JP2012513921A - 共押出し成形型、成形型による押出し成形方法、及びそれにより作製される押出し成形物品 - Google Patents

共押出し成形型、成形型による押出し成形方法、及びそれにより作製される押出し成形物品 Download PDFInfo

- Publication number

- JP2012513921A JP2012513921A JP2011544479A JP2011544479A JP2012513921A JP 2012513921 A JP2012513921 A JP 2012513921A JP 2011544479 A JP2011544479 A JP 2011544479A JP 2011544479 A JP2011544479 A JP 2011544479A JP 2012513921 A JP2012513921 A JP 2012513921A

- Authority

- JP

- Japan

- Prior art keywords

- mold

- zones

- polymeric material

- channels

- channel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000001125 extrusion Methods 0.000 title claims abstract description 45

- 238000000034 method Methods 0.000 title abstract description 21

- 238000000465 moulding Methods 0.000 title description 2

- 239000000463 material Substances 0.000 claims abstract description 83

- 238000005192 partition Methods 0.000 claims abstract description 28

- 238000009826 distribution Methods 0.000 claims abstract description 26

- 239000002861 polymer material Substances 0.000 claims abstract description 16

- 238000005304 joining Methods 0.000 claims description 5

- 238000004519 manufacturing process Methods 0.000 claims description 3

- 235000012438 extruded product Nutrition 0.000 abstract description 2

- 229920000642 polymer Polymers 0.000 description 16

- 239000005038 ethylene vinyl acetate Substances 0.000 description 9

- 229920001200 poly(ethylene-vinyl acetate) Polymers 0.000 description 9

- 230000001070 adhesive effect Effects 0.000 description 7

- 239000010410 layer Substances 0.000 description 7

- 239000000853 adhesive Substances 0.000 description 6

- 239000000049 pigment Substances 0.000 description 6

- -1 polypropylene Polymers 0.000 description 5

- 239000004743 Polypropylene Substances 0.000 description 4

- 239000004820 Pressure-sensitive adhesive Substances 0.000 description 4

- 230000013011 mating Effects 0.000 description 4

- 229920001155 polypropylene Polymers 0.000 description 4

- 230000001154 acute effect Effects 0.000 description 3

- 238000003754 machining Methods 0.000 description 3

- 239000000155 melt Substances 0.000 description 3

- 238000001000 micrograph Methods 0.000 description 3

- 230000005855 radiation Effects 0.000 description 3

- 229920001169 thermoplastic Polymers 0.000 description 3

- 229920001187 thermosetting polymer Polymers 0.000 description 3

- 239000004416 thermosoftening plastic Substances 0.000 description 3

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 2

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- DQXBYHZEEUGOBF-UHFFFAOYSA-N but-3-enoic acid;ethene Chemical compound C=C.OC(=O)CC=C DQXBYHZEEUGOBF-UHFFFAOYSA-N 0.000 description 2

- 238000009760 electrical discharge machining Methods 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 238000010791 quenching Methods 0.000 description 2

- 230000000171 quenching effect Effects 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 229910001220 stainless steel Inorganic materials 0.000 description 2

- 239000010935 stainless steel Substances 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- 229920003345 Elvax® Polymers 0.000 description 1

- XTXRWKRVRITETP-UHFFFAOYSA-N Vinyl acetate Chemical compound CC(=O)OC=C XTXRWKRVRITETP-UHFFFAOYSA-N 0.000 description 1

- 239000002313 adhesive film Substances 0.000 description 1

- 238000001723 curing Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 229910003460 diamond Inorganic materials 0.000 description 1

- 239000010432 diamond Substances 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 238000004049 embossing Methods 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- PNJWIWWMYCMZRO-UHFFFAOYSA-N pent‐4‐en‐2‐one Natural products CC(=O)CC=C PNJWIWWMYCMZRO-UHFFFAOYSA-N 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 238000003847 radiation curing Methods 0.000 description 1

- 230000010076 replication Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 238000001029 thermal curing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/30—Extrusion nozzles or dies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/30—Extrusion nozzles or dies

- B29C48/305—Extrusion nozzles or dies having a wide opening, e.g. for forming sheets

- B29C48/307—Extrusion nozzles or dies having a wide opening, e.g. for forming sheets specially adapted for bringing together components, e.g. melts within the die

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/03—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the shape of the extruded material at extrusion

- B29C48/07—Flat, e.g. panels

- B29C48/08—Flat, e.g. panels flexible, e.g. films

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/16—Articles comprising two or more components, e.g. co-extruded layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/16—Articles comprising two or more components, e.g. co-extruded layers

- B29C48/18—Articles comprising two or more components, e.g. co-extruded layers the components being layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/16—Articles comprising two or more components, e.g. co-extruded layers

- B29C48/18—Articles comprising two or more components, e.g. co-extruded layers the components being layers

- B29C48/19—Articles comprising two or more components, e.g. co-extruded layers the components being layers the layers being joined at their edges

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/16—Articles comprising two or more components, e.g. co-extruded layers

- B29C48/18—Articles comprising two or more components, e.g. co-extruded layers the components being layers

- B29C48/21—Articles comprising two or more components, e.g. co-extruded layers the components being layers the layers being joined at their surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/30—Extrusion nozzles or dies

- B29C48/305—Extrusion nozzles or dies having a wide opening, e.g. for forming sheets

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/18—Longitudinally sectional layer of three or more sections

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Extrusion Moulding Of Plastics Or The Like (AREA)

Abstract

Description

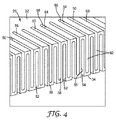

1.第1の押出し成形可能な高分子材料と第2の押出し成形可能な高分子材料とを共押出しするための型であって、

第1の型空洞と、

第2の型空洞と、

前記第1の型空洞及び前記第2の型空洞の少なくとも一部分を分離する隔壁であり、前記隔壁は、前記第1の型空洞の一部分を画定する第1の側面と、前記第2の型空洞の一部分を画定する第2の側面と、分配エッジと、複数の第1の押出しチャネル及び複数の第2の押出しチャネルとを有し、前記複数の第1の押出しチャネルが前記第1の型空洞を前記分配エッジに接続し、前記複数の第2の押出しチャネルが前記第2の型空洞を前記分配エッジに接続し、かつ1つの第1のチャネルが任意の2つの隣接する第2のチャネルの間に配置されるように、前記複数の第1の押出しチャネルと前記複数の第2の押出しチャネルとは前記分配エッジに沿って交互の位置に配置される、隔壁と、

前記第1の押出し可能な高分子材料と前記第2の押出し可能な高分子材料とを含む押出し品が通過して押出される型開口部と、を備える、型。

実施形態1〜9のいずれか1つに記載の共押出し成形型を提供する工程と、

第1の押出し成形可能な高分子材料を前記第1の空洞に供給する工程と、

第2の押出し成形可能な高分子材料を前記第2の空洞に供給する工程と、

前記第1の高分子材料を前記複数の第1のチャネルを通して押出し、前記第2の高分子材料を前記複数の第2のチャネルを通して押出して、前記第1の高分子材料と前記第2の高分子材料との交互のゾーンの幅を有するフローストリームを形成する工程と、

前記フローストリームを、前記型の前記型開口部を通して押出して、1つの第1のゾーンが任意の2つの隣接する第2のゾーンの間に配置されるように前記第2の高分子材料から成る複数の長手方向の第2のゾーンと交互になった前記第1の高分子材料から成る複数の長手方向の第1のゾーンを含む押出し品を形成する工程と、を含む、方法。

3155PPは、ExxonMobil(商標)から入手可能な35メルトフローインデックスのポリプロピレン。

Claims (10)

- 第1の押出し成形可能な高分子材料と第2の押出し成形可能な高分子材料とを共押出しするための型であって、

第1の型空洞と、

第2の型空洞と、

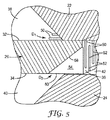

前記第1の型空洞及び前記第2の型空洞の少なくとも一部分を分離する隔壁であり、前記隔壁は、前記第1の型空洞の一部分を画定する第1の側面と、前記第2の型空洞の一部分を画定する第2の側面と、分配エッジと、複数の第1の押出しチャネル及び複数の第2の押出しチャネルとを有し、前記複数の第1の押出しチャネルが記第1の型空洞を前記分配エッジに接続し、前記複数の第2の押出しチャネルが前記第2の型空洞を前記分配エッジに接続し、1つの第1のチャネルが任意の2つの隣接する第2のチャネルの間に配置されるように、前記複数の第1の押出しチャネルと前記複数の第2の押出しチャネルとは前記分配エッジに沿って交互の位置に配置される、隔壁と、

前記第1の押出し可能な高分子材料と前記第2の押出し可能な高分子材料とを含む押出し品が通過して押出される型開口部と、を備える、型。 - 前記チャネルのそれぞれが前記分配エッジの出口開口部を有し、前記出口開口部のそれぞれが約1.5mm以下の最大幅寸法を有する、請求項1に記載の型。

- 前記出口開口部のそれぞれが約50マイクロメートルの最小幅寸法を有する、請求項2に記載の型。

- 前記チャネルのそれぞれが、対向する側壁によって少なくとも部分的に画定され、少なくとも前記第1のチャネルの前記側壁が前記隔壁の前記第1の側面に対して垂直であるか又はある角度で斜めである、請求項1〜3のいずれか1項に記載の型。

- 前記チャネルのそれぞれが、対向する側壁及び接合面によって少なくとも部分的に画定され、少なくとも前記第1のチャネルの前記側壁がそれらの接合面から前記隔壁の前記第1の側面及び前記分配エッジまでテーパーする、請求項1〜3のいずれか1項に記載の型。

- 前記チャネルのそれぞれが、前記分配エッジに出口開口部を有し、少なくとも前記第1のチャネルの出口開口部が、前記隔壁の前記第1の側面から、前記隔壁の前記第2の側面に向かって途中まで延在する、請求項1〜5のいずれか1項に記載の型。

- 押出し成形物品を生産する方法であって、

請求項1〜6のいずれか1項に記載の共押出し成形型を提供する工程と、

第1の押出し成形可能な高分子材料を前記第1の空洞に供給する工程と、

第2の押出し成形可能な高分子材料を前記第2の空洞に供給する工程と、

前記第1の高分子材料を前記複数の第1のチャネルを通して押出し、前記第2の高分子材料を前記複数の第2のチャネルを通して押出して、前記第1の高分子材料と前記第2の高分子材料との交互のゾーンの幅を有するフローストリームを形成する工程と、

前記フローストリームを、前記型の前記型開口部を通して押出して、1つの第1のゾーンが任意の2つの隣接する第2のゾーンの間に配置されるように前記第2の高分子材料から成る複数の長手方向の第2のゾーンと交互になった前記第1の高分子材料から成る複数の長手方向の第1のゾーンを含む押出し品を形成する工程と、を含む、方法。 - 押出し成形物品であって、第2の高分子材料から成る複数の長手方向の第2のゾーンと交互になった第1の高分子材料から成る複数の長手方向の第1のゾーンを含み、1つの第1のゾーンが任意の2つの隣接する第2のゾーンの間に配置され、前記ゾーンが互いに略平行であり、第1のゾーンのそれぞれ及び第2のゾーンのそれぞれの少なくとも1つが約1.5mm以下の最大幅寸法を有する、押出し成形物品。

- 第1のゾーンのそれぞれ及び第2のゾーンのそれぞれの少なくとも1つの最小幅寸法が約50マイクロメートルである、請求項8に記載の押出し成形物品。

- 前記第1のゾーンのそれぞれが互いに分離しており、前記第2のソーンがともに一体に接合されている、請求項8又は9に記載の押出し成形物品。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14177508P | 2008-12-31 | 2008-12-31 | |

| US61/141,775 | 2008-12-31 | ||

| PCT/US2009/068617 WO2010078065A1 (en) | 2008-12-31 | 2009-12-18 | Co-extrusion die, method of extruding with the die, and extruded articles made therefrom |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2012513921A true JP2012513921A (ja) | 2012-06-21 |

| JP2012513921A5 JP2012513921A5 (ja) | 2013-01-31 |

Family

ID=42127628

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011544479A Pending JP2012513921A (ja) | 2008-12-31 | 2009-12-18 | 共押出し成形型、成形型による押出し成形方法、及びそれにより作製される押出し成形物品 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20110268906A1 (ja) |

| EP (1) | EP2389284A1 (ja) |

| JP (1) | JP2012513921A (ja) |

| KR (1) | KR20110111430A (ja) |

| CN (1) | CN102271893A (ja) |

| BR (1) | BRPI0918696A2 (ja) |

| WO (1) | WO2010078065A1 (ja) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102753329B (zh) * | 2010-02-08 | 2016-06-01 | 3M创新有限公司 | 共挤出方法、共挤出模头及其制备的挤出制品 |

| US9643394B2 (en) * | 2011-02-01 | 2017-05-09 | Palo Alto Research Center Incorporated | Oblique angle micromachining of fluidic structures |

| BR112014008353A2 (pt) * | 2011-10-05 | 2017-04-11 | 3M Innovative Properties Co | enredamento tridimensional de mecha polimérica, matrizes e métodos para a produção do mesmo |

| CN102601967B (zh) * | 2012-03-17 | 2014-11-05 | 广东达诚机械有限公司 | 宽幅片材挤出平模头 |

| US10272655B2 (en) | 2012-10-02 | 2019-04-30 | 3M Innovative Properties Company | Film with alternating stripes and strands and apparatus and method for making the same |

| US9944043B2 (en) | 2012-10-02 | 2018-04-17 | 3M Innovative Properties Company | Laminates and methods of making the same |

| US20140248471A1 (en) * | 2013-03-01 | 2014-09-04 | 3M Innovative Properties Company | Film with Layered Segments and Apparatus and Method for Making the Same |

| US20170043520A1 (en) * | 2014-04-28 | 2017-02-16 | Case Western Reserve University | Methods for layer multiplication co-extrusion of high viscous polymeric material systems |

| WO2016064819A1 (en) | 2014-10-23 | 2016-04-28 | 3M Innovative Properties Company | Shim-stack foaming die |

| CN107073900B (zh) | 2014-10-23 | 2019-09-17 | 3M创新有限公司 | 横向聚结的泡沫板 |

| DE102016009261A1 (de) * | 2016-07-29 | 2018-02-01 | Giesecke+Devrient Mobile Security Gmbh | Datenträgerkarte mit coextrudierter Streifenfolie |

| CN111801212B (zh) | 2018-02-28 | 2022-09-06 | 3M创新有限公司 | 共挤出聚合物制品及其制备方法 |

| CN111788060B (zh) | 2018-02-28 | 2022-05-17 | 3M创新有限公司 | 共挤出的聚合物制品及其制造方法 |

| US20200060218A1 (en) * | 2018-08-22 | 2020-02-27 | Land O'lakes, Inc. | Extruded, multi-portioned butter products and system and methods of producing same |

| CN115366505A (zh) * | 2021-09-18 | 2022-11-22 | 山东科化高分子科技股份有限公司 | 一种弹性橡塑复合防水卷材及制备方法 |

| CN114794600B (zh) * | 2022-04-08 | 2024-07-23 | 广州城建职业学院 | 一种方便取放物品的无口袋汉服 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS53143677A (en) * | 1977-05-23 | 1978-12-14 | Toray Ind Inc | Polymeric film or sheet with derection-dependent transmittance |

| JPS5945154A (ja) * | 1982-09-07 | 1984-03-13 | 東レ株式会社 | 多層積層シ−トの製造装置 |

| JPS61125846A (ja) * | 1984-11-22 | 1986-06-13 | 新神戸電機株式会社 | ライトコントロ−ルシ−トの製造法 |

| JP2009522132A (ja) * | 2005-12-29 | 2009-06-11 | スリーエム イノベイティブ プロパティズ カンパニー | マイクロストライプフィルム |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS4990754A (ja) * | 1972-12-30 | 1974-08-29 | ||

| US4435141A (en) * | 1982-04-07 | 1984-03-06 | Polyloom Corporation Of America | Multicomponent continuous film die |

| DE3417452A1 (de) * | 1984-05-11 | 1985-11-14 | Continental Gummi-Werke Ag, 3000 Hannover | Einrichtung zum herstellen von aus zwei oder mehr schichten zusammengesetzten flachen profilstraengen aus plastischen kautschuk- oder kunststoffmischungen |

| JP2928108B2 (ja) * | 1994-11-17 | 1999-08-03 | 三菱レイヨン株式会社 | 複合樹脂シートの製造装置及びその製造方法 |

| US6423140B1 (en) * | 2000-06-08 | 2002-07-23 | Formosa Advanced Coating Technologies, Inc. | Die set for preparing ABCABC multiple-stripe coating |

| CA2443888C (en) * | 2001-02-21 | 2007-08-14 | Kyul-Joo Lee | Method for preparing air channel-equipped film for use in vacuum package |

| MXPA04008540A (es) * | 2002-03-04 | 2004-12-06 | Olebendt Rasmussen | Enchapado transversal de peliculas orientadas, metodo de fabricacion del mismo, y matriz de coextrusion adecuado en el proceso. |

| US7168932B2 (en) * | 2003-12-22 | 2007-01-30 | Kimberly-Clark Worldwide, Inc. | Apparatus for nonwoven fibrous web |

-

2009

- 2009-12-18 BR BRPI0918696A patent/BRPI0918696A2/pt not_active IP Right Cessation

- 2009-12-18 JP JP2011544479A patent/JP2012513921A/ja active Pending

- 2009-12-18 EP EP09796215A patent/EP2389284A1/en not_active Withdrawn

- 2009-12-18 KR KR1020117017604A patent/KR20110111430A/ko not_active Withdrawn

- 2009-12-18 WO PCT/US2009/068617 patent/WO2010078065A1/en active Application Filing

- 2009-12-18 US US13/142,526 patent/US20110268906A1/en not_active Abandoned

- 2009-12-18 CN CN2009801534889A patent/CN102271893A/zh active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS53143677A (en) * | 1977-05-23 | 1978-12-14 | Toray Ind Inc | Polymeric film or sheet with derection-dependent transmittance |

| JPS5945154A (ja) * | 1982-09-07 | 1984-03-13 | 東レ株式会社 | 多層積層シ−トの製造装置 |

| JPS61125846A (ja) * | 1984-11-22 | 1986-06-13 | 新神戸電機株式会社 | ライトコントロ−ルシ−トの製造法 |

| JP2009522132A (ja) * | 2005-12-29 | 2009-06-11 | スリーエム イノベイティブ プロパティズ カンパニー | マイクロストライプフィルム |

Also Published As

| Publication number | Publication date |

|---|---|

| CN102271893A (zh) | 2011-12-07 |

| WO2010078065A1 (en) | 2010-07-08 |

| US20110268906A1 (en) | 2011-11-03 |

| EP2389284A1 (en) | 2011-11-30 |

| BRPI0918696A2 (pt) | 2015-12-01 |

| KR20110111430A (ko) | 2011-10-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2012513921A (ja) | 共押出し成形型、成形型による押出し成形方法、及びそれにより作製される押出し成形物品 | |

| EP2533964B1 (en) | Co-extrusion die, and method of making an extruded article using the same | |

| KR20120109570A (ko) | 공압출 다이 및 시스템, 공압출된 물품을 제조하는 방법 및 이에 의해 제조된 공압출된 물품 | |

| US20170197347A1 (en) | Composite layer | |

| US20130004723A1 (en) | Composite layer | |

| US20030111762A1 (en) | Multilayer coextrusion die and method | |

| US11945149B2 (en) | Coextruded articles, dies and methods of making the same | |

| JP2012532041A (ja) | 押出ダイ要素、押出ダイ、及び多層押出品から多重縞の押出品を製造する方法 | |

| JP2010508175A (ja) | 共押出フィルム用の環状フィードブロック及び方法 | |

| US20110236623A1 (en) | Plastic co-extrusion apparatus with selectable polymer flow control and product produced using the apparatus | |

| JP3584109B2 (ja) | 積層樹脂シート押出成形法とその金型 | |

| US11975469B2 (en) | Coextruded polymeric nettings and method of making the same | |

| TWM498663U (zh) | 中空板成型裝置及其成品 | |

| JPS6154918A (ja) | 各層が実質的に均一な厚さを有する積層体の製造方法及びその方法の実施に使用するための押出し装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121210 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20121210 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20140515 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140520 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20140819 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20140826 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20150203 |