EP3377312B1 - Presse à course imposée comportant un coulisseau - Google Patents

Presse à course imposée comportant un coulisseau Download PDFInfo

- Publication number

- EP3377312B1 EP3377312B1 EP16795009.6A EP16795009A EP3377312B1 EP 3377312 B1 EP3377312 B1 EP 3377312B1 EP 16795009 A EP16795009 A EP 16795009A EP 3377312 B1 EP3377312 B1 EP 3377312B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- motor

- path

- drive shaft

- sliding block

- slide block

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000033001 locomotion Effects 0.000 claims description 30

- 230000007246 mechanism Effects 0.000 claims description 29

- 230000005540 biological transmission Effects 0.000 claims description 14

- 230000000284 resting effect Effects 0.000 claims description 3

- 238000003825 pressing Methods 0.000 description 16

- 238000000034 method Methods 0.000 description 15

- 230000008569 process Effects 0.000 description 15

- 230000008901 benefit Effects 0.000 description 6

- 230000001133 acceleration Effects 0.000 description 3

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 238000005242 forging Methods 0.000 description 3

- 239000010724 circulating oil Substances 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 238000005461 lubrication Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 230000008859 change Effects 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 230000006735 deficit Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000009365 direct transmission Effects 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000005553 drilling Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 239000004519 grease Substances 0.000 description 1

- 230000001050 lubricating effect Effects 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 239000004575 stone Substances 0.000 description 1

- 239000013598 vector Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B1/00—Presses, using a press ram, characterised by the features of the drive therefor, pressure being transmitted directly, or through simple thrust or tension members only, to the press ram or platen

- B30B1/26—Presses, using a press ram, characterised by the features of the drive therefor, pressure being transmitted directly, or through simple thrust or tension members only, to the press ram or platen by cams, eccentrics, or cranks

- B30B1/266—Drive systems for the cam, eccentric or crank axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B1/00—Presses, using a press ram, characterised by the features of the drive therefor, pressure being transmitted directly, or through simple thrust or tension members only, to the press ram or platen

- B30B1/26—Presses, using a press ram, characterised by the features of the drive therefor, pressure being transmitted directly, or through simple thrust or tension members only, to the press ram or platen by cams, eccentrics, or cranks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B1/00—Presses, using a press ram, characterised by the features of the drive therefor, pressure being transmitted directly, or through simple thrust or tension members only, to the press ram or platen

- B30B1/40—Presses, using a press ram, characterised by the features of the drive therefor, pressure being transmitted directly, or through simple thrust or tension members only, to the press ram or platen by wedge means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/0029—Details of, or accessories for, presses; Auxiliary measures in connection with pressing means for adjusting the space between the press slide and the press table, i.e. the shut height

- B30B15/0035—Details of, or accessories for, presses; Auxiliary measures in connection with pressing means for adjusting the space between the press slide and the press table, i.e. the shut height using an adjustable connection between the press drive means and the press slide

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/06—Platens or press rams

- B30B15/068—Drive connections, e.g. pivotal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/32—Discharging presses

Definitions

- the invention relates to a path-bound press according to the preamble of claim 1.

- DE-OS-1 627 435 describes a forging press in which an eccentric of a drive shaft engages in an opening of a sliding block.

- the sliding block is supported with an upper, convex side and a lower, convex side against a correspondingly concave surface of a sliding block.

- the sliding block oscillates around a pendulum axis that runs through a lower area of the sliding block.

- WO 2007/091935 A1 describes a drive for a press in which a first motor drives a flywheel that can be coupled to the press and in which a second motor is also provided to drive the press.

- the JP 2011 136352 A describes a path-bound press according to the preamble of claim 1, comprising at least one drive shaft with a driver eccentric to a shaft axis and a sliding block, wherein the sliding block is driven by the driver to a forced movement.

- the sliding block is guided on at least one pressure-side sliding surface opposite a pressure-side surface of a sliding block, wherein the sliding block has a tension-side sliding surface opposite the pressure-side sliding surface, which is guided on a tension-side surface of the sliding block.

- the pressure-side sliding surface on the sliding block has a concave curvature, wherein the tension-side sliding surface of the sliding block has a convex curvature.

- a similar structure of a sliding block used in a path-bound press is known from SU1289699A1 known.

- the concave or convex shape of the pressure-side sliding surface makes it easy to achieve a force transmission through the sliding block that corresponds to a slider-crank mechanism. At the same time, a large contact surface is achieved in the area of the sliding surface, so that a design for large pressing forces is easily achieved.

- the pressure-side, concave curvature and the tension-side, convex curvature can each be designed in the shape of a circular arc.

- the curvatures are preferably arranged concentrically around the same point through which a pendulum axis of the sliding block also runs. Both sliding surfaces form positively guiding sliding block surfaces of a sliding block gear for the sliding block.

- the sliding block has a concave sliding surface on the pressure side and a convex sliding surface on the tension side. This corresponds to the kinematics of a slider-crank mechanism, in which the dead center of a working stroke or pressing process is in an extended position of the slider-crank mechanism.

- the sliding block has a convex sliding surface on the pressure side and a concave sliding surface on the tension side. This corresponds to the kinematics of a slider-crank mechanism, in which the dead center of a working stroke or pressing process is in a cover position of the slider-crank mechanism.

- a sliding block is understood to be an element that is forcibly moved relative to a sliding surface.

- the sliding surface includes in particular the pressure-side surface and the tension-side surface for guiding the sliding block.

- a driver is understood to mean, for example, an eccentric or a crank pin.

- the driver is preferably an eccentric of the drive shaft, which runs, for example, with a circular circumference in an opening in the sliding block.

- a link is understood to be a movable component of the press that absorbs and transmits a working pressure from the link block during a press stroke or forming process.

- the link can in principle be designed as a common component with a ram of the press. In other embodiments, however, another gear of any design, for example a wedge deflection, can be provided between the link and the ram.

- the link In the area where the force is absorbed in the pressure direction, the link preferably has a pressure piece that has material properties optimized for contact with the link block.

- a press in the sense of the invention generally relates to a press for forging, punching, deep drawing or any other forming process for which path-bound presses are used.

- the design of a path-bound press according to the invention generally allows for a low overall height. This leads to shorter spring lengths for the column, ram and/or link of the press. This improves the rigidity compared to conventional eccentric presses of the same column design.

- the design according to the invention ensures that, for a given height of the press, a particularly large length of a rigid unit made of link and ram. This allows particularly good lateral guidance of the ram or the rigid unit even with high pressing forces.

- the sliding block executes a pendulum movement about a pendulum axis, with the pendulum axis being arranged outside the sliding block.

- the pendulum axis is preferably arranged in a fixed position relative to the sliding block.

- the sliding block then causes a movement transmission in the manner of a slider crank mechanism with respect to the pendulum axis or with respect to the sliding block.

- a different forced guidance of the sliding block is also conceivable depending on the requirements, so that the kinematics of a slider crank mechanism is only one of various possible movement transmissions.

- the invention is not limited to the specifically described variants of slider crank mechanisms.

- Such a design of the gear of the press according to the invention allows a high ratio between a pressing force acting in the guide direction of the pressure piece and a normal force acting perpendicular to it.

- a certain normal force is desired in order to ensure that the sliding block and/or the ram are well positioned on a lateral guide.

- a large inverse pushrod ratio 1/Lambda is possible without having to increase the height of the press.

- the above features allow Even with a low overall height and correspondingly good rigidity, similar pressure contact times (parameter: lambda) can be achieved as with conventional eccentric presses with pressure rods.

- the pendulum axis is on the side of the compression direction with respect to the shaft axis.

- the compression contact time is the same as with conventional presses with a pressure rod for the same rotation time.

- the pendulum axis is on the side of the tension direction with respect to the shaft axis.

- the compression contact time is higher for the same rotation time than with conventional presses with a pressure rod, which can be an advantage for special forming processes or materials.

- an adjusting element preferably in the form of an adjustable, rotatable eccentric ring, is arranged between the driver and the sliding block.

- Such an adjusting element can be used, for example, to adjust the height of a tappet.

- the link is moved substantially in line with a ram of the press during the press stroke. This corresponds to a linear and direct transmission of the press force.

- a force deflection takes place between the link and a ram of the press.

- the force deflection can preferably take place by means of a wedge. This allows the general advantages of a wedge press to be combined with the advantages of a press according to the invention.

- the invention provides an ejection mechanism that is fixed in position relative to the guide rail and has an ejector that can be moved relative to the guide rail and acts on a workpiece, the ejection mechanism being actuated by the movement of the guide rail.

- This allows a workpiece to be ejected easily and effectively after a pressing process.

- Such an ejection mechanism is preferably combined with a guide rail of the second embodiment, in which there is a convex sliding surface on the pressure side. With otherwise identical dimensions, this means that the guide rail has a greater path in the area of the pressure-side sliding surface, which allows particularly easy and effective movement transmission to the ejector.

- the ejector can be actuated, for example, by a ramp, cam or similar structure formed on the guide rail, which actuates the ejector against a restoring spring force when the drive shaft reaches a corresponding position.

- a gear can be arranged between the sliding block and the ejector so that the force and movement of the ejector are further optimized.

- the gear can in particular be a linkage gear, a bell crank or similar.

- a drive of the drive shaft comprises a first motor, a flywheel that can be driven by the first motor and a second motor, wherein the flywheel can be detachably coupled to the drive shaft by means of a coupling, and wherein the drive shaft can be driven via the second motor.

- the first motor essentially serves to drive the flywheel and to at least partially replenish the energy taken from the flywheel.

- the second motor essentially serves to accelerate and/or decelerate the drive shaft decoupled from the flywheel in a state decoupled from the flywheel.

- the second motor can also serve to introduce additional drive energy when coupled.

- the deceleration energy that occurs during deceleration can be fed to the first motor via a converter in a possible detailed design.

- Motors in the sense of the present invention are understood to mean electric motors.

- the clutch is closed in normal operation when the speeds on the drive side and the output side of the clutch are at least approximately the same, with the speeds being adjusted by specifically controlling the second motor. This allows a significant reduction in wear on the clutch.

- the first motor and the flywheel can be arranged coaxially to one another. They are preferably integrated as a structural unit to form a flywheel motor. Such a flywheel motor advantageously dispenses with a space-consuming belt drive and additional motor console.

- the motor and the flywheel are arranged coaxially and connected to one another via a gear, preferably a planetary gear, so that transmission ratios can also be implemented depending on requirements. This can enable particularly small flywheel masses.

- flywheel it is generally advantageous for the flywheel to be coupled to the drive shaft without a gear ratio, with the flywheel being arranged in particular concentrically to the drive shaft.

- Such a simple design without a reduction gear is particularly advantageous when the flywheel is equipped with a sufficient small diameter. This is made possible by the drive concept according to the invention.

- the second motor is designed as a torque motor arranged concentrically to the drive shaft.

- a torque motor is understood to be a high-torque, high-pole motor that usually runs on a hollow shaft. Torque motors also have a high torque even when stationary.

- a brake on the drive shaft is provided concentrically to the torque motor and overlaps the torque motor in the axial direction.

- the brake can be placed in particular in the area of a hollow shaft of the torque motor in order to also use this installation space.

- the brake can be a mechanical brake for generating frictional heat or an electrical recuperation brake.

- the brake can be a holding brake to ensure that the press comes to a standstill when it is not in use. It can particularly preferably be a spring-loaded brake that can be opened pneumatically and closed hydraulically and/or electromagnetically.

- the drive shaft runs through an angle of rotation of more than 360°, starting from a stationary start position via the pressing stroke to a stationary stop position.

- this is an angle of rotation between 370° and 450°. This allows a larger acceleration path before the actual pressing process or a larger braking path after the actual pressing process, so that the corresponding motors and brakes can be dimensioned smaller accordingly. This applies in particular to the second motor.

- a main bearing point of the drive shaft is lubricated by means of a circulating oil lubrication system.

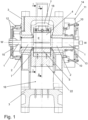

- the path-bound press according to the invention according to the embodiment according to Fig.1 comprises a drive shaft 1 with a shaft axis W, which is rotatably mounted in two main bearings 2 relative to a press frame 3.

- the main bearings 2 preferably have circulating oil lubrication.

- the drive shaft 1 has an eccentric driver in the form of an eccentric 4.

- the eccentric 4 which is circular in cross-section, has an eccentric axis E which is offset by a radial distance R from the shaft axis W.

- the eccentric 4 passes through a sliding block 5 in a bore 6 corresponding to the diameter of the eccentric.

- the sliding block is made up of several parts.

- the sliding block 5 is in turn guided in a guide 7.

- the guide 7 is designed as a housing that can be moved relative to the press frame 3.

- the guide 7 comprises a pressure piece 8 on a pressure side, on which a pressure-side sliding surface 8a is formed.

- a tension-side sliding surface 7a is formed on the guide.

- the sliding block 5 has a pressure-side sliding surface 5a, which rests on the sliding surface 8a of the pressure piece 8, and a tension-side sliding surface 5b, which rests on the tension-side sliding surface 7a of the sliding block 7.

- the pressure-side sliding surface 5a is concavely formed on the sliding block 5.

- the tension-side sliding surface 5b is convexly formed on the sliding block 5.

- the sliding surfaces 5a, 5b, 7a, 8a are each designed as cutouts of a cylinder surface formed, with the cylinder axes running parallel to the shaft axis W.

- the sliding surfaces 5a, 5b, 7a, 8a run concentrically around a pendulum axis P of the sliding block 5 that is parallel to the shaft axis W.

- the pendulum axis P is therefore located on the pressure side and outside the sliding block, since the pressure-side sliding surface 5a of the sliding block 5 is concavely shaped.

- the sliding block 5 undergoes a forced pendulum movement around the pendulum axis P.

- the pendulum axis P is fixed in space with respect to the guide 7 or the pressure piece 8.

- the guide 7 and the pressure piece 8 provided on it are accommodated by lateral guides 9 in which they can each be moved linearly in a direction perpendicular to the shaft axis W.

- a pressing stroke is carried out in which the driving force of the drive shaft 1 acts on the pressure piece 8 via the sliding block 5.

- the driving force of the drive shaft 1 acts on the tension-side sliding surface 7a of the sliding block 7 via the sliding block 5, so that the sliding block 7 and the pressure piece 8 are brought back in the opposite direction to the pressing stroke.

- clamping devices 7b are arranged on the underside of the guide 7, with which a press ram and/or a tool holder and/or a tool can be attached. These perform identical movements to the guide 7 or the pressure piece 8.

- the link 7 or the pressure piece 8 perform a movement analogous to that of a slider crank drive.

- a slider crank drive is the Motion transmission between piston and crankshaft in a conventional internal combustion engine.

- the quantities that characterize the movement are the radial distance R on the one hand and a distance L between the pendulum axis P and the eccentric axis E.

- the ratio R:L corresponds to the push rod ratio lambda.

- the dead center of the working stroke corresponds to the extended position of an analog slider crank mechanism. This means that the distances R and L are collinear and one behind the other at the lowest point of the tool.

- the dead center of the working stroke is also referred to as the bottom dead center.

- the maximum tappet speed In contrast to a pure sinusoidal drive (e.g. a sliding block sliding horizontally in the guide rail with a flat sliding surface on the pressure side), the maximum tappet speed only occurs after 90° after TDC (top dead center).

- a pure sinusoidal drive e.g. a sliding block sliding horizontally in the guide rail with a flat sliding surface on the pressure side

- Fs is the total pressure force exerted by the sliding block 5.

- Fs lies on a straight line that runs perpendicularly through the eccentric axis E and the pendulum axis P.

- Fp is the force component of Fs that acts in the direction of the press stroke or on the workpiece. In the specific design of the press according to Fig.1 This is the vertical force component.

- Fn is the force component of Fs that is perpendicular to Fp and also perpendicular to the guides 9 or the direction of the press stroke.

- the behavior of the moving parts in the guides 9 is largely determined by Fn.

- a respective angle WF between Fp and Fs is an expression of the crank angle and the ratio L:R. Due to the selected ratio L:R, the angle WF in the present example of a press is relatively small.

- a drive of the drive shaft 1 comprises a first motor 10, a flywheel 11 that can be driven by the first motor 10, and a second motor 12.

- the flywheel 11 can be detachably coupled to the drive shaft 1 via a clutch 13.

- the second motor 12 drives the drive shaft 1 directly. In one possible operating mode, deceleration or braking with this drive is not carried out via a brake, but via the second motor 12.

- the flywheel 11 and the first motor 10 are combined to form a structural unit in the form of a flywheel motor 14.

- the first motor 10 and the flywheel 11 are arranged coaxially to one another and to the shaft axis W of the drive shaft 1.

- the motor 10 and the flywheel 11 are directly connected to one another.

- a transmission for example by means of a gear or a belt drive, does not take place here.

- a transmission can be provided between the flywheel and the first motor, for example by means of a planetary gear.

- the clutch 13 is arranged directly on the flywheel motor 14 and is also in a concentric or coaxial position on the shaft axis W. Flywheel motor 14 and clutch 13 are arranged on the same of two ends of the drive shaft 1.

- the second motor 12 is arranged at the second end of the drive shaft 1, opposite the main bearing 2.

- the second motor 12 is also positioned coaxially to the shaft axis W above the drive shaft 1. It drives the drive shaft directly and without gearing.

- the second motor 12 is designed as a torque motor. The second motor 12 therefore has a high torque even when stationary.

- a brake 15 of the drive is positioned concentrically and overlapping the second motor 12 in the axial direction.

- the brake is positioned predominantly in a hollow shaft of the second motor 12, whereby this installation space is used optimally.

- the brake can be designed as an electrical recuperation brake and/or as a mechanical brake that generates frictional heat.

- the brake 15 is preferably spring-loaded and serves as a safety element in possible operating mode when the press is at a standstill. It can be opened pneumatically or closed hydraulically and/or electromagnetically.

- the view Fig.2 makes it clear that the flywheel 11 has a sufficiently small diameter so as not to overlap in height with a working area 16 of the press. This allows optimal access to the working area 16

- the flywheel 11 is permanently held at a desired speed by the first motor 10.

- the second motor 12 serves to accelerate the drive shaft 1 from a resting starting position to a speed that is the same or at least almost the same as the flywheel before a pressing process, while the clutch 13 is still disengaged. If the speed difference is sufficiently small, the clutch 13 is then engaged or closed so that little or no friction loss occurs at the clutch. Accordingly, the clutch is relatively small.

- the subsequent pressing stroke and forming process of a workpiece brakes the drive shaft 1 and energy is extracted from the flywheel 11.

- the first motor 10 and the second motor 12 work together at high power in order to at least partially compensate for the energy extraction. This means that the flywheel is relatively small.

- the drive shaft 1 is decoupled again from the flywheel 11. With the aid of the brake 15, and if necessary also by reversing the second motor 12, the drive shaft 1 is then brought to a standstill.

- an electronic control of the press is designed in such a way that the drive shaft 1, starting from the stationary start position, passes through a rotation angle of more than 360° through the press stroke/forming process to the stationary stop position.

- the rotation angle is preferably between 370° and 450°.

- the angle of rotation is approximately 390°.

- the drive shaft is first rotated back by approximately 30° against the working direction, i.e. 30° before top dead center, before acceleration in the working direction by the second motor 12. This does not cause a collision or impairment of the working area 16, but significantly increases the available acceleration angle for the subsequent rotation of the drive shaft in the working direction.

- the second motor 12 can be designed to be relatively small.

- Fig.3 shows the press Fig.1 in a sectional view with section plane II-II running perpendicular to the drive shaft.

- An adjusting element 17 is provided, by means of which the height of the sliding block 5 can be adjusted. This adjustment can also be made during operation. In one possible operating mode, the adjustment can be made in stages between two successive strokes.

- the adjusting member 17 comprises an eccentric ring 18 which is arranged between the bore 6 in the sliding block 5 and the eccentric 4 of the drive shaft 1.

- the eccentric ring 18 can be rotated in its seat via an actuator 19 so that the bore receiving the eccentric 4 changes its position with respect to the sliding block 5.

- Fig.2 shows a clamp 17a of the adjusting element 17.

- the clamp 17a can be opened hydraulically.

- the closing of the clamp 17a can be hydraulically or mechanical (self-locking) or combined hydraulic and mechanical.

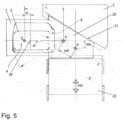

- Fig.5 shows a second embodiment of a press according to the invention.

- a ram and/or tool of the press is not moved directly and linearly by the link 7.

- a force deflection is provided between the pressure piece and a ram of the press.

- the force deflection takes place by means of a wedge 20, which is displaceable relative to a frame-fixed support surface 21 inclined to the direction of the press stroke.

- the wedge 20 is firmly connected to the link 7.

- a ram 22 of the press rests displaceably on a side of the wedge 20 opposite the support surface 21.

- the press stroke HP is considered to run in the direction of this offset in the sense of the invention.

- a movement HS of the ram 22 of the press is redirected by approximately 120° to the press stroke HP of the link 7.

- Such a wedge drive can achieve a particularly uniform force distribution across the width of the ram.

- the second embodiment does not show any changes to the example according to Fig.1 on.

- the sliding block is formed according to a second variant.

- the pressure-side Sliding surface 5a on the sliding block 5 is convexly shaped, in contrast to the concave shape in the previously described examples.

- the tension-side sliding surface 5b on the sliding block 5 is also shaped in the opposite way to the previous examples, i.e. concave.

- the corresponding sliding surfaces 7a, 8a on the sliding block are also curved in the opposite way.

- the sliding surfaces 5a, 5b, 7a, 8a are as in the first variant according to Fig.4 each formed as cutouts of a cylinder surface, with the cylinder axes running parallel to the shaft axis W.

- the sliding surfaces 5a, 5b, 7a, 8a in turn run concentrically around a pendulum axis P of the sliding block 5 that is parallel to the shaft axis W.

- the pendulum axis P is therefore also located outside the sliding block 5. Unlike in the first variant, the pendulum axis P in the second variant is on the tension side with respect to the sliding block 5. For the sliding block 5, rotation of the drive shaft 1 again results in a forced pendulum movement around the pendulum axis P.

- the second variant also corresponds to an analog slider-crank mechanism with the characteristic dimensions L (distance between the pendulum axis P and the shaft axis W) and R (distance between the eccentric axis E and the shaft axis W).

- the dead center of the working stroke corresponds to a cover position of an analog slider-crank mechanism. This means that the distances R and L are collinear and lie one above the other at the lowest point of the tool.

- an ejection mechanism 23 is integrated into the press, which is actuated by means of the movement of the sliding block.

- the ejection mechanism comprises an ejector 24, which runs linearly displaceably in a guide of the ram 22 and can press against a workpiece (not shown) at the lower end of the ram.

- the ejector 24 After a pressing process, the ejector 24 is moved against the workpiece by means of a mechanical positive guide and pushes it out of a tool (not shown). In this way, a reliable workpiece change is made possible in a simple manner.

- the ejector 24 is actuated by means of a ramp 27 on the sliding block 5.

- the ramp 27 rests against a head 28 of the ejector 24, which is in the form of a ball.

- the sliding block performs its pendulum movement around the pendulum axis P, sliding along the pressure-side sliding surfaces 5a, 8a.

- the ejector 24 is initially in a position reset by means of a spring 29, in which it does not press on the workpiece.

- the ramp 27 begins to press in the ejector 24 via the ball 28.

- Fig.7 Approximately the starting point of this ejection process is shown, with the sliding block 5 in the central position and the tappet 22 in a bottom dead center.

- the sliding block 5 moves in the illustration according to Fig.7 further to the left and the ramp 27 moves the ejector 24 relative to the plunger 22 or to the guide 7 against the workpiece.

- the ejector 24 performs a movement by a stroke HA against the force of the spring 29.

- the ejector mechanism is illustrated using the first variant of the sliding block 5 with a concave sliding surface 5a on the pressure side.

- the ejector mechanism can also preferably be combined with the second variant of the sliding block 5 with a convex sliding surface 5a on the pressure side. This has the advantage that the linear path of the sliding block 5 along the sliding surface 5a is larger with otherwise identical dimensions of the press, which allows a less steep design of the ramp 27.

- the stroke HA of the mechanical ejector 23, 24 can be increased. This means that the large force required for ejection is applied by the mechanical ejector with a small stroke HA.

- the hydraulic piston increases the stroke HA by the stroke HH.

- the hydraulic piston 25 is operated via a valve with hydraulic control 34.

- the gear 30 is designed as a reversing lever, which is mounted in a rotary bearing or pivot bearing 31 on the sliding block 7.

- the sliding block 5 is connected to the reversing lever in a rotary bearing 32, with the pivot point of the rotary bearing 32 being aligned with the sliding surface 5a.

- the rotary bearing 32 can be designed as a cam roller. The pivoting movement of the reversing lever is then positively controlled via the cam roller 32 by the cassette guide 33 arranged on the sliding block 5.

- a ramp 27 is formed on the reversing lever 30, which, as in the previous example, engages the ejector 24.

- the reversing lever in particular enables a longer ramp in order to better control the ejector 24.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Press Drives And Press Lines (AREA)

- Control Of Presses (AREA)

- Forging (AREA)

- Presses And Accessory Devices Thereof (AREA)

Claims (13)

- Presse avec fonctionnement relatif au déplacement, comprenantau moins un arbre d'entraînement (1) avec un entraîneur (4) excentrique par rapport à un axe d'arbre (W), etun bloc coulissant (5), le bloc coulissant (5) étant entraîné par l'entraîneur (4) selon un mouvement à guidage positif,dans laquelle le bloc coulissant (5) est guidé sur au moins une surface de glissement côté pression (5a) opposée à une surface côté pression d'une glissière (7) pendant l'exécution d'une course de presse,dans laquelle le bloc coulissant (5) présente une surface de glissement côté tension (5b) opposée à la surface de glissement côté pression (5a), qui est guidée sur une surface côté tension de la glissière, dans laquellela surface de glissement côté pression (5a) du bloc coulissant (5) présente une courbure concave ou convexe, et la surface de glissement côté tension (5b) du bloc coulissant (5) présente une courbure concave ou convexe différente, caractérisée en ce qu'un mécanisme d'éjection (23) fixée sur place par rapport à la glissière (7) est pourvu d'un éjecteur (24) mobile par rapport à la glissière (7) et agissant sur une pièce, le mécanisme d'éjection (23) étant actionné par le mouvement du bloc coulissant (5).

- Presse avec fonctionnement relatif au déplacement selon la revendication 1, caractérisée en ce que le bloc coulissant (5) effectue un mouvement pendulaire autour d'un axe pendulaire (P), l'axe pendulaire (P) étant disposé hors du bloc coulissant (5).

- Presse avec fonctionnement relatif au déplacement selon la revendication 2, caractérisée en ce que l'entraîneur (4) tourne autour d'un axe excentrique (E) in le bloc coulissant (5), l'axe excentrique (E) étant à une distance R de l'axe d'arbre (W), et l'axe excentrique (E) étant à une distance L de l'axe pendulaire (P), où: L:R >= 4, notamment 12 >= L:R >= 5.

- Presse avec fonctionnement relatif au déplacement selon l'une des revendications précédentes, caractérisée en ce qu'un élément de réglage (17), notamment sous la forme d'un anneau excentrique (18) à rotation réglable, est prévu entre l'entraîneur (4) et le bloc coulissant (5).

- Presse avec fonctionnement relatif au déplacement selon l'une des revendications précédentes, caractérisée en ce que la pièce de pression (8) se déplace sensiblement dans le prolongement d'un vérin de la presse pendant la course de presse.

- Presse avec fonctionnement relatif au déplacement selon l'une des revendications 1 bis 4, caractérisée en ce qu'une déviation de force s'effectue entre la pièce de pression (8) et un vérin (22) de la presse, notamment au moyen d'un coin (20).

- Presse avec fonctionnement relatif au déplacement selon l'une des revendications précédentes, caractérisée en ce qu'un engrenage (30) est prévu entre le bloc coulissant (5) et l'éjecteur (24).

- Presse avec fonctionnement relatif au déplacement selon l'une des revendications précédentes, caractérisée en ce qu'un entraînement de l'arbre d'entraînement comprend un premier moteur (10), un volant (11) pouvant être entraîné par le premier moteur, et un deuxième moteur (12), le volant (11) pouvant être couplé de manière amovible à l'arbre d'entraînement (1) à l'aide d'un accouplement (13), et l'arbre d'entraînement (1) pouvant être entraîné via le deuxième moteur (12).

- Presse avec fonctionnement relatif au déplacement selon la revendication 8, caractérisée en ce que le premier moteur (10) et le volant (11) sont disposés de manière coaxiale l'un par rapport à l'autre, en particulier en étant intégrés comme une unité structurelle pour former un moteur à volant (14).

- Presse avec fonctionnement relatif au déplacement selon l'une des revendications 8 bis 9, caractérisée en ce que le volant (11) peut être couplé à l'arbre d'entraînement (1) sans rapport de démultiplication, le volant (11) étant disposé en particulier de manière concentrique par rapport à l'arbre d'entraînement (1).

- Presse avec fonctionnement relatif au déplacement selon l'une des revendications 8 bis 10, caractérisée en ce que le deuxième moteur (12) est réalisé comme moteur couple disposé de manière concentrique par rapport à l'arbre d'entraînement (1).

- Presse avec fonctionnement relatif au déplacement selon la revendication 11, caractérisée en ce qu'un frein (15) de l'arbre d'entraînement (1) est disposé de manière concentrique par rapport au moteur couple (12) et en chevauchant le moteur couple (12) dans la direction axiale.

- Presse avec fonctionnement relatif au déplacement selon l'une des revendications 8 bis 12, caractérisée en ce que l'arbre d'entraînement (1) peut parcourir un angle de rotation supérieur à 360°, notamment compris entre 370° et 450°, à partir d'une position de départ stationnaire sur la course de presse jusqu'à une position d'arrêt stationnaire.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102015222994 | 2015-11-20 | ||

| DE102015222995.5A DE102015222995A1 (de) | 2015-11-20 | 2015-11-20 | Weggebundene Presse mit Kulissenstein |

| PCT/EP2016/077223 WO2017084952A1 (fr) | 2015-11-20 | 2016-11-10 | Presse à course imposée comportant un coulisseau |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3377312A1 EP3377312A1 (fr) | 2018-09-26 |

| EP3377312B1 true EP3377312B1 (fr) | 2024-04-10 |

Family

ID=57286486

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16794605.2A Active EP3377311B1 (fr) | 2015-11-20 | 2016-11-10 | Presse à course imposée dotée d'un coulisseau |

| EP16795009.6A Active EP3377312B1 (fr) | 2015-11-20 | 2016-11-10 | Presse à course imposée comportant un coulisseau |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16794605.2A Active EP3377311B1 (fr) | 2015-11-20 | 2016-11-10 | Presse à course imposée dotée d'un coulisseau |

Country Status (9)

| Country | Link |

|---|---|

| US (2) | US11084240B2 (fr) |

| EP (2) | EP3377311B1 (fr) |

| JP (2) | JP6656374B2 (fr) |

| KR (2) | KR102122225B1 (fr) |

| CN (2) | CN108472903B (fr) |

| BR (2) | BR112018010223B1 (fr) |

| ES (2) | ES2981739T3 (fr) |

| MX (2) | MX2018006191A (fr) |

| WO (2) | WO2017084953A1 (fr) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6656374B2 (ja) * | 2015-11-20 | 2020-03-04 | エス・エム・エス・グループ・ゲゼルシャフト・ミト・ベシュレンクテル・ハフツング | スライディングブロックを有する機械式プレス機械 |

| CN108273914A (zh) * | 2018-01-30 | 2018-07-13 | 武汉市华源达科技有限公司 | 一种曲柄滑块变向增力成形装置 |

| CN109263111B (zh) * | 2018-09-30 | 2020-11-17 | 西安交通大学 | 一种曲柄压力机液压式曲柄偏心量调节装置 |

| CN109848348B (zh) * | 2018-12-29 | 2023-10-20 | 武汉新威奇科技有限公司 | 一种数控直驱式电动螺旋压力机 |

| JP7304842B2 (ja) | 2020-09-28 | 2023-07-07 | アイダエンジニアリング株式会社 | プレス機械 |

| CN113893441B (zh) * | 2021-08-26 | 2023-04-21 | 中国科学院自动化研究所 | 一种介入手术递送装置 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5548500A (en) * | 1978-09-11 | 1980-04-07 | Michio Kuroki | Ram device of press machine |

| SU1289699A1 (ru) * | 1985-10-31 | 1987-02-15 | Всесоюзный заочный машиностроительный институт | Кривошипный пресс |

| JP2011136352A (ja) * | 2009-12-28 | 2011-07-14 | Komatsu Sanki Kk | プレス機械 |

Family Cites Families (35)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE613834A (fr) * | 1961-02-13 | 1962-05-29 | Eumuco Ag Fuer Maschinenbau | Presse à estamper en particulier presse excentrée à double montant |

| US3122033A (en) * | 1962-02-02 | 1964-02-25 | Eumuco Ag Fur Maschb | Die forging press |

| US3358591A (en) * | 1965-10-23 | 1967-12-19 | Textron Inc | Press |

| DE1627435B2 (de) | 1967-03-25 | 1971-06-03 | Schmiedepresse | |

| AT318353B (de) * | 1973-01-10 | 1974-10-10 | Gfm Fertigungstechnik | Schmiedemaschine |

| JPS5714499A (en) * | 1980-06-30 | 1982-01-25 | Komatsu Ltd | High speed mechanical press |

| JP3198533B2 (ja) | 1991-05-14 | 2001-08-13 | 株式会社日立製作所 | 機械式プレス |

| SG48725A1 (en) * | 1992-11-11 | 1998-05-18 | Bruderer Ag | A method of operating a punch press during start-up and stopping |

| CA2132442C (fr) * | 1993-01-22 | 1999-02-23 | Seizo Nakamura | Circuit de detection de la phase instantanee et circuit de generation de signaux de restitution de signaux d'horloge incorpores a un demodulateur differentiel |

| JP3130706B2 (ja) * | 1993-07-27 | 2001-01-31 | 株式会社神戸製鋼所 | 薄肉ウエブリブ部材の成形方法 |

| EP0667197B1 (fr) * | 1994-01-18 | 1997-10-08 | GFM Gesellschaft für Fertigungstechnik und Maschinenbau Aktiengesellschaft | Machine à forger |

| DE4421527C2 (de) * | 1994-06-20 | 1998-06-18 | Langenstein & Schemann Gmbh | Kurbelantrieb einer Kurbelpresse großer Preßkraft |

| US5666838A (en) * | 1995-06-05 | 1997-09-16 | Efco, Incorporated | Forging press for use with automated multi-station transport system |

| JP2001062596A (ja) * | 1999-08-24 | 2001-03-13 | Ns Engineering:Kk | プレス機械の組立方法並びにプレス機械 |

| JP3783520B2 (ja) * | 2000-04-07 | 2006-06-07 | トヨタ車体株式会社 | プレス加工用カムユニット |

| JP2003334696A (ja) * | 2002-05-16 | 2003-11-25 | Aida Eng Ltd | 機械プレス |

| JP4014461B2 (ja) * | 2002-07-10 | 2007-11-28 | アイダエンジニアリング株式会社 | 機械プレスの駆動装置 |

| JP2004114119A (ja) | 2002-09-27 | 2004-04-15 | Aida Eng Ltd | 機械プレス |

| JP2004136336A (ja) * | 2002-10-18 | 2004-05-13 | Aida Eng Ltd | 機械プレス |

| DE10260127A1 (de) * | 2002-12-19 | 2004-07-15 | Siemens Ag | Pressvorrichtung |

| US7013800B2 (en) * | 2003-07-30 | 2006-03-21 | Aida Engineering Co., Ltd | Mechanical press |

| KR101203431B1 (ko) * | 2006-02-06 | 2012-11-21 | 에이비비 리써치 리미티드 | 기계적 프레스 구동 시스템 |

| JP4699263B2 (ja) | 2006-04-03 | 2011-06-08 | 住友重機械テクノフォート株式会社 | クランクプレス |

| DE202006013502U1 (de) * | 2006-09-02 | 2008-01-10 | Aradex Ag | Antriebssystem für eine Umformmaschine |

| JP2008100278A (ja) * | 2006-10-23 | 2008-05-01 | Sumitomo Heavy Industries Techno-Fort Co Ltd | コンロッドレスプレス |

| DE102008034971A1 (de) * | 2008-07-25 | 2010-01-28 | Müller Weingarten AG | Antriebssystem einer Umformpresse |

| JP2010279987A (ja) * | 2009-06-05 | 2010-12-16 | Oiles Ind Co Ltd | カム装置 |

| JP5296631B2 (ja) | 2009-08-06 | 2013-09-25 | コマツ産機株式会社 | プレス機械 |

| JP2011079034A (ja) * | 2009-10-09 | 2011-04-21 | Kurimoto Ltd | 鍛造プレス |

| JP5806032B2 (ja) | 2011-07-29 | 2015-11-10 | 株式会社栗本鐵工所 | 鍛造プレス方法 |

| JP5555679B2 (ja) * | 2011-09-26 | 2014-07-23 | アイダエンジニアリング株式会社 | サーボプレスおよびサーボプレスの制御方法 |

| DE102012109150A1 (de) | 2012-09-27 | 2014-03-27 | Schuler Pressen Gmbh | Verfahren und Einrichtung zum Betreiben einer Werkzeugmaschine wie Presse mit linear bewegbarem Hubelement |

| JP6159614B2 (ja) | 2013-08-07 | 2017-07-05 | 株式会社山田ドビー | 電動サーボプレス機及びその運転方法 |

| CH710761A2 (it) * | 2015-02-20 | 2016-08-31 | Farina Presse S R L | Sistema di recupero dell'energia cinetica delle masse in movimento applicabile a presse meccaniche. |

| JP6656374B2 (ja) * | 2015-11-20 | 2020-03-04 | エス・エム・エス・グループ・ゲゼルシャフト・ミト・ベシュレンクテル・ハフツング | スライディングブロックを有する機械式プレス機械 |

-

2016

- 2016-11-10 JP JP2018526159A patent/JP6656374B2/ja active Active

- 2016-11-10 CN CN201680076124.5A patent/CN108472903B/zh active Active

- 2016-11-10 MX MX2018006191A patent/MX2018006191A/es unknown

- 2016-11-10 KR KR1020187015443A patent/KR102122225B1/ko active IP Right Grant

- 2016-11-10 EP EP16794605.2A patent/EP3377311B1/fr active Active

- 2016-11-10 ES ES16794605T patent/ES2981739T3/es active Active

- 2016-11-10 KR KR1020187015108A patent/KR102099727B1/ko active IP Right Grant

- 2016-11-10 MX MX2018006187A patent/MX2018006187A/es unknown

- 2016-11-10 JP JP2018526165A patent/JP6667635B2/ja active Active

- 2016-11-10 ES ES16795009T patent/ES2980777T3/es active Active

- 2016-11-10 CN CN201680076131.5A patent/CN108472904B/zh active Active

- 2016-11-10 WO PCT/EP2016/077224 patent/WO2017084953A1/fr active Application Filing

- 2016-11-10 US US15/776,827 patent/US11084240B2/en active Active

- 2016-11-10 US US15/775,940 patent/US11186056B2/en active Active

- 2016-11-10 EP EP16795009.6A patent/EP3377312B1/fr active Active

- 2016-11-10 BR BR112018010223-7A patent/BR112018010223B1/pt active IP Right Grant

- 2016-11-10 BR BR112018010151-6A patent/BR112018010151B1/pt active IP Right Grant

- 2016-11-10 WO PCT/EP2016/077223 patent/WO2017084952A1/fr active Application Filing

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5548500A (en) * | 1978-09-11 | 1980-04-07 | Michio Kuroki | Ram device of press machine |

| SU1289699A1 (ru) * | 1985-10-31 | 1987-02-15 | Всесоюзный заочный машиностроительный институт | Кривошипный пресс |

| JP2011136352A (ja) * | 2009-12-28 | 2011-07-14 | Komatsu Sanki Kk | プレス機械 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3377312A1 (fr) | 2018-09-26 |

| WO2017084952A1 (fr) | 2017-05-26 |

| JP6656374B2 (ja) | 2020-03-04 |

| KR102099727B1 (ko) | 2020-04-10 |

| KR20180077237A (ko) | 2018-07-06 |

| MX2018006191A (es) | 2018-08-01 |

| JP2018534148A (ja) | 2018-11-22 |

| JP2018538143A (ja) | 2018-12-27 |

| BR112018010151B1 (pt) | 2022-06-28 |

| BR112018010223A2 (pt) | 2018-11-21 |

| JP6667635B2 (ja) | 2020-03-18 |

| CN108472903B (zh) | 2020-10-09 |

| US20180326683A1 (en) | 2018-11-15 |

| CN108472903A (zh) | 2018-08-31 |

| KR20180079402A (ko) | 2018-07-10 |

| BR112018010151A2 (pt) | 2018-11-21 |

| ES2980777T3 (es) | 2024-10-03 |

| US11084240B2 (en) | 2021-08-10 |

| WO2017084953A1 (fr) | 2017-05-26 |

| BR112018010223A8 (pt) | 2019-02-26 |

| KR102122225B1 (ko) | 2020-06-15 |

| CN108472904B (zh) | 2020-04-28 |

| CN108472904A (zh) | 2018-08-31 |

| US11186056B2 (en) | 2021-11-30 |

| US20180345614A1 (en) | 2018-12-06 |

| EP3377311B1 (fr) | 2024-05-01 |

| EP3377311A1 (fr) | 2018-09-26 |

| ES2981739T3 (es) | 2024-10-10 |

| BR112018010223B1 (pt) | 2022-06-28 |

| BR112018010151A8 (pt) | 2019-02-26 |

| MX2018006187A (es) | 2018-08-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3377312B1 (fr) | Presse à course imposée comportant un coulisseau | |

| DE102011116654B4 (de) | Vorrichtung zum Stanznieten oder Durchsetzfügen unter beengten Platzverhältnissen | |

| WO2006045279A2 (fr) | Système d'entraînement d'une presse de formage | |

| DE102009012111B4 (de) | Mechanische Umformpresse und Verfahren zur Betätigung dieser Umformpresse | |

| DE3626455A1 (de) | Spindelpresse | |

| DE102009055739B4 (de) | Umformmaschine, insbesondere Servopresse | |

| DE69305629T2 (de) | Verfahren und vorrichtung zur herstellung eines kopfes auf einem länglichen werkstück | |

| DE102015222995A1 (de) | Weggebundene Presse mit Kulissenstein | |

| EP2319635B1 (fr) | Entraînement de presse et procédé de production d'un mouvement de levée d'un support d'outils à l'aide d'un entraînement de presses | |

| DE2717755B2 (de) | Stanze bzw. Presse für kleine Schneid- bzw. PreBwege | |

| DE3323428C2 (fr) | ||

| DE2303451C2 (de) | Vorrichtung zum Schmieden von Kurbelwellen, Flanschwellen u.dgl. mittels einer Schmiedepresse | |

| DE69226876T2 (de) | Zweistufiger hebelantrieb und maschine mit verwendung desselben | |

| DE102016209427B3 (de) | Kupplungsaktuator | |

| DE102007060815B4 (de) | Stichsäge | |

| DE102023104739A1 (de) | Pressrestschere sowie Verfahren zum Abscheren eines Pressrestes | |

| DE3736353A1 (de) | Langhub-exzenterpresse | |

| DE2834697C2 (de) | Hydraulische Spindelpresse zum Gesenkschmieden | |

| DE1904723A1 (de) | Einscheiben-Spindelpresse | |

| DE102012210960A1 (de) | Füllschieberanordnung für ein pressengebundenes Blechbearbeitungswerkzeug und pressengebundenes Blechbearbeitungswerkzeug mit solcher Füllschieberanordnung | |

| DE2646401A1 (de) | Hammerpresse | |

| DE2355334C3 (de) | Bewegungsumwandler, insbesondere für Maschinen zum Schweißen thermoplastischer Werkstoffe | |

| DE202018105630U1 (de) | Vorrichtung zum Geschlossen-Halten eines Formenhalters zur Aufnahme einer Form für einen herzustellenden Glasartikel | |

| DE2706351A1 (de) | Vorschubvorrichtung fuer den materialeinzug fuer maschinen oder vorrichtungen | |

| DE2322660A1 (de) | Stempelantrieb, insbesondere fuer stanzmaschinen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: UNKNOWN |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20180620 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20220412 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230707 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B30B 15/32 20060101ALI20231106BHEP Ipc: B30B 15/06 20060101ALI20231106BHEP Ipc: B30B 1/26 20060101AFI20231106BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20231122 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502016016465 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20240410 |

|

| RAP4 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: SMS GROUP GMBH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240410 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2980777 Country of ref document: ES Kind code of ref document: T3 Effective date: 20241003 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240810 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240410 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240711 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240812 |