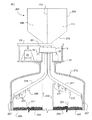

JP2004130304A - 容器の均一な粒子充填のための方法及び装置 - Google Patents

容器の均一な粒子充填のための方法及び装置 Download PDFInfo

- Publication number

- JP2004130304A JP2004130304A JP2003290157A JP2003290157A JP2004130304A JP 2004130304 A JP2004130304 A JP 2004130304A JP 2003290157 A JP2003290157 A JP 2003290157A JP 2003290157 A JP2003290157 A JP 2003290157A JP 2004130304 A JP2004130304 A JP 2004130304A

- Authority

- JP

- Japan

- Prior art keywords

- particles

- orifice

- particle

- conduit

- particle dispersion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000002245 particle Substances 0.000 title claims abstract description 473

- 238000000034 method Methods 0.000 title claims description 41

- 238000003860 storage Methods 0.000 claims abstract description 51

- 238000000429 assembly Methods 0.000 claims abstract description 33

- 230000000712 assembly Effects 0.000 claims abstract description 33

- 239000006185 dispersion Substances 0.000 claims description 184

- 238000012856 packing Methods 0.000 claims description 20

- 238000011068 loading method Methods 0.000 claims description 8

- 230000005484 gravity Effects 0.000 claims description 7

- 230000001105 regulatory effect Effects 0.000 claims description 6

- 230000000977 initiatory effect Effects 0.000 claims description 2

- 239000000843 powder Substances 0.000 claims description 2

- 238000009826 distribution Methods 0.000 description 21

- 238000005192 partition Methods 0.000 description 12

- 230000004888 barrier function Effects 0.000 description 6

- 238000005452 bending Methods 0.000 description 6

- 239000012530 fluid Substances 0.000 description 5

- 239000011236 particulate material Substances 0.000 description 5

- 238000010586 diagram Methods 0.000 description 4

- 238000001179 sorption measurement Methods 0.000 description 4

- 239000000126 substance Substances 0.000 description 4

- 239000003463 adsorbent Substances 0.000 description 3

- 230000007423 decrease Effects 0.000 description 3

- 230000003247 decreasing effect Effects 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 238000000151 deposition Methods 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 238000009827 uniform distribution Methods 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 239000003054 catalyst Substances 0.000 description 1

- 238000006555 catalytic reaction Methods 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 239000011246 composite particle Substances 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 238000004132 cross linking Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000010304 firing Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 238000011084 recovery Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G69/00—Auxiliary measures taken, or devices used, in connection with loading or unloading

- B65G69/04—Spreading out the materials conveyed over the whole surface to be loaded; Trimming heaps of loose materials

- B65G69/0458—Spreading out the materials conveyed over the whole surface to be loaded; Trimming heaps of loose materials with rotating means, e.g. tables, arms

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/0015—Feeding of the particles in the reactor; Evacuation of the particles out of the reactor

- B01J8/002—Feeding of the particles in the reactor; Evacuation of the particles out of the reactor with a moving instrument

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/0015—Feeding of the particles in the reactor; Evacuation of the particles out of the reactor

- B01J8/003—Feeding of the particles in the reactor; Evacuation of the particles out of the reactor in a downward flow

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/0015—Feeding of the particles in the reactor; Evacuation of the particles out of the reactor

- B01J8/004—Feeding of the particles in the reactor; Evacuation of the particles out of the reactor by means of a nozzle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/0242—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid flow within the bed being predominantly vertical

- B01J8/025—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid flow within the bed being predominantly vertical in a cylindrical shaped bed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/04—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds

- B01J8/0446—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds the flow within the beds being predominantly vertical

- B01J8/0461—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds the flow within the beds being predominantly vertical in two or more cylindrical annular shaped beds

- B01J8/0465—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds the flow within the beds being predominantly vertical in two or more cylindrical annular shaped beds the beds being concentric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2208/00—Processes carried out in the presence of solid particles; Reactors therefor

- B01J2208/00743—Feeding or discharging of solids

- B01J2208/00752—Feeding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2208/00—Processes carried out in the presence of solid particles; Reactors therefor

- B01J2208/02—Processes carried out in the presence of solid particles; Reactors therefor with stationary particles

- B01J2208/023—Details

- B01J2208/024—Particulate material

- B01J2208/025—Two or more types of catalyst

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Filling Or Emptying Of Bunkers, Hoppers, And Tanks (AREA)

- Feeding, Discharge, Calcimining, Fusing, And Gas-Generation Devices (AREA)

- Auxiliary Methods And Devices For Loading And Unloading (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/215,463 US6866075B2 (en) | 2002-08-09 | 2002-08-09 | Method and apparatus for uniform particle loading of vessels |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2004130304A true JP2004130304A (ja) | 2004-04-30 |

| JP2004130304A5 JP2004130304A5 (enExample) | 2005-05-26 |

Family

ID=30443741

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003290157A Pending JP2004130304A (ja) | 2002-08-09 | 2003-08-08 | 容器の均一な粒子充填のための方法及び装置 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US6866075B2 (enExample) |

| EP (1) | EP1388368A3 (enExample) |

| JP (1) | JP2004130304A (enExample) |

| CN (1) | CN1283364C (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR102139144B1 (ko) * | 2019-05-13 | 2020-07-29 | 박성근 | 슬라이딩 게이트가 구비된 케익 호퍼 |

Families Citing this family (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8155096B1 (en) | 2000-12-01 | 2012-04-10 | Ipr Licensing Inc. | Antenna control system and method |

| EP1927395B1 (en) * | 2006-12-01 | 2009-08-12 | Haldor Topsoe A/S | Apparatus for loading particulate catalytic material and loading method |

| GB2462797B (en) * | 2008-05-30 | 2012-08-08 | Catalyst Handling Res & Engineering Ltd | Particulate levelling system |

| US7762290B2 (en) * | 2008-11-06 | 2010-07-27 | Poet Research, Inc. | System for loading particulate matter into a transport container |

| WO2011050438A1 (en) * | 2009-10-30 | 2011-05-05 | Dean Jeffrey | Particulate material spreader |

| US20110271833A1 (en) * | 2010-05-05 | 2011-11-10 | Air Products And Chemicals, Inc. | Adsorbent Bed Support |

| CN102991733B (zh) * | 2012-12-13 | 2014-10-22 | 清华大学 | 行星式颗粒物料均匀化混批装置 |

| CN105276972A (zh) * | 2014-07-01 | 2016-01-27 | 三久股份有限公司 | 物料干燥机分散盘 |

| EP3042716A1 (en) * | 2015-01-09 | 2016-07-13 | Haldor Topsøe A/S | Apparatus for loading a plurality of particulate catalytic material |

| CN104764742B (zh) * | 2015-03-16 | 2017-11-17 | 周口师范学院 | 谷物参数检测箱用的谷物籽粒自动分散装置 |

| CN107866906B (zh) * | 2017-11-16 | 2019-05-10 | 重庆市瑞轩豪邦新型建材有限公司 | 干混砂浆筒仓 |

| US10576455B2 (en) | 2018-03-22 | 2020-03-03 | Air Products And Chemicals, Inc. | Particle loading method and apparatus for a radial flow vessel |

| ES3009683T3 (en) | 2018-03-22 | 2025-03-31 | Air Prod & Chem | Particle loading method and apparatus for a radial flow vessel |

| CN108750153B (zh) * | 2018-05-22 | 2020-05-26 | 温州大学瓯江学院 | 一种轴承滚珠的自动装瓶装置 |

| CN109987262B (zh) * | 2019-03-08 | 2021-07-30 | 义乌市亚威机械设备有限公司 | 一种利用离心甩落的塑料粒用分装装置 |

| WO2021161085A1 (en) * | 2020-02-12 | 2021-08-19 | Cs Catalyst Services (Pty) Ltd | Device for handling catalyst and other material in a reactor vessel |

| JP7059315B2 (ja) * | 2020-03-30 | 2022-04-25 | 本田技研工業株式会社 | 粉体塗装装置及び方法 |

| US11471818B2 (en) | 2020-06-24 | 2022-10-18 | Air Products And Chemicals, Inc. | Radial flow adsorption vessel with an integrated loading device |

| CN112089173A (zh) * | 2020-06-24 | 2020-12-18 | 上海浩韵化妆品有限公司 | 一种颗粒分散装置 |

| CN111871760B (zh) * | 2020-07-07 | 2021-09-10 | 山东安和安全技术研究院有限公司 | 粉尘过滤装置 |

| US11596895B2 (en) | 2020-07-17 | 2023-03-07 | Air Products And Chemicals, Inc. | Radial adsorber, adsorption system, and adsorption methods |

| CN111924579A (zh) * | 2020-09-18 | 2020-11-13 | 中央储备粮长乐直属库有限公司 | 浅圆仓“众”字型无动力匀料入仓布料器及其工作方法 |

| US12196486B2 (en) | 2021-07-21 | 2025-01-14 | Air Products And Chemicals, Inc. | Air separation apparatus, adsorber, and method |

| US12247782B2 (en) | 2021-09-23 | 2025-03-11 | Air Products And Chemicals, Inc. | Pre-purification arrangement for air separation and method of hybrid air purification |

| US20240426547A1 (en) | 2023-06-26 | 2024-12-26 | Air Products And Chemicals, Inc. | Adsorber, purification system, and purification method |

| US20250145460A1 (en) | 2023-11-03 | 2025-05-08 | Air Products And Chemicals, Inc. | Adsorbent Material, Adsorption System, and Adsorption Process For Hydrogen Recovery |

| US20250144601A1 (en) | 2023-11-03 | 2025-05-08 | Air Products And Chemicals, Inc. | Adsorbent Material, Adsorption System, and Adsorption Process |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1299568A (fr) | 1960-06-24 | 1962-07-27 | Centre Nat Rech Metall | Procédé et dispositif pour la mise en suspension de matériaux carbonés solides dans un gaz porteur |

| US3265225A (en) * | 1964-03-27 | 1966-08-09 | Robert A Louks | Apparatus for level piling of granular material |

| US3285438A (en) | 1964-09-11 | 1966-11-15 | Bovay Engineers Inc | Particle storage bin |

| US3972686A (en) | 1974-01-31 | 1976-08-03 | Universal Oil Products Company | Device for loading catalyst particles into a reaction zone |

| US4040529A (en) * | 1976-05-17 | 1977-08-09 | Wurdeman Marion E | Grain flow propelled grain spreader |

| US4159785A (en) | 1976-06-01 | 1979-07-03 | Uop Inc. | Method for loading particulate matter in a vessel |

| US4162960A (en) * | 1978-03-29 | 1979-07-31 | Union Oil Company Of California | Shale retorting process and apparatus |

| US4239424A (en) * | 1979-07-25 | 1980-12-16 | Pullman Incorporated | Method and apparatus for distribution of granular material in a railway hopper car |

| US4300725A (en) | 1979-09-13 | 1981-11-17 | Moherek Edward F | Apparatus for uniformly dispensing and distributing material |

| JPS6118430A (ja) | 1984-07-03 | 1986-01-27 | Idemitsu Kosan Co Ltd | 触媒充填方法および触媒充填装置 |

| US5296202A (en) * | 1984-12-07 | 1994-03-22 | Chevron Research And Technology Co. | Apparatus for uniformly loading particulate material into cylindrical beds |

| US5028007A (en) | 1989-08-31 | 1991-07-02 | Lavalley Industries, Inc. | Shower pipe assembly |

| US5324159A (en) | 1992-10-02 | 1994-06-28 | Praxair Technology, Inc. | Particle loader |

| DK171911B1 (da) | 1993-12-02 | 1997-08-11 | Topsoe Haldor As | Fremgangsmåde og indretning til ensartet fyldning af katalysatorrør |

| US5837021A (en) | 1994-12-09 | 1998-11-17 | L'air Liquide, Societe Anonyme Pour L'etude Et L'exploitation Des Procedes Georges Claude | Installation for the treatment of at least one fluid, by passage through two adjacent masses of material |

| US5836362A (en) | 1997-07-15 | 1998-11-17 | Praxair Technology, Inc. | Multiple adsorbent loading method and apparatus for a radial flow vessel |

| US5950694A (en) | 1998-03-04 | 1999-09-14 | Uop Llc | Apparatus for dispensing particulate material |

| US6082639A (en) | 1999-01-25 | 2000-07-04 | Certainteed Corporation | Apparatus for increasing the density of blown insulation materials |

| GB9922940D0 (en) | 1999-09-29 | 1999-12-01 | Ici Plc | Catalytic reactor |

| BR0104080A (pt) | 2000-09-15 | 2002-04-23 | Praxair Technology Inc | Leito adsorvente para uso na separação de um ou mais componentes de uma mistura dos gases da mistura gasosa, e, aparelhagem para carregamento de múltiplos adsorventes para dentro de um leito |

| US6892969B2 (en) | 2001-06-05 | 2005-05-17 | Oramac, Inc. | Pulp washing shower |

-

2002

- 2002-08-09 US US10/215,463 patent/US6866075B2/en not_active Expired - Fee Related

-

2003

- 2003-08-04 EP EP03016698A patent/EP1388368A3/en not_active Withdrawn

- 2003-08-08 CN CN03127565.6A patent/CN1283364C/zh not_active Expired - Fee Related

- 2003-08-08 JP JP2003290157A patent/JP2004130304A/ja active Pending

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR102139144B1 (ko) * | 2019-05-13 | 2020-07-29 | 박성근 | 슬라이딩 게이트가 구비된 케익 호퍼 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1388368A3 (en) | 2004-03-31 |

| US20040025966A1 (en) | 2004-02-12 |

| CN1283364C (zh) | 2006-11-08 |

| CN1485258A (zh) | 2004-03-31 |

| EP1388368A2 (en) | 2004-02-11 |

| US6866075B2 (en) | 2005-03-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2004130304A (ja) | 容器の均一な粒子充填のための方法及び装置 | |

| KR930002241B1 (ko) | 원통형 베드에 미립자 물질을 균일하게 적재하는 방법 및 장치 | |

| JP2893503B2 (ja) | 粒子装填装置 | |

| US4972884A (en) | Method and apparatus for uniformly loading particulate material into cylindrical beds | |

| CN1037830C (zh) | 散粒固体产品装入容器用的设备 | |

| US5836362A (en) | Multiple adsorbent loading method and apparatus for a radial flow vessel | |

| US4433707A (en) | Method and apparatus for level loading of vessels using catalyst oriented packing | |

| US5296202A (en) | Apparatus for uniformly loading particulate material into cylindrical beds | |

| DK154634B (da) | Apparat til indfyldning af partikelmateriale i et rum, f.eks. en silo | |

| US7878428B2 (en) | Device and method for loading a chamber with a divided solid | |

| JP2001046863A (ja) | 容器内で粒状物質を均等に繰り出すための装置 | |

| US7588061B2 (en) | Apparatus for loading a vessel, with solid particles | |

| IE43034B1 (en) | A dispensing apparatus for particulate material | |

| GB2264070A (en) | Supplying catalyst to a reactor | |

| JP2009509761A (ja) | 触媒装入装置 | |

| JP6028068B1 (ja) | 粒子充填装置 | |

| AU772425B2 (en) | Device for dispersing a divided solid material inside a receptacle | |

| JP3950497B2 (ja) | 触媒充填方法および装置 | |

| JP2008529904A (ja) | 少なくとも1種の粒状材料を容器内へ分配する装置、充填装置、およびそのような装置を用いた充填方法 | |

| JPH0644987B2 (ja) | 触媒充▲填▼装置 | |

| CN218689264U (zh) | 连续式浆料分配装置 | |

| JP3708586B2 (ja) | 触媒充填方法および装置 | |

| CA2182895A1 (en) | Apparatus for processing at least one fluid, use thereof for processing an air flow, and method for loading masses of particulate material into said apparatus | |

| US5361811A (en) | Apparatus for and method of dispensing granular material | |

| JP2002058988A (ja) | 触媒充填用分散器 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20040204 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20040204 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20071127 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20080226 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20080229 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080527 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090908 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100216 |