JP2008545886A - 金属ストリップ製品およびその製造方法 - Google Patents

金属ストリップ製品およびその製造方法 Download PDFInfo

- Publication number

- JP2008545886A JP2008545886A JP2008514585A JP2008514585A JP2008545886A JP 2008545886 A JP2008545886 A JP 2008545886A JP 2008514585 A JP2008514585 A JP 2008514585A JP 2008514585 A JP2008514585 A JP 2008514585A JP 2008545886 A JP2008545886 A JP 2008545886A

- Authority

- JP

- Japan

- Prior art keywords

- metal strip

- base alloy

- surface layer

- stainless steel

- manufacturing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 229910052751 metal Inorganic materials 0.000 title claims abstract description 90

- 239000002184 metal Substances 0.000 title claims abstract description 90

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 14

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 claims abstract description 62

- 229910045601 alloy Inorganic materials 0.000 claims abstract description 56

- 239000000956 alloy Substances 0.000 claims abstract description 56

- 239000002344 surface layer Substances 0.000 claims abstract description 42

- 229910052759 nickel Inorganic materials 0.000 claims abstract description 32

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 claims abstract description 17

- 125000004432 carbon atom Chemical group C* 0.000 claims abstract description 17

- 125000004433 nitrogen atom Chemical group N* 0.000 claims abstract description 14

- 150000004767 nitrides Chemical class 0.000 claims abstract description 13

- 229910017052 cobalt Inorganic materials 0.000 claims abstract description 9

- 239000010941 cobalt Substances 0.000 claims abstract description 9

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 claims abstract description 9

- 150000001247 metal acetylides Chemical class 0.000 claims abstract description 9

- 229910052763 palladium Inorganic materials 0.000 claims abstract description 9

- 229910052707 ruthenium Inorganic materials 0.000 claims abstract description 9

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 claims abstract description 8

- KJTLSVCANCCWHF-UHFFFAOYSA-N Ruthenium Chemical compound [Ru] KJTLSVCANCCWHF-UHFFFAOYSA-N 0.000 claims abstract description 8

- 229910052804 chromium Inorganic materials 0.000 claims abstract description 7

- 239000011651 chromium Substances 0.000 claims abstract description 7

- 239000010410 layer Substances 0.000 claims description 32

- 229910001220 stainless steel Inorganic materials 0.000 claims description 30

- 239000010935 stainless steel Substances 0.000 claims description 29

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 26

- 238000000034 method Methods 0.000 claims description 17

- 229910052757 nitrogen Inorganic materials 0.000 claims description 14

- 229910052799 carbon Inorganic materials 0.000 claims description 13

- 239000007789 gas Substances 0.000 claims description 12

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 11

- 239000000758 substrate Substances 0.000 claims description 8

- 238000004881 precipitation hardening Methods 0.000 claims description 7

- 238000000313 electron-beam-induced deposition Methods 0.000 claims description 6

- 229910000734 martensite Inorganic materials 0.000 claims description 6

- 239000011248 coating agent Substances 0.000 claims description 5

- 238000000576 coating method Methods 0.000 claims description 5

- 238000001556 precipitation Methods 0.000 claims description 5

- 229910017840 NH 3 Inorganic materials 0.000 claims description 4

- 238000009713 electroplating Methods 0.000 claims description 3

- 238000005121 nitriding Methods 0.000 claims description 3

- 238000005240 physical vapour deposition Methods 0.000 claims description 3

- 229910002091 carbon monoxide Inorganic materials 0.000 claims description 2

- 238000005566 electron beam evaporation Methods 0.000 claims description 2

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 claims description 2

- 239000000126 substance Substances 0.000 claims description 2

- 239000010953 base metal Substances 0.000 claims 1

- 238000005530 etching Methods 0.000 claims 1

- 238000007747 plating Methods 0.000 claims 1

- 239000000463 material Substances 0.000 description 19

- 230000018199 S phase Effects 0.000 description 11

- 206010016256 fatigue Diseases 0.000 description 9

- 238000005260 corrosion Methods 0.000 description 7

- 230000007797 corrosion Effects 0.000 description 7

- 229910001566 austenite Inorganic materials 0.000 description 5

- 229910000679 solder Inorganic materials 0.000 description 5

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 3

- WGLPBDUCMAPZCE-UHFFFAOYSA-N Trioxochromium Chemical compound O=[Cr](=O)=O WGLPBDUCMAPZCE-UHFFFAOYSA-N 0.000 description 3

- CXOWYMLTGOFURZ-UHFFFAOYSA-N azanylidynechromium Chemical compound [Cr]#N CXOWYMLTGOFURZ-UHFFFAOYSA-N 0.000 description 3

- 238000005452 bending Methods 0.000 description 3

- 229910000423 chromium oxide Inorganic materials 0.000 description 3

- 229910052802 copper Inorganic materials 0.000 description 3

- 239000010949 copper Substances 0.000 description 3

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 2

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 description 2

- MHAJPDPJQMAIIY-UHFFFAOYSA-N Hydrogen peroxide Chemical compound OO MHAJPDPJQMAIIY-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 235000014676 Phragmites communis Nutrition 0.000 description 2

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 2

- 238000005256 carbonitriding Methods 0.000 description 2

- 238000005255 carburizing Methods 0.000 description 2

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 2

- 229910052737 gold Inorganic materials 0.000 description 2

- 239000010931 gold Substances 0.000 description 2

- 229910001105 martensitic stainless steel Inorganic materials 0.000 description 2

- 238000002161 passivation Methods 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 239000011135 tin Substances 0.000 description 2

- 229910052718 tin Inorganic materials 0.000 description 2

- 229910000859 α-Fe Inorganic materials 0.000 description 2

- 239000010963 304 stainless steel Substances 0.000 description 1

- -1 NH 3 Chemical compound 0.000 description 1

- 229910000589 SAE 304 stainless steel Inorganic materials 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 229910001128 Sn alloy Inorganic materials 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 238000005275 alloying Methods 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910021529 ammonia Inorganic materials 0.000 description 1

- 125000004429 atom Chemical group 0.000 description 1

- 229910000963 austenitic stainless steel Inorganic materials 0.000 description 1

- SJKRCWUQJZIWQB-UHFFFAOYSA-N azane;chromium Chemical compound N.[Cr] SJKRCWUQJZIWQB-UHFFFAOYSA-N 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 150000001721 carbon Chemical group 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 238000005229 chemical vapour deposition Methods 0.000 description 1

- UFGZSIPAQKLCGR-UHFFFAOYSA-N chromium carbide Chemical compound [Cr]#C[Cr]C#[Cr] UFGZSIPAQKLCGR-UHFFFAOYSA-N 0.000 description 1

- 238000005097 cold rolling Methods 0.000 description 1

- 239000012792 core layer Substances 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 238000006731 degradation reaction Methods 0.000 description 1

- 229910001039 duplex stainless steel Inorganic materials 0.000 description 1

- 238000007772 electroless plating Methods 0.000 description 1

- 229910001026 inconel Inorganic materials 0.000 description 1

- 238000007641 inkjet printing Methods 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 238000001465 metallisation Methods 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 150000002815 nickel Chemical class 0.000 description 1

- 229910000510 noble metal Inorganic materials 0.000 description 1

- 230000035699 permeability Effects 0.000 description 1

- 239000002244 precipitate Substances 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 239000006104 solid solution Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 238000004381 surface treatment Methods 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

- 229910003470 tongbaite Inorganic materials 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C8/00—Solid state diffusion of only non-metal elements into metallic material surfaces; Chemical surface treatment of metallic material by reaction of the surface with a reactive gas, leaving reaction products of surface material in the coating, e.g. conversion coatings, passivation of metals

- C23C8/02—Pretreatment of the material to be coated

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C19/00—Alloys based on nickel or cobalt

- C22C19/03—Alloys based on nickel or cobalt based on nickel

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/24—Vacuum evaporation

- C23C14/28—Vacuum evaporation by wave energy or particle radiation

- C23C14/30—Vacuum evaporation by wave energy or particle radiation by electron bombardment

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/56—Apparatus specially adapted for continuous coating; Arrangements for maintaining the vacuum, e.g. vacuum locks

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/58—After-treatment

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/58—After-treatment

- C23C14/5846—Reactive treatment

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/58—After-treatment

- C23C14/5846—Reactive treatment

- C23C14/586—Nitriding

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/02—Contact members

- H01R13/03—Contact members characterised by the material, e.g. plating, or coating materials

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12493—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, joint, etc.]

- Y10T428/12771—Transition metal-base component

- Y10T428/12861—Group VIII or IB metal-base component

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Toxicology (AREA)

- Health & Medical Sciences (AREA)

- Solid-Phase Diffusion Into Metallic Material Surfaces (AREA)

- Heat Treatment Of Sheet Steel (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

- Manufacture Of Switches (AREA)

- Contacts (AREA)

- Laminated Bodies (AREA)

- Electroplating Methods And Accessories (AREA)

Abstract

Description

・低い接触抵抗

・優れた電気電導度

・優れたばね特性

・高い疲労強度

・高い耐腐食性

・厚さが3mmより薄く、隣接する少なくとも一方の面が、少なくとも10重量%のクロムを含有する基体合金より成る金属ストリップを備える工程。

・金属ストリップの少なくとも一方の面の基体合金の酸化物層を除去する工程。

・金属ストリップの前記面にニッケル、ルテニウム、コバルト、パラジウムまたはこれらの合金である表面層をコーティングする工程。

・炭素および/または窒素を含むガスを用い、前記表面層を介して基体合金の表面硬化を行い、これにより表面層を介して炭素原子および/または窒素原子を拡散し、炭素原子および/または窒素原子を表面層に隣接する基体合金に溶解し、圧縮応力が表面層に隣接する基体合金に生じる工程であって、表面硬化を炭化物および/または窒化物が形成する温度より低い温度で実施する工程。

厚さ70μm(=0.07mm)のAISI301ステンレス鋼の冷間圧延シートの片方の面を厚さ100nm(=0.1μm)のニッケル層により被覆した。このシートを60%アンモニア中で420℃、17時間窒化した。この処理の後、シートの窒化した面の体積膨張に起因し、シートは湾曲した。このことは、シートが湾曲を避けるのに十分な厚さであれば、窒化により内部圧縮応力を形成することを示している。

Claims (17)

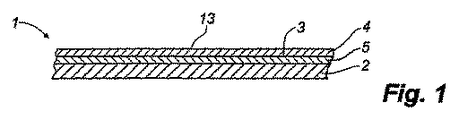

- 隣接する少なくとも一方の面(3)が少なくとも10重量%のクロムを含有する基体合金より成る、厚さが3mmより薄い金属ストリップ(2)を含み、金属ストリップの少なくとも一方の面の基体合金がニッケル、ルテニウム、コバルト、パラジウムまたはこれらの合金の表面層(4)を備える金属ストリップ要素(1)であって、炭素原子および/または窒素原子(5)が、圧縮応力を与える表面層に隣接する基体合金に溶解し、基体合金に炭化物および/または窒化物が実質的に存在しないことを特徴とする金属ストリップ要素(1)。

- 基体合金がステンレス鋼またはニッケル基合金であることを特徴とする請求項1に記載の金属ストリップ要素。

- 金属ストリップ(2)の全体が基体金属より成ることを特徴とする請求項1または2に記載の金属ストリップ部材。

- 基体合金が析出硬化型ステンレス鋼、好ましくはマルテンサイト系析出硬化型ステンレス鋼であることを特徴とする請求項3に記載の金属ストリップ部材。

- 両方の面(3)、(8)が前記表面層(4)を備えていることを特徴とする請求項1〜4のいずれかに記載の金属ストリップ部材。

- 金属ストリップが冷間圧延され、1000MPa以上の引張り強さを有することを特徴とする請求項1〜5のいずれかに記載の金属ストリップ部材。

- 表面層(4)の平均厚さが2μmより薄く、好ましくは0.3μmより薄いことを特徴とする請求項1〜6のいずれかに記載の金属ストリップ部材。

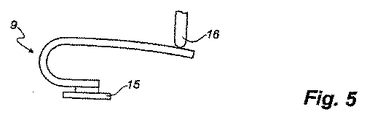

- 請求項1〜7のいずれかに記載の金属ストリップ部材より作られることを特徴とする弾力性を有するコンタクトスプリング部材(9)。

- 厚さが3mmより薄く、隣接する少なくとも一方の面が、少なくとも10重量%のクロムを含有する基体合金より成る金属ストリップを備える工程と、

金属ストリップの少なくとも一方の面の基体合金の酸化物層を除去する工程と、

金属ストリップの前記面にニッケル、ルテニウム、コバルト、パラジウムまたはこれらの合金である表面層をコーティングする工程と、

炭素および/または窒素を含むガスを用い、前記表面層を介して基体合金の表面硬化を行い、これにより表面層を介して炭素原子および/または窒素原子を拡散し、炭素原子および/または窒素原子を表面層に隣接する基体合金に溶解し、圧縮応力が表面層に隣接する基体合金に生じる工程であって、表面硬化を炭化物および/または窒化物が形成する温度より低い温度で実施する工程と、

を含むことを特徴とする請求項1〜7のいずれかに記載の金属ストリップ部材の製造方法。 - 表面硬化がNH3のような窒素を含有するガスを用い、窒化物が形成する温度よりも低い温度、好ましくは約450℃より低い温度で実施する窒化工程であることを特徴とする請求項8に記載の製造方法。

- 表面硬化がCOのような炭素を含有するガスを用い、炭化物が形成する温度よりも低い温度、好ましくは約550℃より低い温度、より好ましくは約510℃よりも低い温度での浸炭工程であることを特徴とする請求項8に記載の製造方法。

- 金属ストリップ(2)の全体が基体合金より成り、基体合金が析出硬化型ステンレス鋼、好ましくはマルテンサイト系析出硬化型ステンレス鋼であることを特徴とする請求項9〜11のいずれかに記載の製造方法。

- 化学めっき法または電気めっき法により表面層を付与することを特徴とする請求項9〜12のいずれかに記載の製造方法。

- 電子ビーム蒸着法のような物理的気相成長法により表面層を付与することを特徴とする請求項9〜12に記載の製造方法。

- 連続的なロールツーロール法で金属ストリップバンドが、電子ビーム蒸着チャンバを通り、電子ビーム蒸着チャンバで表面層が付与され、その後金属ストリップバンドより金属ストリップが切り出されることを特徴とする請求項14に記載の製造方法。

- 電子ビーム蒸着チャンバに入る前に、金属ストリップバンドが、エッチチャンバーを通り、イオンアシストエッチングを実施して酸化物層を除去することを特徴とする請求項15に記載の製造方法。

- 表面硬化の前に、金属ストリップを所望の形状の曲げることを特徴とする請求項9〜16のいずれかに記載の製造方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DKPA200500789 | 2005-05-31 | ||

| US68710205P | 2005-06-03 | 2005-06-03 | |

| PCT/SE2006/000620 WO2006130074A1 (en) | 2005-05-31 | 2006-05-24 | A metal strip product, such as an electrical contact spring, and the manufacturing thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2008545886A true JP2008545886A (ja) | 2008-12-18 |

| JP2008545886A5 JP2008545886A5 (ja) | 2009-07-16 |

Family

ID=37481913

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008514585A Pending JP2008545886A (ja) | 2005-05-31 | 2006-05-24 | 金属ストリップ製品およびその製造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20090068494A1 (ja) |

| EP (1) | EP1891250A1 (ja) |

| JP (1) | JP2008545886A (ja) |

| KR (1) | KR20080012324A (ja) |

| WO (1) | WO2006130074A1 (ja) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011195947A (ja) * | 2010-03-17 | 2011-10-06 | Dong-A Univ Research Foundation For Industry-Academy Cooperation | 耐食性及び高硬度のカラーオーステナイト系ステンレス鋼材及びその製造方法 |

| JP2012025993A (ja) * | 2010-07-22 | 2012-02-09 | Thk Co Ltd | 複合磁性体およびその製造方法、複合磁性体を用いた運動案内装置 |

| KR101273222B1 (ko) * | 2011-04-15 | 2013-06-14 | 한국기계연구원 | 침탄처리된 니켈기 합금 판재 |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE0700476L (sv) * | 2007-02-23 | 2008-08-24 | Sandvik Intellectual Property | Kontaktelement med låg elektrisk impedans för drift i korrosiva miljöer |

| SE0700978L (sv) * | 2007-04-23 | 2008-10-24 | Sandvik Intellectual Property | Kontaktelement hos ett alkaliskt batteri |

| ES2662364T3 (es) * | 2011-04-28 | 2018-04-06 | Expanite Technology A/S | Procedimiento de endurecimiento en solución de una pieza de trabajo deformada en frío de una aleación pasiva |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61177358A (ja) * | 1985-02-01 | 1986-08-09 | Plus Eng Co Ltd | 押出ピン用鋼 |

| WO2004007789A2 (en) * | 2002-07-16 | 2004-01-22 | Danmarks Tekniske Universitet-Dtu | Case-hardening of stainless steel |

| WO2005042797A1 (en) * | 2003-11-04 | 2005-05-12 | Sandvik Intellectual Property Ab | A stainless steel strip coated with a metallic layer |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3837818A (en) * | 1972-09-11 | 1974-09-24 | Texas Instruments Inc | Electrical contact arm material and method of making |

| SE7403411L (ja) * | 1974-03-14 | 1975-09-15 | Nordstjernan Rederi Ab | |

| SE469986B (sv) * | 1991-10-07 | 1993-10-18 | Sandvik Ab | Utskiljningshärdbart martensitiskt rostfritt stål |

| JP3467527B2 (ja) * | 1992-12-17 | 2003-11-17 | 株式会社山王 | 接点材料及びその製造方法 |

| JP4431815B2 (ja) * | 2001-03-27 | 2010-03-17 | シーアールエス ホールディングス,インコーポレイテッド | 超強力析出硬化型ステンレス鋼及び同鋼より作られた長尺なストリップ |

-

2006

- 2006-05-24 US US11/920,453 patent/US20090068494A1/en not_active Abandoned

- 2006-05-24 JP JP2008514585A patent/JP2008545886A/ja active Pending

- 2006-05-24 EP EP06747814A patent/EP1891250A1/en not_active Withdrawn

- 2006-05-24 WO PCT/SE2006/000620 patent/WO2006130074A1/en active Application Filing

- 2006-05-24 KR KR1020077027933A patent/KR20080012324A/ko not_active Application Discontinuation

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61177358A (ja) * | 1985-02-01 | 1986-08-09 | Plus Eng Co Ltd | 押出ピン用鋼 |

| WO2004007789A2 (en) * | 2002-07-16 | 2004-01-22 | Danmarks Tekniske Universitet-Dtu | Case-hardening of stainless steel |

| WO2005042797A1 (en) * | 2003-11-04 | 2005-05-12 | Sandvik Intellectual Property Ab | A stainless steel strip coated with a metallic layer |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011195947A (ja) * | 2010-03-17 | 2011-10-06 | Dong-A Univ Research Foundation For Industry-Academy Cooperation | 耐食性及び高硬度のカラーオーステナイト系ステンレス鋼材及びその製造方法 |

| JP2012025993A (ja) * | 2010-07-22 | 2012-02-09 | Thk Co Ltd | 複合磁性体およびその製造方法、複合磁性体を用いた運動案内装置 |

| KR101273222B1 (ko) * | 2011-04-15 | 2013-06-14 | 한국기계연구원 | 침탄처리된 니켈기 합금 판재 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20080012324A (ko) | 2008-02-11 |

| EP1891250A1 (en) | 2008-02-27 |

| US20090068494A1 (en) | 2009-03-12 |

| WO2006130074A1 (en) | 2006-12-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7431778B2 (en) | Case-hardening of stainless steel | |

| JP2008545886A (ja) | 金属ストリップ製品およびその製造方法 | |

| EP1992712A1 (en) | High-strength stainless steel spring and process for manufacturing the same | |

| US10023924B2 (en) | Method for solution hardening of a cold deformed workpiece of a passive alloy, and a member solution hardened by the method | |

| JP6241896B2 (ja) | 不動態合金の冷間変形された加工物の固溶硬化のための方法、およびこの方法によって固溶硬化された部材 | |

| CN101184863A (zh) | 诸如电接触弹簧的金属条状产品及其制造方法 | |

| JP2008545886A5 (ja) | ||

| JP4789141B2 (ja) | 鉄系部品の製造方法 | |

| EP3614028B1 (en) | Multiple layer hardness ferrule and method | |

| JP3064908B2 (ja) | 浸炭硬化時計部材もしくは装飾品類およびそれらの製法 | |

| KR20170100939A (ko) | 스테인레스강의 표면 경화 처리 방법 | |

| CN109923219B (zh) | 用于对由高合金钢制成的工件进行热处理的方法 | |

| US20220290268A1 (en) | Case-hardened steel part for use in aeronautics | |

| JPH10226873A (ja) | 耐候性に優れたFe−Cr−Ni拡散処理鋼材およびその製造方法 | |

| JPH08158035A (ja) | オーステナイト系金属に対する浸炭処理方法およびそれによって得られたオーステナイト系金属製品 | |

| JP3064909B2 (ja) | 浸炭硬化食器類およびその製法 | |

| WO2003074752A1 (en) | Case hardening of titanium | |

| JPH06306575A (ja) | 耐食性装飾品類 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090521 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090521 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110621 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110628 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20110927 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20111004 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111027 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120515 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20121016 |