JP2005291211A - 振動数調整圧縮機ステータブレード及び関連する方法 - Google Patents

振動数調整圧縮機ステータブレード及び関連する方法 Download PDFInfo

- Publication number

- JP2005291211A JP2005291211A JP2005101052A JP2005101052A JP2005291211A JP 2005291211 A JP2005291211 A JP 2005291211A JP 2005101052 A JP2005101052 A JP 2005101052A JP 2005101052 A JP2005101052 A JP 2005101052A JP 2005291211 A JP2005291211 A JP 2005291211A

- Authority

- JP

- Japan

- Prior art keywords

- base

- stator blade

- compressor stator

- groove

- natural frequency

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/14—Form or construction

- F01D5/16—Form or construction for counteracting blade vibration

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/40—Casings; Connections of working fluid

- F04D29/52—Casings; Connections of working fluid for axial pumps

- F04D29/54—Fluid-guiding means, e.g. diffusers

- F04D29/541—Specially adapted for elastic fluid pumps

- F04D29/542—Bladed diffusers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/66—Combating cavitation, whirls, noise, vibration or the like; Balancing

- F04D29/661—Combating cavitation, whirls, noise, vibration or the like; Balancing especially adapted for elastic fluid pumps

- F04D29/668—Combating cavitation, whirls, noise, vibration or the like; Balancing especially adapted for elastic fluid pumps damping or preventing mechanical vibrations

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/10—Manufacture by removing material

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/4932—Turbomachine making

- Y10T29/49325—Shaping integrally bladed rotor

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/49336—Blade making

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49716—Converting

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49764—Method of mechanical manufacture with testing or indicating

- Y10T29/49771—Quantitative measuring or gauging

- Y10T29/49774—Quantitative measuring or gauging by vibratory or oscillatory movement

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Abstract

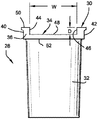

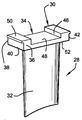

【解決手段】 基部(30)と翼形部(32)とを有する圧縮機ステータブレード(28)を調整して所望の固有振動数を得る方法は、a)圧縮機ステータブレードの固有振動数を特定する段階と、b)圧縮機ステータブレードの異なる目標固有振動数を決定する段階と、c)目標目標固有振動数が得られる量及び形状で圧縮機ステータブレード(28)の基部(30)から材料を取り除く段階とを含む。振動数調整圧縮機ステータブレードは、翼形部(32)と基部(30)とを含み、基部はほぼ直方体形状を有し、少なくとも1つの溝(34)が基部の幅寸法を横切って切削され、溝(34)は翼形部の所定の固有振動数が得られるように選択された寸法を有する。

【選択図】 図3

Description

30 基部

32 翼形部

34 溝

36、38 基部の側面

40、42 基部の端面

44、46 溝の側面

48 溝の底面

50 基部の半径方向内面

52 基部の半径方向外面

D 溝の深さ

W 溝の幅

Claims (10)

- 基部(30)と翼形部(32)とを有する圧縮機ステータブレード(28)を調整して所望の固有振動数を得る方法であって、

a)前記圧縮機ステータブレードの固有振動数を特定する段階と、

b)前記圧縮機ステータブレードの異なる目標固有振動数を決定する段階と、

c)前記目標目標固有振動数が得られる量及び形状で、前記圧縮機ステータブレード(28)の基部(30)から材料を取り除く段階と、

を含む方法。 - 前記段階c)が、前記基部内に少なくとも1つの溝(34)を形成することによって実行される、請求項1記載の方法。

- 前記溝(34)が、ほぼ平行な側面(44、46)とほぼ平坦な底面(48)とを有する、請求項2記載の方法。

- 前記溝(34)が一定の深さを有する、請求項3記載の方法。

- 前記溝(34)が一定の幅を有する、請求項3記載の方法。

- 前記溝(34)が、前記基部(30)の幅を完全に横切って延びる、請求項2記載の方法。

- 前記基部(30)が、一対の比較的長い側面(36、38)、一対の比較的短い端面(40、42)、半径方向内面(50)及び半径方向外面(52)を有するほぼ長方形である、請求項1記載の方法。

- 前記段階c)が、前記基部(30)内に少なくとも1つの溝(34)を形成することによって実行される、請求項7記載の方法。

- 前記溝(34)が、一方の側面(36)から他方の側面(38)まで前記基部(30)を完全に横切って延びる、請求項8記載の方法。

- 翼形部(32)と基部(30)とを含み、前記基部がほぼ直方体形状を有し、少なくとも1つの溝(34)が前記基部の幅寸法を横切って切削され、前記溝(34)が、前記翼形部の所定の固有振動数が得られるように選択した寸法を有する、圧縮機ステータブレード(28)。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/814,221 US7024744B2 (en) | 2004-04-01 | 2004-04-01 | Frequency-tuned compressor stator blade and related method |

| US10/814,221 | 2004-04-01 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005291211A true JP2005291211A (ja) | 2005-10-20 |

| JP4711717B2 JP4711717B2 (ja) | 2011-06-29 |

Family

ID=35034279

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005101052A Expired - Fee Related JP4711717B2 (ja) | 2004-04-01 | 2005-03-31 | 振動数調整圧縮機ステータブレード及び関連する方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7024744B2 (ja) |

| JP (1) | JP4711717B2 (ja) |

| CN (1) | CN100419218C (ja) |

| DE (1) | DE102005014074A1 (ja) |

Families Citing this family (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005006414A1 (de) * | 2005-02-12 | 2006-08-24 | Mtu Aero Engines Gmbh | Verfahren zum Bearbeiten eines integral beschaufelten Rotors |

| GB0601837D0 (en) * | 2006-01-31 | 2006-03-08 | Rolls Royce Plc | An aerofoil assembly and a method of manufacturing an aerofoil assembly |

| US7507073B2 (en) * | 2006-02-24 | 2009-03-24 | General Electric Company | Methods and apparatus for assembling a steam turbine bucket |

| US7618234B2 (en) * | 2007-02-14 | 2009-11-17 | Power System Manufacturing, LLC | Hook ring segment for a compressor vane |

| KR20090087930A (ko) * | 2007-06-22 | 2009-08-18 | 미츠비시 쥬고교 가부시키가이샤 | 정익환 및 이것을 사용한 축류 압축기 |

| US7854583B2 (en) * | 2007-08-08 | 2010-12-21 | Genral Electric Company | Stator joining strip and method of linking adjacent stators |

| DE102007059155A1 (de) * | 2007-12-06 | 2009-06-10 | Rolls-Royce Deutschland Ltd & Co Kg | Verfahren zur Herstellung von in Integralbauweise ausgebildeten Laufrädern für Verdichter und Turbinen |

| US20100166550A1 (en) | 2008-12-31 | 2010-07-01 | Devangada Siddaraja M | Methods, systems and/or apparatus relating to frequency-tuned turbine blades |

| US8381379B2 (en) * | 2009-04-17 | 2013-02-26 | General Electric Company | Apparatus and tools for use with compressors |

| US8534965B2 (en) * | 2009-04-17 | 2013-09-17 | General Electric Company | Apparatus and tools for use with compressors |

| CA2761208C (en) | 2010-12-08 | 2019-03-05 | Pratt & Whitney Canada Corp. | Blade disk arrangement for blade frequency tuning |

| US8757962B2 (en) * | 2011-06-16 | 2014-06-24 | General Electric Company | System and method for adjusting a shroud block in a casing |

| CN104265681B (zh) * | 2014-08-01 | 2016-08-31 | 中国人民解放军第五七一九工厂 | 改变叶片自身固有频率的方法 |

| CN104728170A (zh) * | 2015-03-25 | 2015-06-24 | 北京华清燃气轮机与煤气化联合循环工程技术有限公司 | 一种压气机调频结构 |

| US10215194B2 (en) | 2015-12-21 | 2019-02-26 | Pratt & Whitney Canada Corp. | Mistuned fan |

| US10670041B2 (en) | 2016-02-19 | 2020-06-02 | Pratt & Whitney Canada Corp. | Compressor rotor for supersonic flutter and/or resonant stress mitigation |

| US10533581B2 (en) | 2016-12-09 | 2020-01-14 | United Technologies Corporation | Stator with support structure feature for tuned airfoil |

| US10823203B2 (en) | 2017-03-22 | 2020-11-03 | Pratt & Whitney Canada Corp. | Fan rotor with flow induced resonance control |

| US10458436B2 (en) | 2017-03-22 | 2019-10-29 | Pratt & Whitney Canada Corp. | Fan rotor with flow induced resonance control |

| US10480535B2 (en) | 2017-03-22 | 2019-11-19 | Pratt & Whitney Canada Corp. | Fan rotor with flow induced resonance control |

| US10876417B2 (en) | 2017-08-17 | 2020-12-29 | Raytheon Technologies Corporation | Tuned airfoil assembly |

| CN113606189B (zh) * | 2021-08-23 | 2024-07-02 | 中国联合重型燃气轮机技术有限公司 | 压气机叶片及其调频槽口尺寸的确定方法、压气机和燃气轮机 |

| US12043368B2 (en) | 2022-03-23 | 2024-07-23 | General Electric Company | Rotating airfoil assembly |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61192597U (ja) * | 1985-05-24 | 1986-11-29 | ||

| JPS6487805A (en) * | 1987-08-12 | 1989-03-31 | Snecma | Manufacture of vane row of stator guide vane of compressor or turbine and vane and vane row formed by said method |

| JPH09105310A (ja) * | 1995-06-02 | 1997-04-22 | United Technol Corp <Utc> | ガスタービンエンジン用流れ配向制御要素及び軸流圧縮機 |

| JP2001012390A (ja) * | 1999-06-24 | 2001-01-16 | Hitachi Ltd | ガスタービンの圧縮機翼 |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3326523A (en) * | 1965-12-06 | 1967-06-20 | Gen Electric | Stator vane assembly having composite sectors |

| FR2282550A1 (fr) * | 1974-08-21 | 1976-03-19 | Shur Lok International Sa | Stator de compresseur a carter monobloc |

| US4118147A (en) | 1976-12-22 | 1978-10-03 | General Electric Company | Composite reinforcement of metallic airfoils |

| US5022818A (en) * | 1989-02-21 | 1991-06-11 | Westinghouse Electric Corp. | Compressor diaphragm assembly |

| US5123813A (en) | 1991-03-01 | 1992-06-23 | General Electric Company | Apparatus for preloading an airfoil blade in a gas turbine engine |

| FR2702242B1 (fr) * | 1993-03-03 | 1995-04-07 | Snecma | Etage d'aubes libres à une extrémité. |

| US5939006A (en) | 1995-06-28 | 1999-08-17 | General Electric Company | Method for forming a composite airfoil structure |

| US5720597A (en) | 1996-01-29 | 1998-02-24 | General Electric Company | Multi-component blade for a gas turbine |

| JPH1054204A (ja) | 1996-05-20 | 1998-02-24 | General Electric Co <Ge> | ガスタービン用の多構成部翼 |

| US5931641A (en) | 1997-04-25 | 1999-08-03 | General Electric Company | Steam turbine blade having areas of different densities |

| US6042338A (en) | 1998-04-08 | 2000-03-28 | Alliedsignal Inc. | Detuned fan blade apparatus and method |

| DE19905501B4 (de) | 1999-02-10 | 2005-05-19 | MediGene AG, Gesellschaft für molekularbiologische Kardiologie und Onkologie | Verfahren zur Herstellung eines rekombinanten Adeno-assoziierten Virus, geeignete Mittel hierzu sowie Verwendung zur Herstellung eines Arzneimittels |

| US6331100B1 (en) | 1999-12-06 | 2001-12-18 | General Electric Company | Doubled bowed compressor airfoil |

| US6398489B1 (en) | 2001-02-08 | 2002-06-04 | General Electric Company | Airfoil shape for a turbine nozzle |

| US6604285B2 (en) | 2001-06-07 | 2003-08-12 | General Electric Company | Method and apparatus for electronically determining nozzle throat area and harmonics |

| US6607358B2 (en) | 2002-01-08 | 2003-08-19 | General Electric Company | Multi-component hybrid turbine blade |

-

2004

- 2004-04-01 US US10/814,221 patent/US7024744B2/en not_active Expired - Fee Related

-

2005

- 2005-03-23 DE DE102005014074A patent/DE102005014074A1/de not_active Withdrawn

- 2005-03-31 JP JP2005101052A patent/JP4711717B2/ja not_active Expired - Fee Related

- 2005-04-01 CN CNB2005100626302A patent/CN100419218C/zh not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61192597U (ja) * | 1985-05-24 | 1986-11-29 | ||

| JPS6487805A (en) * | 1987-08-12 | 1989-03-31 | Snecma | Manufacture of vane row of stator guide vane of compressor or turbine and vane and vane row formed by said method |

| JPH09105310A (ja) * | 1995-06-02 | 1997-04-22 | United Technol Corp <Utc> | ガスタービンエンジン用流れ配向制御要素及び軸流圧縮機 |

| JP2001012390A (ja) * | 1999-06-24 | 2001-01-16 | Hitachi Ltd | ガスタービンの圧縮機翼 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP4711717B2 (ja) | 2011-06-29 |

| DE102005014074A1 (de) | 2005-10-20 |

| US7024744B2 (en) | 2006-04-11 |

| CN1690366A (zh) | 2005-11-02 |

| CN100419218C (zh) | 2008-09-17 |

| US20050220615A1 (en) | 2005-10-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4711717B2 (ja) | 振動数調整圧縮機ステータブレード及び関連する方法 | |

| CA2761208C (en) | Blade disk arrangement for blade frequency tuning | |

| JP2007231944A (ja) | 圧縮機の第2フェーズ用のロータブレード | |

| JP2009197649A (ja) | ブリスク | |

| EP2862658B1 (en) | Method for manufacturing a compressor impeller | |

| US7784181B2 (en) | Processing method of a semi-processed product for the production of a rotor equipped with a series of blades integral therewith | |

| JP5734392B2 (ja) | インペラ、インペラ切削用治具、及びインペラの加工方法 | |

| CN102330572B (zh) | 涡轮机的转子 | |

| JP2005048771A (ja) | 所定の輪郭形状のディスクボアを有するディスク | |

| JP2000505001A (ja) | 反対方向に回転する2つの隣接して位置決めされた鋸歯における磁気の形成を防止あるいは低減する方法、およびこの方法の利用のための装置 | |

| KR101174876B1 (ko) | 유리기판용 절단 휠 | |

| US20100018377A1 (en) | Universal 3-TAB center for a cutting disc | |

| EP0155314A1 (en) | SAW BLADE OR BLADE BLADE WITH MEANS FOR COMPENSATING VOLTAGE. | |

| JPH10508262A (ja) | 鋸 刃 | |

| JP2003269449A (ja) | フォイル軸受 | |

| JP4682004B2 (ja) | ホールカッター | |

| JPH0620562Y2 (ja) | 回転鋸用基板の騒音防止装置 | |

| KR102625907B1 (ko) | 스크라이빙 휠 | |

| US6405575B1 (en) | Vibration absorbing reed forming process | |

| JP5662201B2 (ja) | 鋸刃 | |

| JP3864024B2 (ja) | クリスマスカッタ | |

| JP4123241B2 (ja) | セラミック基板の分割方法 | |

| FI3467565T3 (fi) | Tuotantomenetelmä Fabryn-Perot’n interferenssisuodatinta varten | |

| KR100424350B1 (ko) | 골프공의 금속필라멘트 | |

| JPS6374511A (ja) | 千鳥刃サイドカツタ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080327 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20101102 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110201 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20110201 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20110201 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110222 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110322 |

|

| LAPS | Cancellation because of no payment of annual fees |