EP3545370B1 - Rotierender resonator mit flexiblem führungssystem auf basis einer abgelösten ankerhemmung - Google Patents

Rotierender resonator mit flexiblem führungssystem auf basis einer abgelösten ankerhemmung Download PDFInfo

- Publication number

- EP3545370B1 EP3545370B1 EP17803933.5A EP17803933A EP3545370B1 EP 3545370 B1 EP3545370 B1 EP 3545370B1 EP 17803933 A EP17803933 A EP 17803933A EP 3545370 B1 EP3545370 B1 EP 3545370B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- regulating mechanism

- pallet

- equal

- lever

- escapement

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B15/00—Escapements

- G04B15/06—Free escapements

- G04B15/08—Lever escapements

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B15/00—Escapements

- G04B15/14—Component parts or constructional details, e.g. construction of the lever or the escape wheel

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B17/00—Mechanisms for stabilising frequency

- G04B17/20—Compensation of mechanisms for stabilising frequency

- G04B17/28—Compensation of mechanisms for stabilising frequency for the effect of imbalance of the weights, e.g. tourbillon

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B18/00—Mechanisms for setting frequency

- G04B18/02—Regulator or adjustment devices; Indexing devices, e.g. raquettes

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B31/00—Bearings; Point suspensions or counter-point suspensions; Pivot bearings; Single parts therefor

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B17/00—Mechanisms for stabilising frequency

- G04B17/04—Oscillators acting by spring tension

- G04B17/045—Oscillators acting by spring tension with oscillating blade springs

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B17/00—Mechanisms for stabilising frequency

- G04B17/20—Compensation of mechanisms for stabilising frequency

- G04B17/26—Compensation of mechanisms for stabilising frequency for the effect of variations of the impulses

Definitions

- the invention relates to a timepiece regulating mechanism, comprising, arranged on a plate, a resonator mechanism with a quality factor Q, and an escapement mechanism arranged to be subjected to a torque of motor means that a movement comprises, said resonator mechanism comprising an inertial element arranged to oscillate relative to said plate, said inertial element being subjected to the action of elastic return means fixed directly or indirectly to said plate, and said inertial element being arranged to cooperate with an escapement wheel and pinion that said escapement mechanism comprises.

- the invention also relates to a clockwork movement comprising drive means, and such a regulating mechanism, the escapement mechanism of which is subjected to the torque of these drive means.

- the invention also relates to a watch, more particularly a mechanical watch, comprising such a movement, and/or such a regulating mechanism.

- the invention relates to the field of watch regulation mechanisms, in particular for watches.

- the escapement for its part, fulfills two main functions, namely to maintain the back and forth movements of the resonator, and to count these back and forth movements. This escapement must be robust, not disturb the balance far from its point of equilibrium, withstand shocks, avoid jamming the movement (for example when it is overturned), and is therefore a critical component of the watch movement.

- a sprung balance oscillates with an amplitude of 300°, and the lift angle is 50°.

- the lift angle is the angle of the balance at which the lever fork interacts with the balance pin, also called the ellipse. In most current Swiss lever escapements, the lift angle is distributed on either side of the balance balance point (+/- 25°), and the lever swings +/- 7°.

- the Swiss anchor escapement belongs to the category of free escapements, because, beyond the half-lift angle, the resonator no longer touches the anchor. This characteristic is essential to obtain good chronometric properties.

- a mechanical resonator comprises an inertial element, a guide and an elastic return element.

- the balance wheel constitutes the inertial element

- the hairspring constitutes the elastic return element.

- the balance wheel is guided in rotation by pivots, which turn in plain ruby bearings.

- the associated friction is the cause of energy losses and operating disturbances.

- the aim is to eliminate these disturbances, which, moreover, depend on the orientation of the watch in the gravitational field.

- the losses are characterized by the quality factor Q of the resonator.

- the aim is generally to maximize this quality factor Q, in particular to obtain the best possible power reserve. It is understood that the guide is an essential factor of losses.

- the flexible blades generally used in such rotating flexible guides are more rigid than hairsprings. This leads to working at a higher frequency, for example of the order of 20 Hz, and at a lower amplitude, for example from 10° to 20°. This seems at first glance to be incompatible with a Swiss lever type escapement.

- a compatible operating amplitude for a rotating flexible guide resonator, especially with blades, is typically 6° to 15°. This results in a certain lift angle value, which must be twice the minimum operating amplitude.

- a low lift angle escapement can have poor performance and cause too much delay.

- the combination of high frequency and low amplitude allows for balance wheel passage speeds which are acceptable, without being too high, and therefore the efficiency of the escapement is not automatically poor.

- the resonator must have an acceptable size, compatible with its housing in a clockwork movement, it is not possible to date to produce a flexible rotating guide of very large diameter, nor with several pairs of blade levels, which would theoretically allow, by placing successive flexible guides in series, to obtain an oscillation amplitude of the inertial element of several tens of degrees: it is therefore appropriate to use a flexible guide with one or two blade levels at most, for example as known from the document EP3035126 on behalf of THE SWATCH GROUP RESEARCH & DEVELOPMENT Ltd .

- EP2894520A2 in the name of NIVAROX SA, EP3032352A1 on behalf of LVMH SWISS MANUFACTURES SA And EP2990885A1 on behalf of ETA SA.

- the effect of choosing a rotating flexible guide is that the amplitude of the balance is reduced, and that a traditional Swiss lever escapement can no longer be used, which requires a balance amplitude significantly greater than the half-lift angle, i.e. greater than 25°.

- a regulator incorporating a flexible-guided resonator therefore requires a special escapement mechanism, with different dimensions than a conventional Swiss lever escapement designed to operate with the same inertial element of the resonator.

- the present invention has the overall objective of increasing the power reserve and the precision of current mechanical watches. To achieve this objective, the invention combines a rotating flexible guide resonator with an optimized lever escapement to maintain acceptable dynamic losses and limit the chronometric effect of the clearance.

- the invention relates to a regulating mechanism according to claim 1.

- Such resonators with rotating flexible guidance have very high quality factors, for example of the order of 3000, compared with a quality factor of 200 for a usual watch.

- dynamic losses kinetic energy of the escapement wheel and the anchor at the end of the impulse

- These losses can therefore become too significant, at a high quality factor, in relative level compared to the energy transmitted to the balance.

- a plate pin secured to the inertial element must penetrate a certain amount, called penetration, into the opening of the anchor fork.

- this plate pin must then be able, after release of the pin, to be maintained at a certain distance, called safety, from the horn of the fork opposite to that on which it was in contact immediately before its release.

- the invention further seeks to impose a particular relationship between the dimensions of the anchor fork, the penetration and safety values, and the values of the lifting angles of the anchor and the inertial element, to ensure that the pin retracts correctly from the fork, once the half lifting angle has been covered.

- the invention also relates to a clockwork movement comprising drive means, and such a regulating mechanism, the escapement mechanism of which is subjected to the torque of these drive means.

- the invention also relates to a watch, more particularly a mechanical watch, comprising such a movement, and/or such a regulating mechanism.

- the invention combines a rotating flexible-guided resonator, in order to increase the power reserve and precision, with an anchor escapement optimized to maintain acceptable dynamic losses and limit the chronometric effect of the clearance.

- the invention thus relates to a regulator mechanism 300 for a watch, comprising, arranged on a plate 1, a resonator mechanism 100 with a quality factor Q, rotating around a main axis DP, and an escapement mechanism 200, which is subjected to a torque of motor means 400 which comprise a movement 500.

- This resonator mechanism 100 comprises at least one inertial element 2 which is arranged to oscillate relative to the plate 1, around a main axis DP.

- This inertial element 2 is subjected to the action of elastic return means 3 fixed directly or indirectly to the plate 1.

- the inertial element 2 is arranged to cooperate indirectly with an escapement wheel 4, in particular an escape wheel, which the escapement mechanism 200 comprises, and which pivots around an escapement axis DE.

- these elastic return means 3 comprise at least two flexible blades 5 from which this at least one inertial element 2 is suspended, in particular a balance or the like, and which define a flexible guide with a virtual pivot of this at least one inertial element 2.

- This at least one inertial element 2 securely carries a pin 6.

- the escapement mechanism 200 comprises an anchor 7 arranged to pivot about a secondary axis DS, and comprising a anchor fork 8 which is arranged to cooperate with the pin 6.

- This escapement mechanism 200 is a free escapement mechanism, in the operating cycle of which the resonator mechanism 100 has at least one phase of freedom where the pin 6 is at a distance from the anchor fork 8.

- the pin 6 penetrates into the anchor fork 8 with a penetration stroke P greater than or equal to 40 micrometers and less than or equal to 200 micrometers, and in a release phase the pin 6 remains at a distance from the anchor fork 8 with a safety distance S greater than or equal to 10 micrometers and less than or equal to 60 micrometers.

- the pin 6 and the anchor fork 8 are dimensioned so that the width L of the anchor fork 8 is greater than (P+S)/sin( ⁇ /2+ ⁇ /2), the penetration stroke P and the safety distance S being measured radially relative to the main axis DP, where ⁇ is the anchor lift angle which corresponds to the maximum angular stroke of the anchor fork 8, and where ⁇ is the resonator lift angle, during which the pin 6 is in contact with the anchor fork 8.

- the penetration stroke P is greater than or equal to 80 micrometers and less than or equal to 120 micrometers.

- the penetration stroke P is greater than or equal to 100 micrometers.

- the safety distance S is greater than or equal to 20 micrometers and less than or equal to 30 micrometers.

- the safety distance S is greater than or equal to 25 micrometers.

- the anchor lifting angle ⁇ is greater than or equal to 5° and less than or equal to 30°.

- the anchor lifting angle ⁇ is less than or equal to 20°.

- the anchor lifting angle ⁇ is greater than or equal to 12° and less than or equal to 16°.

- the resonator lift angle ⁇ is greater than or equal to 3° and less than or equal to 30°.

- the resonator lift angle ⁇ is greater than or equal to 8° and less than or equal to 12°.

- the resonator lift angle ⁇ is less than or equal to 10°.

- anchor 7 constitutes a bistable stop.

- dynamic multibody simulations i.e. relating to a set of several components each of which is assigned a particular mass and inertia distribution

- dynamic multibody simulations make it possible to evaluate the efficiency and delay of this escapement mechanism as a function of the inertia ratio between the inertia of the inertial element and the inertia of the anchor, which standard kinematic simulations do not make it possible to establish.

- the analytical model of the system thus showed that, if we want to limit dynamic losses, a particular condition links the inertia of the anchor, the inertia of the inertial element, the quality factor of the resonator, and the lifting angles of the anchor and the inertial element: for a coefficient ⁇ of dynamic losses, the inertia I B of all the inertial elements 2 relative to the main axis DP on the one hand, and the inertia I A of the anchor 7 relative to the secondary axis DS on the other hand, are such that the ratio I B /I A is greater than 2Q. ⁇ 2 /( ⁇ . ⁇ . ⁇ 2 ), where ⁇ is the lifting angle of the anchor which corresponds to the maximum angular travel of the anchor fork 8.

- the inertia I B of this at least one inertial element 2 with respect to the main axis DP on the one hand, and the inertia I A of the anchor 7 with respect to the secondary axis DS on the other hand are such that the ratio I B /I A is greater than 2Q. ⁇ 2 /(0.1. ⁇ . ⁇ 2 ), where ⁇ is the lifting angle of the anchor which corresponds to the maximum angular travel of the anchor fork 8.

- the resonator lift angle ⁇ which is an overall angle, taken on either side of the rest position, is less than twice the amplitude angle by which the inertial element 2 deviates at most from a rest position, in only one direction of its movement.

- the amplitude angle, from which the inertial element 2 deviates as much as possible from a rest position is between 5° and 40°.

- the pin 6 penetrates into the anchor fork 8 with a penetration stroke P greater than 100 micrometers, and in a release phase the pin 6 remains at a distance from the anchor fork 8 with a safety distance S greater than 25 micrometers.

- the fork 8 of the lever 7 is thus widened compared to what would be a classic Swiss lever fork, which is much narrower and allows less freedom for the pin 6, which would not be able to enter and exit the fork of a classic Swiss lever with such a small angular amplitude.

- This concept of a widened fork makes it possible to operate a lever escapement even though the amplitude of the resonator is much lower than in a classic balance spring, which is particularly interesting for resonators with flexible guides, which have a low amplitude, as in this case. Indeed, it is important that, during the operating cycle, the balance is completely free at certain times.

- the pin 6 and the anchor fork 8 are advantageously dimensioned so that the width L of the anchor fork 8 is greater than (P+S)/sin( ⁇ /2+ ⁇ /2), the penetration stroke P and the safety distance S being measured radially relative to the main axis DP.

- the useful width L1 of the dowel 6, visible on the figure 6 is slightly less than the width L of the anchor fork 8, and, more particularly, less than or equal to 98% of L.

- This dowel 6 is advantageously tapered behind its surface of useful width L1, the dowel may in particular have a prismatic shape of triangular section as suggested in the figure, or similar.

- the eccentricity E2 of the pin 6 relative to the balance wheel axis, and the eccentricity E7 of the fork horn 8 relative to the axis of the anchor 7, are between 40% and 60% of the center distance E between the axis of the anchor 7 and the balance shaft. More specifically, the eccentricity E2 is between 55% and 60% of the center distance E, and the eccentricity E7 is between 40% and 45% of the center distance E. More specifically, the interference zone between the pin 6 and the fork 8 extends over 5% to 10% of the center distance E.

- the invention defines, by construction, a new pin-fork layout, which has a very particular characteristic, according to which the horns of the fork are further apart, and the pin is wider, than for a Swiss anchor mechanism of known type with a usual lifting angle of 50°.

- the anchor 7 also comprises two anchor horns, first horn 81 and second horn 82, which together define such an enlarged fork according to the invention, arranged to cooperate with the balance pin 6 sized according to the invention.

- the balance wheel 2 comprises a radial arm carrying an impulse pallet 610, which is arranged to cooperate with the direct impulse teeth 41 of the escapement wheel 4.

- the direct impulse teeth 41 and the indirect impulse teeth 43 of the illustrated variant have a very reduced radial extension compared to that of the rest teeth 42, in particular between 20% and 35%; in the illustrated example, the radial extension of the indirect impulse teeth 43 is 25% of that of the rest teeth 42, and the radial extension of the direct impulse teeth 41 is 31% of that of the rest teeth 42, which is of the order of 49% of the center distance E between the axis DP of the balance 2 and that DS of the anchor 7.

- the bulk of the balance wheel is, however, increased compared to a balance wheel of a sprung balance wheel for a Swiss anchor, since it is advantageous to move the pin 6 away from the pivot axis of the inertial mass.

- the external surface 60 of the pin 6 is here on a radius of 120% relative to the radial extension of the rest teeth 42, or, to refer to the center distance E between the axis of the balance wheel and that of the anchor, at 59% of E.

- the radial dimension of the end of the rest pallets 71 and 72 is here 60% or 30% of E, that of the impulse pallet 73 is 95%, or 47% of E, just like those of the horns 81 and 82.

- the center distance between the axis D4 of the escape wheel 4 and that DS of the anchor 7 is here 58% of E, and the center distance between the axis DP of the balance wheel 2 and that D4 of the escape wheel 4 is 89% of E.

- FIG 21 shows the indirect impulse: the rotation of the escape wheel 4 released in the counterclockwise direction E, stop of an indirect impulse tooth 43 of the escape wheel 4 on the impulse pallet 73 of the anchor 7.

- the anchor 7 is driving, turns in the clockwise direction C until it catches up with the balance 2, by the cooperation of the second anchor horn 82 with the pin 6 on a second edge 62, thus indirectly transmitting the impulse of the escape wheel 4 to the balance 2, through the anchor 7.

- FIG 23 shows the clearance lifted in, after the end of the free arc of the balance, there is a reversal of the direction of rotation of the balance 2 which starts again in a clockwise direction B, the pin 6 rests on the second horn 82 of the anchor 7 and drives it counterclockwise D, until clearance between the entry rest pallet 71 of the anchor 7 and the rest tooth 42 of the escape wheel 4, thus allowing rotation of the escape wheel 4.

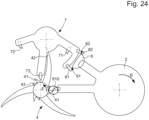

- FIG 24 shows the indirect impulse: stopping of a direct impulse tooth 41 of the escape wheel 4 on the impulse pallet 610 of the balance wheel 2, allowing the direct drive of the balance wheel 2 by the escapement wheel 4.

- the anchor 7 remains driven by its second horn 82 pushed by the pin 6.

- this construction makes it possible to dispense with the presence of a dart on the anchor 7, which allows the manufacture of the latter on a single level, for example in micro-machinable material, silicon or similar, by “LIGA” or “MEMS” process or similar.

- the first horn 81 presses on the pin 6 when the balance 2 travels its free arc, which prevents the anchor from pivoting in the event of an impact, which makes the presence of a dart unnecessary, and, a fortiori, of a small plate on the balance 2, which can thus also be produced on a single level.

- the anchor 7 is made of silicon, which allows a miniaturized and very precise execution, with a density less than a third of that of steel. Having a silicon anchor allows to reduce its inertia compared to a metal anchor. A low inertia of the anchor with respect to the balance is crucial to have a correct performance at low amplitude and high frequency, in the present case of resonators with flexible guides.

- the balance wheel is, when the watch range allows it, advantageously made of a heavy metal or alloy, including gold, platinum, tungsten, or similar, and may include weights of similar constitution. Failing this, the balance wheel is conventionally made of CuBe2 copper-beryllium alloy, or similar, and weighted with balancing weights and/or adjustment weights made of nickel silver or other alloy.

- this anchor 7 is on a single level of silicon, attached to a shaft, metallic or similar, such as ceramic, or other, pivoted relative to the plate 1.

- the escapement wheel 4 is an escape wheel made of micro-machinable material, in particular silicon or similar.

- the anchor 7 is perforated to minimize its inertia I A relative to the secondary axis DS.

- the anchor 7 is symmetrical with respect to the secondary axis DS, so as to avoid any imbalance, and to avoid parasitic torques during linear impacts, in particular in translation.

- An additional advantage is then the great ease of assembly of this very small component, which the operator carrying out the assembly can handle from any side.

- the largest dimension of this at least one inertial element 2 is greater than half of the largest dimension of the plate 1.

- the main axis DP, the secondary axis DS and the pivot axis of the escapement wheel 4 are arranged according to a right-angle pointing whose apex is on the secondary axis DS. It is understood that thus, with reference to a classic Swiss anchor in the shape of a T with a rod and two arms, the rod is removed, which becomes one of the two arms 76, visible on the figure 7 , which carries the horns 81 and 82 and the output pallet 72 almost merged with the horn 82, the other arm 75 carrying the input pallet 73.

- the comparison with the Swiss anchor is to be continued with regard to the means of preventing overturning, usually consisting of a dart located on a plane offset from the anchor.

- This function is important to avoid any jamming of the balance.

- the balance is devoid of small plate and therefore of a plate notch provided to cooperate with such a dart.

- the pin is never far from the fork.

- the anti-overturning function is then advantageously fulfilled by the combination of the circular arc-shaped circumference 60 of the pin 6, and by the corresponding surface 810, 820, of the relevant anchor horn 81, 82: this horn plays the usual role of a dart, and the circumference of the pin plays the role of the small plate.

- the additional advantage which results from this is that, as regards its cooperation with the anchor of a single level, the balance can also be, locally, at a single level, which simplifies its manufacture and reduces its cost.

- the resonator thus has an anisochronism curve which compensates for the delay caused by the escapement. That is to say that the free resonator is designed with an isochronism defect opposite to the defect caused by the lever escapement. The escapement delay is therefore compensated for by the design of the resonator.

- each flexible blade 5 is identical and are positioned symmetrically. More particularly still, each flexible blade 5 belongs to a single-piece assembly 50, in one piece with two solid parts 51, 55, and with its first alignment means 52A, 52B, and fixing means 54 on the plate 1, or, advantageously and as visible on the figure 10 , for fixing on an intermediate elastic suspension blade 9 fixed to the plate 1 and which is arranged to allow movement of the flexible guide and of this at least one inertial element 2 in the direction of the main axis DP, so as to ensure good protection against impacts of direction Z perpendicular to the plane of such a single-piece assembly 10, and therefore to avoid the breakage of the flexible guide blades.

- This intermediate elastic suspension blade 9 is advantageously made of “Durimphy” alloy or similar.

- the first alignment means are a first V 52A and a first flat 52B, and the first fixing means comprise at least a first bore 54.

- a first plating blade 53 provides support on the first fixing means.

- the single-piece assembly 50 comprises, for its fixing on the inertial element 2, second alignment means which are a second V 56A and a second flat 56B, and the second fixing means comprise at least a second bore 58.

- a second plating blade 57 provides support on the second fixing means.

- the flexible guide 3 with crossed blades 5 is advantageously made up of two identical 50-piece silicon monobloc assemblies, assembled symmetrically to form the crossing of the blades, and precisely aligned with each other thanks to the integrated alignment means and to auxiliary means such as pins and screws, not shown in the figures.

- At least the resonator mechanism 100 is fixed on an intermediate elastic suspension blade 9 fixed to the plate 1 and arranged to allow a movement of the resonator mechanism 100 in the direction of the main axis DP, and the plate 1 comprises at least one shock-absorbing stop 11, 12, at least in the direction of the main axis DP, and preferably at least two such shock-absorbing stops 11, 12, which are arranged to cooperate with at least one rigid element of this at least one inertial element 2, for example a flange 21 or 22 added during the assembly of the inertial element with the flexible guide 3 comprising the blades 5.

- the elastic suspension blade 9, or a similar device allows movements of the entire resonator 100 substantially in the direction defined by the virtual axis of rotation DP of the guide.

- the purpose of this device is to prevent the blades 5 from breaking in the event of a transverse impact in the direction DP.

- the flange 21 or 22 comprises a bore 211 and a face 212, capable of cooperating respectively in shock-proof stop support with a journal 121 and a complementary surface 122 at the stop 21 or 22.

- the inertial element 2 comprises weights 20 for adjusting the speed and the imbalance.

- the dowel 6 is a single piece with a flexible blade 5, or more particularly, such a single piece assembly 50 as illustrated in the figures.

- the anchor 7 comprises bearing surfaces arranged to cooperate in bearing with teeth that the escapement wheel 4 comprises and to limit the angular travel of the anchor 7. These supports make it possible to limit the angular travel of the anchor, as would do pins.

- the angular travel of the anchor 78 can also be conventionally limited by limiting pins 700.

- the flexible guide 3 is made of oxidized silicon to compensate for the effects of temperature on the operation of the regulating mechanism 300.

- the invention also relates to a clockwork movement 500 comprising motor means 400, and such a regulating mechanism 300, the escapement mechanism 200 of which is subjected to the torque of these motor means 400.

- the present invention makes it possible to increase the power reserve and/or the precision of current mechanical watches.

- the autonomy of the watch can be quadrupled and the regulating power of the watch doubled. This amounts to saying that the invention allows a gain of a factor of 8 on the performance of the movement.

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Micromachines (AREA)

- Piezo-Electric Or Mechanical Vibrators, Or Delay Or Filter Circuits (AREA)

- Electromechanical Clocks (AREA)

Claims (35)

- Reguliermechanismus (300) für Uhrmacherei, der, auf einer Platine (1) angeordnet, einen Resonator-Mechanismus (100) mit einem Qualitätsfaktor Q, der um eine Hauptachse (DP) drehend ist, und einen Hemmungsmechanismus (200) beinhaltet, der angeordnet ist, um einem Paar von Antriebsmitteln (400) zu unterliegen, die ein Uhrwerk (500) beinhaltet, wobei der Resonator-Mechanismus (100) mindestens ein Trägheitselement (2) beinhaltet, das angeordnet ist, um in Bezug auf die Platine (1) zu oszillieren, wobei das mindestens eine Trägheitselement (2) der Wirkung von elastischen Rückstellmitteln (3) unterliegt, die direkt oder indirekt an der Platine (1) befestigt sind, und wobei das mindestens eine Trägheitselement (2) angeordnet ist, um indirekt mit einem Hemmungsdrehteil (4) zusammenzuwirken, den der Hemmungsmechanismus (200) beinhaltet, wobei die elastischen Rückstellmittel (3) mindestens zwei flexible Klingen (5) beinhalten, an denen das mindestens eine Trägheitselement (2) aufgehängt ist, und die eine flexible Führung mit virtuellem Zapfen des mindestens einen Trägheitselements (2) definieren, wobei das mindestens eine Trägheitselement (2) fest verbunden einen Stift (6) trägt, wobei der Hemmungsmechanismus (200) einen Anker (7) beinhaltet, der angeordnet ist, um um eine Sekundärachse (DS) herum zu schwenken, und eine Ankergabel (8) beinhaltet, die angeordnet ist, um mit dem Zapfen (6) zusammenzuwirken, und ein freier Hemmungsmechanismus ist, in dessen Betriebszyklus der Resonator-Mechanismus (100) mindestens eine Freiheitsphase besitzt, in welcher der Stift (6) von der Ankergabel (8) beabstandet ist, wobei der Reguliermechanismus konfiguriert ist, damit der Stift (6) bei jeder Halbschwingung in einer Kontaktphase mit einem Eindringweg (P) in die Ankergabel (8) eindringt, der größer oder gleich 40 Mikrometer und kleiner oder gleich 200 Mikrometer ist, und der Stift (6) in einer Freigabephase von der Ankergabel (8) mit einem Sicherheitsabstand (S), der größer oder gleich 10 Mikrometer und kleiner oder gleich 60 Mikrometer ist, beabstandet bleibt, wobei der Stift (6) und die Ankergabel (8) bemessen sind, damit die Breite (L) der Ankergabel (8) größer ist als (P+S)/sin(α/2+β/2), wobei der Eindringweg (P) und der Sicherheitsabstand (S) radial in Bezug auf die Hauptachse (DP) gemessen werden, wobei α der globale Hubwinkel des Ankers ist, der dem maximalen Winkelhub der Ankergabel (8) entspricht, und wobei β der Resonator-Hubwinkel ist, bei dem der Stift (6) in Kontakt mit der Ankergabel (8) ist, wobei die größte Abmessung des mindestens einen Trägheitselements (2) größer ist als die Hälfte der größten Abmessung der Platine (1).

- Reguliermechanismus (300) nach Anspruch 1, dadurch gekennzeichnet, dass der Eindringweg (P) größer oder gleich 80 Mikrometer, und kleiner oder gleich 120 Mikrometer ist.

- Reguliermechanismus (300) nach Anspruch 1 oder 2, dadurch gekennzeichnet, dass der Eindringweg (P) größer oder gleich 100 Mikrometer ist.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, dass der Sicherheitsabstand (S) größer als oder gleich 20 Mikrometer, und kleiner als oder gleich 30 Mikrometer ist.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, dass der Sicherheitsabstand (S) größer oder gleich 25 Mikrometer ist.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, dass der Hubwinkel des Ankers (α) größer oder gleich 5° und kleiner oder gleich 30° ist.

- Reguliermechanismus (300) nach Anspruch 6, dadurch gekennzeichnet, dass der Hubwinkel des Ankers (α) kleiner oder gleich 20° ist.

- Reguliermechanismus (300) nach Anspruch 7, dadurch gekennzeichnet, dass der Hubwinkel des Ankers (α) größer oder gleich 12° und kleiner oder gleich 16° ist.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 9, dadurch gekennzeichnet, dass der Resonator-Hubwinkel (β) größer als oder gleich 3° und kleiner als oder gleich 30° ist.

- Reguliermechanismus (300) nach Anspruch 9, dadurch gekennzeichnet, dass der Resonator-Hubwinkel (β) größer oder gleich 8° und kleiner oder gleich 12° ist.

- Reguliermechanismus (300) nach Anspruch 9 oder 10, dadurch gekennzeichnet, dass der Resonator-Hubwinkel (β) kleiner oder gleich 10° ist.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 11, dadurch gekennzeichnet, dass der Anker (7) eine bistabile Arretierung darstellt.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 12, dadurch gekennzeichnet, dass die Trägheit IB der Gesamtheit der Trägheitselemente (2) in Bezug auf die Hauptachse (DP) einerseits, und die Trägheit IA des Ankers (7) in Bezug auf die Nebenachse (DS) andererseits derart sind, dass das Verhältnis IB/IA größer als 2Q.α2/(π.β2/10) ist, wobei α der globale Hubwinkel des Ankers ist, der dem maximalen Winkelhub der Ankergabel (8) entspricht.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 13, dadurch gekennzeichnet, dass der globale Resonator-Hubwinkel (β) kleiner als das Doppelte des Amplitudenwinkels ist, um den das mindestens eine Trägheitselement (2) in einer einzigen Richtung seiner Bewegung maximal von einer Ruheposition abweicht.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 14, dadurch gekennzeichnet, dass der Amplitudenwinkel, um den das mindestens eine Trägheitselement (2) maximal von einer Ruheposition abweicht, zwischen 5° und 40° liegt.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 15, dadurch gekennzeichnet, dass der Anker (7) aus einer einzigen Siliziumebene besteht, die auf einer Welle beigebracht ist, die in Bezug auf die Platine (1) gedreht wird.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 16, dadurch gekennzeichnet, dass der Hemmungsdrehteil (4) ein Hemmungsrad aus Silizium ist.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 17, dadurch gekennzeichnet, dass der Hemmungsdrehteil (4) ein Hemmungsrad ist, das durchbrochen ist, um seine Trägheit in Bezug auf seine Schwenkachse zu minimieren.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 18, dadurch gekennzeichnet, dass der Anker (7) durchbrochen ist, um seine Trägheit (IA) in Bezug auf die Sekundärachse (DS) zu minimieren.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 19, dadurch gekennzeichnet, dass der Anker (7) in Bezug auf die Nebenachse (DS) symmetrisch ist.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 20, dadurch gekennzeichnet, dass die Hauptachse (DP), die Nebenachse (DS) und die Schwenkachse (DE) des Hemmungsdrehteils (4) in einer rechtwinkligen Ankörnung angeordnet sind, dessen Scheitelpunkt auf der Nebenachse (DS) liegt.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 21, dadurch gekennzeichnet, dass die flexible Führung zwei flexible Klingen (5) umfasst, die in Projektion auf einer Ebene senkrecht zur Hauptachse (DP), auf Höhe des virtuellen Drehpunkts, der die Hauptachse (DP) definiert, gekreuzt sind, und sich in zwei parallelen und unterschiedlichen Ebenen befinden.

- Reguliermechanismus (300) nach Anspruch 22, dadurch gekennzeichnet, dass die beiden flexiblen Klingen (5) in Projektion auf einer Ebene senkrecht zur Hauptachse (DP) zwischen sich einen Winkel zwischen 59,5° und 69,5° bilden und sich zwischen 10,75% und 14,75% ihrer Länge kreuzen, um dem Resonator-Mechanismus (100) einen beabsichtigten Isochronismus-Fehler entgegengesetzt zum Hemmungsnachlauffehler des Hemmungsmechanismus (200) zu verschaffen.

- Reguliermechanismus (300) nach Anspruch 22 oder 23, dadurch gekennzeichnet, dass die beiden flexiblen Klingen (5) identisch sind und symmetrisch positioniert sind.

- Reguliermechanismus (300) nach einem der Ansprüche 22 bis 24, dadurch gekennzeichnet, dass jede der flexiblen Klingen (5) einer einteiligen Einheit (50) aus einem Stück mit ihren Mitteln zur Ausrichtung und Befestigung an der Platine (1) oder an einer elastischen Zwischenaufhängungsklinge (9) angehört, die an der Platine (1) befestigt und angeordnet ist, um eine Verschiebung der flexiblen Führung und des mindestens einen Trägheitselements (2) in Richtung der Hauptachse (DP) zuzulassen.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 25, dadurch gekennzeichnet, dass mindestens der Resonator-Mechanismus (100) an einer elastischen Zwischenaufhängungsklinge (9) befestigt ist, die an der Platine (1) befestigt und angeordnet ist, um eine Verschiebung des Resonator-Mechanismus (100) in Richtung der Hauptachse (DP) zuzulassen, und dadurch, dass die Platine (1) mindestens einen stosssicheren Anschlag (11, 12) mindestens in Richtung der Hauptachse (DP) beinhaltet, der angeordnet ist, um mit mindestens einem starren Element des mindestens einen Trägheitselements (2) zusammenzuwirken.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 26, dadurch gekennzeichnet, dass das mindestens eine Trägheitselement (2) Gewichtchen zur Einstellung des Gangs und der Unwucht beinhaltet.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 27, dadurch gekennzeichnet, dass der Stift (6) in einem Stück mit einer flexiblen Klinge (5) ist.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 28, dadurch gekennzeichnet, dass der Anker (7) Auflageflächen beinhaltet, die angeordnet sind, um in Auflage mit Zähnen zusammenwirken, die der Hemmungsdrehteil (4) beinhaltet, und um den Winkelhub des Ankers (7) zu begrenzen.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 29, dadurch gekennzeichnet, dass die flexible Führung aus oxidiertem Silizium besteht, um die Auswirkungen der Temperatur auf den Lauf des Reguliermechanismus (300) zu kompensieren.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 30, dadurch gekennzeichnet, dass der Hemmungsmechanismus (200) ein koaxialer Hemmungsmechanismus ist.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 30, dadurch gekennzeichnet, dass der Hemmungsmechanismus (200) ein Fasoldt-Hemmungsmechanismus ist.

- Reguliermechanismus (300) nach einem der Ansprüche 1 bis 30, dadurch gekennzeichnet, dass der Hemmungsmechanismus (200) ein Hemmungsmechanismus mit gelenkiger Arretierung ist.

- Uhrwerk (500) für Uhrmacherei, das Antriebsmittel (400) und einen Reguliermechanismus (300) nach einem der Ansprüche 1 bis 33 beinhaltet, wobei der Hemmungsmechanismus (200) dem Drehmoment der Antriebsmittel (400) unterliegt.

- Uhr (1000), die ein Uhrwerk (500) nach Anspruch 34 und/oder einen Reguliermechanismus (300) nach einem der Ansprüche 1 bis 33 beinhaltet.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP16200152.3A EP3327515B1 (de) | 2016-11-23 | 2016-11-23 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| PCT/EP2017/080121 WO2018095997A2 (fr) | 2016-11-23 | 2017-11-22 | Resonateur rotatif a guidage flexible entretenu par un echappement libre a ancre |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3545370A2 EP3545370A2 (de) | 2019-10-02 |

| EP3545370B1 true EP3545370B1 (de) | 2024-10-09 |

Family

ID=57391852

Family Applications (9)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16200152.3A Active EP3327515B1 (de) | 2016-11-23 | 2016-11-23 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17745179.6A Active EP3545364B1 (de) | 2016-11-23 | 2017-07-27 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17746073.0A Active EP3545366B1 (de) | 2016-11-23 | 2017-07-27 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17745180.4A Active EP3545365B1 (de) | 2016-11-23 | 2017-07-27 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17749674.2A Active EP3545367B1 (de) | 2016-11-23 | 2017-07-27 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17752312.3A Active EP3545368B1 (de) | 2016-11-23 | 2017-07-27 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17745178.8A Active EP3545363B1 (de) | 2016-11-23 | 2017-07-27 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17794727.2A Active EP3545369B1 (de) | 2016-11-23 | 2017-11-07 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17803933.5A Active EP3545370B1 (de) | 2016-11-23 | 2017-11-22 | Rotierender resonator mit flexiblem führungssystem auf basis einer abgelösten ankerhemmung |

Family Applications Before (8)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16200152.3A Active EP3327515B1 (de) | 2016-11-23 | 2016-11-23 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17745179.6A Active EP3545364B1 (de) | 2016-11-23 | 2017-07-27 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17746073.0A Active EP3545366B1 (de) | 2016-11-23 | 2017-07-27 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17745180.4A Active EP3545365B1 (de) | 2016-11-23 | 2017-07-27 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17749674.2A Active EP3545367B1 (de) | 2016-11-23 | 2017-07-27 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17752312.3A Active EP3545368B1 (de) | 2016-11-23 | 2017-07-27 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17745178.8A Active EP3545363B1 (de) | 2016-11-23 | 2017-07-27 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

| EP17794727.2A Active EP3545369B1 (de) | 2016-11-23 | 2017-11-07 | Sich drehender resonator mit einer flexiblen führung, der von einer freien ankerhemmung gehalten wird |

Country Status (6)

| Country | Link |

|---|---|

| US (6) | US11619909B2 (de) |

| EP (9) | EP3327515B1 (de) |

| JP (6) | JP6931392B2 (de) |

| CN (6) | CN109983409B (de) |

| CH (1) | CH713150A2 (de) |

| WO (8) | WO2018099616A2 (de) |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH713150A2 (fr) * | 2016-11-23 | 2018-05-31 | Eta Sa Mft Horlogere Suisse | Mécanisme régulateur à résonateur rotatif à guidage flexible entretenu par un échappement libre à ancre. |

| EP3326963B1 (de) * | 2016-11-23 | 2020-01-01 | The Swatch Group Research and Development Ltd | Flexibles blatt für uhrwerk und herstellungsverfahren |

| CH713960B1 (fr) * | 2017-07-07 | 2023-08-31 | Eta Sa Mft Horlogere Suisse | Elément sécable pour oscillateur d'horlogerie. |

| EP3438762A3 (de) * | 2017-07-28 | 2019-03-13 | The Swatch Group Research and Development Ltd | Uhrwerkoszillator mit flexiblen führungen mit grosser winkelförmiger laufbahn |

| EP3561607B1 (de) | 2018-04-23 | 2022-03-16 | ETA SA Manufacture Horlogère Suisse | Stossdämpfungsschutz eines resonatormechanismus mit flexibler drehführung |

| EP3561609B1 (de) * | 2018-04-23 | 2022-03-23 | ETA SA Manufacture Horlogère Suisse | Stossdämpfungsschutz eines resonatormechanismus mit flexibler drehführung |

| US11454932B2 (en) * | 2018-07-24 | 2022-09-27 | The Swatch Group Research And Development Ltd | Method for making a flexure bearing mechanism for a mechanical timepiece oscillator |

| JP6843191B2 (ja) * | 2018-07-24 | 2021-03-17 | ザ・スウォッチ・グループ・リサーチ・アンド・ディベロップメント・リミテッド | 長い角ストロークを有するフレクシャーベアリングを備えた計時器用発振器 |

| EP3627237B1 (de) * | 2018-09-20 | 2022-04-06 | ETA SA Manufacture Horlogère Suisse | Komponente aus mikrobearbeitbarem material für resonator mit hohem qualitätsfaktor |

| JP7485506B2 (ja) * | 2018-10-12 | 2024-05-16 | ロレックス・ソシエテ・アノニム | 小型時計ムーブメント用の調速装置 |

| EP3997525B1 (de) | 2019-07-12 | 2024-09-25 | Patek Philippe SA Genève | Einstellverfahren eines uhrwerk-oszillators mit flexiblem zapfen |

| EP3783445B1 (de) * | 2019-08-22 | 2023-06-14 | ETA SA Manufacture Horlogère Suisse | Einstellmechanismus einer uhr mit hohem qualitätsfaktor und minimaler schmierung |

| EP3812842B1 (de) * | 2019-10-24 | 2023-11-29 | The Swatch Group Research and Development Ltd | Schwenkbare führungsvorrichtung für eine schwenkbare masse, und resonatormechanismus einer uhr |

| EP3812843B1 (de) * | 2019-10-25 | 2025-04-23 | ETA SA Manufacture Horlogère Suisse | Flexible führung und gesamtheit von übereinander angeordneten flexiblen führungen für sich drehenden resonatormechanismus, insbesondere für uhrwerk |

| EP3926412A1 (de) * | 2020-06-16 | 2021-12-22 | Montres Breguet S.A. | Regulator eines uhrwerks |

| EP3971655A1 (de) * | 2020-09-18 | 2022-03-23 | ETA SA Manufacture Horlogère Suisse | Stossdämpfungsschutz mit anschlag eines resonatormechanismus mit flexibler drehführung |

| EP3982204A1 (de) | 2020-10-08 | 2022-04-13 | The Swatch Group Research and Development Ltd | Uhrresonator, der mindestens eine flexible führung umfasst |

| EP4134754A1 (de) * | 2021-08-13 | 2023-02-15 | ETA SA Manufacture Horlogère Suisse | Trägheitsmasse, die mit einem flexiblen trägheitselement ausgestattet ist, insbesondere für uhrwerke |

| EP4160323A1 (de) | 2021-10-04 | 2023-04-05 | CSEM Centre Suisse d'Electronique et de Microtechnique SA - Recherche et Développement | Mechanische einstellvorrichtung für uhr mit selbstanlaufendem, halb freistehendem hemmungsmechanismus mit geringem anstellwinkel |

| EP4187326A1 (de) * | 2021-11-29 | 2023-05-31 | Omega SA | Spiralfeder für resonatormechanismus eines uhrwerks, der mit mitteln zum ausgleichen der starrheit ausgestattet ist |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH703464A2 (fr) * | 2010-07-19 | 2012-01-31 | Nivarox Sa | Mécanisme oscillant à pivot élastique. |

| WO2015097066A2 (fr) * | 2013-12-23 | 2015-07-02 | Eta Sa Manufacture Horlogère Suisse | Mouvement horloger mecanique a echappement magnetique |

Family Cites Families (41)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2663139A (en) * | 1949-10-31 | 1953-12-22 | Gibbs Mfg And Res Corp | Pallet lever construction |

| NL94759C (de) * | 1952-07-14 | |||

| CH469299A (fr) | 1967-03-31 | 1969-04-15 | Centre Electron Horloger | Résonateur mécanique pour pièce d'horlogerie |

| GB1195432A (en) | 1967-05-15 | 1970-06-17 | Horstmann Magnetics Ltd | Electromechanical Oscillators |

| CH490701A (de) * | 1967-08-02 | 1970-01-30 | Meyer Hans | Elastischer Schwinger für Zeitmessgerät |

| US3834155A (en) * | 1974-02-19 | 1974-09-10 | Timex Corp | Offset pallet lever for watch escapement |

| CH1020375A4 (de) * | 1975-08-05 | 1977-06-30 | ||

| JPH02273323A (ja) | 1989-04-14 | 1990-11-07 | Fuji Electric Co Ltd | 強磁性体のスパツタリング装置 |

| CH698105B1 (fr) * | 2004-10-20 | 2009-05-29 | Vaucher Mft Fleurier Sa | Dispositif de remontoir et de mise à l'heure. |

| ES2325099T3 (es) * | 2007-03-09 | 2009-08-25 | Eta Sa Manufacture Horlogere Suisse | Escape de relojeria con impulsos tangenciales. |

| CH705276B1 (fr) * | 2007-12-28 | 2013-01-31 | Chopard Technologies Sa | Organe d'entraînement et de transmission pour un échappement à ancre, plateau et échappement en étant équipés, et pièce d'horlogerie les comportant. |

| EP2230572B1 (de) | 2009-03-17 | 2012-01-25 | Nivarox-FAR S.A. | Radialverschlusssystem für Uhrwerkskomponente |

| CH700640B1 (fr) * | 2009-03-19 | 2014-09-30 | Mhvj Manufacture Horlogère Vallée De Joux | Pièce d'horlogerie allegée et renforcée. |

| CH701421B1 (fr) * | 2009-07-10 | 2014-11-28 | Manuf Et Fabrique De Montres Et Chronomètres Ulysse Nardin Le Locle Sa | Oscillateur mécanique. |

| EP2363762B1 (de) | 2010-03-04 | 2017-11-22 | Montres Breguet SA | Uhr mit einem mechanischen Hochfrequenzuhrwerk |

| EP2407830B1 (de) * | 2010-07-15 | 2014-11-05 | Rolex Sa | Uhr |

| CN103097965B (zh) | 2010-07-19 | 2015-05-13 | 尼瓦洛克斯-法尔股份有限公司 | 具有弹性枢轴的振荡机构和用于传递能量的可动元件 |

| EP2413202B1 (de) | 2010-07-30 | 2017-11-15 | ETA SA Manufacture Horlogère Suisse | Verfahren zur Verbesserung der Verschleiss- und Stossfestigkeit einer Uhrwerkskomponente. Verschleiß- und stoßfester Anker für Uhrwerk |

| KR101208560B1 (ko) | 2010-09-03 | 2012-12-05 | 엘지전자 주식회사 | 무선 접속 시스템에서 할당 세컨더리 캐리어의 스캐닝 수행 방법 및 장치 |

| CN103261975A (zh) * | 2010-12-14 | 2013-08-21 | 萧邦科技公司 | 杠杆和具有此种杠杆的擒纵机构 |

| EP2557460A1 (de) * | 2011-08-12 | 2013-02-13 | Nivarox-FAR S.A. | Metallanker mit Polymer-Hörnern |

| EP2574994A1 (de) * | 2011-09-29 | 2013-04-03 | Asgalium Unitec SA | Stimmgabelresonator für ein mechanisches Uhrwerk |

| CN104204966B (zh) * | 2012-03-29 | 2017-02-22 | 尼瓦洛克斯-法尔股份有限公司 | 具有可移动框架的柔性擒纵机构 |

| EP2706416B1 (de) * | 2012-09-07 | 2015-11-18 | The Swatch Group Research and Development Ltd | Flexibler Anker mit konstanter Kraft |

| CH706924A2 (fr) * | 2012-09-07 | 2014-03-14 | Nivarox Sa | Ancre flexible à force constante et échappement muni d'une telle ancre. |

| JP6355102B2 (ja) * | 2013-09-04 | 2018-07-11 | セイコーインスツル株式会社 | 定力装置、ムーブメントおよび機械式時計 |

| EP2863273B1 (de) * | 2013-10-16 | 2016-01-13 | Montres Breguet SA | Hemmungsmechanismus für Uhrwerk einer Armbanduhr |

| CH709291A2 (fr) * | 2014-02-20 | 2015-08-28 | Suisse Electronique Microtech | Oscillateur de pièce d'horlogerie. |

| EP2977830B1 (de) * | 2014-07-23 | 2017-08-30 | Nivarox-FAR S.A. | Uhrhemmungsmechanismus mit konstanter Kraft |

| RU2679927C2 (ru) * | 2014-09-09 | 2019-02-14 | Те Свотч Груп Рисерч Энд Дивелопмент Лтд | Комбинированный резонатор с улучшенной изохронностью |

| EP3021174A1 (de) * | 2014-11-17 | 2016-05-18 | LVMH Swiss Manufactures SA | Monolithischer Uhrregler, Uhrwerk und Uhr mit einem solchem Uhrregler |

| EP3032352A1 (de) | 2014-12-09 | 2016-06-15 | LVMH Swiss Manufactures SA | Uhrregler, Uhrwerk und Uhr mit solch einem Regler |

| CH710537A2 (fr) * | 2014-12-18 | 2016-06-30 | Swatch Group Res & Dev Ltd | Oscillateur d'horlogerie à diapason. |

| CH710524A2 (fr) | 2014-12-18 | 2016-06-30 | Swatch Group Res & Dev Ltd | Résonateur d'horlogerie à lames croisées. |

| EP3254158B1 (de) | 2015-02-03 | 2023-07-05 | ETA SA Manufacture Horlogère Suisse | Isochroner resonator für uhr |

| CH710759A2 (fr) * | 2015-02-20 | 2016-08-31 | Nivarox Far Sa | Oscillateur pour une pièce d'horlogerie. |

| BR112018011994B1 (pt) * | 2015-12-14 | 2022-07-19 | Max-Planck-Gesellschaft Zur Forderung Der Wissenschaften E.V | Derivados solúveis em água de compostos 3,5-difenil-diazólicos, seus usos, e composição |

| PL230779B1 (pl) * | 2016-06-03 | 2018-12-31 | Int Tobacco Machinery Poland Spolka Z Ograniczona Odpowiedzialnoscia | Urządzenie do identyfikacji parametrów fizycznych artykułów prętopodobnych przemysłu tytoniowego |

| US20180025794A1 (en) * | 2016-07-22 | 2018-01-25 | Westinghouse Electric Company Llc | Spray methods for coating nuclear fuel rods to add corrosion resistant barrier |

| US10494323B2 (en) * | 2016-08-15 | 2019-12-03 | Givaudan Sa | Process for the preparation of indanones |

| CH713150A2 (fr) | 2016-11-23 | 2018-05-31 | Eta Sa Mft Horlogere Suisse | Mécanisme régulateur à résonateur rotatif à guidage flexible entretenu par un échappement libre à ancre. |

-

2016

- 2016-11-23 CH CH01544/16A patent/CH713150A2/fr unknown

- 2016-11-23 EP EP16200152.3A patent/EP3327515B1/de active Active

-

2017

- 2017-07-27 CN CN201780072276.2A patent/CN109983409B/zh active Active

- 2017-07-27 WO PCT/EP2017/069039 patent/WO2018099616A2/fr not_active Ceased

- 2017-07-27 EP EP17745179.6A patent/EP3545364B1/de active Active

- 2017-07-27 WO PCT/EP2017/069040 patent/WO2018095594A1/fr not_active Ceased

- 2017-07-27 EP EP17746073.0A patent/EP3545366B1/de active Active

- 2017-07-27 WO PCT/EP2017/069038 patent/WO2018095593A2/fr not_active Ceased

- 2017-07-27 WO PCT/EP2017/069041 patent/WO2018095595A1/fr not_active Ceased

- 2017-07-27 JP JP2019526552A patent/JP6931392B2/ja active Active

- 2017-07-27 CN CN201780072304.0A patent/CN110023845B/zh active Active

- 2017-07-27 EP EP17745180.4A patent/EP3545365B1/de active Active

- 2017-07-27 US US16/344,567 patent/US11619909B2/en active Active

- 2017-07-27 JP JP2019527346A patent/JP6931395B2/ja active Active

- 2017-07-27 EP EP17749674.2A patent/EP3545367B1/de active Active

- 2017-07-27 US US16/347,286 patent/US11520289B2/en active Active

- 2017-07-27 WO PCT/EP2017/069037 patent/WO2018095592A1/fr not_active Ceased

- 2017-07-27 CN CN201780072327.1A patent/CN110023846B/zh active Active

- 2017-07-27 US US16/462,801 patent/US11487245B2/en active Active

- 2017-07-27 JP JP2019547760A patent/JP6828179B2/ja active Active

- 2017-07-27 JP JP2019527338A patent/JP6931394B2/ja active Active

- 2017-07-27 CN CN201780072284.7A patent/CN109983410B/zh active Active

- 2017-07-27 EP EP17752312.3A patent/EP3545368B1/de active Active

- 2017-07-27 WO PCT/EP2017/069043 patent/WO2018095596A2/fr not_active Ceased

- 2017-07-27 EP EP17745178.8A patent/EP3545363B1/de active Active

- 2017-11-07 JP JP2019547766A patent/JP6828180B2/ja active Active

- 2017-11-07 EP EP17794727.2A patent/EP3545369B1/de active Active

- 2017-11-07 US US16/462,812 patent/US11467537B2/en active Active

- 2017-11-07 WO PCT/EP2017/078497 patent/WO2018103978A2/fr not_active Ceased

- 2017-11-07 CN CN201780072329.0A patent/CN110023847B/zh active Active

- 2017-11-22 CN CN201780072330.3A patent/CN110235064B/zh active Active

- 2017-11-22 US US16/343,509 patent/US11493882B2/en active Active

- 2017-11-22 EP EP17803933.5A patent/EP3545370B1/de active Active

- 2017-11-22 WO PCT/EP2017/080121 patent/WO2018095997A2/fr not_active Ceased

- 2017-11-22 JP JP2019524176A patent/JP6810800B2/ja active Active

-

2019

- 2019-05-21 US US16/418,697 patent/US11675312B2/en active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH703464A2 (fr) * | 2010-07-19 | 2012-01-31 | Nivarox Sa | Mécanisme oscillant à pivot élastique. |

| WO2015097066A2 (fr) * | 2013-12-23 | 2015-07-02 | Eta Sa Manufacture Horlogère Suisse | Mouvement horloger mecanique a echappement magnetique |

| CH710025A2 (fr) * | 2013-12-23 | 2016-02-29 | Eta Sa Manufacture Horlogère Suisse | Mouvement horloger mécanique à échappement magnétique. |

Also Published As

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3545370B1 (de) | Rotierender resonator mit flexiblem führungssystem auf basis einer abgelösten ankerhemmung | |

| EP3029530B1 (de) | Wirbelmechanismus | |

| EP3182216B1 (de) | Gekoppelte oszillatoren einer uhr | |

| CH709328B1 (fr) | Echappement, mouvement de pièce d'horlogerie et pièce d'horlogerie. | |

| CH714361A2 (fr) | Résonateur rotatif à guidage flexible entretenu par un échappement libre à ancre. | |

| CH713530A2 (fr) | Echappement, mouvement de pièce d'horlogerie et pièce d'horlogerie. | |

| EP3451073B1 (de) | Uhrwerkoszillator mit flexiblen führungen mit grosser winkelförmiger laufbahn | |

| WO2025012772A1 (fr) | Mécanisme horloger | |

| EP3761122B1 (de) | Drehteil für uhrhemmung, entsprechender hemmungsmechanismus und entsprechendes uhrenteil | |

| CH713531A2 (fr) | Echappement, mouvement de pièce d'horlogerie et pièce d'horlogerie. | |

| EP3781993B1 (de) | Frei direkthemmung mechanismus für uhren. | |

| EP3663868A1 (de) | Uhrwerk, das ein tourbillon mit einem festen magnetischen rad umfasst | |

| EP3561603A1 (de) | Reguliermechanismus einer uhr mit verbundenen resonatoren | |

| CH710487B1 (fr) | Mécanisme de tourbillon pour mouvement horloger. | |

| CH717573A2 (fr) | Mouvement d'horlogerie comportant un résonateur à masse inertielle à guidage flexible et un mécanisme d'échappement. | |

| CH717575A2 (fr) | Mouvement d'horlogerie comportant un résonateur à masse inertielle à guidage flexible et un mécanisme d'échappement. | |

| CH717580A2 (fr) | Mouvement d'horlogerie comportant un résonateur à masse inertielle et un mécanisme d'échappement. | |

| CH717572A2 (fr) | Mouvement d'horlogerie comportant un résonateur à masse inertielle à guidage flexible et un mécanisme d'échappement. | |

| CH714927A2 (fr) | Mécanisme régulateur d'horlogerie à résonateurs articulés. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: UNKNOWN |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20190624 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20210923 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230701 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 602017085386 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: G04B0015080000 Ipc: G04B0031000000 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: G04B 17/26 20060101ALN20240620BHEP Ipc: G04B 18/02 20060101ALI20240620BHEP Ipc: G04B 17/04 20060101ALI20240620BHEP Ipc: G04B 17/28 20060101ALI20240620BHEP Ipc: G04B 15/08 20060101ALI20240620BHEP Ipc: G04B 15/14 20060101ALI20240620BHEP Ipc: G04B 31/00 20060101AFI20240620BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20240705 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602017085386 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20241022 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20241122 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20241121 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20241201 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20241009 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1731239 Country of ref document: AT Kind code of ref document: T Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250209 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250110 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602017085386 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241122 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20241130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241009 |

|

| 26N | No opposition filed |

Effective date: 20250710 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241122 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: U11 Free format text: ST27 STATUS EVENT CODE: U-0-0-U10-U11 (AS PROVIDED BY THE NATIONAL OFFICE) Effective date: 20251201 |