JP2013503060A - 不均一な厚さを有する部品の射出成形 - Google Patents

不均一な厚さを有する部品の射出成形 Download PDFInfo

- Publication number

- JP2013503060A JP2013503060A JP2012526889A JP2012526889A JP2013503060A JP 2013503060 A JP2013503060 A JP 2013503060A JP 2012526889 A JP2012526889 A JP 2012526889A JP 2012526889 A JP2012526889 A JP 2012526889A JP 2013503060 A JP2013503060 A JP 2013503060A

- Authority

- JP

- Japan

- Prior art keywords

- mold surface

- mold

- injection molding

- thermoplastic material

- sidewalls

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000001746 injection moulding Methods 0.000 title claims abstract description 38

- 238000000034 method Methods 0.000 claims abstract description 21

- 238000000465 moulding Methods 0.000 claims abstract description 13

- 239000012815 thermoplastic material Substances 0.000 claims description 26

- 230000033001 locomotion Effects 0.000 claims description 12

- 230000003287 optical effect Effects 0.000 claims description 10

- 238000001816 cooling Methods 0.000 claims description 7

- 238000010438 heat treatment Methods 0.000 claims description 4

- 230000006835 compression Effects 0.000 claims description 3

- 238000007906 compression Methods 0.000 claims description 3

- 229920003229 poly(methyl methacrylate) Polymers 0.000 claims description 3

- 239000004926 polymethyl methacrylate Substances 0.000 claims description 3

- 239000004417 polycarbonate Substances 0.000 claims description 2

- 229920000515 polycarbonate Polymers 0.000 claims description 2

- -1 polycyclic olefins Chemical class 0.000 claims description 2

- 239000000463 material Substances 0.000 abstract description 8

- 229920001169 thermoplastic Polymers 0.000 abstract 1

- 239000004416 thermosoftening plastic Substances 0.000 abstract 1

- 239000004033 plastic Substances 0.000 description 12

- 229920003023 plastic Polymers 0.000 description 12

- 238000010586 diagram Methods 0.000 description 5

- 238000002347 injection Methods 0.000 description 5

- 239000007924 injection Substances 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 3

- 241000699670 Mus sp. Species 0.000 description 1

- 239000012141 concentrate Substances 0.000 description 1

- 230000008602 contraction Effects 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 229910003460 diamond Inorganic materials 0.000 description 1

- 239000010432 diamond Substances 0.000 description 1

- 230000002452 interceptive effect Effects 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000012768 molten material Substances 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/33—Moulds having transversely, e.g. radially, movable mould parts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D11/00—Producing optical elements, e.g. lenses or prisms

- B29D11/00663—Production of light guides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/20—Opening, closing or clamping

- B29C33/26—Opening, closing or clamping by pivotal movement

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/46—Means for plasticising or homogenising the moulding material or forcing it into the mould

- B29C45/56—Means for plasticising or homogenising the moulding material or forcing it into the mould using mould parts movable during or after injection, e.g. injection-compression moulding

- B29C45/561—Injection-compression moulding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/76—Measuring, controlling or regulating

- B29C45/80—Measuring, controlling or regulating of relative position of mould parts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/46—Means for plasticising or homogenising the moulding material or forcing it into the mould

- B29C45/57—Exerting after-pressure on the moulding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2011/00—Optical elements, e.g. lenses, prisms

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Health & Medical Sciences (AREA)

- Ophthalmology & Optometry (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Injection Moulding Of Plastics Or The Like (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US12/548,147 | 2009-08-26 | ||

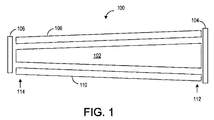

| US12/548,147 US7931847B2 (en) | 2009-08-26 | 2009-08-26 | Injection molding of part having nonuniform thickness |

| PCT/US2010/046397 WO2011028493A2 (en) | 2009-08-26 | 2010-08-24 | Injection molding of part having nonuniform thickness |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2013503060A true JP2013503060A (ja) | 2013-01-31 |

| JP2013503060A5 JP2013503060A5 (enExample) | 2013-08-29 |

Family

ID=43623638

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012526889A Pending JP2013503060A (ja) | 2009-08-26 | 2010-08-24 | 不均一な厚さを有する部品の射出成形 |

Country Status (10)

| Country | Link |

|---|---|

| US (2) | US7931847B2 (enExample) |

| EP (1) | EP2470346B1 (enExample) |

| JP (1) | JP2013503060A (enExample) |

| KR (1) | KR101764448B1 (enExample) |

| CN (1) | CN102470590B (enExample) |

| BR (1) | BR112012004238A2 (enExample) |

| CA (1) | CA2768071A1 (enExample) |

| MY (1) | MY160933A (enExample) |

| RU (1) | RU2566770C2 (enExample) |

| WO (1) | WO2011028493A2 (enExample) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7931847B2 (en) * | 2009-08-26 | 2011-04-26 | Microsoft Corporation | Injection molding of part having nonuniform thickness |

| US8628321B2 (en) * | 2010-10-13 | 2014-01-14 | Microsoft Corporation | Molding of nonuniform object having undercut structure |

| US9108369B2 (en) | 2011-07-25 | 2015-08-18 | Microsoft Technology Licensing, Llc | Wedge light guide |

| CN105479780A (zh) * | 2015-11-24 | 2016-04-13 | 上海复合材料科技有限公司 | 一种纤维-树脂复合材料的制备方法及该方法的用途 |

| CN113710446B (zh) * | 2019-04-18 | 2023-11-14 | 帝人碳纤维欧洲有限公司 | 楔形填料预成型坯 |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3117474A1 (de) * | 1981-05-02 | 1982-11-18 | Fa. Carl Zeiss, 7920 Heidenheim | Verfahren und vorrichtung zum herstellen von formteilen mit asphaerischen oberflaechen |

| JPH0733034B2 (ja) * | 1988-09-05 | 1995-04-12 | 富士写真フイルム株式会社 | 射出圧縮成形用金型 |

| JPH07121545B2 (ja) * | 1988-09-19 | 1995-12-25 | 株式会社小松製作所 | 射出圧縮成形機とその制御方法 |

| US5015169A (en) * | 1989-06-08 | 1991-05-14 | General Electric Company | Apparatus for die forming thermoplastic sheet material |

| JP3037988B2 (ja) * | 1990-09-29 | 2000-05-08 | キーパー株式会社 | 合成樹脂製蛇腹製品の射出ブロー成形方法 |

| DE4313015C1 (de) * | 1993-04-21 | 1994-05-19 | Moebius & Ruppert | Vorrichtung zur Herstellung eines großflächigen Kunststoffgegenstandes geringer Wanddicke |

| DE19517024C1 (de) * | 1995-05-10 | 1996-06-13 | Moebius & Ruppert | Vorrichtung zur Herstellung eines großflächigen Kunststoffgegenstandes geringer Wanddicke |

| SG65615A1 (en) * | 1996-07-25 | 1999-06-22 | Advanced Systems Automation Pt | Bga moulding assembly for encapsulating bga substrates of varying thickness |

| ES2190599T3 (es) * | 1997-08-07 | 2003-08-01 | Decoma Int Inc | Sistema de gestion de luz delgado para orientar y distribuir la luz de una o mas fuentes luminosas y metodo de fabricacion de estructuras opticas para su uso en el sistema. |

| JP2002036323A (ja) * | 2000-07-21 | 2002-02-05 | Meiki Co Ltd | 楔形断面の薄板部材の成形方法および楔形断面の薄板部材の成形用型締装置 |

| DE10057160A1 (de) * | 2000-11-16 | 2002-05-29 | Sms Demag Ag | Verfahren und Vorrichtung zum Herstellen von Dünnbrammen |

| US6579485B2 (en) * | 2000-12-15 | 2003-06-17 | Haun Drop Forge Co. Ltd. | Method of injection molding around the surface of an object |

| DE10115647B4 (de) * | 2001-03-30 | 2008-05-15 | Kraussmaffei Technologies Gmbh | Vorrichtung und Verfahren zum Spritzgießen von Kunststoffteilen mit Dickenunterschieden |

| JP2002303734A (ja) * | 2001-04-05 | 2002-10-18 | Sumitomo Chem Co Ltd | 導光板 |

| DE10202246B8 (de) * | 2002-01-21 | 2006-04-20 | Franz Josef Summerer | Vorrichtung und Verfahren zum Herstellen optischer Formteile aus Kunststoff |

| DE10302102B3 (de) * | 2003-01-21 | 2004-09-16 | Franz Josef Summerer | Verfahren und Vorrichtung zum Herstellen von Formteilen aus Kunststoff |

| JP2005238456A (ja) * | 2004-02-24 | 2005-09-08 | Sumitomo Chemical Co Ltd | 偏肉大型導光板の製造方法 |

| US20070083086A1 (en) * | 2005-10-11 | 2007-04-12 | Levahn Intellectual Property Holding Company, Llc | Shaped retractor blade |

| DE102008027522A1 (de) * | 2007-06-11 | 2009-02-05 | Kabushiki Kaisha Daisan, Ashikaga-shi | Dünnwandiger Formgegenstand |

| KR100846746B1 (ko) | 2007-11-28 | 2008-07-17 | 범진공업 (주) | 사출물 수축보상을 위한 금형 |

| DK1939386T3 (da) | 2008-01-08 | 2013-04-22 | Nina Nielsen | Kile med en slids |

| US7931847B2 (en) * | 2009-08-26 | 2011-04-26 | Microsoft Corporation | Injection molding of part having nonuniform thickness |

-

2009

- 2009-08-26 US US12/548,147 patent/US7931847B2/en not_active Expired - Fee Related

-

2010

- 2010-08-24 MY MYPI2012000400A patent/MY160933A/en unknown

- 2010-08-24 EP EP10814217.5A patent/EP2470346B1/en not_active Not-in-force

- 2010-08-24 RU RU2012106613/05A patent/RU2566770C2/ru not_active IP Right Cessation

- 2010-08-24 JP JP2012526889A patent/JP2013503060A/ja active Pending

- 2010-08-24 KR KR1020127004875A patent/KR101764448B1/ko not_active Expired - Fee Related

- 2010-08-24 CN CN201080037825.0A patent/CN102470590B/zh not_active Expired - Fee Related

- 2010-08-24 CA CA2768071A patent/CA2768071A1/en not_active Abandoned

- 2010-08-24 WO PCT/US2010/046397 patent/WO2011028493A2/en not_active Ceased

- 2010-08-24 BR BR112012004238A patent/BR112012004238A2/pt not_active Application Discontinuation

-

2011

- 2011-03-17 US US13/050,738 patent/US8216493B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN102470590A (zh) | 2012-05-23 |

| MY160933A (en) | 2017-03-31 |

| EP2470346A4 (en) | 2014-03-12 |

| RU2566770C2 (ru) | 2015-10-27 |

| RU2012106613A (ru) | 2013-08-27 |

| KR20120069670A (ko) | 2012-06-28 |

| EP2470346B1 (en) | 2016-04-20 |

| CN102470590B (zh) | 2014-07-16 |

| CA2768071A1 (en) | 2011-03-10 |

| US8216493B2 (en) | 2012-07-10 |

| BR112012004238A2 (pt) | 2016-04-05 |

| US20110049736A1 (en) | 2011-03-03 |

| WO2011028493A3 (en) | 2011-07-07 |

| US7931847B2 (en) | 2011-04-26 |

| US20110163467A1 (en) | 2011-07-07 |

| WO2011028493A2 (en) | 2011-03-10 |

| EP2470346A2 (en) | 2012-07-04 |

| KR101764448B1 (ko) | 2017-08-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103158236B (zh) | 薄成形品的成形方法 | |

| US20090085235A1 (en) | Method and apparatus for making a microstructured or nanostructured article | |

| US8512608B2 (en) | Injection molding method and injection molding device | |

| CN102416686B (zh) | 具有底切结构的不均匀物体的模制 | |

| JP2013503060A (ja) | 不均一な厚さを有する部品の射出成形 | |

| US7820084B2 (en) | Minute shape molding method and apparatus thereof | |

| JP2013503060A5 (enExample) | ||

| CN101279312A (zh) | 一种模内涂装方法及其装置 | |

| JPH0331124B2 (enExample) | ||

| JP2006281765A (ja) | 光学素子の表面精度改善方法及びその装置 | |

| JP2008055713A (ja) | 射出成形機、金型、及び射出成形方法 | |

| JPH05293861A (ja) | 成形装置 | |

| US20070010303A1 (en) | High quality optical windows for mobile phones and cameras | |

| JP5666851B2 (ja) | 加工用素体,その製造方法及び装置,加工用素体を利用した試作品及びその製造方法 | |

| JP7074047B2 (ja) | 樹脂部品の製造方法 | |

| WO2020137379A1 (ja) | 樹脂部品及びその製造方法 | |

| KR101394846B1 (ko) | 박육 성형품의 성형 방법 | |

| CN1942299A (zh) | 光学部件的树脂成形方法、金属模装置及浇口衬套 | |

| JP4032996B2 (ja) | 射出成形方法 | |

| CN112118954A (zh) | 用于制造光学透镜的方法和利用所述方法制造的光学透镜 | |

| JPS60132719A (ja) | プラスチツクレンズの製造方法 | |

| JP6089297B2 (ja) | 熱硬化性樹脂成形品金型および熱硬化性樹脂成形品の成形方法 | |

| JP2022170105A (ja) | 成形用金型、射出成形装置および樹脂成形品の製造方法 | |

| JP2013233779A (ja) | 金型内塗装用金型、射出成形装置及び積層成形品の金型内塗装方法 | |

| JPH0139336B2 (enExample) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130708 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130708 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20140310 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140312 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140529 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20140929 |