EP3889340A1 - Séchoir - Google Patents

Séchoir Download PDFInfo

- Publication number

- EP3889340A1 EP3889340A1 EP19890726.3A EP19890726A EP3889340A1 EP 3889340 A1 EP3889340 A1 EP 3889340A1 EP 19890726 A EP19890726 A EP 19890726A EP 3889340 A1 EP3889340 A1 EP 3889340A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- drum

- rear case

- dryer

- rotor

- shaft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000012546 transfer Methods 0.000 claims description 76

- 238000009434 installation Methods 0.000 claims description 50

- 238000001035 drying Methods 0.000 claims description 31

- 230000001131 transforming effect Effects 0.000 claims description 20

- 230000008878 coupling Effects 0.000 description 60

- 238000010168 coupling process Methods 0.000 description 60

- 238000005859 coupling reaction Methods 0.000 description 60

- 238000010586 diagram Methods 0.000 description 18

- 238000010438 heat treatment Methods 0.000 description 12

- 238000007789 sealing Methods 0.000 description 8

- 235000012489 doughnuts Nutrition 0.000 description 7

- 238000004519 manufacturing process Methods 0.000 description 7

- 238000001816 cooling Methods 0.000 description 6

- 238000013461 design Methods 0.000 description 6

- 239000000463 material Substances 0.000 description 5

- 238000004891 communication Methods 0.000 description 4

- 230000003247 decreasing effect Effects 0.000 description 4

- 229910000831 Steel Inorganic materials 0.000 description 3

- 230000004323 axial length Effects 0.000 description 3

- 238000001746 injection moulding Methods 0.000 description 3

- 239000010959 steel Substances 0.000 description 3

- 229930040373 Paraformaldehyde Natural products 0.000 description 2

- 238000007599 discharging Methods 0.000 description 2

- 238000011038 discontinuous diafiltration by volume reduction Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 229920006351 engineering plastic Polymers 0.000 description 2

- 230000033001 locomotion Effects 0.000 description 2

- 238000005192 partition Methods 0.000 description 2

- 229920006324 polyoxymethylene Polymers 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 230000002787 reinforcement Effects 0.000 description 2

- 230000003319 supportive effect Effects 0.000 description 2

- 238000013459 approach Methods 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 230000002452 interceptive effect Effects 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F58/00—Domestic laundry dryers

- D06F58/02—Domestic laundry dryers having dryer drums rotating about a horizontal axis

- D06F58/04—Details

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F39/00—Details of washing machines not specific to a single type of machines covered by groups D06F9/00 - D06F27/00

- D06F39/12—Casings; Tubs

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F58/00—Domestic laundry dryers

- D06F58/02—Domestic laundry dryers having dryer drums rotating about a horizontal axis

- D06F58/04—Details

- D06F58/08—Driving arrangements

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F58/00—Domestic laundry dryers

- D06F58/20—General details of domestic laundry dryers

Definitions

- An object of one embodiment of the present disclosure is to provide a DD dryer capable of securing a space within a case and increasing degree of freedom in flow path design by disposing a motor in a space outside a case instead of an inner space of the case in which a drum is installed.

- the first planet gear and the second planet gear may have the same radius and a height (or thickness) of the second planet gear may be greater than that of the first planet gear.

- the dryer may include a flow path duct coupled to the rear case on an outside of the rear case so as to form an air flow space with the rear case in between by covering the air intake area and the air supply area.

- a prescribed section for supplying air into the drum may be preferably provided to a rear case outside, i.e., a case outside through the flow path duct.

- the dryer includes a connector provided between the stator and the rear case to fix the stator to the rear case and forming a front-rear space between the stator and the rear case.

- the first sun gear is located in front of the rotor shaft and formed with the rotor shaft as an integral part.

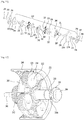

- the drive unit may include a power transfer unit transferring a rotation force of the rotor to the drum and the power transfer unit may be provided between the rotor and the drum.

- the power transfer unit may preferably transfer power so that the rotor and the drum can have the same axis.

- a portion of the connector may be inserted in the hollow part of the stator. Therefore, the stator may be fixed to the connector more solidly by stamping.

- the first carrier, the second sun gear and the middle shaft may be formed as an integral part.

- the heated air is guided into the flow path duct, which is a drying outside, by the blower fan.

- the heated air enters the drum from the rear side of the drum through the flow path duct.

- the air heat-exchanged in the drum is discharged through the front side of the drum.

- the discharged humid air is changed into dry air in a manner of being cooled in an evaporator of the heat pump to condense moisture, and the dry air is headed in a condenser of the heat pump.

- the heated air enters the drum again.

- an air circulation structure may be configured.

- the stator 280 is preferably provided to an outside of the rear case 130.

- the stator 280 is preferably provided as fixed to the outside of the rear case 130.

- the rear case 130 is configured to form an appearance of the dryer on the rear side of the dryer 10 and also form an inner space of the dryer.

- the rear case 130 is configured to be fixed.

- the stator 280 is fixed to the outside of the rear case 130, it can be fixed solidly.

- the decelerator housing 231 may be fixed and coupled to the rear side of the rear case 130.

- the drum shaft perforated hole 232 of the decelerator housing 231 may be further extended in the front direction by passing through the shaft perforated hole 130a.

- the drum rear wall and the drum shaft 210 are coupled together.

- the rotor 270 and the rotor shaft 220 are coupled together.

- the holes 26 are not formed in the radial bridges 27 and the circumferential bridge 28. Therefore, as a support structure supportive of the air intake area 24 of the mesh type attributed to a plurality of the holes 26, the radial bridges 27 and the circumferential bridge 28 may be formed. Preferably, to reinforce self-rigidity, the radial bridges 27 and the circumferential bridge 28 may be formed convex in front or rear direction.

- the inner gasket 40 includes a fixing part 41 and an extension part 42, and a fastening part 43 may be formed in the fixing part 41.

- the inner gasket 40 may be mounted on an inner surface of the rear case through the fixing part 41 and the fastening part 43, and the extension part 42 may be formed in a manner of being extended from the fixing part 41 in a direction of the drum rear wall 22.

- the extension part 42 is configured to contact with the drum rear wall, whereby sealing can be performed.

- the extension part 42 may be slantly extended toward an inside from a radial outside. Namely, the extension part 42 may be located on a radial inside of the fixing part 41.

- the extension part 42/52 of the inner/outer gasket 40/50 may be slantly extended from the fixing part 41/51 toward the drum rear wall. Through this, air sealing may be performed while the frictional force between the rotating drum and the end of the extension part 42/52.

- a plurality of openings 260a may be formed in the rotor 260. As the rotor rotates, air may flow into the rotor from an outside of the rotor. The inflow air may flow toward the stator 280.

- the fastening part 231c may be provided to the rear housing 231b.

- the rear housing 231b is inserted in the hollow part 250a of the connector and then coupled and fixed to the connector 250 through the fastening part 231c.

- the first planet gear 223 is provided rotatably centering on a roller shaft 222, and the roller shaft 222 may be fixed to a first carrier 243.

- a first carrier supporter 224 may be provided for the front-rear position fixing of the first planet gear and the fixing of the roller shaft.

- the first planet gear 223 may be rotatably provided to the first carrier 243.

- the first planet gear 223 revolves around the first sun gear 221, the first carrier 243 rotates.

- the middle shaft 241 may configure an integral part with the first carrier 243 and the second sun gear 242. Namely, they may include a single component or part. Hence, the middle shaft 241 and the first carrier 243 may rotate as an integral part. This means that a rotation speed of the first carrier is different from a rotation speed of each of the rotor shaft and the drum shaft.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Detail Structures Of Washing Machines And Dryers (AREA)

- Drying Of Solid Materials (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR20180152885 | 2018-11-30 | ||

| KR1020190136803A KR102791282B1 (ko) | 2018-11-30 | 2019-10-30 | 건조기 |

| PCT/KR2019/016580 WO2020111817A1 (fr) | 2018-11-30 | 2019-11-28 | Séchoir |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3889340A1 true EP3889340A1 (fr) | 2021-10-06 |

| EP3889340A4 EP3889340A4 (fr) | 2022-07-20 |

Family

ID=71082108

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19890726.3A Pending EP3889340A4 (fr) | 2018-11-30 | 2019-11-28 | Séchoir |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20210404107A1 (fr) |

| EP (1) | EP3889340A4 (fr) |

| KR (1) | KR102791282B1 (fr) |

| CN (12) | CN118374956A (fr) |

| AU (12) | AU2019386525B2 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20220074110A1 (en) * | 2020-09-04 | 2022-03-10 | Lg Electronics Inc. | Laundry treating apparatus |

Families Citing this family (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR102747588B1 (ko) * | 2020-09-04 | 2024-12-27 | 엘지전자 주식회사 | 의류처리장치 |

| KR102754833B1 (ko) * | 2020-09-04 | 2025-01-14 | 엘지전자 주식회사 | 의류처리장치 |

| KR102747589B1 (ko) * | 2020-09-04 | 2024-12-27 | 엘지전자 주식회사 | 의류처리장치 |

| JP7551909B2 (ja) * | 2020-09-04 | 2024-09-17 | エルジー エレクトロニクス インコーポレイティド | 乾燥機 |

| KR102827374B1 (ko) * | 2020-09-04 | 2025-07-01 | 엘지전자 주식회사 | 의류처리장치 및 의류처리장치의 제어방법 |

| KR102719447B1 (ko) * | 2020-09-04 | 2024-10-22 | 엘지전자 주식회사 | 의류처리장치 |

| KR102758940B1 (ko) * | 2020-09-04 | 2025-01-23 | 엘지전자 주식회사 | 건조기 |

| KR102664421B1 (ko) * | 2020-09-04 | 2024-05-08 | 엘지전자 주식회사 | 의류처리장치 |

| US12139838B2 (en) | 2020-09-04 | 2024-11-12 | Lg Electronics Inc. | Apparatus for treating laundry |

| KR102757404B1 (ko) * | 2020-09-04 | 2025-01-20 | 엘지전자 주식회사 | 건조기 |

| EP3964634A1 (fr) * | 2020-09-04 | 2022-03-09 | LG Electronics Inc. | Appareil de traitement du linge |

| KR102707196B1 (ko) * | 2020-09-04 | 2024-09-20 | 엘지전자 주식회사 | 의류처리장치 |

| TWI845892B (zh) * | 2021-02-08 | 2024-06-21 | 南韓商Lg電子股份有限公司 | 衣物處理裝置 |

| WO2022169229A1 (fr) | 2021-02-08 | 2022-08-11 | Lg Electronics Inc. | Appareil de traitement de linge |

| WO2022169313A1 (fr) | 2021-02-08 | 2022-08-11 | Lg Electronics Inc. | Appareil de traitement du linge |

| US12392079B2 (en) * | 2021-02-08 | 2025-08-19 | Lg Electronics Inc. | Laundry treating apparatus |

| KR20220122241A (ko) | 2021-02-26 | 2022-09-02 | 엘지전자 주식회사 | 의류처리장치 |

| KR20220126428A (ko) * | 2021-03-09 | 2022-09-16 | 엘지전자 주식회사 | 의류처리장치 |

| KR20220126429A (ko) * | 2021-03-09 | 2022-09-16 | 엘지전자 주식회사 | 의류처리장치 |

| KR102757411B1 (ko) * | 2021-04-21 | 2025-01-21 | 엘지전자 주식회사 | 의류처리장치 |

| KR102776912B1 (ko) * | 2021-04-21 | 2025-03-10 | 엘지전자 주식회사 | 의류처리장치 |

| KR102776910B1 (ko) * | 2021-04-21 | 2025-03-10 | 엘지전자 주식회사 | 의류처리장치 |

| KR102761867B1 (ko) * | 2021-11-02 | 2025-02-04 | 엘지전자 주식회사 | 의류처리장치 |

Family Cites Families (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3060593A (en) * | 1959-08-07 | 1962-10-30 | Gen Motors Corp | Clothes drier |

| US3167409A (en) * | 1961-12-21 | 1965-01-26 | Gen Motors Corp | Rotary clothes dryer with direct drive motor and speed reducer assembly |

| JPS5914888Y2 (ja) * | 1978-03-25 | 1984-05-02 | 日本コロムビア株式会社 | ト−ンア−ム駆動装置 |

| JPS576698A (en) * | 1980-06-16 | 1982-01-13 | Matsushita Electric Industrial Co Ltd | Driving device for rotating drum type drier |

| DE19547456A1 (de) * | 1995-12-19 | 1997-06-26 | Bosch Siemens Hausgeraete | Antriebsvorrichtung für eine von vorn beschickbare Waschmaschine |

| JP2000000396A (ja) * | 1998-06-12 | 2000-01-07 | Toshiba Corp | 衣類乾燥機 |

| KR100786060B1 (ko) * | 2000-12-05 | 2007-12-18 | 엘지전자 주식회사 | 드럼세탁기 |

| US7107798B2 (en) * | 2002-08-27 | 2006-09-19 | Whirlpool Corporation | Drive mechanism for an automatic washer |

| KR100463545B1 (ko) * | 2002-12-23 | 2004-12-29 | 엘지전자 주식회사 | 드럼세탁기 |

| KR100504867B1 (ko) * | 2003-01-16 | 2005-07-29 | 엘지전자 주식회사 | 인덕션모터를 구비한 드럼 세탁기 |

| KR20050052079A (ko) * | 2003-11-29 | 2005-06-02 | 삼성전자주식회사 | 의류건조기 |

| KR100634802B1 (ko) * | 2004-07-20 | 2006-10-16 | 엘지전자 주식회사 | 드럼 세탁기 |

| KR100712912B1 (ko) * | 2005-02-03 | 2007-05-02 | 엘지전자 주식회사 | 세탁물 처리 기기 및 그 제어 방법 |

| CN101086130A (zh) * | 2006-06-08 | 2007-12-12 | 南京乐金熊猫电器有限公司 | 滚筒式衣物烘干机及其控制方法 |

| JP4314283B2 (ja) * | 2007-03-22 | 2009-08-12 | 株式会社東芝 | 洗濯乾燥機 |

| KR100823328B1 (ko) * | 2007-07-13 | 2008-04-17 | 주식회사 대일냉각기 | 의류건조기용 필터조립체 |

| KR20100096388A (ko) * | 2009-02-24 | 2010-09-02 | 엘지전자 주식회사 | 건조기 |

| KR20120070763A (ko) * | 2010-12-22 | 2012-07-02 | 엘지전자 주식회사 | 건조기 및 건조기의 제어 방법 |

| KR101555897B1 (ko) * | 2011-07-27 | 2015-10-07 | 삼성전자 주식회사 | 세탁기용 모터와 이를 구비한 세탁기 |

| EP2788539B1 (fr) * | 2011-12-08 | 2016-06-01 | LG Electronics Inc. | Guide de filtre muni d'un dispositif de verrouillage de capot de filtre et sèche-linge utilisant ledit guide de filtre |

| WO2014024400A1 (fr) * | 2012-08-09 | 2014-02-13 | パナソニック株式会社 | Sèche-linge |

| EP2843114B1 (fr) * | 2013-08-27 | 2018-05-02 | Electrolux Appliances Aktiebolag | Sèche-linge à tambour rotatif |

| JP6397254B2 (ja) * | 2014-08-04 | 2018-09-26 | アクア株式会社 | ドラム式洗濯機 |

| KR20150016175A (ko) * | 2014-08-04 | 2015-02-11 | 뉴모텍(주) | 세탁기용 모터 어셈블리 |

| KR101644561B1 (ko) * | 2014-09-24 | 2016-08-01 | 동아대학교 산학협력단 | 세탁기의 구동장치 및 이를 이용한 세탁기의 구동 방법 |

| KR101639022B1 (ko) * | 2015-01-26 | 2016-07-13 | 주식회사 아모텍 | 드럼 구동장치, 이를 구비한 드럼 세탁기 및 구동방법 |

| TR201705287A2 (tr) * | 2017-04-10 | 2018-10-22 | Arcelik As | Yatay eksenli̇ bi̇r çamaşir kurutma maki̇nesi̇ |

| CN106868828B (zh) * | 2017-04-12 | 2023-07-25 | 广东美的厨房电器制造有限公司 | 微波干衣机 |

| KR102351705B1 (ko) * | 2017-05-12 | 2022-01-14 | 뉴모텍(주) | 직결식 세탁기용 구동 장치 |

| KR101885203B1 (ko) * | 2017-05-12 | 2018-08-03 | 뉴모텍(주) | 감속 구동이 가능한 직결식 세탁기용 구동 장치 |

| CN108457047B (zh) * | 2018-04-27 | 2019-09-27 | 广东威灵电机制造有限公司 | 滚筒洗衣机的驱动系统及滚筒洗衣机 |

-

2019

- 2019-10-30 KR KR1020190136803A patent/KR102791282B1/ko active Active

- 2019-11-28 CN CN202410639723.XA patent/CN118374956A/zh active Pending

- 2019-11-28 CN CN201980079267.5A patent/CN113167011B/zh active Active

- 2019-11-28 AU AU2019386525A patent/AU2019386525B2/en active Active

- 2019-11-28 CN CN202410640169.7A patent/CN118374958A/zh active Pending

- 2019-11-28 CN CN202410640165.9A patent/CN118374957A/zh active Pending

- 2019-11-28 CN CN202410639719.3A patent/CN118374955A/zh active Pending

- 2019-11-28 CN CN202410640172.9A patent/CN118374959A/zh active Pending

- 2019-11-28 CN CN202410639718.9A patent/CN118374954A/zh active Pending

- 2019-11-28 CN CN202410639435.4A patent/CN118374952A/zh active Pending

- 2019-11-28 EP EP19890726.3A patent/EP3889340A4/fr active Pending

- 2019-11-28 US US17/298,401 patent/US20210404107A1/en active Pending

- 2019-11-28 CN CN202410639433.5A patent/CN118374951A/zh active Pending

- 2019-11-28 CN CN202410640181.8A patent/CN118374960A/zh active Pending

- 2019-11-28 CN CN202410639438.8A patent/CN118374953A/zh active Pending

- 2019-11-28 CN CN202410640182.2A patent/CN118374961A/zh active Pending

-

2023

- 2023-08-08 AU AU2023214251A patent/AU2023214251B2/en active Active

- 2023-11-10 AU AU2023263561A patent/AU2023263561A1/en active Pending

- 2023-11-10 AU AU2023263559A patent/AU2023263559B2/en active Active

- 2023-11-10 AU AU2023263555A patent/AU2023263555B2/en active Active

- 2023-12-06 AU AU2023278044A patent/AU2023278044A1/en active Pending

-

2024

- 2024-10-17 AU AU2024227423A patent/AU2024227423A1/en active Pending

- 2024-10-17 AU AU2024227422A patent/AU2024227422A1/en active Pending

- 2024-10-17 AU AU2024227424A patent/AU2024227424A1/en active Pending

- 2024-10-17 AU AU2024227420A patent/AU2024227420A1/en active Pending

- 2024-10-17 AU AU2024227426A patent/AU2024227426A1/en active Pending

- 2024-10-17 AU AU2024227425A patent/AU2024227425A1/en active Pending

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20220074110A1 (en) * | 2020-09-04 | 2022-03-10 | Lg Electronics Inc. | Laundry treating apparatus |

| US12241197B2 (en) * | 2020-09-04 | 2025-03-04 | Lg Electronics Inc. | Laundry treating apparatus |

| US12291814B2 (en) | 2020-09-04 | 2025-05-06 | Lg Electronics Inc. | Laundry treating apparatus |

Also Published As

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| AU2023214251B2 (en) | Dryer | |

| KR102811268B1 (ko) | 건조기 | |

| KR102747586B1 (ko) | 건조기 | |

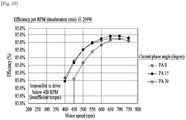

| KR102354435B1 (ko) | 송풍팬 용 교류 전동기 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20210630 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Free format text: PREVIOUS MAIN CLASS: D06F0058040000 Ipc: D06F0058080000 |

|

| A4 | Supplementary search report drawn up and despatched |

Effective date: 20220620 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: D06F 58/04 20060101ALN20220614BHEP Ipc: D06F 39/12 20060101ALI20220614BHEP Ipc: D06F 58/08 20060101AFI20220614BHEP |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20230504 |