JP2004238670A - コンデンサ用電極材料及びその製造方法並びに電解コンデンサ - Google Patents

コンデンサ用電極材料及びその製造方法並びに電解コンデンサ Download PDFInfo

- Publication number

- JP2004238670A JP2004238670A JP2003028517A JP2003028517A JP2004238670A JP 2004238670 A JP2004238670 A JP 2004238670A JP 2003028517 A JP2003028517 A JP 2003028517A JP 2003028517 A JP2003028517 A JP 2003028517A JP 2004238670 A JP2004238670 A JP 2004238670A

- Authority

- JP

- Japan

- Prior art keywords

- intermetallic compound

- fine particles

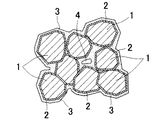

- porous body

- electrode material

- capacitor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000003990 capacitor Substances 0.000 title claims abstract description 67

- 239000007772 electrode material Substances 0.000 title claims abstract description 57

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 28

- 229910000765 intermetallic Inorganic materials 0.000 claims abstract description 83

- 239000010419 fine particle Substances 0.000 claims abstract description 82

- 238000006243 chemical reaction Methods 0.000 claims abstract description 27

- 239000000126 substance Substances 0.000 claims abstract description 25

- 238000005245 sintering Methods 0.000 claims abstract description 21

- 238000010438 heat treatment Methods 0.000 claims abstract description 20

- 239000002245 particle Substances 0.000 claims abstract description 16

- 229910018575 Al—Ti Inorganic materials 0.000 claims abstract description 14

- 238000000034 method Methods 0.000 claims description 21

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 12

- 229910001873 dinitrogen Inorganic materials 0.000 claims description 12

- 238000005121 nitriding Methods 0.000 claims description 12

- 238000000465 moulding Methods 0.000 claims description 11

- 239000000463 material Substances 0.000 claims description 8

- 150000004767 nitrides Chemical class 0.000 description 13

- 229910052782 aluminium Inorganic materials 0.000 description 5

- 239000007864 aqueous solution Substances 0.000 description 5

- WNLRTRBMVRJNCN-UHFFFAOYSA-N adipic acid Chemical compound OC(=O)CCCCC(O)=O WNLRTRBMVRJNCN-UHFFFAOYSA-N 0.000 description 4

- FLDCSPABIQBYKP-UHFFFAOYSA-N 5-chloro-1,2-dimethylbenzimidazole Chemical compound ClC1=CC=C2N(C)C(C)=NC2=C1 FLDCSPABIQBYKP-UHFFFAOYSA-N 0.000 description 3

- 239000001741 Ammonium adipate Substances 0.000 description 3

- 229910010038 TiAl Inorganic materials 0.000 description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 3

- 235000019293 ammonium adipate Nutrition 0.000 description 3

- KGBXLFKZBHKPEV-UHFFFAOYSA-N boric acid Chemical compound OB(O)O KGBXLFKZBHKPEV-UHFFFAOYSA-N 0.000 description 3

- 239000004327 boric acid Substances 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 239000000843 powder Substances 0.000 description 3

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- 229910003077 Ti−O Inorganic materials 0.000 description 2

- 239000001361 adipic acid Substances 0.000 description 2

- 235000011037 adipic acid Nutrition 0.000 description 2

- 229910045601 alloy Inorganic materials 0.000 description 2

- 239000000956 alloy Substances 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- 239000003989 dielectric material Substances 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 229910018580 Al—Zr Inorganic materials 0.000 description 1

- 239000004254 Ammonium phosphate Substances 0.000 description 1

- 229910000148 ammonium phosphate Inorganic materials 0.000 description 1

- 235000019289 ammonium phosphates Nutrition 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- MNNHAPBLZZVQHP-UHFFFAOYSA-N diammonium hydrogen phosphate Chemical compound [NH4+].[NH4+].OP([O-])([O-])=O MNNHAPBLZZVQHP-UHFFFAOYSA-N 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 239000008151 electrolyte solution Substances 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000001307 helium Substances 0.000 description 1

- 229910052734 helium Inorganic materials 0.000 description 1

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

Images

Landscapes

- Powder Metallurgy (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003028517A JP2004238670A (ja) | 2003-02-05 | 2003-02-05 | コンデンサ用電極材料及びその製造方法並びに電解コンデンサ |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003028517A JP2004238670A (ja) | 2003-02-05 | 2003-02-05 | コンデンサ用電極材料及びその製造方法並びに電解コンデンサ |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2004238670A true JP2004238670A (ja) | 2004-08-26 |

| JP2004238670A5 JP2004238670A5 (enExample) | 2006-02-23 |

Family

ID=32955970

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003028517A Pending JP2004238670A (ja) | 2003-02-05 | 2003-02-05 | コンデンサ用電極材料及びその製造方法並びに電解コンデンサ |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2004238670A (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2339110C1 (ru) * | 2007-11-12 | 2008-11-20 | Ооо "Восток" | Многослойный анод |

| CN100465311C (zh) * | 2007-07-12 | 2009-03-04 | 北京科技大学 | 一种制备高铌钛铝多孔材料的方法 |

| WO2013162720A1 (en) * | 2012-04-26 | 2013-10-31 | Applied Materials, Inc. | Contact and interconnect metallization for solar cells |

-

2003

- 2003-02-05 JP JP2003028517A patent/JP2004238670A/ja active Pending

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN100465311C (zh) * | 2007-07-12 | 2009-03-04 | 北京科技大学 | 一种制备高铌钛铝多孔材料的方法 |

| RU2339110C1 (ru) * | 2007-11-12 | 2008-11-20 | Ооо "Восток" | Многослойный анод |

| WO2013162720A1 (en) * | 2012-04-26 | 2013-10-31 | Applied Materials, Inc. | Contact and interconnect metallization for solar cells |

| US9184333B2 (en) | 2012-04-26 | 2015-11-10 | Applied Materials, Inc. | Contact and interconnect metallization for solar cells |

| TWI662716B (zh) * | 2012-04-26 | 2019-06-11 | 美商應用材料股份有限公司 | 太陽能電池之阻障金屬膏 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6350406B1 (en) | Method of manufacturing anode unit for solid electrolytic capacitor, anode unit for solid electrolytic capacitor, continuous sintering apparatus, and method of manufacturing secondary particles of valve-action metal powder | |

| JP4676546B2 (ja) | コンデンサの陽極用焼結体 | |

| US8562765B2 (en) | Process for heat treating metal powder and products made from the same | |

| RU2282264C2 (ru) | Способ получения оксида ниобия | |

| CN1263570C (zh) | 铌或钽粉末及其制造方法和成型体 | |

| CN100339917C (zh) | 铌烧结体及其生产方法以及使用这种铌烧结体的电容器 | |

| EP1158552B2 (en) | Niobium capacitor and method of manufacture thereof | |

| US7729104B2 (en) | Tantalum powder and solid electrolyte capacitor including the same | |

| JP2004238670A (ja) | コンデンサ用電極材料及びその製造方法並びに電解コンデンサ | |

| EP1328952B1 (en) | Powder for capacitor, sintered body and capacitor using the sintered body | |

| KR20020079800A (ko) | 커패시터용 니오브 분말, 그 소결체 및 소결체를 이용한커패시터 | |

| JP5289669B2 (ja) | Nb化合物の微粉末の製造方法、Nb化合物の微粉末を用いた固体電解コンデンサの製造方法 | |

| JP2008270754A (ja) | 固体電解コンデンサおよびその製造方法 | |

| JP2007073570A (ja) | 多孔質焼結体、これを用いた固体電解コンデンサ、およびこれらの製造方法 | |

| JPH1050564A (ja) | タンタルコンデンサ素子の製造方法 | |

| WO2013094252A1 (ja) | タングステンコンデンサの陽極及びその製造方法 | |

| JP2005325448A (ja) | タンタル粉末およびこれを用いた固体電解コンデンサ | |

| JP2002217070A (ja) | ニオブ粉末及び固体電解コンデンサ用アノード | |

| JP2004238670A5 (enExample) | ||

| JP2001307963A (ja) | コンデンサ用ニオブ粉、それを用いた焼結体及びそれを用いたコンデンサ | |

| JP5497076B2 (ja) | Nb化合物の微粉末、多孔質焼結体、これを用いた固体電解コンデンサ、およびこれらの製造方法 | |

| JP2002008952A (ja) | ニオブ焼結体、その製造方法及びその焼結体を用いたコンデンサ | |

| JP2005005572A (ja) | 固体電解コンデンサ素子の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Effective date: 20051229 Free format text: JAPANESE INTERMEDIATE CODE: A523 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20051229 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20080310 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080325 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20080729 |