EP3379552B1 - Élément d'actionnement destiné au déplacement d'un élément de construction mobile - Google Patents

Élément d'actionnement destiné au déplacement d'un élément de construction mobile Download PDFInfo

- Publication number

- EP3379552B1 EP3379552B1 EP17162441.4A EP17162441A EP3379552B1 EP 3379552 B1 EP3379552 B1 EP 3379552B1 EP 17162441 A EP17162441 A EP 17162441A EP 3379552 B1 EP3379552 B1 EP 3379552B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- actuating element

- actuating

- threaded body

- component

- contact

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H3/00—Mechanisms for operating contacts

- H01H3/32—Driving mechanisms, i.e. for transmitting driving force to the contacts

- H01H3/42—Driving mechanisms, i.e. for transmitting driving force to the contacts using cam or eccentric

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B15/00—Other details of locks; Parts for engagement by bolts of fastening devices

- E05B15/04—Spring arrangements in locks

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B17/00—Accessories in connection with locks

- E05B17/22—Means for operating or controlling lock or fastening device accessories, i.e. other than the fastening members, e.g. switches, indicators

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B63/00—Locks or fastenings with special structural characteristics

- E05B63/0056—Locks with adjustable or exchangeable lock parts

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H13/00—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch

- H01H13/02—Details

- H01H13/12—Movable parts; Contacts mounted thereon

- H01H13/14—Operating parts, e.g. push-button

- H01H13/18—Operating parts, e.g. push-button adapted for actuation at a limit or other predetermined position in the path of a body, the relative movement of switch and body being primarily for a purpose other than the actuation of the switch, e.g. door switch, limit switch, floor-levelling switch of a lift

- H01H13/186—Operating parts, e.g. push-button adapted for actuation at a limit or other predetermined position in the path of a body, the relative movement of switch and body being primarily for a purpose other than the actuation of the switch, e.g. door switch, limit switch, floor-levelling switch of a lift wherein the pushbutton is rectilinearly actuated by a lever pivoting on the housing of the switch

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H3/00—Mechanisms for operating contacts

- H01H3/02—Operating parts, i.e. for operating driving mechanism by a mechanical force external to the switch

- H01H3/16—Operating parts, i.e. for operating driving mechanism by a mechanical force external to the switch adapted for actuation at a limit or other predetermined position in the path of a body, the relative movement of switch and body being primarily for a purpose other than the actuation of the switch, e.g. for a door switch, a limit switch, a floor-levelling switch of a lift

- H01H3/161—Operating parts, i.e. for operating driving mechanism by a mechanical force external to the switch adapted for actuation at a limit or other predetermined position in the path of a body, the relative movement of switch and body being primarily for a purpose other than the actuation of the switch, e.g. for a door switch, a limit switch, a floor-levelling switch of a lift for actuation by moving a closing member, e.g. door, cover or lid

- H01H3/163—Operating parts, i.e. for operating driving mechanism by a mechanical force external to the switch adapted for actuation at a limit or other predetermined position in the path of a body, the relative movement of switch and body being primarily for a purpose other than the actuation of the switch, e.g. for a door switch, a limit switch, a floor-levelling switch of a lift for actuation by moving a closing member, e.g. door, cover or lid associated with locking or manipulating means of the closing member

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H3/00—Mechanisms for operating contacts

- H01H3/22—Power arrangements internal to the switch for operating the driving mechanism

- H01H3/30—Power arrangements internal to the switch for operating the driving mechanism using spring motor

- H01H3/3042—Power arrangements internal to the switch for operating the driving mechanism using spring motor using a torsion spring

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B63/00—Locks or fastenings with special structural characteristics

- E05B63/18—Locks or fastenings with special structural characteristics with arrangements independent of the locking mechanism for retaining the bolt or latch in the retracted position

- E05B63/20—Locks or fastenings with special structural characteristics with arrangements independent of the locking mechanism for retaining the bolt or latch in the retracted position released automatically when the wing is closed

Definitions

- the invention relates to an actuating element according to claim 1. Furthermore, the invention relates to a system according to claim 13.

- Switches for position detection of movable components are basically known from the prior art.

- microswitches can be used as such switches.

- a microswitch e.g. B. in door locks

- an actuating element is required, with its relative movement to a switching flag of the microswitch, a switching signal is generated.

- the more exact the size of the microswitch decreases (miniaturization) the greater the demands placed on the positioning accuracy of the actuating element.

- the adjustability of the switching position of the actuating element is imperative.

- the distance between the actuating element and the microswitch can be functionally critical.

- the actuating element In the case of known actuating elements, the actuating element is displaced until the correct switching point is reached at the switch in order to set the switching point. The actuating element is then fixed in this position. A later readjustment is difficult, sometimes impossible.

- the position of the microswitch In the case of rigid, non-adjustable actuating elements, the position of the microswitch can in turn be changed, but this is not possible in the case of microswitches fixed to the circuit board. In this case, the switch flags are adjusted.

- Some actuating elements are designed to be dimensionally elastic in order to enable tolerance compensation in the switching position of the actuating element, as a result of which the adjustability of the switching position is no longer necessary. However, it is disadvantageous that the microswitch can be damaged by excessive deformation of the actuating element.

- a movable component to which the actuating element is attached is referred to as a movable component.

- the movable element that is to be moved by the movable component with the aid of the actuating element is referred to as a movable component.

- An actuator for actuating a switch flag of a switch is from the DE-A-2815888 known.

- Features and details that are described in connection with the actuating element according to the invention apply, of course, also in connection with the system according to the invention and vice versa, so that with respect to the disclosure of the individual aspects of the invention, reference is always made or can be made to one another.

- the object is also achieved by a system with an actuating element according to the invention, in particular with an actuating element according to one of claims 1 to 12.

- a lock with a system according to the invention is also placed under protection.

- the lock according to the invention can comprise an actuating element according to the invention, in particular an actuating element according to one of claims 1 to 12, and / or an inventive system, in particular with a system according to one of claims 13 to 15.

- an actuating element for moving a movable component in particular a switching flag of a switch, which is formed with a threaded body for fastening the actuating element to a movable component and a contact element for moving the movable component, the threaded body being designed for adjusting the contact element ,

- the switch can be designed as a microswitch.

- the switch can be used to detect the position of the movable component.

- the movable component can move a movable component.

- the movable component and the movable component z. B. be part of a transmission.

- a point at which the movable component contacts the movable component can be adjustable by the adjustment. Due to the adjustment, the position at which the movable component contacts the movable component can be changed, in particular shifted, in its spatial position. The spatial extent of the point at which the movable component contacts the movable component preferably remains unchanged.

- the idea of the invention is to design the actuating element with a threaded body and at least one, in particular terminal, contact element, the contact element projecting beyond the threaded body of the actuating element.

- the threaded body can be formed from a spring wire or from a monolithic body, for example made of plastic, with an external thread.

- the threaded body can serve as a screw insert for fastening the actuating element, for example in a threaded receptacle, to the movable component.

- the threaded body can thus be screwed to the movable component, the position of which can be detected.

- the contact element can extend from the threaded body axially or at the end and preferably eccentrically to the threaded body.

- the contact element is in the screwed-in state from one end of the threaded body.

- the contact element lies in the actuation area of a switching flag of a microswitch.

- the adjustment can e.g. B. take place in order to ensure a simple and precise setting of the switching point or switching range on the switch, for example on the microswitch. It is also advantageous that a subsequent readjustment of the switching point or switching range on the switch is easily possible at any time. It is also possible to create an exact translation or a specific lever by adjusting.

- the threaded body can also advantageously have a pretension in an axial and / or radial direction in order to secure the actuating element in the threaded receptacle on the movable component.

- the threaded body can have a self-locking in order to hold the actuating element in the set position with respect to the switch.

- the actuating element according to the invention is a simple, robust component and has a long service life. This can be ensured in particular by the elastic properties of the contact element.

- the switch can remain in operation for a long time without problems.

- the actuating element can be formed from a spring wire.

- a screw insert for example for threading, can thus be provided on the movable component with simple means and from inexpensive materials.

- the Spring wire can form the threaded body through windings and the contact element through a protruding end, which can extend in an axial direction of the threaded body beyond the threaded part of the spring wire.

- the turns in the thread body can correspond to a counter contour in the thread receptacle.

- Such an actuating element can simply be screwed to the movable component.

- the outer diameter of the threaded body can also be selected so that it is oversized compared to the thread holder.

- the pitch of the turns can be selected to be smaller or greater than the pitch of the turns in the thread receptacle. Due to the radial and / or axial flexibility of the wound thread body, its turns can nestle against the thread grooves of the thread receptacle when screwed in. A spring-elastic pretension can thus be provided in the threaded body of the actuating element in order to achieve self-locking of the screw insert in the set position on the movable component by means of static friction. This allows the set position of the contact element to be permanently secured. A subsequent securing of the set position of the contact element or fixing of the contact element is advantageously no longer necessary.

- the actuating element can be formed in one piece, in particular monolithically. The manufacture, the fastening and the handling of the actuating element can thus be simplified.

- a web running transverse to an axis of rotation of the threaded body can be provided as an assembly aid for attaching the threaded body to the movable component.

- the transverse web has the advantage that a user or a fitter can comfortably grasp this web in order to screw the threaded body into the threaded receptacle on the movable component.

- the thread receptacle can be designed as a through opening. This can make it easier to grip the web.

- the web can be locked in a corresponding contour in the thread receptacle.

- the latching can, for. B. may be provided on a bottom of the thread receiving means.

- the thread receptacle is designed as a blind hole to secure the set position of the contact element.

- the contact element is designed to be resilient.

- the contact element can yield elastically during the movement of the movable component. This can prevent breakage.

- the web can be formed between the threaded body and the contact element.

- the contact element can thus in particular connect to the web.

- the threaded body is located between the contact element and the web.

- the wire of the threaded body at one end of the threaded body into the wire of the web and the wire of the threaded body at the other end of the threaded body into the wire of the contact element.

- the contact element extends partially into the threaded body.

- the contact element can be passed through from one end to another end of the threaded body in the axial direction of the threaded body and can extend over the threaded body at the other end.

- the contact element may have been handled accordingly. The advantage can thus be achieved that the contact element can be made longer in order to allow a particularly flexible cushioning of the contact element to protect the actuating element in addition to a precise adjustment of the position.

- a predetermined breaking point can be provided between the threaded body and the web.

- the web can be formed at one end and the contact element at another end of the threaded body, wherein the threaded receptacle can be designed as a through hole with an internal thread.

- the web can be separated, for example broken off, after the threaded body has been screwed into the movable component, so that it no longer stands in the way after the actuating element has been fastened to the movable component, and in order to possibly carry out a connecting screw through the threaded body to the movable component can.

- the contact element can be aligned axially and / or eccentrically to the threaded body.

- the contact element aligned axially to the threaded body can advantageously protrude from the threaded body in order to contact the movable component, in particular in order to get into the switching area of the switch.

- the advantage of a contact element aligned eccentrically to the threaded body is that its relative position to the movable component, in particular to the switch lug of the switch, can be made possible by simply rotating the threaded body in the threaded receptacle on the movable component.

- the contact element can have a contact area for moving the movable component.

- the contact element with the contact area touches the switch during the actuation process. Through the contact area z. B. a switch flag of the switch can be moved.

- the contact element can be formed in a straight line.

- the contact area can be formed in a straight line.

- the contact area is preferably formed laterally.

- the contact area is provided deviating from an end of the contact element facing away from the threaded body.

- the contact area can be arranged outside a tip of the contact element. In the event that the contact element yields elastically when the movable component moves, the contact element can be elastically bent laterally.

- the contact area is preferably not perpendicular to the axis of rotation of the threaded body.

- z. B. include a straight line through the contact area and the axis of rotation an angle between 0 ° and 20 °, preferably between 0 ° and 10 °, particularly preferably between 0 ° and 5 °.

- the contact area and the axis of rotation are particularly preferably aligned parallel to one another. This makes z. B. an adjustment of the actuating element possible without reducing the contact with the movable component, in particular with the switching flag.

- the actuating element is preferably provided to move the movable component, in particular to actuate the switch, by a lateral movement.

- the actuating element does not move in the direction of the axis of rotation for moving the movable component.

- a movement of the actuating element for moving the movable component, in particular for actuating the switch, can take place in deviation from the direction of the axis of rotation.

- the direction of movement of the actuating element for moving the movable component is particularly preferably orthogonal to the axis of rotation.

- the The course of movement of the actuating element can be linear or curved. In the first case, the movable component in particular moves linearly with the actuating element, in the second case the movable component is pivoted.

- the switch in particular the switching flag, has a switching area which the contact element touches or comes closest to when the switch is actuated. Provision can be made for the spatial position of the switching area to be changed, in particular shifted, by adjusting the actuating element. A changed switching position of the actuating element can therefore result in a changed switching range of the switch.

- the spatial size of the switching region preferably remains unchanged when the contact element is adjusted.

- the threaded body can be designed such that an axial and / or radial internal prestress can be built up in the threaded body in the attached state on the movable component.

- a radial internal preload in the threaded body can be set by the choice of the outer diameter of the threaded body, which can have an oversize compared to the inner diameter of the threaded receptacle on the movable component.

- An axial internal prestress in the threaded body can be set by the choice of the pitch of the turns of the threaded body, which can differ from the pitch of the turns in the threaded receptacle.

- a self-locking of the actuating element in the thread holder on the movable component can be achieved by elastic deformation of the threaded body in the thread holder.

- the advantage can thus be achieved that the set switching position of the contact element with respect to the contact lug on the switch can be reliably secured without a separate securing of the contact element.

- the windings in the threaded body can bear against one another in such a way that a pre-tension can be realized in the threaded body before screwing into the threaded receptacle.

- the threaded body can have a surface structure in order to secure the threaded body on the movable component in the fastened state.

- the surface structure can be designed as a roughened and / or structured surface on the threaded body.

- the threaded body can be firmly attached to the threaded receptacle, in particular by an adhesive.

- an adhesive for example, a varnish can be applied to the threaded body, which contains microcapsules with adhesive when applied. The microcapsules can burst in the thread holder and release the adhesive.

- the thread body can be fixed to the thread receptacle with the aid of the adhesive from the microcapsules. As a result, the threaded body can be fastened particularly evenly in the thread receptacle.

- the actuating element in the context of the invention, it is also possible for the actuating element to be formed from an electrically conductive material.

- the actuating element can serve as an electrical connection for the transmission of electrical energy and / or as equipotential bonding.

- An electrical connection between the movable component and the movable component can be made possible in a simple manner, at least when the movable component is moved.

- the actuating element can have an electrically insulating casing.

- An electrically insulating sheathing can be advantageous in order to be able to grip the actuating element safely during assembly and to protect the surrounding components from unwanted current transmission during operation of the actuating element.

- the actuating element can be formed from a dielectric material.

- Such an actuating element can be advantageous for mechanically actuated switches, for example pressure switches.

- the actuating element can be formed from a temperature-dependent shape memory material.

- Such an actuating element can advantageously not only transmit elastic deformation, but also forces. It may be possible that the actuator can be heated and eventually deformed by the application of electricity.

- the actuating element can be formed from a thermally conductive material. This has the advantage that the actuating element can be used to generate a thermal bridge between two components.

- the actuating element can be formed from a hollow wire, wherein in particular the actuating element can be designed to receive a medium.

- a tubular channel can thus be formed in the actuating element in order to be able to transfer liquid and / or gaseous media between two components.

- the object according to the invention is achieved by a system, in particular for a door lock, according to claim 13.

- the door lock can in particular be a self-locking panic lock.

- the system is designed with a stationary component, at least one movable component, at least one movable component, in particular the switching flag of a switch, an actuating element for moving the movable component being provided, which is provided with a threaded body for fastening the actuating element in a threaded receptacle on movable component and a contact element for moving the movable component.

- the movable component can be a linearly displaceable component. In particular, however, it can be provided that the movable component is a pivotable component.

- the movable component is z. B. pivoted to move the movable component.

- a first movable component can be a trap, in particular an auxiliary trap, and / or a second movable component can be a nut, wherein in particular the actuating element can be designed as described above.

- the stationary component can be a fixed housing and / or a faceplate.

- the actuating element according to the invention can thus be used for function monitoring of the door lock.

- the actuating element according to the invention is advantageously suitable for detecting the position of a linearly displaceable latch, a linearly displaceable auxiliary latch, and for detecting the position of a rotatable nut, for example in comparison to the stationary component.

- the actuating element according to the invention can advantageously be used universally. Conceivable uses for the actuating element according to the invention are in all mechatronic products in which, due to lack of space, the adjustability of microswitches with the known solutions is only possible with considerable effort, for. B. TV, matrix, T ⁇ FF, etc. With the free-form terminal element there are diverse applications and uses of the actuating element, for example.

- the actuating element according to the invention is advantageous in various locks, including: motorized panic lock, mechanically actuated panic lock with electrical contacts, mechanically actuated panic lock with an electrical connection function, mechanically actuated lock with electrical connection function.

- the system according to the invention can also be used in lock components on single and double-leaf doors, on full-leaf doors and profile doors with different backset dimensions and faceplate designs.

- Figure 1 shows an actuating element 10 according to the invention for a switch 21, 22, in particular for a microswitch 21, 22, which is subsequently in the Figures 2a and 2b will be shown.

- the switch 21, 22 is used for position detection of a movable component 1, 2.

- Die Figure 1 also shows the movable component 1, 2, in which a threaded receptacle 1a, 2a is formed for the actuating element 10.

- the actuating element 10 is formed with a threaded body 11 for screwing the actuating element 10 into the threaded receptacle 1a, 2a on the movable component 1, 2 and a contact element 12 for actuating the switch 21, 22.

- the contact element 12 comes into contact with a switch lug 21a, 22a of the switch 21, 22.

- the precise positioning of the contact element 12 for actuating the switch 21, 22 is functionally essential.

- the threaded body 11 is designed to change the switching position of the contact element 12 with respect to the position of the contact element 12 by rotating the threaded body 11 in the thread receptacle 1a, 2a Switch lug 21a, 22a to be set precisely, ie in order to adjust the contact element 12 in an adjustment direction J.

- the direction of rotation and the direction of adjustment are below in the Figure 2b shown.

- the Figure 2a shows a microswitch 21, 22, which has a switching flag 21a, 22a.

- the microswitch 21, 22 can be actuated, for example, with the aid of a conventional actuating element 10 'when the actuating element 10' is moved downwards relative to the switching flag 21a, 22a.

- known actuating elements 10 ' the actuating element 10' is shifted closer to the switching lug 21a, 22a until the actuating element 10 'can touch the switching lug 21a, 22a while driving past in order to set the switching point x.

- the actuating element 10 ' is then fixed in this position on the movable component 1, 2. Such positioning of the actuator 10 'is difficult and inaccurate. In addition, a later readjustment of the actuating element 10 'is also difficult if not impossible.

- the Figure 2b shows the thread holder 1a, 2a on the movable component 1, 2 for the actuating element 10 according to the invention in a sectional view.

- the switch 21, 22 is positioned above the threaded receptacle 1a, 2a, which has a distance x between the switching flag 21a, 22a and a corresponding contact 21.4, 22.4 on the switch 21, 22. By closing this distance x, the switches 21, 22 can be actuated or closed. In microswitches 21, 22, this distance x is very small and is, for example, less than 3 mm.

- the actuating element 10 according to the invention can be set very precisely. When the threaded body 11 is rotated in the direction of rotation D, the switching position of the contact element 12 on the switching lug 21a, 22a can be set precisely in the adjustment direction J, so that this distance x can be closed reliably.

- the Figure 2c shows the actuating element 10 according to the invention, which overcomes the disadvantages known from the prior art.

- the Figure 2c furthermore shows that the contact element 12 is aligned axially and eccentrically to the threaded body 11, so that the contact element 12 can reach the switching area x of the switch 21, 22 in the adjustment direction J.

- a subsequent readjustment of the switching point x on the switch 21, 22 is advantageously possible at any time in the sense of the invention, the switching point x in the Figure 2b is shown.

- the actuating element 10 can be formed from a spring wire and can be screwed in as a screw insert in the threaded receptacle 1a, 2a on the movable component 1, 2, the threaded receptacle 1a, 2a in the Figure 1 is shown.

- the spring wire forms the threaded body 11 by means of windings and the contact element 12 by a protruding end which extends in an axial direction of the threaded body 11 beyond the threaded part. It is conceivable that the spring wire can have a diameter of approximately 0.4 mm. Then a slope h2 between two adjacent turns can be approximately 0.8 mm.

- the actuating element 10 can be made from a monolithic body with an external thread.

- the windings in the threaded body 11 can correspond to a counter-contour in the threaded receptacle 1a, 2a, which has corresponding grooves for the turns of the threaded body 11.

- the outer diameter d2 of the threaded body 11 can also have an oversize compared to an inner diameter d1 of the grooves in the threaded receptacle 1a, 2a, as a result of which the turns of the threaded body 11 can nestle into the corresponding grooves in the threaded receptacle 1a, 2a.

- the pitch h2 between the turns can be selected to be larger or smaller than the pitch h1 of the furrows in the thread receptacle 1a, 2a.

- Self-locking of the actuating element 10 in the set switching position of the contact element 12 can thus be made possible.

- This The effect is in interaction with the dimensions d1, h1 of the thread holder 1a, 2b in detail in the Figure 6a shown.

- a resilient preload V can thus be set in the threaded body 11 of the actuating element 10.

- the windings in the threaded body 11 can bear against one another in such a way that a pre-tension V can be realized in the threaded body 11 before screwing into the threaded receptacle 1a, 2a.

- the set switching position of the contact element 12 Due to the self-locking of the actuating element 10 in the set position on the movable component 1, 2, the set switching position of the contact element 12 can be permanently secured. Subsequent fixing of the set switching position of the contact element 12, as is the case, for example, in the conventional actuating element 10 ' Figure 2a is necessary, is no longer necessary according to the invention.

- the actuator 10 according to the Figure 2c is also formed in one piece, which can facilitate its manufacture, attachment and handling.

- a web 13 extending transversely to an axis of rotation of the threaded body 11 can be provided on the threaded body 11 as an assembly aid for attaching the threaded body 11 to the movable component 1, 2.

- a user or a mechanic can comfortably grasp this web 13 in order to screw the threaded body 11 into the threaded receptacle 1a, 2a.

- the contact element 12 can be formed at one end and the web 13 at another end of the threaded body 11.

- the web 13 can be detachable from the threaded body 11 by a predetermined breaking point 13.1, for example after the actuating element 10 has been mounted on the movable component 1, 2. It is also conceivable that a locking screw, not shown, can be screwed into the threaded body 11 in order to to secure the actuating element 10 as an additional protection against rotation on the movable component 1, 2. Alternatively, the web 13 can be unwound from one end of the threaded body 11 and pass continuously into the contact element 12, as shown in FIGS Figures 3 to 5c is shown below. Such a web 13 remains on the actuating element 10 during operation.

- the web 13 can also serve as a locking element, which is in a corresponding locking guide on the floor of the threaded receptacle 1a, 2a can latch in order to reliably hold the set position of the contact element 12 during operation of the actuating element 10.

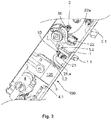

- the Figure 3 shows a system 100 according to the invention for a lock 101, for example for a self-locking panic lock 101.

- the actuating element 10 according to the invention is used therein for position detection of at least one auxiliary latch 1.1 and one latch 2.1.

- the system 100 has a stationary component 3, for example in the form of a cuff 3, with respect to which the position detection of the auxiliary trap 1.1 and the trap 2.1 takes place.

- a stationary component 3 any fixed part of the panic lock 101 can also be understood, such as. B. a housing or a housing part.

- Microswitches 21, 22 are used for position detection.

- the microswitches 21, 22 each have a switching flag 21a, 22a, which is actuated by the contact element 12 when the actuating element 10 drives past.

- the first actuating element 10 according to the invention is attached to the movable component 1 of the auxiliary latch 1.1, which is moved linearly.

- the second actuating element 10 according to the invention is fastened to a rotatable nut 2.

- the panic lock 101 has a locking cylinder 4, it also being conceivable that a third actuating element 10 according to the invention can be provided for position detection of the locking cylinder 4.

- the panic lock 101 is shown in a state in which the panic lock 101 is unlocked, a bolt 4.1 is inserted into a lock housing behind the faceplate 3, a corresponding door, not shown, is open and the nut 2 is in an actuated or tightened position located.

- the Figures 4a and 4b show in an enlarged view the area from the Figure 3 around the first movable component 1, which is connected to the auxiliary trap 1.1, from above and from below.

- a plateau 1.3 is provided on the first movable component 1, which is fastened to the movable component 1 with the aid of a bolt 1.2.

- the plateau 1.3 moves with the movable component 1.

- a thread holder 1a is provided for the threaded body 11 of the first actuating element 10.

- the first Microswitch 21 is attached to a circuit board (not shown) with the help of contacts 21.1, 21.2, 21.3.

- the extended position of the auxiliary latch 1.1 is detected, the terminal contact element 12 abutting the switching lug 21a and thus actuating the first microswitch 21.

- the auxiliary latch 1.1 is pressed back into the lock housing behind the faceplate 3 by the door frame.

- the actuating element 10 moves back with the first movable component 1 and releases the switching lug 21a of the switch 21.

- the switch 21 is thus opened, whereby a retracted position of the auxiliary latch 1.1 can be detected.

- the auxiliary latch 1.1 moves out of a corresponding opening in the faceplate 3 out of the lock housing. In this position, the switch 21 is operated again.

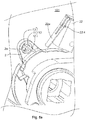

- the Figures 5a and 5b show in an enlarged view the area from the Figure 3 around the second movable component 2 in the form of a nut 2 each from above and from below.

- a thread receptacle 2a for the threaded body 11 of the second actuating element 10 is provided in the nut 2.

- the second microswitch 22 is fastened to a circuit board (not shown) with the aid of the contacts 22.1, 22.2, 22.3.

- the nut 2 is tightened in the shown state of the panic lock 101, in which the panic lock 101 is unlocked.

- the terminal contact element 12 is located at a distance from the switching lug 22a, as a result of which the second microswitch 22 is opened.

- the nut 2 is pivoted clockwise, as a result of which the contact element 12 again comes into the switching region x on the switching lug 22a in order to actuate the second microswitch 22. A rest position of the nut 2 can thus be detected.

- the Figure 5c essentially shows the area from the Figure 5a , wherein the actuating element 10 according to the invention is removed from the thread holder 2a on the nut 2. It can be seen that the actuating element 10 has a threaded body 11 with a developed transverse web 13 and a subsequent one, which runs through the threaded body 11 and out of which Threaded body 11 has extending contact element 12. In the exemplary embodiment of the invention shown, the web 13 is located between the threaded body 11 and the contact element 12. Thus, the contact element 12 can have a longer actuating arm. Alternatively, however, it is conceivable that the transverse web 13 and the contact element 12 can be unwound at different ends of the threaded body 11, as is shown, for example, in FIG Figure 1 is shown.

- the Figure 6a shows again in detail how an internal preload V in the threaded body 11 can be set, namely by an excess of the outer diameter d2 of the threaded body 11 with respect to the inner diameter d1 in the grooves in the thread receptacle 1a, 2a on the movable component 1, 2, or by a deviation of the slope d2 between the turns of the threaded body 11 from the slope d1 of the turns in the thread receptacle 1a, 2a.

- the self-locking of the actuator 10 can be realized in the set position.

- the threaded body 11 can have a surface structure 11.1 in order to secure the threaded body 11 on the movable component 1, 2 by static friction in the fastened state. It is conceivable that the surface structure 11.1 can be formed as a roughened and / or structured surface on the threaded body 11.

- the actuating element 10 can be formed from an electrically conductive material, for example to enable an electrical connection between the switch 21, 22 and the movable component 1, 2. It is conceivable that the actuating element 10 can have an electrically insulating casing 15, as is shown in FIG Figure 6c is shown. The electrically insulating sheath 15 can prevent unwanted current transmission from the actuating element 10. Alternatively, however, it is also conceivable that the actuating element 10 can be formed from a non-conductive material.

- an optical and / or magnetic sensor element 14 for interacting with an optical and / or magnetic sensor can be attached to the contact element 12 as an alternative switch 21, 22.

- the actuating element 10 can be formed from a hollow wire, wherein a tubular channel 16 can be formed in the actuating element 10 in order to be able to transfer liquid and / or gaseous media between two components.

- the embodiment of the invention is not limited to the exemplary embodiments of the invention described above. Rather, a large number of variants are conceivable in which form and from which materials the actuating element 10 can be formed. Materials such as a temperature-dependent shape memory material and / or a thermally conductive material etc. are conceivable.

- the actuating element 10 can be used in all mechatronic, optical and / or magnetic systems with movable components for their position detection.

Landscapes

- Engineering & Computer Science (AREA)

- Computer Security & Cryptography (AREA)

- Structural Engineering (AREA)

- Push-Button Switches (AREA)

Claims (15)

- Elément d'actionnement (10) pour l'actionnement d'un élément de composant (21a, 22a) actionnable,

tout particulièrement une lame de commutation (21a, 22a) d'un commutateur (21, 22), avec un élément de contact (12) pour l'actionnement de l'élément de composant (21a, 22a) actionnable,

caractérisé par un corps de filetage (11) pour l'attachement de l'élément d'actionnement (10) sur un composant (1, 2) mobile,

dans lequel le corps de filetage (11) est aménagé pour l'ajustage de l'élément de contact (12). - Elément d'actionnement (10) selon la revendication 1,

caractérisé en ce

que l'élément d'actionnement (10) est aménagé d'un fil d'acier pour ressort,

dans lequel tout particulièrement l'élément d'actionnement (10) est aménagé intégralement. - Elément d'actionnement (10) selon la revendication 1 ou 2,

caractérisé en ce

qu'une barrette (13) s'étendant transversalement à un axe de rotation du corps de filetage (11) est prévue comme aide au montage pour monter le corps de filetage (11) sur le composant (1, 2) mobile,

dans lequel tout particulièrement la barrette (13) est aménagée entre le corps de filetage (1) et l'élément de contact (12). - Elément d'actionnement (10) selon la revendication 3,

caractérisé en ce

qu'un point de rupture programmé (13.1) est prévu entre le corps de filetage (11) et la barrette (13). - Elément d'actionnement (10) selon l'une des revendications précédentes,

caractérisé en ce

que l'élément de contact (12) est orienté axialement et/ou excentriquement par rapport au corps de filetage (11). - Elément d'actionnement (10) selon l'une des revendications précédentes,

caractérisé en ce

que l'élément de contact (12) est aménagé élastiquement souple, tout particulièrement que l'élément de contact (12) cède élastiquement lors de l'actionnement de l'élément de composant (21a, 22a) actionnable. - Elément d'actionnement (10) selon l'une des revendications précédentes,

caractérisé en ce

que l'élément de contact (12) comporte une région de contact latérale pour l'actionnement de l'élément de composant (21a, 22a) actionnable. - Elément d'actionnement (10) selon l'une des revendications précédentes,

caractérisé en ce

que le corps de filetage (11) est aménagé de telle façon que, dans la condition attachée sur le composant (1, 2) mobile, une prétension axiale et/ou radiale intérieure (V) est établissable dans le corps de filetage (11). - Elément d'actionnement (10) selon l'une des revendications précédentes,

caractérisé en ce

que le corps de filetage (11) présente une texture à la surface (11.1) pour sécuriser, dans la condition attachée, le corps de filetage (11) sur le composant mobile (1, 2). - Elément d'actionnement (10) selon l'une des revendications précédentes,

caractérisé en ce

que l'élément d'actionnement (10) est aménagé d'une matière électriquement conductible,

dans lequel tout particulièrement l'élément d'actionnement (10) présente un enrobage (15) électriquement isolant,

ou que l'élément d'actionnement (10) est aménagé en une matière diélectrique. - Elément d'actionnement (10) selon l'une des revendications précédentes,

caractérisé en ce

que l'élément d'actionnement (10) est aménagé en une matière à mémoire de forme dépendant de la température,

et/ou en ce que l'élément d'actionnement (10) est aménagé en une matière thermiquement conductible. - Elément d'actionnement (10) selon l'une des revendications précédentes,

caractérisé en ce

que l'élément d'actionnement (10) est aménagé d'un fil d'acier creux,

dans lequel tout particulièrement l'élément d'actionnement (10) est aménagé pour la réception d'un médium. - Système (100) pour une serrure de porte (101), tout particulièrement préféré pour une serrure anti-panique auto-verrouillante (101), avec un composant (3) stationnaire,

au moins un composant (1, 2) mobile,

au moins un élément de composant actionnable, tout particulièrement une lame de commutation (21a, 22a) d'un commutateur (21, 22),

dans lequel un élément d'actionnement (10) est prévue pour l'actionnement d'un élément de composant actionnable (21a, 22a),

et dans lequel l'élément d'actionnement (10) est aménagé avec

un élément de contact (12) pour l'actionnement de l'élément de composant (21a, 22a) actionnable,

caractérisé par un corps de filetage (11) pour l'attachement de l'élément d'actionnement (10) dans une réception de filetage (1a, 2a) sur le composant (1, 2) mobile,

dans lequel le corps de filetage (11) est aménagé pour l'ajustage de l'élément de contact (12). - Système (100) selon la revendication 13,

caractérisé en ce

qu'un premier composant (1) mobile est un pêne demi-tour, tout particulièrement un pêne demi-tour auxiliaire (1), et/ou un deuxième composant (2) mobile sont/est un fouillot (2),

dans lequel tout particulièrement l'élément actionnement (10) est aménagé suivant l'une des revendications précédentes 1 à 12. - Système (100) selon la revendication 13 ou 14,

caractérisé en ce

que le composant (1) mobile pour l'actionnement de l'élément de composant (21a, 22a) actionnable est pivotable.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DK17162441.4T DK3379552T3 (da) | 2017-03-22 | 2017-03-22 | Betjeningselement til betjening af et bevægeligt komponentelement |

| EP17162441.4A EP3379552B1 (fr) | 2017-03-22 | 2017-03-22 | Élément d'actionnement destiné au déplacement d'un élément de construction mobile |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP17162441.4A EP3379552B1 (fr) | 2017-03-22 | 2017-03-22 | Élément d'actionnement destiné au déplacement d'un élément de construction mobile |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3379552A1 EP3379552A1 (fr) | 2018-09-26 |

| EP3379552B1 true EP3379552B1 (fr) | 2020-02-12 |

Family

ID=58401511

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17162441.4A Active EP3379552B1 (fr) | 2017-03-22 | 2017-03-22 | Élément d'actionnement destiné au déplacement d'un élément de construction mobile |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP3379552B1 (fr) |

| DK (1) | DK3379552T3 (fr) |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3715530A (en) * | 1971-08-24 | 1973-02-06 | Westran Corp | Actuating device |

| US4182941A (en) * | 1977-08-03 | 1980-01-08 | Kabushiki Kaisha Saginomiya Seisakusho | Improved pressure switch |

| FI83802C (fi) * | 1988-11-25 | 1991-08-26 | Abloy Security Ltd Oy | Elektromekaniskt doerrlaos. |

| DE29503880U1 (de) * | 1995-03-07 | 1995-05-11 | Theodor Kromer GmbH & Co KG Spezialfabrik für Sicherheitsschlösser, 79224 Umkirch | Permutationsschloß mit einer Nockenscheibe und mehreren Zuhaltungsscheiben |

| US6032760A (en) * | 1997-08-05 | 2000-03-07 | Atoma International, Inc. | Bi-directional spring holder assembly for an actuator |

-

2017

- 2017-03-22 EP EP17162441.4A patent/EP3379552B1/fr active Active

- 2017-03-22 DK DK17162441.4T patent/DK3379552T3/da active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3379552A1 (fr) | 2018-09-26 |

| DK3379552T3 (da) | 2020-03-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2395605B1 (fr) | Elément de serrage de ressort et bornier | |

| EP0646688B1 (fr) | Poignée extérieure pour une porte spécialement pour porte de véhicule automobile | |

| DE102021102920A1 (de) | Batteriebaugruppe | |

| EP2998483A1 (fr) | Bouton rotatif destiné à actionner un adaptateur de cylindre d'un barillet | |

| DE102018126469B3 (de) | Federanschlusseinrichtung zum Anschließen eines elektrischen Leiters | |

| EP3474303B1 (fr) | Actionneur | |

| DE4006707C2 (de) | Vorreiberverschluß | |

| DE102005059383B4 (de) | System zum Ausgleich von Längendifferenzen zwischen einem in eine Öffnung eines Türblattes einzusetzenden Zylinderschloss und dem Türblatt | |

| DE202009013488U1 (de) | Vorrichtung zum Fixieren eines Baukörpers in einer Gebäudeöffnung | |

| EP3379552B1 (fr) | Élément d'actionnement destiné au déplacement d'un élément de construction mobile | |

| EP1997986B1 (fr) | Serrure, en particulier serrure anti-panique dotée d'un capteur de position à actionnement au pied | |

| EP1709711A1 (fr) | Dispositif de connexion d'un cable coaxial a un boitier | |

| EP2782199B1 (fr) | Appareil d'émission d'instructions et/ou de signaux doté d'un raccord à fiche | |

| DE19961370A1 (de) | Türaußengriffanordnung für eine Kraftfahrzeugtür, Kraftfahrzeugtür und Verfahren zur Montage eines Türaußengriffs | |

| DE102017106223A1 (de) | Betätigungselement für einen Schalter | |

| EP2998463B1 (fr) | Armature pour une porte de bâtiment et procédé | |

| DE102022128727A1 (de) | Schutztürüberwachungsmodul | |

| EP3478911A1 (fr) | Poignée comprenant un élément d'ajustement | |

| DE2458652B2 (de) | Elektrische Alarmvorrichtung für eine schUeözylinderbetätigte Verriegelungsvorrichtung | |

| DE102022113577A1 (de) | Stangenverschluss | |

| EP3611318B1 (fr) | Fermeture et système de fermeture | |

| EP3343580B1 (fr) | Moyen de retenue permettant de fixer un appareil de commande à une carte de circuit imprimé | |

| WO2000024022A1 (fr) | Dispositif de couplage | |

| DE4207128A1 (de) | Kontaktvorrichtung zur elektrischen ueberwachung von eingangstueren | |

| DE102021000442B4 (de) | Türgriff zur Türschlossbetätigung, insbesondere für ein Fahrzeug |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20190326 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E05B 15/04 20060101ALI20190807BHEP Ipc: E05B 17/22 20060101ALI20190807BHEP Ipc: H01H 3/16 20060101ALI20190807BHEP Ipc: H01H 3/42 20060101AFI20190807BHEP Ipc: H01H 3/30 20060101ALI20190807BHEP Ipc: E05B 63/20 20060101ALN20190807BHEP Ipc: H01H 13/18 20060101ALI20190807BHEP Ipc: E05B 63/00 20060101ALI20190807BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20190830 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1233203 Country of ref document: AT Kind code of ref document: T Effective date: 20200215 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: FREI PATENTANWALTSBUERO AG, CH |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502017003723 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 Effective date: 20200325 |

|

| REG | Reference to a national code |

Ref country code: FI Ref legal event code: FGE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NO Ref legal event code: T2 Effective date: 20200212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20200212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200612 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200512 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200513 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200705 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502017003723 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20200331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200322 |

|

| 26N | No opposition filed |

Effective date: 20201113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200412 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200331 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20210322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200212 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1233203 Country of ref document: AT Kind code of ref document: T Effective date: 20220322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220322 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20250321 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250319 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20250326 Year of fee payment: 9 Ref country code: FI Payment date: 20250324 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NO Payment date: 20250321 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20250401 Year of fee payment: 9 |