JP2005194574A - 転炉スラグの改質方法 - Google Patents

転炉スラグの改質方法 Download PDFInfo

- Publication number

- JP2005194574A JP2005194574A JP2004001897A JP2004001897A JP2005194574A JP 2005194574 A JP2005194574 A JP 2005194574A JP 2004001897 A JP2004001897 A JP 2004001897A JP 2004001897 A JP2004001897 A JP 2004001897A JP 2005194574 A JP2005194574 A JP 2005194574A

- Authority

- JP

- Japan

- Prior art keywords

- slag

- converter

- discharged

- reforming

- mixed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B5/00—Treatment of metallurgical slag ; Artificial stone from molten metallurgical slag

- C04B5/06—Ingredients, other than water, added to the molten slag or to the granulating medium or before remelting; Treatment with gases or gas generating compounds, e.g. to obtain porous slag

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Ceramic Engineering (AREA)

- Materials Engineering (AREA)

- Structural Engineering (AREA)

- Organic Chemistry (AREA)

- Furnace Details (AREA)

- Carbon Steel Or Casting Steel Manufacturing (AREA)

Abstract

【解決手段】 転炉スラグを膨張しないように改質することを目的として、同一の転炉または、2基の転炉を連続で用いて1チャージ分の溶鋼を溶製する際にスラグを2回以上排出する方法において、1回目に排出されたスラグの上に2回目以降のスラグを排出させて2つのスラグを混合させることを特徴とする転炉スラグの改質方法。

【選択図】 なし

Description

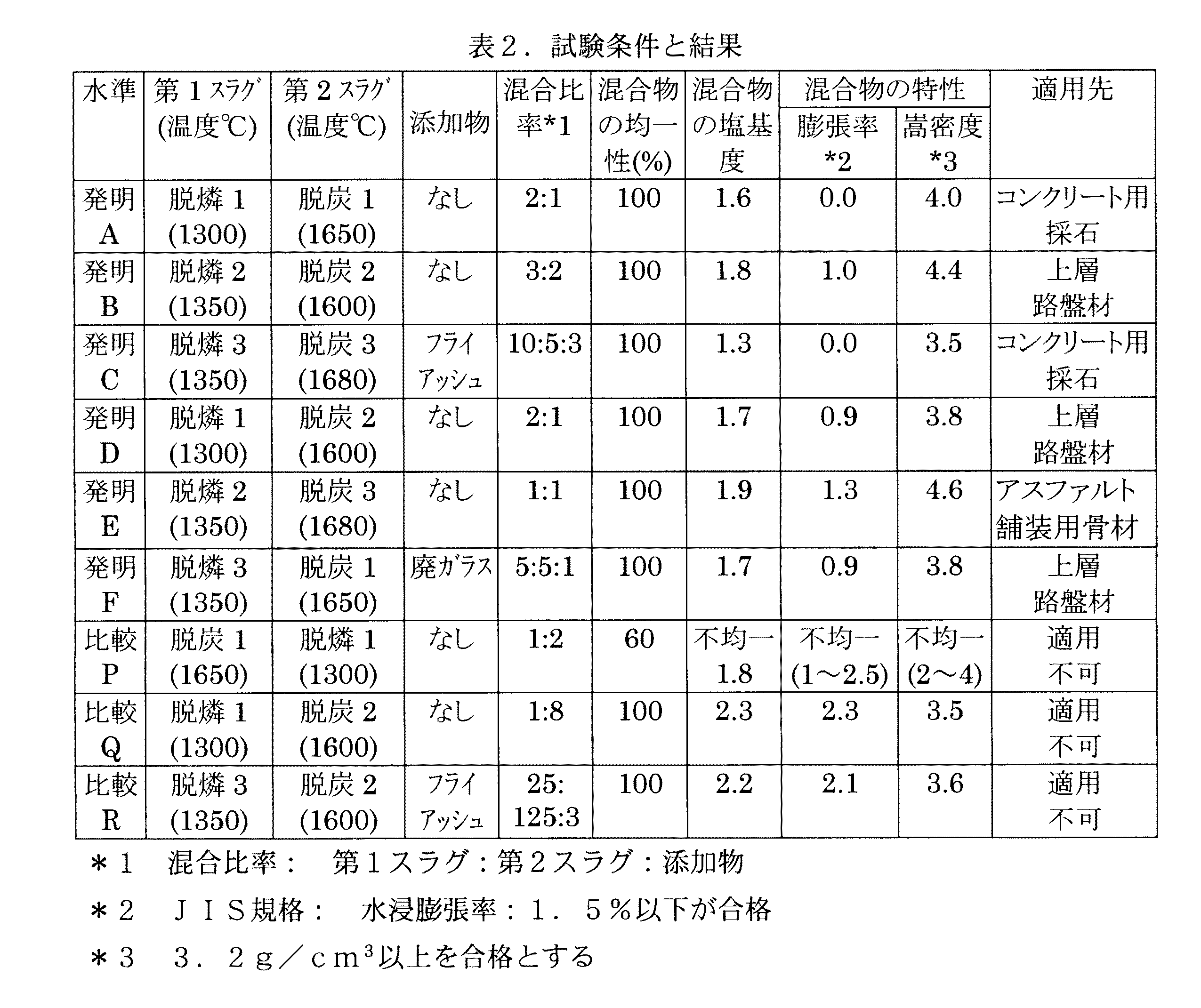

(1)同一の転炉または、2基の転炉を連続で用いて1チャージ分の溶鋼を溶製する際にスラグを2回以上排出する際に、1回目に排出されたスラグの上に2回目以降のスラグを排出させて2つのスラグを混合し、混合したスラグ中のCaOとSiO2の質量濃度比が2以下にすることを特徴とする転炉スラグの改質方法。

(2)2つのスラグを混合させる際に、前記スラグ以外に1種以上の酸化物を主体とする物質を添加して混合させることを特徴とする上記(1)に記載の転炉スラグの改質方法。

Claims (2)

- 同一の転炉または、2基の転炉を連続で用いて1チャージ分の溶鋼を溶製する際に、生成スラグを2回以上排出する際に、1回目に排出されたスラグの上に2回目以降のスラグを排出させて混合し、該混合したスラグ中のCaOとSiO2の質量濃度比が2以下にすることを特徴とする転炉スラグの改質方法。

- 2つのスラグを混合させる際に、前記スラグ以外に1種以上の酸化物を主体とする物質を添加して混合させることを特徴とする請求項1に記載の転炉スラグの改質方法。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004001897A JP4189326B2 (ja) | 2004-01-07 | 2004-01-07 | 転炉スラグの改質方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004001897A JP4189326B2 (ja) | 2004-01-07 | 2004-01-07 | 転炉スラグの改質方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005194574A true JP2005194574A (ja) | 2005-07-21 |

| JP4189326B2 JP4189326B2 (ja) | 2008-12-03 |

Family

ID=34817277

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004001897A Expired - Lifetime JP4189326B2 (ja) | 2004-01-07 | 2004-01-07 | 転炉スラグの改質方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4189326B2 (ja) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009040650A (ja) * | 2007-08-10 | 2009-02-26 | Jfe Steel Kk | 鉄鋼スラグの処理方法 |

| JP2009040653A (ja) * | 2007-08-10 | 2009-02-26 | Jfe Steel Kk | 高炉水砕スラグの処理方法 |

| CN104310810A (zh) * | 2014-10-12 | 2015-01-28 | 韶关学院 | 一种用于电炉白渣调质处理的调节材料制备方法及其应用 |

-

2004

- 2004-01-07 JP JP2004001897A patent/JP4189326B2/ja not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009040650A (ja) * | 2007-08-10 | 2009-02-26 | Jfe Steel Kk | 鉄鋼スラグの処理方法 |

| JP2009040653A (ja) * | 2007-08-10 | 2009-02-26 | Jfe Steel Kk | 高炉水砕スラグの処理方法 |

| CN104310810A (zh) * | 2014-10-12 | 2015-01-28 | 韶关学院 | 一种用于电炉白渣调质处理的调节材料制备方法及其应用 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP4189326B2 (ja) | 2008-12-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN105779682B (zh) | 一种利用石灰石在脱磷转炉中冶炼不锈钢的工艺 | |

| CN103443298B (zh) | 环保钢水脱硫熔剂 | |

| CN101368244A (zh) | 低碳锰铁的生产工艺 | |

| CA2410200C (fr) | Procede de traitement oxydant des laitiers d'acierie et scories ld obtenues | |

| JP5343506B2 (ja) | 溶銑の脱燐方法 | |

| JP4189326B2 (ja) | 転炉スラグの改質方法 | |

| JP2016188423A (ja) | 溶銑の脱燐および脱炭方法 | |

| JP2003239009A (ja) | 溶銑の脱りん精錬方法 | |

| JP2002220615A (ja) | 転炉製鋼方法 | |

| JP4695312B2 (ja) | 溶銑の予備処理方法 | |

| CN102649987A (zh) | 转炉sgrp工艺冶炼改进脱磷阶段化渣效果的方法 | |

| JP2002371311A (ja) | 溶湯の脱燐法とそれに用いられる低温滓化性脱燐剤およびその製造法 | |

| JP4411934B2 (ja) | 低燐溶銑の製造方法 | |

| JPH10265827A (ja) | クロム含有鋼精錬スラグの再生利用方法および該スラグに含有される金属成分の回収利用方法 | |

| JP4639943B2 (ja) | 溶銑の脱硫方法 | |

| JP4414544B2 (ja) | 転炉型溶銑脱燐炉の精錬方法 | |

| CN116356102B (zh) | 转炉吹炼用造渣材料、制备方法及转炉吹炼方法 | |

| KR100554139B1 (ko) | 저망간 용선의 전로 조업을 위한 저융점 매용제 조성물과그 조업방법 | |

| KR100840264B1 (ko) | 제강 전로용 MgO-C 코팅제 | |

| KR101412546B1 (ko) | 용선의 탈황방법 | |

| JP3994988B2 (ja) | クロム含有鋼精錬スラグに含有される金属成分の回収利用方法 | |

| JPH0557327B2 (ja) | ||

| JPH0377246B2 (ja) | ||

| KR20240045560A (ko) | 폐산슬러지를 활용한 전로 공정 | |

| JPH03122210A (ja) | 複合転炉を用いた2段向流精錬製鋼法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060907 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20080430 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080520 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080709 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20080909 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20080912 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 4189326 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110919 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120919 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120919 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130919 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130919 Year of fee payment: 5 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130919 Year of fee payment: 5 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130919 Year of fee payment: 5 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| EXPY | Cancellation because of completion of term |