EP3299552B1 - Verrou modulaire - Google Patents

Verrou modulaire Download PDFInfo

- Publication number

- EP3299552B1 EP3299552B1 EP17191596.0A EP17191596A EP3299552B1 EP 3299552 B1 EP3299552 B1 EP 3299552B1 EP 17191596 A EP17191596 A EP 17191596A EP 3299552 B1 EP3299552 B1 EP 3299552B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- module

- lock

- modules

- slide plate

- follower

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B63/00—Locks or fastenings with special structural characteristics

- E05B63/0056—Locks with adjustable or exchangeable lock parts

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B47/00—Operating or controlling locks or other fastening devices by electric or magnetic means

- E05B47/02—Movement of the bolt by electromagnetic means; Adaptation of locks, latches, or parts thereof, for movement of the bolt by electromagnetic means

- E05B47/026—Movement of the bolt by electromagnetic means; Adaptation of locks, latches, or parts thereof, for movement of the bolt by electromagnetic means the bolt moving rectilinearly

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B47/00—Operating or controlling locks or other fastening devices by electric or magnetic means

- E05B47/06—Controlling mechanically-operated bolts by electro-magnetically-operated detents

- E05B47/0676—Controlling mechanically-operated bolts by electro-magnetically-operated detents by disconnecting the handle

- E05B47/0684—Controlling mechanically-operated bolts by electro-magnetically-operated detents by disconnecting the handle radially

- E05B47/0688—Controlling mechanically-operated bolts by electro-magnetically-operated detents by disconnecting the handle radially with a pivotally moveable coupling element

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B59/00—Locks with latches separate from the lock-bolts or with a plurality of latches or lock-bolts

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B63/00—Locks or fastenings with special structural characteristics

- E05B63/18—Locks or fastenings with special structural characteristics with arrangements independent of the locking mechanism for retaining the bolt or latch in the retracted position

- E05B63/20—Locks or fastenings with special structural characteristics with arrangements independent of the locking mechanism for retaining the bolt or latch in the retracted position released automatically when the wing is closed

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B65/00—Locks or fastenings for special use

- E05B65/10—Locks or fastenings for special use for panic or emergency doors

- E05B65/1086—Locks with panic function, e.g. allowing opening from the inside without a ley even when locked from the outside

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05C—BOLTS OR FASTENING DEVICES FOR WINGS, SPECIALLY FOR DOORS OR WINDOWS

- E05C21/00—Arrangements or combinations of wing fastening, securing, or holding devices, not covered by a single preceding main group; Locking kits

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05C—BOLTS OR FASTENING DEVICES FOR WINGS, SPECIALLY FOR DOORS OR WINDOWS

- E05C9/00—Arrangements of simultaneously actuated bolts or other securing devices at well-separated positions on the same wing

Definitions

- the invention relates to a lock for a pivotably mounted leaf of a door or window according to the features of the preamble of claim 1.

- a lock which comprises a lock faceplate and a lock housing.

- individual extensions can be connected to the lock housing, which can include, for example, additional locking elements or drive devices. This makes it possible to individually upgrade the lock and adapt it to increased security requirements.

- a lock which comprises a locking cylinder module, a nut module and a slide plate.

- the locking cylinder module is connected to the slide plate via a connecting element.

- the object of the present invention is to provide a lock which covers a wide range of applications and can be manufactured in a simple manner.

- the lock should be as inexpensive to manufacture as possible.

- the lock base has mechanical receptacles for holding at least two different modules, each of which is designed as an assembly, and that the modules each have a module carrier which carries several module components of the module and is held on the receptacles of the lock base and that at least one of the modules is connected to the slide plate.

- the at least two modules each have a connecting element which establishes a connection between a module and the slide plate.

- the lock can be individually adapted to different conditions using the modules held in the lock base.

- a major advantage is that the installation space required for the lock does not change, as the modules are arranged within the lock housing. This makes it easy to manufacture and handle because each module has a module carrier that holds individual module components and combines them into an independent assembly, so to speak. By inserting this module carrier or connecting this module carrier to the lock base, the respective module is mechanically firmly and stably connected to the lock base. Individual modules can be selected for the configuration of the lock in order to put together a specific lock configuration. In addition, depending on the application, the lock can be equipped with more or fewer modules, depending on which functions the lock has to fulfill.

- the slide plate controls the extension of one or more locking elements and connects one locking element or several locking elements to one or more modules.

- the slide plate connects two or more modules to one another. These two or more modules are motion-coupled by the slide plate and connected to the locking element or several locking elements. This makes it possible to control complex locking processes.

- the at least two modules are motion-coupled to one another in order to control complex locking processes.

- one lock housing can be used to create either a simple key-operated lock, a self-locking panic lock with a control latch or auxiliary latch, or a motor lock.

- the slide plate extends from the locking element to a module arranged at a distance from the locking element or to several modules arranged at a distance from the locking element.

- the slide plate runs parallel to the lock cover or the lock base and is mounted so that it can be moved in a linear, translational manner in order to transfer a movement from one module to another module and/or from one module to the locking element or the locking elements.

- a pivotable mounting of the slide plate in the lock housing can also be provided.

- the lock is designed for a pivoting wing of a door or window in order to lock this wing against a frame.

- the lock housing can be used as a built-in housing It comprises a lock faceplate, a lock base and a removable lock cover.

- a locking element for example a lock bolt or a lock latch, is provided which passes through the lock faceplate and serves to lock the sash against a frame.

- the locking element is actuated by a slide plate and moved between a locked position excluded from the lock housing and an unlocked position retracted into the lock housing.

- the slide plate is coupled in terms of movement to the locking element.

- the mechanical mounts of the lock base can, for example, be designed as form-fitting mounts into which a module carrier is inserted. Alternatively or additionally, the mechanical mounts can also be designed as screw connections or snap or clip connections. Riveting to accommodate and hold a module carrier is also possible in this sense.

- a module carrier is understood to mean a component that is designed as a flat plate or as a preferably angled profile. Individual components of a module can be mechanically attached to this or movably mounted.

- the module carrier mechanically connects these individual module components of a module to one another to form an assembly.

- This assembly is preferably designed as an independent assembly or as an exchangeable assembly. In particular, it is provided that the assembly is designed as a part that can be handled independently of the other lock components.

- the lock base has mechanical mounts for holding at least three different modules or four different modules, depending on the requirements for the variety of functions of the lock.

- Such mechanical mounts can comprise a positive connection or a force-locking connection.

- the mounts can be designed as threads or as fitting holes or as recesses that can be gripped behind or as pins.

- the at least two modules each have a connection element that creates a connection between a module and the slide plate.

- the slide plate connects two of the modules or several of the modules to one another, in particular by the slide plate being connected to the connection elements of the modules or holding the connection elements of the modules.

- a connection element creates a connection between a module and another module.

- the connection element can be designed as a pin connection or as a screw connection or as a clip connection and accordingly have a pin, a screw or a clip. It is essential that the connection element creates a mechanically stable connection between a module and the slide plate or between a module and another module.

- connection element is movably mounted relative to the lock base and/or module carrier and transmits a movement from the module to the slide plate or another module or transmits a movement from the slide plate to the module.

- the at least two modules each have a module component that is movably mounted relative to the module carrier and/or relative to the lock base, preferably that the movably mounted module component is designed as a connection element or is connected to the connection element.

- a module is designed as an additional latch module, comprising an additional latch module carrier that carries an additional latch and a spring that acts on the additional latch and at least one gear element that can be actuated by the additional latch and a latch module connection element for connecting the additional latch to the slide plate and/or another module.

- a lock bolt can be controlled via the additional latch module in order to trigger a locking of the lock bolt in a self-locking lock as soon as the door is in the closed position.

- the additional latch module can have a sequence control that includes tamper protection and prevents the lock bolt from being locked out of the lock housing when the additional latch is accidentally actuated when the door is open.

- a module is designed as a nut module, comprising a nut module carrier which carries a lock nut or at least two nut parts and a pusher mandrel holder, as well as a nut connection element for connecting the nut module to the slide plate and/or another module.

- the nut module carrier can be provided with a lock nut which has at least two nut parts and in addition one or more pawls for coupling and/or uncoupling the nut parts are held on the nut parts or the nut module carrier.

- a module is designed as a coupling module, comprising a coupling module carrier which has a coupling motor, a coupling gear and a coupling module connection element for connecting the coupling module to the nut module.

- a module in order to enable convenient operation of the lock, one embodiment can provide for a module to be designed as a drive module, comprising a drive module carrier, a drive motor and a drive gear as well as a drive module connection element for connecting the drive module to the slide plate and/or to another module.

- the drive module can, for example, drive the locking elements of the lock and thus enable remote-controlled motorized unlocking and/or locking of the lock.

- a module is designed as a spring accumulator, comprising a spring module carrier, which has a spring, a spring guide and a spring module connection element for connecting the spring accumulator to the slide plate or another module.

- the spring accumulator can, for example, interact with the slide plate and/or a locking element in order to store the energy generated when the lock is opened. A self-locking lock can then be realized via the spring accumulator by the The energy contained in the spring accumulator is transferred to the locking element or the slide plate to lock the lock.

- the procedure is such that first the at least two modules are inserted into the lock base and fastened there and then a connection is created between the at least two modules and/or a locking element via one or more connecting elements and in a subsequent step the slide plate is inserted and connected to several of the connecting elements and at least one locking element.

- the lock housing can then be closed by attaching the lock cover.

- the at least two modules are designed as independent assemblies and are prefabricated before the modules are inserted into the lock base.

- prefabricating the modules it is possible to manufacture a lock in a modular manner within a short period of time.

- the modules are provided in stock as finished, independent assemblies and are inserted into the lock as a finished, tested and functional component when a lock is manufactured. In this way, it is possible to manufacture a lock within a significantly shorter period of time and with significantly increased quality and functional reliability.

- At least two different module types are prefabricated from one module and that a module to be inserted into the lock floor is selected from these different module types are selected.

- two module types with different drive forces are made from one module.

- the appropriate module is selected depending on the general conditions and requirements of the lock. For a lock that has less stringent requirements, the module with the lower drive force can then be selected. If the lock is to be used for heavier doors or in a harsh environment, a module with a higher drive force can be selected and inserted into the lock base.

- a production kit comprising at least two prefabricated modules that are designed as pre-assembled components and can be connected to the lock base. This production kit makes it easy to manufacture a corresponding lock or configure it individually without great mechanical effort.

- At least one module is prefabricated as a set of at least two different module types and that a specific module type is selected from this set before a module is inserted into the lock base. This makes it possible to provide a production kit with which A lock can be manufactured in different ways and adapted to different requirements.

- Another advantageous aspect of the lock according to the invention is the ease of maintenance and simple repair of the lock.

- the modular design makes it possible to easily repair the lock by replacing a module, without the need for complex disassembly and assembly, as is the case with a conventional lock, which consists of a large number of individual parts.

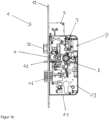

- FIGS. 1a-1c show an embodiment of the modular lock 1 according to the invention.

- the lock 1 is shown in a side view with the lock cover 14 removed.

- the Fig. 1b shows the same lock in side view with the slide plate 17 removed.

- Fig. 1c the castle 1 with castle ceiling 14 is shown.

- the lock 1 has a lock housing 11.

- the lock housing 11 comprises a lock base 13, a lock cover 14 and a lock faceplate 12 arranged on the front.

- Locking elements in the form of a lock latch 15 and a lock bolt 16 are mounted in the lock housing 11.

- these locking elements are extended from the lock housing 11 and engage in a bolt receiving space that is arranged on a door frame or window frame.

- the movably mounted leaf of a door or window is locked against the door frame by the lock 1.

- the locking elements 15, 16 can be moved back into the lock housing 11 and thereby release the leaf.

- the lock housing 11 has a slide plate 17 to control or operate the locking elements 15, 16.

- the slide plate 17 has a guide slot into which a pin arranged on the locking element 16 engages. When the pin on the locking element 16 engages the slot of the slide plate 17, a movement of the slide plate 17 is converted into a movement of the locking element 16.

- the slide plate 17 and the locking element 16 are thus motion-coupled.

- a movement of the slide plate 17 in a vertical upward direction causes a movement of the locking element 16 in the locking direction; the locking element 16 moves into the lock housing 11.

- a movement of the slide plate 17 in a vertical downward direction causes a movement of the locking element in the pre-locking direction; the locking element 16 moves out of the lock housing 11.

- the slide plate 17 is used to implement a sequence control. The pre-closure of the locking element 16 is only triggered when the locking element 15 is first actuated and then released again when the additional latch 42 is actuated.

- the additional latch 42 is described in detail below.

- This sequence control serves to implement a self-locking mechanism.

- the self-locking mechanism causes the locking element 15 to automatically pre-lock, i.e. when the wing has reached its closed position on the door frame or window frame. In this position of the wing, the locking element 15 automatically extends from the lock housing 11 and engages in the locking receiving space arranged on the door frame or window frame.

- a lock nut 52 is mounted in the lock housing 11 to accommodate a door handle.

- the latch 15 and/or the bolt 16 can be unlocked via the lock nut or a door handle.

- a removable drive bolt device 2 is connected to the top of the lock housing 11.

- the drive bolt device 2 is designed as an optional module and can be removed from the lock housing 11. It serves to actuate a locking bar (not shown) of a switch lock in order to create an additional locking point for a door leaf or a window leaf.

- the lock housing 11 has several separate spaces for accommodating modules. As shown in Fig. 1b As shown, several modules are accommodated in the lock housing.

- a nut module 5 works together with a spring-loaded module 3.

- a drive module 7 is arranged in the rear area of the lock 1 in order to operate the lock 1 remotely and/or by motor.

- a latch module 4 is arranged on the faceplate side, i.e. in the front area of the lock 1, in order to control the bolt extension of the bolt 16.

- the lock housing 11 has a further installation space in the area next to the lock cylinder holder and below the drive module 16, into which an optional coupling module can be inserted. In the example shown, this installation space is empty. With the help of a coupling module, the lock 1 can be upgraded to remotely couple the lock nut with a motor and thus control the panic functions of the lock 1.

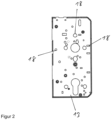

- FIG. 2 The lock base 13 is shown without any built-in parts.

- Figure 2 the receptacles 18 are visible, which are formed in the lock base and serve for the mechanical mounting of modules, such as the spring-loaded module 3 and/or the additional latch module 4 and/or the nut module 5 and/or the coupling module 6 and/or the drive module 7.

- the receptacles 18 are designed as punched-outs and/or dowel pins and/or threaded connections and are arranged in the lock base.

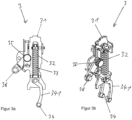

- the spring-loaded module 3 is in the Figures 3a and 3b shown.

- the Fig. 3a shows the spring-loaded module 3 in a side view.

- the Fig. 3b shows a 3D representation of the spring storage module 3.

- the spring storage module 3 comprises a spring module carrier 31.

- the spring module carrier 31 holds all components of the spring module 3.

- a compression spring 32 and a spring guide 33 are arranged on the spring module carrier 31.

- the compression spring 32 is firmly connected to the spring module carrier 31 at its upper end. Its other end is movable relative to the spring module carrier 31 and is connected to a swivel arm 341.

- the swivel arm 341 has a connection element 34 at its lower end, via which the swivel arm 341 can be connected to the nut module 5.

- the spring module also has a Torsion spring 35 which is held on the spring module carrier 31. This torsion spring 35 acts on a rotary lever, at the end of which a second connection element 36 is arranged

- the embodiments shown are a spring module 3 for a two-part nut. Accordingly, the spring storage module 3 has two springs 32 and two pivot arms 341 and two connection elements 34. In an alternative embodiment, the spring storage module 3 can also be designed as a spring storage module for a one-part nut and therefore only have one spring 32, one pivot arm 341 and one connection element 34. In addition, it is provided to design the spring storage module 3 in different spring strengths in order to adapt the spring force acting on the lock nut to the respective requirements.

- the additional trap module 4 is shown.

- the Figure 4a shows the additional trap module 4 in a side view.

- the Figure 4b shows the additional latch module 4 in a 3D view.

- the additional latch module 4 has an additional latch module carrier 41, on which the elements of the additional latch module 4 are mounted or attached.

- the additional latch module 4 is connected to the lock base 13 via the additional latch module carrier 41.

- the additional latch module 4 also has an additional latch or auxiliary latch 42 that is slidably mounted on the additional latch module carrier 41. This is acted upon by a compression spring 43 and passes through, as shown in the Figures 1a-1c shown, the lock faceplate 12.

- the additional latch module 4 has a sequence control which makes it possible to control the locking of the lock bolt 16 in a self-locking lock 1.

- the lock bolt 16 automatically closes as soon as the door or window is in the closed position.

- the additional latch module 4 is intended to prevent the lock bolt 16 from coming out of the lock housing 16 in the event of a manipulation attempt as long as the lock 1 or the leaf is not in the closed position.

- the lock latch module 4 also comprises gear elements, for example a pivoted lever 45 with a connecting element 44.

- the connecting element 44 interacts with the slide plate 17 of the lock 1 to control the bolt closure. It is intended that several types of additional latch modules are provided. For example, the logic of the sequence control or the strength of the spring 43 can be designed differently in order to be able to cover the widest possible range of applications.

- a nut module 5 is shown.

- the Fig. 5a shows the nut module in a side or top view.

- the Fig. 5b shows the nut module 5 in a three-dimensional representation.

- the nut module has a nut module carrier 51.

- Two nut parts namely the first nut part 521 and the second nut part 522, are movably mounted on the nut module carrier 51.

- a handle holder 53 is arranged in the first nut part 521 and the second nut part 522.

- two locking pawls 551, 552 are arranged on the nut module carrier 51, which are rotatably mounted on the nut module carrier 51 and each interact with a nut part 521 or 522 in order to couple or uncouple this nut part.

- this is coupled in and takes the lock nut with it when it rotates.

- the locking pawl out the corresponding nut part is uncoupled and rotates hollow when actuated without the lock nut being taken along. This makes it possible to control the handle-operated opening of the lock and different panic functions can be implemented depending on the position of the pawls.

- the nut module can be connected directly or indirectly via a transmission element to a latch module (not shown) and/or the slide plate 17 and/or the additional latch module 4 via a nut connection element 54. It is also possible to design different module types for the nut module 5.

- a nut module 5 can be provided which has only a one-piece nut or, as in the illustrated Figures 5a and 5b shown, comprises a multi-part nut.

- the coupling module 6 has a coupling module carrier 61 on which a coupling motor 62 is held.

- the coupling motor 62 actuates a coupling slide 64, which is designed as a connection element, via a coupling gear.

- the coupling module can be connected to the nut module 5 via the coupling slide 64 in order to actuate the locking pawls of the nut module 5.

- the coupling module 6 is inserted into the lock base or a receptacle 18 of the lock base 13 via the coupling module carrier 61 and held there.

- the Figures 7a and 7b show a drive module 7.

- the Fig. 7a shows a top view and the Fig. 7b shows a three-dimensional representation of the drive module 7.

- the drive module 7 has a drive module carrier 71 on which the components of the drive module 7 are held.

- the drive module carrier 71 can be used to install the drive module in the lock 1 inserted into a recess 18 in the lock base and is held there mechanically stable.

- a drive motor 52 is mounted on the drive module carrier 71 and actuates a connecting element 74 via a drive gear 73.

- the connecting element 74 is movably mounted on the drive module carrier 71 and can be moved linearly by the motor 52.

- the connecting element 74 interacts with the slide plate 17 of the lock 1 in order to actuate the locking elements, in particular the lock bolt 16 and/or the lock latch 15, i.e. to unlock or lock them.

- the drive module 7 is designed in different module types. For example, a cost-effective and/or space-saving drive module 7 can be provided, in which a smaller drive motor 52 is used. Furthermore, an additional drive module type can be provided, in which a larger drive motor 72 is used in order to achieve a higher actuation force. Depending on the requirements placed on the lock 1, the corresponding drive module 7 can be selected and inserted into the lock base 13. This makes it possible to adapt the lock 1 to a wide variety of requirements in a simple manner, without the need for a structural revision of the lock.

- the lock base 13 can be manufactured as a separate part and provided with the exceptions 18.

- the individual modules are prefabricated and are already available as stock items. It is intended that different module types can be manufactured from individual modules. which differ, for example, in terms of strength or robustness.

- the modules suitable for the planned application are determined or selected.

- the modules selected for the lock 1 to be manufactured are then inserted into the lock base 13. After the modules have been inserted into the lock base, they are connected to one another or to the locking elements via the slide plate 17. After the lock cover 14 has been attached, the lock 1 is then fully assembled and can be tested for functionality or used.

Landscapes

- Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Business, Economics & Management (AREA)

- Emergency Management (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Lock And Its Accessories (AREA)

- Power-Operated Mechanisms For Wings (AREA)

Claims (14)

- Serrure pour un battant pivotant d'une porte ou d'une fenêtre avec un boîtier de serrure (11) comprenant une têtière de serrure (12), un fond de serrure (13) et un couvercle de serrure amovible (14), ainsi qu'au moins un élément de verrouillage (15, 16) traversant la têtière de serrure (12) et une plaque coulissante (17) coopérant avec l'élément de verrouillage, la plaque coulissante (17) étant couplée en mouvement avec l'élément de verrouillage (15, 16),où il est prévuen ce que le fond de serrure (13) présente des logements mécaniques (18) pour le maintien d'au moins deux modules différents (3, 4, 5, 6, 7), qui sont réalisés chacun sous la forme d'un ensemble, eten ce que les modules présentent chacun un support de module (31, 41, 51, 61, 71) qui porte plusieurs composants du module et qui est maintenu sur les logements (18) du fond de serrure (13), et en ce qu'au moins un des modules (3, 4, 5, 6, 7) est relié à la plaque coulissante (17),caractérisé en ce queles au moins deux modules (3, 4, 5, 6, 7) présentent chacun un élément de raccordement (34, 44, 54, 64, 74) qui établit une liaison entre un module et la plaque coulissante (17).

- Serrure selon la revendication 1,

caractérisé en ce que

les au moins deux modules (3, 4, 5, 6, 7) présentent chacun un composant de module logé de manière mobile par rapport au support de module (31, 41, 51, 61, 71) et/ou par rapport au fond de serrure (13), de préférence que le composant de module logé de manière mobile est conçu comme élément de raccordement (34, 44, 54, 64, 74) ou est relié à l'élément de raccordement (34, 44, 54, 64, 74). - Serrure selon l'une des revendications précédentes,

caractérisé en ce que

un module est conçu comme module de pêne demi-tour supplémentaire (4), comprenant un support de module de pêne demi-tour supplémentaire (41), qui porte un pêne demi-tour supplémentaire (42) et un ressort (43) sollicitant le pêne demi-tour supplémentaire et au moins un élément de transmission (45) pouvant être actionné par le pêne demi-tour supplémentaire et un élément de raccordement de module de pêne demi-tour (44) pour relier le module de pêne demi-tour supplémentaire (4) à la plaque coulissante (17) et/ou à un autre module. - Serrure selon l'une des revendications précédentes,

caractérisé en ce que

un module est conçu comme module de fouillot (5), comprenant un support de module de fouillot (51) qui porte un fouillot de serrure (52) ou au moins deux pièces de fouillot (521, 522) ainsi qu'un logement de broche de poignée (53), ainsi qu'un élément de raccordement de fouillot (54) pour relier le module de fouillot à la plaque coulissante (17) et/ou à un autre module. - Serrure selon la revendication 4,

caractérisé en ce que

le support de module de noix (51) porte un fouillot de serrure qui présente au moins deux pièces de fouillot (521, 522) et qu'en outre un ou plusieurs cliquets d'arrêt (551, 552) sont maintenus soit sur les pièces de fouillot soit sur le support de module de fouillot pour l'accouplement et/ou le désaccouplement des pièces de fouillot. - Serrure selon l'une des revendications précédentes,

caractérisé en ce que

un module est conçu comme module de couplage (6), comprenant un support de module de couplage (61), qui présente un moteur de couplage (62), un engrenage de couplage (63) ainsi qu'un élément de raccordement de module de couplage (64) pour le raccordement du module de couplage (6) au module de fouillot (5). - Serrure selon l'une des revendications précédentes,

caractérisé en ce que

un module est conçu comme module d'entraînement (7), comprenant un support de module d'entraînement (71), un moteur d'entraînement (72) et un engrenage d'entraînement (73) ainsi qu'un élément de raccordement de module d'entraînement (74) pour le raccordement du module d'entraînement (7) à la plaque coulissante (17) et/ou à un autre module. - Serrure selon l'une des revendications précédentes,

caractérisé en ce que

un module est conçu comme un accumulateur à ressort (3), comprenant un support de module à ressort (31) qui présente un ressort (32), un guidage de ressort (33) et un élément de raccordement de module à ressort (34) pour le raccordement de l'accumulateur à ressort à la plaque coulissante (17) ou à un autre module. - Procédé de fabrication d'une serrure selon l'une quelconque des revendications précédentes,

caractérisé en ce que

tout d'abord les au moins deux modules (3, 4, 5, 6, 7) sont insérés dans le fond de serrure (13) et y sont fixés et en ce qu'ensuite une liaison entre les au moins deux modules (3, 4, 5, 6, 7) et/ou un élément de verrouillage (15, 16) est établie par l'intermédiaire d'un ou plusieurs éléments de raccordement et, dans une étape suivante, la plaque coulissante (17) est insérée et reliée à plusieurs des éléments de raccordement (34, 44, 54, 64, 74) et à un élément de verrouillage (16). - Procédé de fabrication d'une serrure selon la revendication 9,

caractérisé en ce que

dans une étape suivante, le boîtier de serrure (11) est fermé par la mise en place du couvercle de serrure (14). - Procédé de fabrication d'une serrure selon la revendication 9 ou 10, caractérisé en ce que

les au moins deux modules (3, 4, 5, 6, 7) sont réalisés sous forme d'ensembles indépendants et sont préfabriqués avant l'insertion des modules (3, 4, 5, 6, 7) dans le fond de serrure (13). - Procédé de fabrication d'une serrure selon l'une quelconque des revendications 9 à 11,

caractérisé en ce que

au moins deux types de modules différents sont préfabriqués à partir d'un module (3, 4, 5, 6, 7) et qu'un module à insérer dans le fond de serrure (13) est choisi par une sélection parmi ces différents types de modules. - Kit de fabrication pour la fabrication d'une serrure selon l'une quelconque des revendications 1 à 8,

comprenant au moins deux modules préfabriqués (3, 4, 5, 6, 7), qui sont réalisés sous forme d'ensembles prémontés et peuvent être reliés au fond de serrure (13). - Kit de fabrication pour la fabrication d'une serrure selon la revendication 13,

caractérisé en ce que

au moins un module (3, 4, 5, 6, 7) est préfabriqué sous forme d'un set d'au moins deux types de modules différents et qu'avant l'insertion d'un module (3, 4, 5, 6, 7) dans le fond de serrure (13), une sélection d'un type de module déterminé est effectuée dans ce set.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102016118119.6A DE102016118119A1 (de) | 2016-09-26 | 2016-09-26 | Modulares Schloss |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3299552A1 EP3299552A1 (fr) | 2018-03-28 |

| EP3299552B1 true EP3299552B1 (fr) | 2024-07-31 |

Family

ID=59895230

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17191596.0A Active EP3299552B1 (fr) | 2016-09-26 | 2017-09-18 | Verrou modulaire |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP3299552B1 (fr) |

| DE (1) | DE102016118119A1 (fr) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102016118119A1 (de) | 2016-09-26 | 2018-03-29 | Assa Abloy (Schweiz) Ag | Modulares Schloss |

| TWI650473B (zh) * | 2018-06-07 | 2019-02-11 | 一德金屬工業股份有限公司 | 模組化的電動鎖閂控制設備 |

| DE102019125144A1 (de) * | 2019-09-18 | 2021-03-18 | WILKA Schließtechnik GmbH | Modular aufgebautes Schloss mit Antipanik-Funktion |

| AT17862U1 (de) * | 2022-01-24 | 2023-05-15 | Roto Frank Fenster Und Tuertechnologie Gmbh | Automatikschloss |

| DE102022134993B4 (de) | 2022-12-29 | 2025-02-20 | Assa Abloy Sicherheitstechnik Gmbh | Antipanikschloss mit Fluchttüröffner |

Citations (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4014046A1 (de) | 1990-05-02 | 1991-11-07 | Fuhr Carl Gmbh & Co | Schliesszylinderbetaetigbares treibstangenschloss |

| DE9208526U1 (de) | 1992-06-25 | 1992-09-10 | Gretsch-Unitas GmbH Baubeschläge, 7257 Ditzingen | Schloß, insbesondere Einsteckschloß für eine Außentür |

| EP0668425A1 (fr) | 1994-02-21 | 1995-08-23 | Hellmüller + Zingg AG | Serrure pour porte |

| EP0792980A1 (fr) | 1996-02-29 | 1997-09-03 | DORMA GmbH + Co. KG | Serrure |

| EP0961001A2 (fr) | 1998-05-28 | 1999-12-01 | Marantec Antriebs- und Steuerungstechnik GmbH & Co. KG. | Commande de porte |

| EP0987391A2 (fr) | 1998-09-16 | 2000-03-22 | Carl Fuhr GmbH & Co. | Serrure à crémone avec pêne demi-tour à mode d'actuation convertible |

| DE20101144U1 (de) | 2001-01-22 | 2001-07-19 | Gretsch-Unitas GmbH Baubeschläge, 71254 Ditzingen | Schloßkasten sowie Türschloß mit einem derartigen Schloßkasten |

| EP1154102A2 (fr) | 2000-05-12 | 2001-11-14 | MOTTURA SERRATURE DI SICUREZZA S.p.A. | Serrure de sécurité pour portes de bâtiment ou similaires |

| WO2003027422A1 (fr) | 2001-09-28 | 2003-04-03 | Assa Ab | Dispositif de verrouillage comportant un element de plaque |

| WO2003033845A1 (fr) | 2001-10-16 | 2003-04-24 | Assa Ab | Bloc moteur destine a etre place dans un systeme de verrouillage |

| WO2003078767A1 (fr) | 2002-03-15 | 2003-09-25 | Assa Ab | Dispositif de serrure avec verrou a poucier |

| EP1431481A2 (fr) | 2002-12-20 | 2004-06-23 | GEZE GmbH | Serrure |

| DE202007003890U1 (de) | 2007-03-16 | 2008-07-31 | Carl Fuhr Gmbh & Co. Kg | Schloss, insbesondere Panikschloss mit Nussbetätigungsstellungssensor |

| WO2009096892A1 (fr) | 2008-02-01 | 2009-08-06 | Assa Ab | Verrou doté d'un pêne à ressort |

| DE202009007735U1 (de) | 2009-05-30 | 2009-08-27 | Carl Fuhr Gmbh & Co. Kg | Schloß, insbesondere Zentralschloß für eine Schließanlage mit Mehrfachverriegelung |

| EP2206858A1 (fr) | 2009-01-12 | 2010-07-14 | Glutz AG | Verrou de porte |

| EP2264263A2 (fr) | 2009-06-15 | 2010-12-22 | BKS GmbH | Serrure |

| EP2327849A2 (fr) * | 2009-11-25 | 2011-06-01 | Assa Ab | Serrure |

| EP2520746A1 (fr) | 2011-05-06 | 2012-11-07 | Steinbach & Vollmann GmbH & Co. KG | Serrure actionnée de manière électrique |

| EP2543802A2 (fr) | 2011-07-06 | 2013-01-09 | MACO Technologie GmbH | Serrure |

| DE202013009023U1 (de) | 2013-10-11 | 2013-11-07 | Kfv Karl Fliether Gmbh & Co. Kg | Drückerbetätigbares selbstverriegelndes Schloss |

| EP2862992A2 (fr) | 2013-10-17 | 2015-04-22 | DORMA Deutschland GmbH | Multi-serrure |

| EP2873790A1 (fr) | 2013-11-13 | 2015-05-20 | Assa Ab | Serrure avec boulon à crochet |

| DE102014113621A1 (de) | 2014-09-22 | 2016-03-24 | SÜD-Metall Schließsysteme Leipzig GmbH | Schloss und elektronisches Schließsystem |

| EP3106593A1 (fr) | 2015-06-08 | 2016-12-21 | MSL Schloss- und Beschlägefabrik AG | Serrure insonorisee |

| EP3112563A1 (fr) | 2015-06-15 | 2017-01-04 | GEZE GmbH | Serrure |

| EP3299552A1 (fr) | 2016-09-26 | 2018-03-28 | ASSA ABLOY (Schweiz) AG | Verrou modulaire |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWM362879U (en) | 2009-03-06 | 2009-08-11 | Tong Lung Metal Ind Co Ltd | Apparatus for adjusting axis distance of lock-latch |

| WO2013114409A1 (fr) | 2012-01-30 | 2013-08-08 | Cisa S.P.A. | Serrure pour portes |

-

2016

- 2016-09-26 DE DE102016118119.6A patent/DE102016118119A1/de active Pending

-

2017

- 2017-09-18 EP EP17191596.0A patent/EP3299552B1/fr active Active

Patent Citations (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4014046A1 (de) | 1990-05-02 | 1991-11-07 | Fuhr Carl Gmbh & Co | Schliesszylinderbetaetigbares treibstangenschloss |

| DE9208526U1 (de) | 1992-06-25 | 1992-09-10 | Gretsch-Unitas GmbH Baubeschläge, 7257 Ditzingen | Schloß, insbesondere Einsteckschloß für eine Außentür |

| EP0575701A1 (fr) | 1992-06-25 | 1993-12-29 | Gretsch-Unitas GmbH Baubeschläge | Serrure, notamment serrure à fourreau pour une porte extérieure |

| EP0668425A1 (fr) | 1994-02-21 | 1995-08-23 | Hellmüller + Zingg AG | Serrure pour porte |

| EP0792980A1 (fr) | 1996-02-29 | 1997-09-03 | DORMA GmbH + Co. KG | Serrure |

| EP0961001A2 (fr) | 1998-05-28 | 1999-12-01 | Marantec Antriebs- und Steuerungstechnik GmbH & Co. KG. | Commande de porte |

| EP0987391A2 (fr) | 1998-09-16 | 2000-03-22 | Carl Fuhr GmbH & Co. | Serrure à crémone avec pêne demi-tour à mode d'actuation convertible |

| EP1154102A2 (fr) | 2000-05-12 | 2001-11-14 | MOTTURA SERRATURE DI SICUREZZA S.p.A. | Serrure de sécurité pour portes de bâtiment ou similaires |

| DE20101144U1 (de) | 2001-01-22 | 2001-07-19 | Gretsch-Unitas GmbH Baubeschläge, 71254 Ditzingen | Schloßkasten sowie Türschloß mit einem derartigen Schloßkasten |

| WO2003027422A1 (fr) | 2001-09-28 | 2003-04-03 | Assa Ab | Dispositif de verrouillage comportant un element de plaque |

| WO2003033845A1 (fr) | 2001-10-16 | 2003-04-24 | Assa Ab | Bloc moteur destine a etre place dans un systeme de verrouillage |

| WO2003078767A1 (fr) | 2002-03-15 | 2003-09-25 | Assa Ab | Dispositif de serrure avec verrou a poucier |

| EP1431481A2 (fr) | 2002-12-20 | 2004-06-23 | GEZE GmbH | Serrure |

| DE202007003890U1 (de) | 2007-03-16 | 2008-07-31 | Carl Fuhr Gmbh & Co. Kg | Schloss, insbesondere Panikschloss mit Nussbetätigungsstellungssensor |

| EP1997986B1 (fr) | 2007-03-16 | 2011-06-08 | Carl Fuhr GmbH & Co. KG | Serrure, en particulier serrure anti-panique dotée d'un capteur de position à actionnement au pied |

| WO2009096892A1 (fr) | 2008-02-01 | 2009-08-06 | Assa Ab | Verrou doté d'un pêne à ressort |

| EP2206858A1 (fr) | 2009-01-12 | 2010-07-14 | Glutz AG | Verrou de porte |

| DE202009007735U1 (de) | 2009-05-30 | 2009-08-27 | Carl Fuhr Gmbh & Co. Kg | Schloß, insbesondere Zentralschloß für eine Schließanlage mit Mehrfachverriegelung |

| EP2264263A2 (fr) | 2009-06-15 | 2010-12-22 | BKS GmbH | Serrure |

| EP2327849A2 (fr) * | 2009-11-25 | 2011-06-01 | Assa Ab | Serrure |

| EP2520746A1 (fr) | 2011-05-06 | 2012-11-07 | Steinbach & Vollmann GmbH & Co. KG | Serrure actionnée de manière électrique |

| EP2543802A2 (fr) | 2011-07-06 | 2013-01-09 | MACO Technologie GmbH | Serrure |

| DE202013009023U1 (de) | 2013-10-11 | 2013-11-07 | Kfv Karl Fliether Gmbh & Co. Kg | Drückerbetätigbares selbstverriegelndes Schloss |

| EP2862992A2 (fr) | 2013-10-17 | 2015-04-22 | DORMA Deutschland GmbH | Multi-serrure |

| EP2873790A1 (fr) | 2013-11-13 | 2015-05-20 | Assa Ab | Serrure avec boulon à crochet |

| DE102014113621A1 (de) | 2014-09-22 | 2016-03-24 | SÜD-Metall Schließsysteme Leipzig GmbH | Schloss und elektronisches Schließsystem |

| EP3106593A1 (fr) | 2015-06-08 | 2016-12-21 | MSL Schloss- und Beschlägefabrik AG | Serrure insonorisee |

| EP3112563A1 (fr) | 2015-06-15 | 2017-01-04 | GEZE GmbH | Serrure |

| EP3299552A1 (fr) | 2016-09-26 | 2018-03-28 | ASSA ABLOY (Schweiz) AG | Verrou modulaire |

Non-Patent Citations (39)

| Title |

|---|

| D17 - schematische Darstellung des HZ-Lock RR 35, 19010 (kommerziell von der Glutz AG seit Juni 2014 erhältlich) |

| D18 - Übersichtsliste über die Aufträge für den HZ-Lock RR 35, 19010 mit derinternen Nr. 237927 |

| D19 - exemplarischer Auftrag für den HZ-Lock RR 35, 19010 – Auftragsbestätigung für den Auftrag Nr. 12175996 |

| D20 - Laufkarte Nr. 10-12175996-0020 für das Schloss HZ-Lock RR 35, 19010 mit der internen Nr. 237927 |

| D21 - Laufkarte Nr. 10-12175996-0010 für das Schloss HZ-Lock RR 35, 19010 mit der internen Nr. 241921 |

| D22 - Zuordnung Einzelteile für das Schloss HZ-Lock RR 35, 19010 mit der internen Nr. 237927 zu den jeweiligen Zeichnungen |

| D23 - Zuordnung Einzelteile für das Schloss HZ-Lock RR 35, 19010 mit der internen Nr. 241921 zu den jeweiligen Zeichnungen |

| D24 - Lieferschein Nr. 14183039 vom 01.07.2014 zum Auftrag Nr. 2175996 |

| D25 - Rechnung Nr. 5105309 vom 01.07.2014 zum Auftrag Nr. 12175996 |

| D26 - Arbeitsanweisung für den Aufbau des HZ-Lock RR 35, 19010 vom 30.01.2015 |

| D27 - schematische Darstellung des HZ-Lock (RZ 74 mm und PZ 72 mm) (kommerziell von der Glutz AG seit Mai 2012 erhältlich) |

| D28 - Übersichtsliste über die Aufträge für den HZ-Lock |

| D29 - exemplarischer Auftrag für den HZ-Lock – Auftragsbestätigung für den Auftrag Nr. 12164431 |

| D30 - Laufkarte Nr. 10-12164431-0010 für das Schloss HZ-Lock mit der internen Nr. 213961 |

| D31 - Zuordnung Einzelteile für das Schloss HZ-Lock mit der internen Nr. 213961 zu den jeweiligen Zeichnungen |

| D32 - Lieferschein Nr. 14169862 vom 15.01.2014 zum Auftrag Nr. 12164431 |

| D33 - Rechnung Nr. 5093808 vom 15.01.2014 zum Auftrag Nr. 12164431 |

| D34 - Arbeitsanweisung für den Aufbau des HZ-Lock vom 28.08.2012, die im Januar 2018 durch eine neue Variante abgelöst wurde |

| D35 - schematische Darstellung des MINT SV 18945 (kommerziell von der Glutz AG seit Juni 2015 erhältlich) |

| D36 - Übersichtsliste über die Aufträge für den MINT SV 18945 |

| D37 - exemplarischer Auftrag für den MINT SV 18945 – Auftragsbestätigung für den Auftrag Nr. 12202745 |

| D38 - Laufkarte Nr. 10-12202745-0010 für das Schloss MINT SV 18945 mit der internen Nr. 256756 |

| D39 - Zuordnung Einzelteile für das Schloss MINT SV 18945 mit der internen Nr. 256756 zu den jeweiligen Zeichnungen |

| D40 - Lieferschein Nr. 14216241 vom 08.09.2015 zum Auftrag Nr12202745 |

| D41 - Rechnung Nr. 5135653 vom 08.09.2015 zum Auftrag Nr. 12202745 |

| D42 - Arbeitsanweisung für den Aufbau des MINT SV 18945 |

| D43 - Übersichtsliste über die Aufträge für den HZ-Lock RR 35, 19010 mit der internen Nr. 241918 |

| D44 - exemplarischer Auftrag für den HZ-Lock RR 35, 19010 mit der internen Nr. 241918 inkl. Tagesbetrieb (interne Nr. 241924) |

| D45 - Laufkarte Nr. 10-12176097-0010 für das Schloss HZ-Lock RR 35, 19010 mit der internen Nr. 241918 |

| D46 - Laufkarte Nr. 10-12176097-0020 für den Tagesbetrieb des Schlosses HZ-Lock RR 35, 19010 mit der internen Nr. 241924 |

| D47 - Zuordnung Einzelteile für das Schloss HZ-Lock RR 35, 19010 mit der internen Nr. 241918 zu den jeweiligen Zeichnungen |

| D48 - Zuordnung Einzelteile für den Tagesbetrieb des Schlosses HZ-Lock RR35, 19010 mit der internen Nr. 241924 zu den jeweiligen Reichnungen |

| D49 - Lieferschein Nr.14181661 vom 16.06.2014 zum Auftrag Nr.12176097 |

| D50 - Rechnung Nr. 5104085 vom 16.06.2014 zum Auftrag Nr. 12176097 |

| D51 - Relevante Zeichnungen des HZ-Lock RR 35, 19010 mit der internen Nr.237927 und der internen Nr. 241921 |

| D52 - Relevante Zeichnungen des HZ-Lock RR 35, 19010 mit der internen Nr.241918 und des Tagesbetriebs mit der internen Nr. 241924 |

| D53 - Relevante Zeichnungen des HZ-Lock mit der internen Nr. 213961 |

| D54 - Relevante Zeichnungen des MINT SV 18945 mit der internen Nr. 256756 |

| D67 - D55 Ausschnitt aus Fig. 2 der D45 (EP-A 2 264 263) |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3299552A1 (fr) | 2018-03-28 |

| DE102016118119A1 (de) | 2018-03-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3299552B1 (fr) | Verrou modulaire | |

| EP0472774B1 (fr) | Système de verrouillage | |

| EP1932989B1 (fr) | Système de fermeture pour portes, fenêtres ou analogues, en particulier crémone-serrure à fonction d'urgence et de verrouillage à plusieurs points | |

| EP3219885B1 (fr) | Barre de poussée comprenant un dispositif d'entraînement modulaire | |

| EP3219886B1 (fr) | Barre de poussée comprenant un dispositif d'entraînement | |

| EP0861960B1 (fr) | Serrure de sécurité | |

| DE102012203602A1 (de) | Baugruppe eines Fensters oder einer Tür für ein Gebäude | |

| DE102022133020A1 (de) | Arretierungskomponente für eine türbetätigungsanordnung | |

| DE19730552C1 (de) | Einrichtung zum Entriegeln eines mechanisch selbstverriegelnden Mehrfachschlosses | |

| DE102013000286A1 (de) | Türschlossvorrichtung für eine Tür mit mindestens einem Türflügel | |

| EP2339096B1 (fr) | Serrure à crémone dotée d'une fonction anti-panique et d'un verrouillage multiple | |

| DE29619007U1 (de) | Verriegelungsvorrichtung | |

| DE10151862A1 (de) | Vorrichtung zur Betätigung eines Verschlusses von Türen oder Klappen, insbesondere an Fahrzeugen | |

| EP2924207A1 (fr) | Gâchette | |

| EP1908899A2 (fr) | Système de verrouillage | |

| EP2322744B1 (fr) | Serrure, serrure à crochet pivotant et système de verrouillage, notamment pour le verrouillage à plusieurs points d'une porte ou d'une fenêtre | |

| EP3219887B1 (fr) | Barre de poussée | |

| DE102004059840B4 (de) | Vorrichtung zur Ver- und Entriegelung einer Tür oder Klappe | |

| EP2466044B1 (fr) | Dispositif de fermeture | |

| EP2998475B1 (fr) | Levier de jour pour une serrure a battant passif | |

| DE4032677C2 (de) | Automatische Türanlage mit motorisch angetriebenen Flügeln | |

| EP2998476B1 (fr) | Serrure à battant passif dotée de dispositif de tige de verrouillage et d'ouverture de porte | |

| DE102022134993B4 (de) | Antipanikschloss mit Fluchttüröffner | |

| EP1953312A1 (fr) | Verrou pour une porte | |

| EP1801325B1 (fr) | Système de verrouillage |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17P | Request for examination filed |

Effective date: 20180911 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| 17Q | First examination report despatched |

Effective date: 20181008 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230908 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E05C 9/00 20060101ALN20240124BHEP Ipc: E05B 65/10 20060101ALI20240124BHEP Ipc: E05B 63/20 20060101ALI20240124BHEP Ipc: E05B 59/00 20060101ALI20240124BHEP Ipc: E05B 47/06 20060101ALI20240124BHEP Ipc: E05B 47/02 20060101AFI20240124BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E05C 9/00 20060101ALN20240227BHEP Ipc: E05B 65/10 20060101ALI20240227BHEP Ipc: E05B 63/20 20060101ALI20240227BHEP Ipc: E05B 59/00 20060101ALI20240227BHEP Ipc: E05B 47/06 20060101ALI20240227BHEP Ipc: E05B 47/02 20060101AFI20240227BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20240312 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502017016300 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20240731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241031 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241031 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241031 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241130 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241101 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502017016300 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240918 |

|

| 26 | Opposition filed |

Opponent name: KFV KARL FLIETHER GMBH & CO. KG Effective date: 20250429 |

|

| 26 | Opposition filed |

Opponent name: GLUTZ AG Effective date: 20250430 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20241031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241031 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20240930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240918 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240731 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: U11 Free format text: ST27 STATUS EVENT CODE: U-0-0-U10-U11 (AS PROVIDED BY THE NATIONAL OFFICE) Effective date: 20251001 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250813 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20250827 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20251001 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20170918 |