの平面視の中央部に打ち抜き加工を施して、平面視が矩形状の貫通孔を形成すると共に、残部の平坦なグリーンシートにおけるパッケージ領域ごとの適所に打ち抜き加工を施して、比較的小径のビアホールを形成した。

次に、上記矩形状の貫通孔がパッケージ領域ごとに形成された一部のグリーンシートの表面全体に対し、W、Mo、Cu、またはAg粉末などを含む導電性ペーストをスクリーン印刷して、未焼成の前記メタライズ層11を形成した。

一方、残部の上記ビアホールがパッケージ領域ごとに形成されたグリーンシートのビアホールごとに上記同様の導電性ペーストを充填して未焼成のビア導体を形成した後、該ビア導体ごとの上端面および下端面が露出するパッケージ領域ごとの表面および裏面に上記同様の導電性ペーストをスクリーン印刷して、未焼成の前記電極14および外部接続端子を形成した。

The package 1a as described above was manufactured as follows, for example.

Prepare a plurality of multi-sheet green sheets that have multiple package areas both vertically and horizontally in plan view, and punch the center part of each of these green sheets in plan view for each package area. A through hole having a rectangular shape was formed, and a via hole having a relatively small diameter was formed by punching in an appropriate place for each package region in the remaining flat green sheet.

Next, a conductive paste containing W, Mo, Cu, or Ag powder is screen-printed on the entire surface of a part of the green sheet in which the rectangular through-holes are formed for each package region. The metallized

On the other hand, after forming the unfired via conductor by filling the same conductive paste into each via hole of the green sheet in which the remaining via hole is formed for each package region, the upper end surface and the lower end surface for each via conductor The conductive paste similar to the above was screen-printed on the front surface and back surface of each package region where the surface was exposed to form the

次いで、上記2種類のグリーンシート複数枚を定盤の上で積層した後、得られたグリーンシート積層体の表面に下向きの押圧治具を押し付けつつ熱圧着した。この際、最上層のグリーンシートにおいて互いに隣接する四つのパッケージ領域間を区画する縦横の境界線が交差する位置付近ごとには、上記押圧治具の凹圧面を工夫して、四個の垂れ下がり面部4aを形成した。

更に、上記縦横の境界線が交差する位置を中心として、前記グリーンシート積層体の表面と裏面との間に断面円形の貫通孔を形成した後、該貫通孔ごとの内壁面に沿って前記同様の導電性ペーストを円筒形状に塗布した。次いで、前記縦横の境界線ごとに沿って、表面側から切断刃の挿入あるいはレーザ加工を施して、平面視が格子形状で且つ一定の深さの分割溝を形成した

加えて、以上のようなグリーンシート積層体を焼成した後、得られた多数個取り用のパッケージ集合体を、Niメッキ用およびAuメッキ用の電解メッキ槽ごとに順次浸漬し、この際、上記集合体の周辺に予め設けたメッキ電極を活用して、前記メタライズ層11や電極14などの表面に、Niメッキ膜12およびAuメッキ膜13を所要の厚みで順次被覆した。

最後に、上記パッケージ集合体を、前記分割溝に沿って剪断加工して個片化を行うことによって、前記パッケージ1aを複数個同時に得ることができた。

Subsequently, after laminating a plurality of the above two types of green sheets on a surface plate, thermocompression bonding was performed while pressing a downward pressing jig against the surface of the obtained green sheet laminate. At this time, in the vicinity of the position where the vertical and horizontal boundary lines that divide between the four adjacent package regions in the uppermost green sheet cross each other, the concave pressure surface of the pressing jig is devised to provide four hanging surface portions. 4a was formed.

Further, a through hole having a circular cross section is formed between the front surface and the back surface of the green sheet laminate around the position where the vertical and horizontal boundary lines intersect, and then the same as described above along the inner wall surface of each through hole. The conductive paste was applied in a cylindrical shape. Next, along each of the vertical and horizontal boundary lines, a cutting blade was inserted from the surface side or laser processing was performed to form a dividing groove having a lattice shape and a certain depth in plan view. After firing the green sheet laminate, the obtained multi-package assembly is sequentially immersed in each of the electrolytic plating baths for Ni plating and Au plating. Using the plated electrode, the

Finally, a plurality of the packages 1a can be obtained simultaneously by shearing the package assembly along the dividing grooves into individual pieces.

図6は、前記パッケージ1aの表面3上などに位置する金属メッキ層12,13の上方に、ロウ材16を介して、金属製の蓋板18を接合した状態を示す垂直断面図、図7は、図6中の一点鎖線部分Zの拡大図である。

図6,図7に示すように、予め、キャビティ7の底面8上に形成された一対の電極14上に、図示しないロウ材を介して、例えば、水晶振動子15を実装した後、金属メッキ層13の上に、予め平面視でパッケージ本体2aの表面3と相似形状とした矩形枠状のロウ材16を載置し、更に、該ロウ材16の上に金属製の蓋板18を載置した。尚、該蓋板18は、例えば、コバールからなる平板である。

次いで、上記ロウ材16および蓋板18が載置されたパッケージ1aを、該蓋板18を下向きに加圧しつつ、図示しない加熱炉内に挿入して、所定温度帯で加熱した。その結果、上記ロウ材16は、全体が軟化し且つ表層部が溶融状態となって、上記蓋板18をAuメッキ層13の上方にロウ付け(接合)できた。その後、該ロウ材16は、上記加熱炉から取り出されると冷却された。

FIG. 6 is a vertical sectional view showing a state in which a

As shown in FIGS. 6 and 7, for example, after mounting a

Next, the package 1a on which the

図7に示すように、前記ロウ材16は、パッケージ本体2aの前記垂れ下がり面部4aごとの真上において、該ロウ材16の溜まり領域16aを形成していた。その結果、該ロウ材16の凹んだ曲面からなる外側面17は、前記蓋板18の側面の中間付近が最上端となり、該蓋板18の上面に這い上がっていなかった。

更に、前記ロウ材16の加熱および冷却に連れて、前記蓋板18も平面方向および厚み方向に沿って熱膨張および冷却収縮を行っていた。かかる蓋板18の熱変形に伴って生じる応力も、上記ロウ材16の溜まり領域16aによって緩和された。その結果、上記応力が最も顕著に生じ易い上記蓋板18の四隅付近の真下に位置するパッケージ本体2aの前記垂れ下がり面部4aごと、およびこれらに隣接する表面3のセラミックにクラックなどの局部的な破損が生じなかった。

尚、前記ロウ付けに替えて、一対のローラ電極を前記蓋板18における対向する二辺ごとに沿って、下向きに押し付けつつ転動させるシーム溶接を行っても、上記同様に、ロウ材16の這い上がりと、表面3のセラミックの破損とを防止できる。かかる方法においては、上記一対のローラ電極を、前記蓋板18における対向する二辺ごとの全長に沿って、容易且つ確実に転動させることができる。

As shown in FIG. 7, the

Further, as the

Note that, instead of the brazing, seam welding in which a pair of roller electrodes are rolled while being pressed downward along two opposing sides of the

また、前記パッケージ本体2aの垂れ下がり面部4aに替えて、図8(A)に示すように、平面視で全体が扇形状を呈し且つ側面視で上向きに凸の曲面からなる垂れ下がり面部4bをパッケージ1aに用いても前記同様の作用が成される。

更に、図8(B)に示すように、平面視で全体が扇形状を呈し且つ側面視が単一の傾斜面からなる垂れ下がり面部4cを前記パッケージ1aに用いても前記同様の作用が成される。該垂れ下がり面部4cは、図8(B)中の直線の破線で示すように、表面3との境界線を平面視で斜めの直線にした形態としても良い。

Further, in place of the sagging

Further, as shown in FIG. 8 (B), the same operation as described above can be achieved even when a hanging

以上のようなパッケージ1aによれば、パッケージ本体2aの表面3上に被覆したメタライズ層11および金属メッキ層12,13の上方に、ロウ材16を介して金属製の蓋板18を接合した際に、上記表面3の四隅付近に位置する四つの垂れ下がり面部4aの真上には、上記ロウ材16の溜まり領域16aが形成され、該溜まり領域16aを四隅付近に含む矩形枠状のロウ材層16を介して、上記蓋板18が接合される。その結果、上記蓋板18をその上面側からロウ材層16側に向けて押しつつ前記接合を行っても、該ロウ材16の一部が上記蓋板18の上面に這い上がる事態を容易に防止することができる。

更に、上記接合時における上記蓋板18の熱膨張および冷却収縮に伴って生じる応力を、該応力が最も作用し易いパッケージ本体2aの表面3における四隅付近ごとに位置している垂れ下がり面部4aごとの真上のロウ材16の溜まり領域16aによって緩和される。そのため、上記応力を受けても、パッケージ本体2aの表面3付近におけるセラミックにクラックなどの破損が生じにくくし得る。

従って、前記キャビティ(開口部)7内に実装した前記振動子15などの素子を長期間にわたって正常に作動させる気密信頼性の高いセラミックパッケージ1aを提供することが可能となる。

According to the package 1a as described above, when the

Furthermore, the stress generated along with the thermal expansion and cooling contraction of the

Therefore, it is possible to provide a ceramic package 1a with high hermetic reliability that allows elements such as the

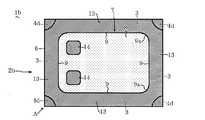

図9は、異なる形態のパッケージ1bを示す平面図、図10(A)は、そのパッケージ本体2bの表面3における隅部付近を例示する部分斜視図である。

上記パッケージ1bは、図9に示すように、前記同様の表面3、裏面5、側面6、キャビティ(開口部)7、メタライズ層11、金属めっき層12,13、および電極14などを有しているが、そのパッケージ本体2bの表面3における四隅付近には、前記凹溝10がなく、隣接する二つの側面6同士の垂直辺が平面視の隅となっている。そのため、図10(A)に示すように、パッケージ本体2bの表面3の四隅付近ごとには、平面視が四分の一の円形である扇形状を呈し、且つ側面視が上向きに凸の曲面からなる垂れ下がり面部4dが位置している。

FIG. 9 is a plan view showing a

As shown in FIG. 9, the

前記のようなパッケージ1bも前記と同様の方法によって製造される。

以上のようなパッケージ1bによっても、前記蓋板18を接合した際において、前記パッケージ1aと同様な作用が成されると共に、前記と同様な効果を奏することが可能である。

尚、図10(B)に示すように、前記垂れ下がり面部4dに替えて、パッケージ本体2bの表面3の四隅付近ごとに、平面視が円形の四分の一の扇形状を呈し、且つ側面視が下向きに凸の曲面からなる垂れ下がり面部4eにしても良い。

更に、図10(C)に示すように、平面視が円形の四分の一の扇形状を呈し、且つ側面視が単一の傾斜した直線の単一面からなる垂れ下がり面部4eにしても良い。該垂れ下がり面部4fは、図10(C)中の直線の破線で示すように、表面3との境界線を平面視で斜めの直線にした形態としても良い。

The

Even with the

In addition, as shown in FIG. 10 (B), instead of the sagging

Further, as shown in FIG. 10 (C), a drooping surface portion 4e having a single fan shape having a circular shape in a plan view and a single inclined straight line in a side view may be used. The drooping surface portion 4f may have a form in which a boundary line with the

図11は、前記各形態とは別形態の垂れ下がり面部4gを示す部分平面図である。図11に示すように、前記同様の基板本体2aの平面視における隅部において、垂れ下がり面部4gは、前記同様の基準線Lと交差する最外部と最内部との全長W1に対し、上記基準線Lと交差する最外部と最内部(交点S)との全長W2とが共通していると共に、隣接する2つの辺状の表面3ごととの境界線Rが、平面視でキャビティ7における内面9,9間の曲面9aの中央部に接している。かかる扇形状の垂れ下がり面部4gは、凹溝10側を最低位置とする前記同様の傾斜面あるいは曲面である。

FIG. 11 is a partial plan view showing a sagging

図12は、前記各形態とは更に別形態の垂れ下がり面部4hを示す部分平面図である。図12に示すように、前記同様の基板本体2aの平面視における隅部において、垂れ下がり面部4hは、前記同様の基準線Lと交差する最外部と最内部との全長W1に対し、上記基準線Lと交差する最外部と最内部との全長W2とが共通している。更に、垂れ下がり面部4hと隣接する2つの辺状の表面3ごととの境界線Rは、該2つの表面3,3ごとに2分割され、該境界線Rと上記基準線Lとが交差すべき交点Sは、上記2つの境界線R間を接続する仮想の曲線rと交差している。かかる扇形状の垂れ下がり面部4hも、凹溝10側を最低位置とする前記同様の傾斜面あるいは曲面である。

以上のような垂れ下がり面部4g,4hによっても、キャビティ7の開口部に前記蓋板18を接合した際において、前記パッケージ1aと同様な作用が成されると共に、前記と同様な効果を奏することが可能である。

尚、前記垂れ下がり面部4g,4hは、四隅ごとに凹溝10のないパッケージ本体2bを備えた前記セラミックパッケージ1bにも適用可能である。

FIG. 12 is a partial plan view showing a sagging

Even with the above-described

The sagging

本発明は、以上において説明した各形態に限定されるものではない。

例えば、前記パッケージ本体2a,2bの表面3および裏面5の平面視による外形は、正方形(矩形)状であっても良い。

また、前記垂れ下がり面部4a〜4fは、平面視におけるパッケージ本体2a,2bの表面3との境界線が、各隅部側に凸とした円弧形状の曲線であっても良い。

更に、前記パッケージ本体2a,2bの表面3における四辺の表面3の中間部には、該辺ごとの長手方向において、その側面6側に平面視が半円形状あるいはは半楕円形状を呈して位置し且つその側面6側の中央部が裏面5側に垂れ下がった単数または複数の垂れ下がり面部を有していても良い。

また、前記パッケージ本体2a,2bは、それらの裏面5にも、前記同様のキャビティ7や凹部などの開口部が更に配置されている形態としても良い。

更に、前記垂れ下がり面部は、該垂れ下がり面部を挟む2つの前記辺状の表面3の隣接する側面6に沿った長さが異なっている場合には、該2つの長さのうち短い方を基準として、前記最外部から10%以上の範囲で配設される。

また、前記ロウ材16は、Agロウ以外からなるものであっても良い。

加えて、前記蓋板18は、平面視が矩形の平板と、該平板の四辺に沿って下向きの垂直壁とからなる全体が平坦な箱形状を呈する形態であっても良い。

The present invention is not limited to the embodiments described above.

For example, the outer shape of the front and

Further, the sagging

Further, in the middle part of the

Further, the

Further, when the lengths of the sagging surface portions along the

Further, the

In addition, the

本発明によれば、セラミックからなるパッケージ本体の表面に形成した平面視が矩形枠状のメタライズ層の上に金属製の蓋板をロウ材を介して接合しても、該ロウ材の一部が前記蓋板の上面に這い上がりにくくできると共に、上記蓋板の熱変形による応力を緩和して、パッケージ本体のセラミックが破損しにくいセラミックパッケージを提供できる。 According to the present invention, even if a metal lid plate is joined via a brazing material on a metallized layer having a rectangular frame shape in plan view formed on the surface of a package body made of ceramic, a part of the brazing material However, it is possible to provide a ceramic package in which the ceramic of the package body is less likely to be damaged by relieving stress due to thermal deformation of the lid plate.

1a,1bセラミックパッケージ

2a,2bパッケージ本体

3……………表面

4a〜4f…垂れ下がり面部

5……………裏面

6……………側面

7……………キャビティ(開口部)

11…………メタライズ層

12,13…金属メッキ層

16…………ロウ材

18…………金属製の蓋板

M1,M2…最高位置

V,U………交点

L……………基準線

S……………垂れ下がり面部の内側の位置

1a, 1b

11 …………

Claims (3)

上記パッケージ本体の表面側に開口し且つ平面視が矩形状の開口部と、を備えたセラミックパッケージであって、

上記矩形状を呈する表面の四つの隅部には、該隅部ごとを挟んで隣接する2つの辺状の表面ごとの最高位置を基準面として、かかる2つの基準面よりも上記パッケージ本体の裏面側に垂れ下がった垂れ下がり面部を設けてなり、

上記垂れ下がり面部は、平面視における上記パッケージ本体の隣接する2つの側面同士の交点と、上記開口部における隣接する2つの内面同士の交点とを通過する内外方向に沿った基準線上において、該基準線と交差する最外部と最内部との全長における該最外部の位置から10%以上の位置までに設けられている、

ことを特徴とするセラミックパッケージ。 A package main body made of ceramic and including a front surface and a back surface having a rectangular outer shape in plan view, and four side surfaces located between the sides of the front surface and the back surface;

A ceramic package having an opening on the surface side of the package body and having a rectangular opening in plan view,

At the four corners of the rectangular surface, the back surface of the package body is more than the two reference surfaces, with the highest positions of the two adjacent side surfaces sandwiching the corners as reference surfaces. A hanging surface part that hangs down on the side,

The sagging surface portion is a reference line on a reference line along an inner / outer direction passing through an intersection of two adjacent side surfaces of the package body in plan view and an intersection of two adjacent inner surfaces of the opening. Is provided at a position of 10% or more from the outermost position in the entire length of the outermost part and the innermost part intersecting with

A ceramic package characterized by that.

ことを特徴とする請求項1に記載のセラミックパッケージ。 The rectangular surface of the package body is covered with a metallized layer and a metal plating layer, including the hanging surface portions located at the four corners of the surface,

The ceramic package according to claim 1.

ことを特徴とする請求項2に記載のセラミックパッケージ。 Above the metal plating layer, a metal lid plate is joined via a brazing material,

The ceramic package according to claim 2.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014033570A JP2015159204A (en) | 2014-02-25 | 2014-02-25 | ceramic package |

| CN201510085220.3A CN104867879A (en) | 2014-02-25 | 2015-02-16 | Ceramic package |

| TW104105221A TWI559462B (en) | 2014-02-25 | 2015-02-16 | Ceramic package |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014033570A JP2015159204A (en) | 2014-02-25 | 2014-02-25 | ceramic package |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2015159204A true JP2015159204A (en) | 2015-09-03 |

| JP2015159204A5 JP2015159204A5 (en) | 2015-10-15 |

Family

ID=53913623

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014033570A Pending JP2015159204A (en) | 2014-02-25 | 2014-02-25 | ceramic package |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP2015159204A (en) |

| CN (1) | CN104867879A (en) |

| TW (1) | TWI559462B (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016152733A1 (en) * | 2015-03-24 | 2016-09-29 | 京セラ株式会社 | Electronic component accommodating substrate and electronic component mounting package |

| JP2018085631A (en) * | 2016-11-24 | 2018-05-31 | 日本電波工業株式会社 | Piezoelectric device and base |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR3048305A1 (en) * | 2016-02-26 | 2017-09-01 | Stmicroelectronics (Grenoble 2) Sas | LOCALLY ENCAPSULATING BLOCK ELECTRONIC DEVICE WITH REDUCED THICKNESS |

| US11152911B2 (en) * | 2016-09-16 | 2021-10-19 | Daishinku Corporation | Piezoelectric resonator device |

| CN107285274B (en) * | 2017-05-10 | 2019-03-01 | 中国航空工业集团公司西安飞行自动控制研究所 | A kind of three-dimension packaging method of micromachined process |

| CN111010102B (en) * | 2019-03-18 | 2023-12-15 | 天津大学 | MEMS device assembly and electronic equipment of thin film encapsulation taking shape into consideration |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5760465A (en) * | 1996-02-01 | 1998-06-02 | International Business Machines Corporation | Electronic package with strain relief means |

| TWI227556B (en) * | 2003-07-15 | 2005-02-01 | Advanced Semiconductor Eng | Chip structure |

| CN201113937Y (en) * | 2007-08-16 | 2008-09-10 | 台晶(宁波)电子有限公司 | Quartz crystal oscillator ceramic packaging structure |

| JP5763962B2 (en) * | 2011-04-19 | 2015-08-12 | 日本特殊陶業株式会社 | Ceramic wiring board, multi-cavity ceramic wiring board, and manufacturing method thereof |

| JP6006474B2 (en) * | 2011-04-25 | 2016-10-12 | 日本特殊陶業株式会社 | Wiring board, multi-cavity wiring board, and manufacturing method thereof |

| EP3544067B1 (en) * | 2011-05-16 | 2020-09-09 | Nichia Corporation | Light diode emitting device and method for manufacturing the same |

| JP5836796B2 (en) * | 2011-12-28 | 2015-12-24 | 日本特殊陶業株式会社 | Ceramic package |

-

2014

- 2014-02-25 JP JP2014033570A patent/JP2015159204A/en active Pending

-

2015

- 2015-02-16 CN CN201510085220.3A patent/CN104867879A/en active Pending

- 2015-02-16 TW TW104105221A patent/TWI559462B/en not_active IP Right Cessation

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016152733A1 (en) * | 2015-03-24 | 2016-09-29 | 京セラ株式会社 | Electronic component accommodating substrate and electronic component mounting package |

| JPWO2016152733A1 (en) * | 2015-03-24 | 2018-01-25 | 京セラ株式会社 | Electronic component storage board and electronic component mounting package |

| US10396002B2 (en) | 2015-03-24 | 2019-08-27 | Kyocera Corporation | Electronic component storage substrate and housing package |

| JP2018085631A (en) * | 2016-11-24 | 2018-05-31 | 日本電波工業株式会社 | Piezoelectric device and base |

Also Published As

| Publication number | Publication date |

|---|---|

| TWI559462B (en) | 2016-11-21 |

| TW201537695A (en) | 2015-10-01 |

| CN104867879A (en) | 2015-08-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2015159204A (en) | ceramic package | |

| US9232643B2 (en) | Ceramic wiring board, multi-piece ceramic wiring board, and method for producing same | |

| JP5836796B2 (en) | Ceramic package | |

| JP6450612B2 (en) | Electronic component device and manufacturing method thereof | |

| JP2017011045A (en) | Ceramic package, method of manufacturing the same, and method of manufacturing electronic component device | |

| JP5791283B2 (en) | Electronic component storage package and electronic device including the same | |

| JP6193622B2 (en) | Wiring board unit and method for manufacturing wiring board with leads | |

| JP4511311B2 (en) | Multi-circuit board and electronic device | |

| JP5898561B2 (en) | Ceramic package | |

| JP6838961B2 (en) | Wiring board and its manufacturing method | |

| JP6321477B2 (en) | Electronic component storage package, package assembly, and method of manufacturing electronic component storage package | |

| JP6298363B2 (en) | Wiring board | |

| JP2016225957A (en) | Ceramic package | |

| JP4520801B2 (en) | Package and manufacturing method thereof | |

| JP2013243232A (en) | Metal frame for ceramic package and ceramic package | |

| JP5192860B2 (en) | package | |

| JP4511335B2 (en) | Multi-circuit board and electronic device | |

| JP2006041310A (en) | Multi-pattern wiring board | |

| JP2005050935A (en) | Multi-piece wiring board | |

| JP6506132B2 (en) | Multi-cavity wiring board and wiring board | |

| JP2018181964A (en) | Ceramic substrate and manufacturing method thereof | |

| JP2007266039A (en) | Multi-pattern substrate, and electronic part mounting substrate | |

| JP2007234657A (en) | Multiple patterning wiring board | |

| JP2015122600A (en) | Wiring board | |

| JP2006066656A (en) | Multiple patterning wiring substrate, electronic component housing package, and electronic device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150803 |