JP2006247734A - 中空材のねじり加工法 - Google Patents

中空材のねじり加工法 Download PDFInfo

- Publication number

- JP2006247734A JP2006247734A JP2005070862A JP2005070862A JP2006247734A JP 2006247734 A JP2006247734 A JP 2006247734A JP 2005070862 A JP2005070862 A JP 2005070862A JP 2005070862 A JP2005070862 A JP 2005070862A JP 2006247734 A JP2006247734 A JP 2006247734A

- Authority

- JP

- Japan

- Prior art keywords

- shaft

- hole

- container

- center portion

- shaft material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES, PROFILES OR LIKE SEMI-MANUFACTURED PRODUCTS OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C23/00—Extruding metal; Impact extrusion

- B21C23/001—Extruding metal; Impact extrusion to improve the material properties, e.g. lateral extrusion

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Extrusion Of Metal (AREA)

- Forging (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005070862A JP2006247734A (ja) | 2005-03-14 | 2005-03-14 | 中空材のねじり加工法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005070862A JP2006247734A (ja) | 2005-03-14 | 2005-03-14 | 中空材のねじり加工法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006247734A true JP2006247734A (ja) | 2006-09-21 |

| JP2006247734A5 JP2006247734A5 (enExample) | 2008-03-21 |

Family

ID=37088744

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005070862A Pending JP2006247734A (ja) | 2005-03-14 | 2005-03-14 | 中空材のねじり加工法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2006247734A (enExample) |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009131884A (ja) * | 2007-11-30 | 2009-06-18 | Rinascimetalli:Kk | 金属加工装置 |

| JP2009172657A (ja) * | 2008-01-25 | 2009-08-06 | National Institute Of Advanced Industrial & Technology | 高性能マグネシウム合金部材及びその製造方法 |

| CN101966536A (zh) * | 2010-09-22 | 2011-02-09 | 上海交通大学 | 扭转式往复挤压装置及其加工方法 |

| WO2013145815A1 (ja) * | 2012-03-29 | 2013-10-03 | 株式会社Lixil | スパイラル管押出成形方法及びスパイラル管押出成形機 |

| CN103480789A (zh) * | 2013-10-18 | 2014-01-01 | 核工业理化工程研究院 | 高强度铝合金碟形工件压扭成型方法 |

| JP2015223621A (ja) * | 2014-05-29 | 2015-12-14 | 荻野工業株式会社 | 鍛造装置 |

| CN108714631A (zh) * | 2018-05-17 | 2018-10-30 | 北京科技大学 | 一种扭-挤复合强塑变成形方法及工艺装置 |

| CN110014155A (zh) * | 2019-04-10 | 2019-07-16 | 厦门理工学院 | 一种高纯高致密粉末冶金制品的压扭锻成型方法 |

| WO2019208209A1 (ja) | 2018-04-23 | 2019-10-31 | 住友重機械工業株式会社 | 圧縮ねじり成形装置 |

| JP2020044547A (ja) * | 2018-09-19 | 2020-03-26 | 長野鍛工株式会社 | 相当ひずみの導入方法 |

| CN111421009A (zh) * | 2020-02-27 | 2020-07-17 | 北京科技大学 | 一种螺杆泵转子转模挤压成形工艺及成形装置 |

| JP2020521636A (ja) * | 2017-03-28 | 2020-07-27 | 華南理工大学 | 熱間加工図に基づく筒状部材の熱間強回転形状/特性一体化の制御方法 |

| CN113804559A (zh) * | 2021-09-29 | 2021-12-17 | 中北大学 | 一种细晶试样的高压扭转挤压方法 |

| CN114393157A (zh) * | 2020-10-30 | 2022-04-26 | 舒金·瓦来里·牙科罗维奇 | 一种轴类零件的横向楔形轧制方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS49124677A (enExample) * | 1973-04-02 | 1974-11-28 | ||

| JPH0289599A (ja) * | 1988-09-27 | 1990-03-29 | Idea Res:Kk | 金属材料又は合成樹脂材料等の強化方法 |

| JP2003073787A (ja) * | 2001-09-06 | 2003-03-12 | Japan Science & Technology Corp | 金属材料の結晶粒微細化方法及び結晶粒微細化装置 |

-

2005

- 2005-03-14 JP JP2005070862A patent/JP2006247734A/ja active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS49124677A (enExample) * | 1973-04-02 | 1974-11-28 | ||

| JPH0289599A (ja) * | 1988-09-27 | 1990-03-29 | Idea Res:Kk | 金属材料又は合成樹脂材料等の強化方法 |

| JP2003073787A (ja) * | 2001-09-06 | 2003-03-12 | Japan Science & Technology Corp | 金属材料の結晶粒微細化方法及び結晶粒微細化装置 |

Cited By (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009131884A (ja) * | 2007-11-30 | 2009-06-18 | Rinascimetalli:Kk | 金属加工装置 |

| JP2009172657A (ja) * | 2008-01-25 | 2009-08-06 | National Institute Of Advanced Industrial & Technology | 高性能マグネシウム合金部材及びその製造方法 |

| CN101966536A (zh) * | 2010-09-22 | 2011-02-09 | 上海交通大学 | 扭转式往复挤压装置及其加工方法 |

| CN101966536B (zh) * | 2010-09-22 | 2012-08-22 | 上海交通大学 | 扭转式往复挤压装置及其加工方法 |

| WO2013145815A1 (ja) * | 2012-03-29 | 2013-10-03 | 株式会社Lixil | スパイラル管押出成形方法及びスパイラル管押出成形機 |

| JP2013202664A (ja) * | 2012-03-29 | 2013-10-07 | Lixil Corp | スパイラル管押出成形方法及びスパイラル管押出成形機 |

| CN103480789A (zh) * | 2013-10-18 | 2014-01-01 | 核工业理化工程研究院 | 高强度铝合金碟形工件压扭成型方法 |

| CN103480789B (zh) * | 2013-10-18 | 2015-11-18 | 核工业理化工程研究院 | 铝合金碟形工件压扭成型方法 |

| JP2015223621A (ja) * | 2014-05-29 | 2015-12-14 | 荻野工業株式会社 | 鍛造装置 |

| JP2020521636A (ja) * | 2017-03-28 | 2020-07-27 | 華南理工大学 | 熱間加工図に基づく筒状部材の熱間強回転形状/特性一体化の制御方法 |

| EP3785818A4 (en) * | 2018-04-23 | 2022-01-19 | Sumitomo Heavy Industries, Ltd. | TORSION FORMING DEVICE BY COMPRESSION |

| CN112004619A (zh) * | 2018-04-23 | 2020-11-27 | 住友重机械工业株式会社 | 压缩扭转成型装置 |

| US11826808B2 (en) | 2018-04-23 | 2023-11-28 | Sumitomo Heavy Industries, Ltd. | Compressive torsion forming device |

| CN112004619B (zh) * | 2018-04-23 | 2022-03-01 | 住友重机械工业株式会社 | 压缩扭转成型装置 |

| WO2019208209A1 (ja) | 2018-04-23 | 2019-10-31 | 住友重機械工業株式会社 | 圧縮ねじり成形装置 |

| CN108714631A (zh) * | 2018-05-17 | 2018-10-30 | 北京科技大学 | 一种扭-挤复合强塑变成形方法及工艺装置 |

| JP7288255B2 (ja) | 2018-09-19 | 2023-06-07 | 長野鍛工株式会社 | 相当ひずみの導入方法 |

| JP2020044547A (ja) * | 2018-09-19 | 2020-03-26 | 長野鍛工株式会社 | 相当ひずみの導入方法 |

| CN110014155A (zh) * | 2019-04-10 | 2019-07-16 | 厦门理工学院 | 一种高纯高致密粉末冶金制品的压扭锻成型方法 |

| CN111421009A (zh) * | 2020-02-27 | 2020-07-17 | 北京科技大学 | 一种螺杆泵转子转模挤压成形工艺及成形装置 |

| CN111421009B (zh) * | 2020-02-27 | 2021-06-29 | 北京科技大学 | 一种螺杆泵转子转模挤压成形工艺及成形装置 |

| CN114393157A (zh) * | 2020-10-30 | 2022-04-26 | 舒金·瓦来里·牙科罗维奇 | 一种轴类零件的横向楔形轧制方法 |

| CN114393157B (zh) * | 2020-10-30 | 2023-12-08 | 舒金·瓦来里·牙科罗维奇 | 一种轴类零件的横向楔形轧制方法 |

| CN113804559A (zh) * | 2021-09-29 | 2021-12-17 | 中北大学 | 一种细晶试样的高压扭转挤压方法 |

| CN113804559B (zh) * | 2021-09-29 | 2024-02-06 | 中北大学 | 一种细晶试样的高压扭转挤压方法 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Mao et al. | A review on mechanical properties and microstructure of ultrafine grained metals and alloys processed by rotary swaging | |

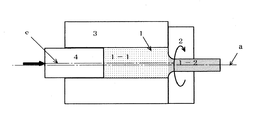

| JP2006247734A (ja) | 中空材のねじり加工法 | |

| JP2005000990A (ja) | 材料のねじり押出し加工法 | |

| US7096705B2 (en) | Shear-extrusion method | |

| US7601232B2 (en) | α-β titanium alloy tubes and methods of flowforming the same | |

| Bochniak et al. | Theoretical and practical aspects of the production of thin-walled tubes by the KOBO method | |

| JPWO2007114439A6 (ja) | 超微細粒組織を有する材料およびその製造方法 | |

| JPWO2007114439A1 (ja) | 超微細粒組織を有する材料およびその製造方法 | |

| CN1329676A (zh) | 由金属和合金加工坯料的方法及产品 | |

| JP2008194749A (ja) | ひずみ分布制御ねじり押出し法 | |

| WO2005068098A1 (ja) | 継目無管の製造方法 | |

| US7152448B2 (en) | Continuous equal channel angular pressing | |

| Sadasivan et al. | Severe plastic deformation of tubular materials–Process methodology and its influence on mechanical properties–A review | |

| US6826940B2 (en) | Method of metal and alloy billet treatment | |

| JP4305163B2 (ja) | 材料の偏熱ねじり押出し法 | |

| ZA200506720B (en) | A method for processing a steel product, and product produced using said method | |

| JP2005000996A (ja) | 材料のねじり据え込み側方押出し法およびその装置 | |

| Djavanroodi et al. | Experimental investigation of three different tube equal channel angular pressing techniques | |

| Kurzydlowski et al. | Effect of severe plastic deformation on the microstructure and mechanical properties of Al and Cu | |

| RU2361687C1 (ru) | Способ получения длинномерных заготовок с мелкозернистой структурой | |

| JP2005000991A (ja) | 材料の高温ねじり押出し法 | |

| US6892559B2 (en) | Method and apparatus for manufacturing tubes | |

| RU2277992C2 (ru) | Способ получения заготовок с мелкозернистой структурой | |

| JP4487282B2 (ja) | 材料のねじり据え込み押出し法およびその装置 | |

| JP2005000993A (ja) | 材料の非軸対称ねじり押出し法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Effective date: 20080131 Free format text: JAPANESE INTERMEDIATE CODE: A523 |

|

| A621 | Written request for application examination |

Effective date: 20080131 Free format text: JAPANESE INTERMEDIATE CODE: A621 |

|

| A977 | Report on retrieval |

Effective date: 20091116 Free format text: JAPANESE INTERMEDIATE CODE: A971007 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20091208 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100420 |