JP2010279860A - 含液スラッジの脱液・固形化方法およびその装置 - Google Patents

含液スラッジの脱液・固形化方法およびその装置 Download PDFInfo

- Publication number

- JP2010279860A JP2010279860A JP2009133232A JP2009133232A JP2010279860A JP 2010279860 A JP2010279860 A JP 2010279860A JP 2009133232 A JP2009133232 A JP 2009133232A JP 2009133232 A JP2009133232 A JP 2009133232A JP 2010279860 A JP2010279860 A JP 2010279860A

- Authority

- JP

- Japan

- Prior art keywords

- liquid

- sludge

- pressurizing chamber

- containing sludge

- briquette

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000010802 sludge Substances 0.000 title claims abstract description 227

- 239000007788 liquid Substances 0.000 title claims abstract description 160

- 238000000034 method Methods 0.000 title claims abstract description 60

- 239000004484 Briquette Substances 0.000 claims abstract description 91

- 239000002184 metal Substances 0.000 claims abstract description 29

- 229910052751 metal Inorganic materials 0.000 claims abstract description 29

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 15

- 238000007711 solidification Methods 0.000 claims description 36

- 230000008023 solidification Effects 0.000 claims description 36

- 239000000126 substance Substances 0.000 claims description 19

- 238000007599 discharging Methods 0.000 claims description 18

- 239000012530 fluid Substances 0.000 claims description 17

- 230000003028 elevating effect Effects 0.000 claims description 16

- 230000002093 peripheral effect Effects 0.000 claims description 16

- 238000001914 filtration Methods 0.000 claims description 15

- 238000004140 cleaning Methods 0.000 claims description 14

- 238000011084 recovery Methods 0.000 claims description 13

- 239000013076 target substance Substances 0.000 claims description 10

- 230000007423 decrease Effects 0.000 claims description 5

- 230000018044 dehydration Effects 0.000 claims description 4

- 238000006297 dehydration reaction Methods 0.000 claims description 4

- 238000000926 separation method Methods 0.000 claims 2

- 239000002699 waste material Substances 0.000 claims 1

- 239000000463 material Substances 0.000 description 16

- 239000002826 coolant Substances 0.000 description 13

- 239000010814 metallic waste Substances 0.000 description 9

- 238000012545 processing Methods 0.000 description 5

- 238000003825 pressing Methods 0.000 description 3

- 239000010801 sewage sludge Substances 0.000 description 3

- 238000005520 cutting process Methods 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000005304 joining Methods 0.000 description 2

- 238000012423 maintenance Methods 0.000 description 2

- 150000002739 metals Chemical class 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 230000002411 adverse Effects 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 238000005429 filling process Methods 0.000 description 1

- 239000010794 food waste Substances 0.000 description 1

- 239000002440 industrial waste Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 238000004064 recycling Methods 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

Images

Landscapes

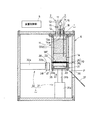

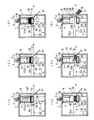

- Grinding-Machine Dressing And Accessory Apparatuses (AREA)

- Treatment Of Sludge (AREA)

- Filtration Of Liquid (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009133232A JP2010279860A (ja) | 2009-06-02 | 2009-06-02 | 含液スラッジの脱液・固形化方法およびその装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009133232A JP2010279860A (ja) | 2009-06-02 | 2009-06-02 | 含液スラッジの脱液・固形化方法およびその装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010279860A true JP2010279860A (ja) | 2010-12-16 |

| JP2010279860A5 JP2010279860A5 (enExample) | 2012-07-12 |

Family

ID=43537115

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009133232A Pending JP2010279860A (ja) | 2009-06-02 | 2009-06-02 | 含液スラッジの脱液・固形化方法およびその装置 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2010279860A (enExample) |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011011205A (ja) * | 2009-06-02 | 2011-01-20 | Nisshin Seisakusho:Kk | 磁気フィルタ装置および工作機械のクーラント浄化装置 |

| JP2012170845A (ja) * | 2011-02-18 | 2012-09-10 | Metawater Co Ltd | 加圧装置及び加圧方法 |

| JP2016150416A (ja) * | 2015-02-18 | 2016-08-22 | 株式会社日進製作所 | スラッジの脱液・固形化装置 |

| JP2016165775A (ja) * | 2015-03-10 | 2016-09-15 | 株式会社日進製作所 | 液体浄化システム |

| JP2017060922A (ja) * | 2015-09-25 | 2017-03-30 | 株式会社フジワラテクノアート | 固液分離装置 |

| CN109442882A (zh) * | 2018-10-31 | 2019-03-08 | 广东博昊实业集团有限公司 | 一种炼油用防堵塞的环保型油渣分离设备 |

| WO2019216447A1 (ko) * | 2018-05-08 | 2019-11-14 | Jo Myeong Ryul | 탈수장치 |

| JP2020015011A (ja) * | 2018-07-26 | 2020-01-30 | 産機テクノス株式会社 | フィルタ式スラッジ回収装置 |

| CN112939255A (zh) * | 2021-02-01 | 2021-06-11 | 桂林电子科技大学 | 一种用于处理地下水挥发性有机物污染的装置 |

| CN114130276A (zh) * | 2021-11-29 | 2022-03-04 | 普瑞凯高分子材料(山东)有限公司 | 一种涂料生产用定量控料装置 |

| CN114477694A (zh) * | 2021-12-13 | 2022-05-13 | 博科丝特工业技术(江苏)有限公司 | 一种泥浆循环处理系统及其处理装置 |

| CN118976376A (zh) * | 2024-10-18 | 2024-11-19 | 山东招金膜天股份有限公司 | 一种反渗透膜性能检测装置及其方法 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58119495A (ja) * | 1982-01-11 | 1983-07-15 | Toyo Seisakusho:Kk | 空気圧搾汚泥脱水装置 |

| JPH10128016A (ja) * | 1996-10-25 | 1998-05-19 | Elf Atochem Sa | 特に液体肥料のためのスラッジ濾過装置、濾過プラント 及び濾過プロセス |

| JP2000288360A (ja) * | 1999-04-02 | 2000-10-17 | Daicel Chem Ind Ltd | 濾過膜エレメント |

| JP2002126472A (ja) * | 2000-10-27 | 2002-05-08 | Daicel Chem Ind Ltd | 固液分離膜 |

| JP2002126475A (ja) * | 2000-10-27 | 2002-05-08 | Daicel Chem Ind Ltd | 固液分離方法 |

| JP2006231177A (ja) * | 2005-02-23 | 2006-09-07 | Mitsubishi Heavy Ind Ltd | 内分泌撹乱化学物質分解方法及び装置 |

-

2009

- 2009-06-02 JP JP2009133232A patent/JP2010279860A/ja active Pending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58119495A (ja) * | 1982-01-11 | 1983-07-15 | Toyo Seisakusho:Kk | 空気圧搾汚泥脱水装置 |

| JPH10128016A (ja) * | 1996-10-25 | 1998-05-19 | Elf Atochem Sa | 特に液体肥料のためのスラッジ濾過装置、濾過プラント 及び濾過プロセス |

| JP2000288360A (ja) * | 1999-04-02 | 2000-10-17 | Daicel Chem Ind Ltd | 濾過膜エレメント |

| JP2002126472A (ja) * | 2000-10-27 | 2002-05-08 | Daicel Chem Ind Ltd | 固液分離膜 |

| JP2002126475A (ja) * | 2000-10-27 | 2002-05-08 | Daicel Chem Ind Ltd | 固液分離方法 |

| JP2006231177A (ja) * | 2005-02-23 | 2006-09-07 | Mitsubishi Heavy Ind Ltd | 内分泌撹乱化学物質分解方法及び装置 |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011011205A (ja) * | 2009-06-02 | 2011-01-20 | Nisshin Seisakusho:Kk | 磁気フィルタ装置および工作機械のクーラント浄化装置 |

| JP2012170845A (ja) * | 2011-02-18 | 2012-09-10 | Metawater Co Ltd | 加圧装置及び加圧方法 |

| JP2016150416A (ja) * | 2015-02-18 | 2016-08-22 | 株式会社日進製作所 | スラッジの脱液・固形化装置 |

| KR20170091743A (ko) | 2015-02-18 | 2017-08-09 | 가부시키가이샤 닛신세이사쿠쇼 | 슬러지 탈액 및 고형화 장치 |

| JP2016165775A (ja) * | 2015-03-10 | 2016-09-15 | 株式会社日進製作所 | 液体浄化システム |

| WO2016143516A1 (ja) * | 2015-03-10 | 2016-09-15 | 株式会社日進製作所 | 液体浄化システム |

| JP2017060922A (ja) * | 2015-09-25 | 2017-03-30 | 株式会社フジワラテクノアート | 固液分離装置 |

| WO2019216447A1 (ko) * | 2018-05-08 | 2019-11-14 | Jo Myeong Ryul | 탈수장치 |

| JP2020015011A (ja) * | 2018-07-26 | 2020-01-30 | 産機テクノス株式会社 | フィルタ式スラッジ回収装置 |

| CN109442882A (zh) * | 2018-10-31 | 2019-03-08 | 广东博昊实业集团有限公司 | 一种炼油用防堵塞的环保型油渣分离设备 |

| CN112939255A (zh) * | 2021-02-01 | 2021-06-11 | 桂林电子科技大学 | 一种用于处理地下水挥发性有机物污染的装置 |

| CN114130276A (zh) * | 2021-11-29 | 2022-03-04 | 普瑞凯高分子材料(山东)有限公司 | 一种涂料生产用定量控料装置 |

| CN114130276B (zh) * | 2021-11-29 | 2024-03-08 | 普瑞凯高分子材料(山东)有限公司 | 一种涂料生产用定量控料装置 |

| CN114477694A (zh) * | 2021-12-13 | 2022-05-13 | 博科丝特工业技术(江苏)有限公司 | 一种泥浆循环处理系统及其处理装置 |

| CN114477694B (zh) * | 2021-12-13 | 2023-11-21 | 博科丝特工业技术(江苏)有限公司 | 一种泥浆循环处理系统及其处理装置 |

| CN118976376A (zh) * | 2024-10-18 | 2024-11-19 | 山东招金膜天股份有限公司 | 一种反渗透膜性能检测装置及其方法 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2010279860A (ja) | 含液スラッジの脱液・固形化方法およびその装置 | |

| JP2011011205A (ja) | 磁気フィルタ装置および工作機械のクーラント浄化装置 | |

| JP2010279860A5 (enExample) | ||

| US5364539A (en) | Method and means for screening solids from a liquid medium | |

| US3796316A (en) | Water filtering apparatus | |

| US6495031B1 (en) | Enclosed belt filter apparatus | |

| EP3838851A1 (en) | Apparatus and method for dewatering and compacting sludge, wastes, pasty materials and liquid suspensions | |

| KR101181893B1 (ko) | 슬러리 및 자원 재활용 여과장치 | |

| CN201026414Y (zh) | 一种油过滤装置 | |

| JP2005138064A (ja) | 濾過装置および該濾過装置に用いられる濾過袋 | |

| JP2018192431A (ja) | 固液分離装置および固液混合物の固液分離方法 | |

| JP3858167B2 (ja) | 食用油の再生装置 | |

| JP6612401B1 (ja) | フィルタ式スラッジ回収装置 | |

| JP2014014786A (ja) | ろ過方法及びろ過装置 | |

| KR101128329B1 (ko) | 슬러리 및 자원 재활용 여과장치 | |

| KR20190026242A (ko) | 압착필터 장치 | |

| JP2007029857A (ja) | スラリー状体の固液分離方法および装置 | |

| JP3781297B2 (ja) | ろ過機におけるセイフティースクリーンの洗浄装置 | |

| CN107207304B (zh) | 淤渣的脱液及固态化装置 | |

| JP2019118911A (ja) | 袋状濾過部材 | |

| CN214344861U (zh) | 一种用于切削液废水处理的固液分离器 | |

| KR20130018279A (ko) | 고체 액체 분리 방법 | |

| IE930968A1 (en) | Method and means for screening solids from a liquid medium | |

| JP2007029855A (ja) | スラリー状体の固液分離装置 | |

| JP2696666B2 (ja) | 加圧濾過装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120529 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20120529 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130121 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130219 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20130903 |