JP2008543689A - 排気装置付き貯蔵袋 - Google Patents

排気装置付き貯蔵袋 Download PDFInfo

- Publication number

- JP2008543689A JP2008543689A JP2008518117A JP2008518117A JP2008543689A JP 2008543689 A JP2008543689 A JP 2008543689A JP 2008518117 A JP2008518117 A JP 2008518117A JP 2008518117 A JP2008518117 A JP 2008518117A JP 2008543689 A JP2008543689 A JP 2008543689A

- Authority

- JP

- Japan

- Prior art keywords

- valve element

- storage bag

- internal volume

- side wall

- exhaust

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 239000000463 material Substances 0.000 claims description 46

- 239000012530 fluid Substances 0.000 claims description 31

- 238000000034 method Methods 0.000 claims description 14

- 238000007789 sealing Methods 0.000 claims description 13

- 238000004891 communication Methods 0.000 claims description 12

- 239000007788 liquid Substances 0.000 claims description 10

- 229920001169 thermoplastic Polymers 0.000 claims description 7

- 239000004416 thermosoftening plastic Substances 0.000 claims description 7

- 239000003570 air Substances 0.000 description 67

- 239000010410 layer Substances 0.000 description 48

- 235000011389 fruit/vegetable juice Nutrition 0.000 description 23

- 239000000853 adhesive Substances 0.000 description 9

- 230000001070 adhesive effect Effects 0.000 description 9

- 230000004888 barrier function Effects 0.000 description 9

- -1 polypropylene, ethylene vinyl acetate Polymers 0.000 description 9

- 239000012815 thermoplastic material Substances 0.000 description 8

- 230000008901 benefit Effects 0.000 description 6

- 229920001903 high density polyethylene Polymers 0.000 description 5

- 239000004700 high-density polyethylene Substances 0.000 description 5

- 229920001684 low density polyethylene Polymers 0.000 description 4

- 239000004702 low-density polyethylene Substances 0.000 description 4

- 239000002356 single layer Substances 0.000 description 4

- 230000009471 action Effects 0.000 description 3

- 230000006870 function Effects 0.000 description 3

- 239000007789 gas Substances 0.000 description 3

- 230000005484 gravity Effects 0.000 description 3

- 238000000926 separation method Methods 0.000 description 3

- 239000004677 Nylon Substances 0.000 description 2

- 239000004698 Polyethylene Substances 0.000 description 2

- 239000012080 ambient air Substances 0.000 description 2

- 239000006261 foam material Substances 0.000 description 2

- 229920005669 high impact polystyrene Polymers 0.000 description 2

- 239000004797 high-impact polystyrene Substances 0.000 description 2

- 239000004745 nonwoven fabric Substances 0.000 description 2

- 229920001778 nylon Polymers 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 229920000573 polyethylene Polymers 0.000 description 2

- 229920000219 Ethylene vinyl alcohol Polymers 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 230000002745 absorbent Effects 0.000 description 1

- 239000002250 absorbent Substances 0.000 description 1

- 230000004913 activation Effects 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 238000005056 compaction Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 229920001971 elastomer Polymers 0.000 description 1

- 239000000806 elastomer Substances 0.000 description 1

- 239000004715 ethylene vinyl alcohol Substances 0.000 description 1

- 239000004519 grease Substances 0.000 description 1

- RZXDTJIXPSCHCI-UHFFFAOYSA-N hexa-1,5-diene-2,5-diol Chemical compound OC(=C)CCC(O)=C RZXDTJIXPSCHCI-UHFFFAOYSA-N 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 1

- 229920002554 vinyl polymer Polymers 0.000 description 1

- 239000011345 viscous material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D15/00—Containers having bodies formed by interconnecting or uniting two or more rigid, or substantially rigid, sections made of different materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D81/00—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents

- B65D81/18—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents providing specific environment for contents, e.g. temperature above or below ambient

- B65D81/20—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents providing specific environment for contents, e.g. temperature above or below ambient under vacuum or superatmospheric pressure, or in a special atmosphere, e.g. of inert gas

- B65D81/2007—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents providing specific environment for contents, e.g. temperature above or below ambient under vacuum or superatmospheric pressure, or in a special atmosphere, e.g. of inert gas under vacuum

- B65D81/2038—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents providing specific environment for contents, e.g. temperature above or below ambient under vacuum or superatmospheric pressure, or in a special atmosphere, e.g. of inert gas under vacuum with means for establishing or improving vacuum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B1/00—Packaging fluent solid material, e.g. powders, granular or loose fibrous material, loose masses of small articles, in individual containers or receptacles, e.g. bags, sacks, boxes, cartons, cans, or jars

- B65B1/04—Methods of, or means for, filling the material into the containers or receptacles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B31/00—Packaging articles or materials under special atmospheric or gaseous conditions; Adding propellants to aerosol containers

- B65B31/04—Evacuating, pressurising or gasifying filled containers or wrappers by means of nozzles through which air or other gas, e.g. an inert gas, is withdrawn or supplied

- B65B31/046—Evacuating, pressurising or gasifying filled containers or wrappers by means of nozzles through which air or other gas, e.g. an inert gas, is withdrawn or supplied the nozzles co-operating, or being combined, with a device for opening or closing the container or wrapper

- B65B31/047—Evacuating, pressurising or gasifying filled containers or wrappers by means of nozzles through which air or other gas, e.g. an inert gas, is withdrawn or supplied the nozzles co-operating, or being combined, with a device for opening or closing the container or wrapper the nozzles co-operating with a check valve in the opening of the container or wrapper

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Packages (AREA)

- Bag Frames (AREA)

- Vacuum Packaging (AREA)

- Food Preservation Except Freezing, Refrigeration, And Drying (AREA)

- Storage Of Harvested Produce (AREA)

Abstract

Description

本願は、2005年1月20日に出願され参照により全体が本明細書に組み込まれた同時係属米国特許出願番号11/039,735の一部継続出願である。

Claims (32)

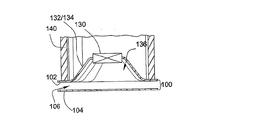

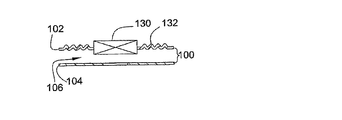

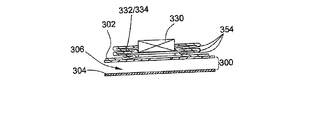

- 食物などを蓄えるためのシステムであって、

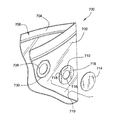

内部容積を提供する軟質の側壁と、軟質の側壁に取り付けられ、内部容積と連通する逆止め弁要素とを有する貯蔵袋と、

弁要素のまわりの側壁と隣接して配置されるように適応された吸気口を備えたハウジングを有する排気装置とを含むシステム。 - 吸気口は第1の径を有し、弁要素は第2の径を有し、第1の径は第2の径より大きい、請求項1に記載のシステム。

- 排気装置は作動したときに連続動作するように構成された、請求項1に記載のシステム。

- 排気装置は気流発生ユニットを含む、請求項3に記載のシステム。

- 気流発生ユニットはハウジング内に密閉されている、請求項4に記載のシステム。

- ハウジングと排気装置の吸気口は硬質材料で作成されている、請求項1に記載のシステム。

- 硬質材料は熱可塑性である、請求項1に記載のシステム。

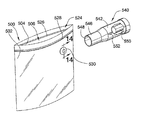

- 貯蔵袋は内部容積への出入を可能にするために側壁に開けられた開口部を有する、請求項1に記載のシステム。

- 貯蔵袋は、開口部を閉じるための閉鎖要素を有する、請求項8に記載のシステム。

- 閉鎖要素は第1と第2の噛み合い式の固締ストリップを有する、請求項9に記載のシステム。

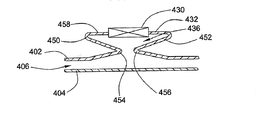

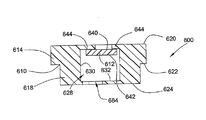

- 弁要素は硬質の弁体と可動弁ディスクを有する、請求項1に記載のシステム。

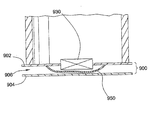

- 弁要素は、側壁に開けられた穴の上に取り付けられた軟質の下部層と、下部層に重なる上部層とを有する、請求項1に記載のシステム。

- 貯蔵袋は空気から液体を分離するために弁要素を覆う不織布材料を有する、請求項1に記載のシステム。

- 不織布材料は内部容積内に配置された、請求項13に記載のシステム。

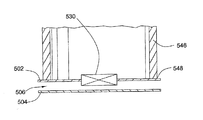

- 貯蔵袋を排気する方法であって、

(i)内部容積を画定する軟質の側壁、内部容積から出し入れするための封止可能な穴、および側壁に取り付けられ内部容積と連通する逆止め弁要素とを有する貯蔵袋を提供する工程と、

(ii)穴を密閉する工程と、

(iii)排気装置のノズルを弁要素のまわりの側壁と隣接して配置する工程と、

(iv)内部容積から排気する工程と、

を含む方法。 - ノズルは、硬質材料で構成された、請求項15に記載の方法。

- 硬質材料は、熱可塑性である、請求項16に記載の方法。

- ノズルは第1の径を有し、弁要素は第2の径を有し、第1の径は第2の径より大きい、請求項15に記載の方法。

- (v)弁要素を不織布材料で覆う工程と、

(vi)内部容積からの空気を不織布材料に通して液体を分離する工程と、

を更に含む、請求項15に記載の方法。 - 排気装置は活動化されたとき連続動作するように構成された、請求項15に記載の方法。

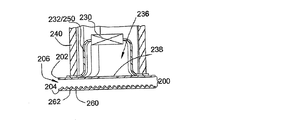

- 食物などを蓄えるためのシステムであって、

内部容積を提供する柔軟な側壁を有する貯蔵袋と、

軟質の側壁に取り付けられ内部容積と連通する軟質の第1の層を有する逆止め弁要素と、

弁要素と流体連通するように動作する排気装置との組み合わせを含むシステム。 - 貯蔵袋は内部容積への出入を可能にするために側壁に開けられた穴を有する、請求項21に記載のシステム。

- 貯蔵袋は穴を閉じるための閉鎖要素を有する、請求項22に記載のシステム。

- 閉鎖要素は第1と第2の噛み合わせ式の固締ストリップを有する、請求項23に記載のシステム。

- 軟質の第1の層は側壁に開けられた開口の上に取り付けられており、弁要素は第1の層の上に重なる第2の層を有する、請求項21に記載のシステム。

- 第2の層は開口からずれた位置に少なくとも1つの穿孔を有する、請求項25に記載のシステム。

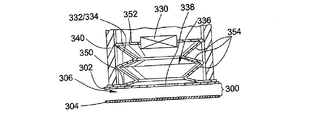

- 食物などを蓄えるためのシステムであって、

内部容積を提供する軟質の側壁を有し、側壁が内側面と外側面とを有する貯蔵袋と、

軟質の側壁の外側面だけに取り付けられ、内部容積と連通する逆止め弁要素と、

逆止め弁要素を通して内部容積を排気するために、弁要素のまわりに配置される吸気口を備えたハウジングを有する排気装置と、

を有し、

逆止め弁要素は、非排気状態で内側面の上に延在するシステム。 - 貯蔵袋は内部容積から出し入れするために側壁に開けられた穴を有する、請求項27に記載のシステム。

- 貯蔵袋は穴を閉じるための閉鎖要素を有する、請求項28に記載のシステム。

- 閉鎖要素は第1と第2の噛み合わせ式の固締ストリップを有する、請求項29に記載のシステム。

- 弁要素は側壁に開けられた開口部の上に取り付けられた軟質の第1の層と、第1の層の上に重なっている第2の層とを有する、請求項27に記載のシステム。

- 第2の層は開口部からずれた位置に少なくとも1つの穿孔を有する、請求項31に記載のシステム。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/166,574 US7422369B2 (en) | 2005-01-20 | 2005-06-24 | Storage bag with fluid separator |

| PCT/US2005/045963 WO2007001469A1 (en) | 2005-06-24 | 2005-12-16 | Storage bag with evacuation device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2008543689A true JP2008543689A (ja) | 2008-12-04 |

| JP2008543689A5 JP2008543689A5 (ja) | 2009-02-12 |

Family

ID=37595420

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008518117A Withdrawn JP2008543689A (ja) | 2005-06-24 | 2005-12-16 | 排気装置付き貯蔵袋 |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US20080190512A1 (ja) |

| EP (1) | EP1893490A4 (ja) |

| JP (1) | JP2008543689A (ja) |

| KR (1) | KR20080029959A (ja) |

| CN (1) | CN101094790B (ja) |

| AU (1) | AU2005333559A1 (ja) |

| CA (1) | CA2589298A1 (ja) |

| MX (1) | MX2007006971A (ja) |

| NZ (1) | NZ555480A (ja) |

| WO (1) | WO2007001469A1 (ja) |

| ZA (1) | ZA200704469B (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2012056738A1 (ja) * | 2010-10-28 | 2012-05-03 | 大洋化学株式会社 | 収納袋用排気弁 |

| JP2017024725A (ja) * | 2015-07-15 | 2017-02-02 | 株式会社サンエー化研 | 減容可能な収容袋 |

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7685793B2 (en) * | 2005-04-06 | 2010-03-30 | Avery Dennison Corporation | Evacuatable container |

| KR20090018070A (ko) * | 2006-05-31 | 2009-02-19 | 더 글래드 프로덕츠 컴파니 | 저장 백의 공기 배출 장치 및 방법 |

| US7857514B2 (en) | 2006-12-12 | 2010-12-28 | Reynolds Foil Inc. | Resealable closures, polymeric packages and systems and methods relating thereto |

| US8181490B2 (en) * | 2007-04-25 | 2012-05-22 | Seamless Technologies. LLC | Vacuum sealed paint roller cover package and method of making the same |

| AU2008347597B2 (en) * | 2008-01-14 | 2014-07-31 | Pi-Design Ag | Double-walled vessel having pressure equalization opening |

| WO2010041967A1 (en) * | 2008-10-08 | 2010-04-15 | Nardone, Jennifer, R. | Portable vacuumable juicer |

| US20100147425A1 (en) * | 2008-12-17 | 2010-06-17 | Illinois Tool Works Inc. | Water-resistant asset protection bag |

| WO2011097113A2 (en) * | 2010-02-02 | 2011-08-11 | Seamless Technologies, Llc | Vacuum sealed paint roller cover package and method of making the same |

| KR101199894B1 (ko) | 2010-06-16 | 2012-11-09 | 주식회사 롤팩 | 진공 밸브 및 이를 제조하는 방법 |

| US8397958B2 (en) | 2010-08-05 | 2013-03-19 | Ds Smith Plastics Limited | Closure valve assembly for a container |

| GB2506370B (en) * | 2012-09-26 | 2014-10-15 | Medicart Int Ltd | Vacuum storage system |

| US20150198413A1 (en) * | 2014-01-10 | 2015-07-16 | Jorge Alberto Preciat Cervera | Evacuable Firearm Enclosure |

| JP2016519022A (ja) * | 2014-02-12 | 2016-06-30 | サンビーム プロダクツ, インコーポレイテッドSunbeam Products, Inc. | 拡張可能部を備えた保存容器 |

| WO2017069640A1 (en) * | 2015-10-24 | 2017-04-27 | Many Rivers Design Limited | Foaming apparatus and method of use |

| US20170320642A1 (en) * | 2016-05-03 | 2017-11-09 | LaserSharp FlexPak Services, LLC | Coffee Bag Vent |

| US10781023B2 (en) | 2018-01-15 | 2020-09-22 | LaserSharp FlexPak Services, LLC | Device for controlling gas, vapor, pressure within a package |

| US10783805B2 (en) | 2018-01-15 | 2020-09-22 | LaserSharp FlexPak Services, LLC | Microchannel device for controlling gas, vapor, pressure within a package |

| CN113316547B (zh) * | 2018-09-28 | 2023-06-27 | 布瑞威利美国公司 | 真空低温袋、组件、系统和方法 |

| USD1050358S1 (en) | 2021-05-14 | 2024-11-05 | Hms Mfg Co. | Valve |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2927722A (en) * | 1954-11-10 | 1960-03-08 | Melvin R Metzger | Vacuum type valve-equipped containers |

| US5142970A (en) * | 1992-02-24 | 1992-09-01 | Erkenbrack Kenneth B | Apparatus for storing matter out of contact with gas |

| US5332095A (en) * | 1993-11-02 | 1994-07-26 | Hans Wu | Bag with means for vacuuming an internal space thereof |

| US5450963A (en) * | 1994-02-22 | 1995-09-19 | Carson; James A. | Air removal device for sealed storage container |

| FR2724152B1 (fr) * | 1994-09-07 | 1996-12-06 | Cif | Dispositif pour evacuer l'air contenu dans un sac de conditionnement |

| US6056439A (en) * | 1999-01-28 | 2000-05-02 | Fres-Co System Usa, Inc. | High flow/volume valve for flexible packaging |

| US6581641B2 (en) * | 2001-04-05 | 2003-06-24 | Illinois Tool Works Inc. | One-way valve for use with vacuum pump |

| US6604634B2 (en) * | 2001-07-18 | 2003-08-12 | Fu-Long Su | Receiving bag with enhanced airtight effect |

| JP3933420B2 (ja) * | 2001-07-24 | 2007-06-20 | 出光ユニテック株式会社 | 収納袋の排気弁 |

| US20040000503A1 (en) * | 2002-06-28 | 2004-01-01 | Shah Ketan N. | Recloseable storage bag with porous evacuation portal |

| US6971417B2 (en) * | 2002-10-22 | 2005-12-06 | Keystone Manufacturing Co., Inc. | Apparatus for evacuating bags |

-

2005

- 2005-12-16 JP JP2008518117A patent/JP2008543689A/ja not_active Withdrawn

- 2005-12-16 US US11/720,042 patent/US20080190512A1/en not_active Abandoned

- 2005-12-16 CA CA002589298A patent/CA2589298A1/en not_active Abandoned

- 2005-12-16 KR KR1020077012884A patent/KR20080029959A/ko not_active Application Discontinuation

- 2005-12-16 EP EP05854637A patent/EP1893490A4/en not_active Withdrawn

- 2005-12-16 CN CN200580045782XA patent/CN101094790B/zh not_active Expired - Fee Related

- 2005-12-16 NZ NZ555480A patent/NZ555480A/en not_active IP Right Cessation

- 2005-12-16 AU AU2005333559A patent/AU2005333559A1/en not_active Abandoned

- 2005-12-16 MX MX2007006971A patent/MX2007006971A/es unknown

- 2005-12-16 WO PCT/US2005/045963 patent/WO2007001469A1/en active Application Filing

-

2007

- 2007-05-30 ZA ZA200704469A patent/ZA200704469B/xx unknown

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2012056738A1 (ja) * | 2010-10-28 | 2012-05-03 | 大洋化学株式会社 | 収納袋用排気弁 |

| JP2012091848A (ja) * | 2010-10-28 | 2012-05-17 | Taiyo Kagaku Kk | 収納袋の排気弁 |

| JP2017024725A (ja) * | 2015-07-15 | 2017-02-02 | 株式会社サンエー化研 | 減容可能な収容袋 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1893490A1 (en) | 2008-03-05 |

| KR20080029959A (ko) | 2008-04-03 |

| CN101094790B (zh) | 2010-12-08 |

| EP1893490A4 (en) | 2009-08-12 |

| ZA200704469B (en) | 2008-08-27 |

| MX2007006971A (es) | 2007-06-22 |

| US20080190512A1 (en) | 2008-08-14 |

| WO2007001469A1 (en) | 2007-01-04 |

| NZ555480A (en) | 2010-10-29 |

| CN101094790A (zh) | 2007-12-26 |

| CA2589298A1 (en) | 2007-01-04 |

| AU2005333559A1 (en) | 2007-01-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2008543689A (ja) | 排気装置付き貯蔵袋 | |

| US7614430B2 (en) | Storage bag with fluid separator | |

| ZA200704708B (en) | Storage bag with fluid separator | |

| US8061899B2 (en) | Storage bag | |

| MXPA04012999A (es) | Bolsa de almacenamiento que se puede volver a cerrar, con portal de evacuacion poroso. | |

| US20100014789A1 (en) | Vacuum storage bag | |

| MX2008015286A (es) | Dispositivo y metodo para evacuar una bolsa de almacenamiento. | |

| CA2663092A1 (en) | Valve element | |

| US20090008582A1 (en) | Valve element | |

| US20240017902A1 (en) | Storage Bag Having an Integrated Manual Pump | |

| KR20050023346A (ko) | 다공성 배기구를 구비한 재잠금 가능한 저장 백 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20081212 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20081212 |

|

| RD01 | Notification of change of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7426 Effective date: 20101028 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20101028 |

|

| A761 | Written withdrawal of application |

Free format text: JAPANESE INTERMEDIATE CODE: A761 Effective date: 20101118 |