JP2006229034A - 配線基板とその製造方法 - Google Patents

配線基板とその製造方法 Download PDFInfo

- Publication number

- JP2006229034A JP2006229034A JP2005042170A JP2005042170A JP2006229034A JP 2006229034 A JP2006229034 A JP 2006229034A JP 2005042170 A JP2005042170 A JP 2005042170A JP 2005042170 A JP2005042170 A JP 2005042170A JP 2006229034 A JP2006229034 A JP 2006229034A

- Authority

- JP

- Japan

- Prior art keywords

- hole

- plating

- layers

- sheet

- layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/10—Apparatus or processes for manufacturing printed circuits in which conductive material is applied to the insulating support in such a manner as to form the desired conductive pattern

- H05K3/18—Apparatus or processes for manufacturing printed circuits in which conductive material is applied to the insulating support in such a manner as to form the desired conductive pattern using precipitation techniques to apply the conductive material

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/40—Forming printed elements for providing electric connections to or between printed circuits

- H05K3/42—Plated through-holes or plated via connections

- H05K3/422—Plated through-holes or plated via connections characterised by electroless plating method; pretreatment therefor

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/40—Forming printed elements for providing electric connections to or between printed circuits

- H05K3/4038—Through-connections; Vertical interconnect access [VIA] connections

- H05K3/4084—Through-connections; Vertical interconnect access [VIA] connections by deforming at least one of the conductive layers

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/09—Shape and layout

- H05K2201/09009—Substrate related

- H05K2201/09081—Tongue or tail integrated in planar structure, e.g. obtained by cutting from the planar structure

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/09—Shape and layout

- H05K2201/09009—Substrate related

- H05K2201/091—Locally and permanently deformed areas including dielectric material

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/09—Shape and layout

- H05K2201/09209—Shape and layout details of conductors

- H05K2201/095—Conductive through-holes or vias

- H05K2201/09563—Metal filled via

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2201/00—Indexing scheme relating to printed circuits covered by H05K1/00

- H05K2201/09—Shape and layout

- H05K2201/09818—Shape or layout details not covered by a single group of H05K2201/09009 - H05K2201/09809

- H05K2201/09827—Tapered, e.g. tapered hole, via or groove

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2203/00—Indexing scheme relating to apparatus or processes for manufacturing printed circuits covered by H05K3/00

- H05K2203/02—Details related to mechanical or acoustic processing, e.g. drilling, punching, cutting, using ultrasound

- H05K2203/0221—Perforating

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2203/00—Indexing scheme relating to apparatus or processes for manufacturing printed circuits covered by H05K3/00

- H05K2203/05—Patterning and lithography; Masks; Details of resist

- H05K2203/0502—Patterning and lithography

- H05K2203/0517—Electrographic patterning

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2203/00—Indexing scheme relating to apparatus or processes for manufacturing printed circuits covered by H05K3/00

- H05K2203/07—Treatments involving liquids, e.g. plating, rinsing

- H05K2203/0703—Plating

- H05K2203/0709—Catalytic ink or adhesive for electroless plating

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/10—Apparatus or processes for manufacturing printed circuits in which conductive material is applied to the insulating support in such a manner as to form the desired conductive pattern

- H05K3/12—Apparatus or processes for manufacturing printed circuits in which conductive material is applied to the insulating support in such a manner as to form the desired conductive pattern using thick film techniques, e.g. printing techniques to apply the conductive material or similar techniques for applying conductive paste or ink patterns

- H05K3/1266—Apparatus or processes for manufacturing printed circuits in which conductive material is applied to the insulating support in such a manner as to form the desired conductive pattern using thick film techniques, e.g. printing techniques to apply the conductive material or similar techniques for applying conductive paste or ink patterns by electrographic or magnetographic printing

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/10—Apparatus or processes for manufacturing printed circuits in which conductive material is applied to the insulating support in such a manner as to form the desired conductive pattern

- H05K3/18—Apparatus or processes for manufacturing printed circuits in which conductive material is applied to the insulating support in such a manner as to form the desired conductive pattern using precipitation techniques to apply the conductive material

- H05K3/181—Apparatus or processes for manufacturing printed circuits in which conductive material is applied to the insulating support in such a manner as to form the desired conductive pattern using precipitation techniques to apply the conductive material by electroless plating

- H05K3/182—Apparatus or processes for manufacturing printed circuits in which conductive material is applied to the insulating support in such a manner as to form the desired conductive pattern using precipitation techniques to apply the conductive material by electroless plating characterised by the patterning method

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

- Y10T29/49117—Conductor or circuit manufacturing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

- Y10T29/49117—Conductor or circuit manufacturing

- Y10T29/49124—On flat or curved insulated base, e.g., printed circuit, etc.

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

- Y10T29/49117—Conductor or circuit manufacturing

- Y10T29/49124—On flat or curved insulated base, e.g., printed circuit, etc.

- Y10T29/49155—Manufacturing circuit on or in base

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

- Y10T29/49117—Conductor or circuit manufacturing

- Y10T29/49124—On flat or curved insulated base, e.g., printed circuit, etc.

- Y10T29/49155—Manufacturing circuit on or in base

- Y10T29/49165—Manufacturing circuit on or in base by forming conductive walled aperture in base

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

- Y10T29/49117—Conductor or circuit manufacturing

- Y10T29/49124—On flat or curved insulated base, e.g., printed circuit, etc.

- Y10T29/49155—Manufacturing circuit on or in base

- Y10T29/49165—Manufacturing circuit on or in base by forming conductive walled aperture in base

- Y10T29/49167—Manufacturing circuit on or in base by forming conductive walled aperture in base with deforming of conductive path

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24802—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.]

- Y10T428/24917—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.] including metal layer

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Printing Elements For Providing Electric Connections Between Printed Circuits (AREA)

- Manufacturing Of Printed Wiring (AREA)

Abstract

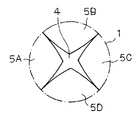

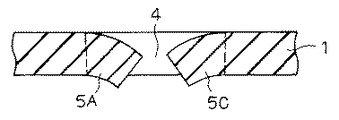

【解決手段】シート状絶縁基材1の表裏両面に、所望の配線パターンを有する第1および第2のめっき下地層2、6を印刷形成する。これらのうち少なくとも一方のめっき下地層2を有するシート状絶縁基材1に針状部材3を挿通し、針状部材3の挿通部分にめっき下地層2を有する切片5を残存させつつ貫通孔4を形成する。めっき下地層2、6に無電解めっき処理を施して、金属めっき層からなる第1および第2の配線層7、8を形成すると同時に、切片5上のめっき下地層2、6を用いて貫通孔4内に第1および第2の配線層7、8間を接続する金属めっき層9を形成してスルーホール接続部とする。

【選択図】図2

Description

まず、電子写真式印刷に使用する金属微粒子含有トナーとして、クレゾールノボラック型エポキシ樹脂に平均粒子径が0.7μmの銅粉末を50質量%の比率で添加、混合したものを用意した。このような金属微粒子含有トナーを用いて、シート状絶縁基材の表面側に第1のめっき下地層を印刷形成した。シート状絶縁基材としては、厚さ50μmのガラス−エポキシシート(実施例1)、厚さ25μmのポリイミドシート(実施例2)、厚さ50μmのポリイミドシート(実施例3)、厚さ75μmのポリイミドシート(実施例4)、厚さ50μmのPETシート(実施例5)を用いた。また、金属微粒子含有トナーの印刷は解像度600dpiのオフィス用複写機を用いて行った。

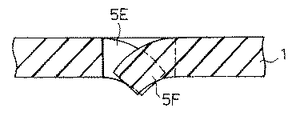

まず、実施例1〜5と同様なシート状絶縁基材に対して、レーザ加工を適用して貫通孔を形成した。この際、レーザ出力を制御してテーパー状貫通孔を形成した。また、レーザによる加工角度を調整して全体傾斜貫通孔を形成した。これら傾斜状貫通孔を形成したシート状絶縁基材に、それぞれ実施例1〜5と同様な金属微粒子含有トナーを用いて第1および第2のめっき下地層を順に印刷形成した。この後、各シート状絶縁基材に実施例1〜5と同様にして無電解銅めっき処理を施して、それぞれ第1および第2の配線層とスルーホール接続部を形成した。このようにして得た各配線基板の導通検査を実施したところ、実施例1〜5と同様に良好な結果が得られた。

Claims (5)

- シート状絶縁基材と、

前記シート状絶縁基材の表裏両面に所望の配線パターンに応じて形成され、金属微粒子を含有する樹脂層からなる第1および第2のめっき下地層と、

前記第1および第2のめっき下地層上にそれぞれ形成された金属めっき層からなる第1および第2の配線層と、

前記シート状絶縁基材の表裏両面間を接続するように形成された貫通孔と、前記貫通孔の形成部分に前記シート状絶縁基材と連続した状態で残存させた切片と、前記切片の表面の少なくとも一部を覆うめっき下地層と、前記第1および第2の配線層間を接続するように前記切片上の前記めっき下地層を介して形成された金属めっき層とを有するスルーホール接続部と

を具備することを特徴とする配線基板。 - シート状絶縁基材と、

前記シート状絶縁基材の表裏両面に所望の配線パターンに応じて形成され、金属微粒子を含有する樹脂層からなる第1および第2のめっき下地層と、

前記第1および第2のめっき下地層上にそれぞれ形成された金属めっき層からなる第1および第2の配線層と、

前記シート状絶縁基材の表裏両面間を接続するように形成された傾斜状貫通孔と、前記傾斜状貫通孔の内壁面の少なくとも一部を覆うめっき下地層と、前記第1および第2の配線層間を接続するように前記傾斜状貫通孔の内壁面上の前記めっき下地層を介して形成された金属めっき層とを有するスルーホール接続部と

を具備することを特徴とする配線基板。 - 請求項1または請求項2記載の配線基板において、

前記スルーホール接続部は複数の前記貫通孔を有することを特徴とする配線基板。 - シート状絶縁基材の表裏両面に、所望の配線パターンを有する第1および第2のめっき下地層を印刷形成する工程と、

前記第1および第2のめっき下地層の少なくとも一方を有する前記シート状絶縁基材に針状部材を挿通し、前記針状部材の挿通部分に前記めっき下地層を有する切片を残存させつつ、前記シート状絶縁基材の表裏両面間を接続する貫通孔を形成する工程と、

前記めっき下地層に無電解めっきを施して、前記第1および第2のめっき下地層上に金属めっき層からなる第1および第2の配線層を形成すると共に、前記切片上の前記めっき下地層を用いて前記貫通孔内に前記第1および第2の配線層間を接続する金属めっき層を形成する工程と

を具備することを特徴とする配線基板の製造方法。 - シート状絶縁基材の表裏両面間を接続する傾斜状貫通孔を形成する工程と、

前記傾斜状貫通孔を有するシート状絶縁基材の表裏両面に、所望の配線パターンを有する第1および第2のめっき下地層を、前記傾斜状貫通孔の内壁面の少なくとも一部を覆いつつ印刷形成する工程と、

前記めっき下地層に無電解めっきを施して、前記第1および第2のめっき下地層上に金属めっき層からなる第1および第2の配線層を形成すると共に、前記傾斜状貫通孔の内壁面上に存在する前記めっき下地層を用いて前記傾斜状貫通孔内に前記第1および第2の配線層間を接続する金属めっき層を形成する工程と

を具備することを特徴とする配線基板の製造方法。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005042170A JP2006229034A (ja) | 2005-02-18 | 2005-02-18 | 配線基板とその製造方法 |

| TW095103920A TW200638471A (en) | 2005-02-18 | 2006-02-06 | Wiring board and manufacturing method thereof |

| US11/356,215 US7350297B2 (en) | 2005-02-18 | 2006-02-17 | Method of manufacturing a wiring substrate |

| KR1020060015355A KR100681999B1 (ko) | 2005-02-18 | 2006-02-17 | 배선 기판과 그 제조 방법 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005042170A JP2006229034A (ja) | 2005-02-18 | 2005-02-18 | 配線基板とその製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2006229034A true JP2006229034A (ja) | 2006-08-31 |

Family

ID=36932250

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005042170A Pending JP2006229034A (ja) | 2005-02-18 | 2005-02-18 | 配線基板とその製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7350297B2 (ja) |

| JP (1) | JP2006229034A (ja) |

| KR (1) | KR100681999B1 (ja) |

| TW (1) | TW200638471A (ja) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102011014820A1 (de) * | 2011-03-23 | 2012-09-27 | Giesecke & Devrient Gmbh | Substrat mit durchkontaktierten leitfähigen Strukturen und Verfahren zu dessen Herstellung |

| GB2562768A (en) * | 2017-05-25 | 2018-11-28 | Saralon Gmbh | Method of producing an electrical through connection between opposite surfaces of a flexible substrate |

| JP7063095B2 (ja) * | 2018-05-07 | 2022-05-09 | 住友電気工業株式会社 | プリント配線板及びプリント配線板の製造方法 |

| US11594477B2 (en) * | 2021-04-15 | 2023-02-28 | Taiwan Semiconductor Manufacturing Company, Ltd. | Semiconductor package and method of manufacturing semiconductor package |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0348495A (ja) * | 1989-07-17 | 1991-03-01 | Nec Corp | 多層セラミツク基板 |

| JPH0483393A (ja) * | 1990-07-26 | 1992-03-17 | Casio Comput Co Ltd | 両面配線基板の製造方法 |

| JPH05335712A (ja) * | 1992-06-01 | 1993-12-17 | Alps Electric Co Ltd | プリント配線板のスルーホールおよびその形成方法 |

| JPH06188560A (ja) * | 1992-12-18 | 1994-07-08 | Toshiba Corp | プリント配線板の製造方法 |

| JPH0964513A (ja) * | 1995-08-23 | 1997-03-07 | Japan Aviation Electron Ind Ltd | フレキシブルプリント基板の製法及びこの製法により形成されたフレキシブルプリント基板 |

| JP2002198649A (ja) * | 2000-12-27 | 2002-07-12 | Kyocera Corp | 多層配線基板の製造方法 |

| JP2002335059A (ja) * | 2001-05-10 | 2002-11-22 | Hitachi Cable Ltd | 配線基板及びその製造方法 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3099608A (en) * | 1959-12-30 | 1963-07-30 | Ibm | Method of electroplating on a dielectric base |

| US4100037A (en) * | 1976-03-08 | 1978-07-11 | Western Electric Company, Inc. | Method of depositing a metal on a surface |

| JPS59230741A (ja) * | 1983-06-15 | 1984-12-25 | 株式会社日立製作所 | 形状記憶複合材料 |

| US4581301A (en) * | 1984-04-10 | 1986-04-08 | Michaelson Henry W | Additive adhesive based process for the manufacture of printed circuit boards |

| JPH01152794A (ja) * | 1987-12-10 | 1989-06-15 | Nec Corp | 混成集積回路装置用基板の製法 |

| JPH02133988A (ja) * | 1988-11-15 | 1990-05-23 | Shindo Denshi Kogyo Kk | 両面プラスチックフィルム回路基板のスルーホール形成方法 |

| JPH02192793A (ja) * | 1989-01-20 | 1990-07-30 | Casio Comput Co Ltd | 両面配線基板の製造方法 |

| US5049244A (en) * | 1989-01-20 | 1991-09-17 | Casio Computer Co., Ltd. | Method of manufacturing double-sided wiring substrate |

| US4964947A (en) * | 1989-01-20 | 1990-10-23 | Casio Computer Co., Ltd. | Method of manufacturing double-sided wiring substrate |

| JPH02246193A (ja) | 1989-03-17 | 1990-10-01 | Sharp Corp | フレキシブル両面回路基板の製造方法 |

| JPH0368194A (ja) * | 1989-08-05 | 1991-03-25 | Nippon Mektron Ltd | 可撓性回路基板に於ける両面導通部の形成法 |

| JPH07263841A (ja) | 1994-03-18 | 1995-10-13 | Toshiba Corp | 配線基板 |

| US5599744A (en) * | 1995-02-06 | 1997-02-04 | Grumman Aerospace Corporation | Method of forming a microcircuit via interconnect |

| JP2004048030A (ja) * | 2002-07-15 | 2004-02-12 | Toshiba Corp | 電子回路の製造方法および電子回路の製造装置 |

-

2005

- 2005-02-18 JP JP2005042170A patent/JP2006229034A/ja active Pending

-

2006

- 2006-02-06 TW TW095103920A patent/TW200638471A/zh not_active IP Right Cessation

- 2006-02-17 KR KR1020060015355A patent/KR100681999B1/ko not_active IP Right Cessation

- 2006-02-17 US US11/356,215 patent/US7350297B2/en active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0348495A (ja) * | 1989-07-17 | 1991-03-01 | Nec Corp | 多層セラミツク基板 |

| JPH0483393A (ja) * | 1990-07-26 | 1992-03-17 | Casio Comput Co Ltd | 両面配線基板の製造方法 |

| JPH05335712A (ja) * | 1992-06-01 | 1993-12-17 | Alps Electric Co Ltd | プリント配線板のスルーホールおよびその形成方法 |

| JPH06188560A (ja) * | 1992-12-18 | 1994-07-08 | Toshiba Corp | プリント配線板の製造方法 |

| JPH0964513A (ja) * | 1995-08-23 | 1997-03-07 | Japan Aviation Electron Ind Ltd | フレキシブルプリント基板の製法及びこの製法により形成されたフレキシブルプリント基板 |

| JP2002198649A (ja) * | 2000-12-27 | 2002-07-12 | Kyocera Corp | 多層配線基板の製造方法 |

| JP2002335059A (ja) * | 2001-05-10 | 2002-11-22 | Hitachi Cable Ltd | 配線基板及びその製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20060093050A (ko) | 2006-08-23 |

| TW200638471A (en) | 2006-11-01 |

| KR100681999B1 (ko) | 2007-02-15 |

| TWI296822B (ja) | 2008-05-11 |

| US20060194031A1 (en) | 2006-08-31 |

| US7350297B2 (en) | 2008-04-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69936319T2 (de) | Leitender verbindungsstift und baugruppenplatte | |

| JP5462914B2 (ja) | プリント配線板およびその製造方法 | |

| US20090044971A1 (en) | Printed Wiring Board, Process for Producing the Same and Usage of the Same | |

| TW200945985A (en) | Multilayer wiring board | |

| US20090114431A1 (en) | Circuit board and manufacturing method thereof | |

| TW200920194A (en) | Wiring substrate and method of manufacturing the same | |

| US20050053772A1 (en) | Wiring board and multilayer wiring board | |

| US7939171B2 (en) | Metal-containing resin particle, metal-containing resin layer, method of forming metal-containing resin layer, and substrate for electronic circuit | |

| KR100681999B1 (ko) | 배선 기판과 그 제조 방법 | |

| TW526683B (en) | Printed-wiring substrate and method for fabricating the same | |

| KR20100126638A (ko) | 콘택 부품과 그 제조방법 및 콘택 부품을 구비한 검사 기구 | |

| US20090218123A1 (en) | Multilayer interconnection board | |

| TWI294263B (en) | Process for manufacturing a wiring substrate | |

| JP4166686B2 (ja) | 金属微粒子含有樹脂粒子、金属微粒子含有樹脂層および金属微粒子含有樹脂層の形成方法 | |

| JPH1187869A (ja) | プリント配線板及びその製造方法 | |

| JP4748553B2 (ja) | ウエハ一括コンタクトボード用コンタクト部品及びその製造方法 | |

| JP2007134458A (ja) | 配線基板の製造方法および半導体装置の製造方法 | |

| JP2005197007A (ja) | 金属微粒子含有樹脂粒子および金属微粒子含有樹脂層の形成方法 | |

| Yamaguchi et al. | Wiring Process by Electrophotography and Electroless Plating | |

| Aoki et al. | A study of electrophotography process for manufacturing printed circuit board | |

| JP7403958B2 (ja) | 異方導電性シート | |

| KR100633818B1 (ko) | 전자 회로의 제조 방법 및 전자 회로 | |

| JP2025018626A (ja) | 配線基板およびそれを用いた実装構造体 | |

| JP2006222324A (ja) | 配線基板の製造方法 | |

| JPH10125372A (ja) | 異方導電性コネクタおよびその製法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20071212 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100618 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100622 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100823 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20100823 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20110215 |