EP3290586A1 - Fraiseuse et procédé de fonctionnement d'une fraiseuse - Google Patents

Fraiseuse et procédé de fonctionnement d'une fraiseuse Download PDFInfo

- Publication number

- EP3290586A1 EP3290586A1 EP17186317.8A EP17186317A EP3290586A1 EP 3290586 A1 EP3290586 A1 EP 3290586A1 EP 17186317 A EP17186317 A EP 17186317A EP 3290586 A1 EP3290586 A1 EP 3290586A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- operating

- milling

- assembly

- function

- parameter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01C—CONSTRUCTION OF, OR SURFACES FOR, ROADS, SPORTS GROUNDS, OR THE LIKE; MACHINES OR AUXILIARY TOOLS FOR CONSTRUCTION OR REPAIR

- E01C23/00—Auxiliary devices or arrangements for constructing, repairing, reconditioning, or taking-up road or like surfaces

- E01C23/06—Devices or arrangements for working the finished surface; Devices for repairing or reconditioning the surface of damaged paving; Recycling in place or on the road

- E01C23/08—Devices or arrangements for working the finished surface; Devices for repairing or reconditioning the surface of damaged paving; Recycling in place or on the road for roughening or patterning; for removing the surface down to a predetermined depth high spots or material bonded to the surface, e.g. markings; for maintaining earth roads, clay courts or like surfaces by means of surface working tools, e.g. scarifiers, levelling blades

- E01C23/085—Devices or arrangements for working the finished surface; Devices for repairing or reconditioning the surface of damaged paving; Recycling in place or on the road for roughening or patterning; for removing the surface down to a predetermined depth high spots or material bonded to the surface, e.g. markings; for maintaining earth roads, clay courts or like surfaces by means of surface working tools, e.g. scarifiers, levelling blades using power-driven tools, e.g. vibratory tools

- E01C23/088—Rotary tools, e.g. milling drums

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21C—MINING OR QUARRYING

- E21C25/00—Cutting machines, i.e. for making slits approximately parallel or perpendicular to the seam

- E21C25/06—Machines slitting solely by one or more cutting rods or cutting drums which rotate, move through the seam, and may or may not reciprocate

- E21C25/10—Rods; Drums

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01C—CONSTRUCTION OF, OR SURFACES FOR, ROADS, SPORTS GROUNDS, OR THE LIKE; MACHINES OR AUXILIARY TOOLS FOR CONSTRUCTION OR REPAIR

- E01C23/00—Auxiliary devices or arrangements for constructing, repairing, reconditioning, or taking-up road or like surfaces

- E01C23/06—Devices or arrangements for working the finished surface; Devices for repairing or reconditioning the surface of damaged paving; Recycling in place or on the road

- E01C23/12—Devices or arrangements for working the finished surface; Devices for repairing or reconditioning the surface of damaged paving; Recycling in place or on the road for taking-up, tearing-up, or full-depth breaking-up paving, e.g. sett extractor

- E01C23/122—Devices or arrangements for working the finished surface; Devices for repairing or reconditioning the surface of damaged paving; Recycling in place or on the road for taking-up, tearing-up, or full-depth breaking-up paving, e.g. sett extractor with power-driven tools, e.g. oscillated hammer apparatus

- E01C23/127—Devices or arrangements for working the finished surface; Devices for repairing or reconditioning the surface of damaged paving; Recycling in place or on the road for taking-up, tearing-up, or full-depth breaking-up paving, e.g. sett extractor with power-driven tools, e.g. oscillated hammer apparatus rotary, e.g. rotary hammers

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21C—MINING OR QUARRYING

- E21C29/00—Propulsion of machines for slitting or completely freeing the mineral from the seam

- E21C29/22—Propulsion of machines for slitting or completely freeing the mineral from the seam by wheels, endless tracks or the like

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21C—MINING OR QUARRYING

- E21C35/00—Details of, or accessories for, machines for slitting or completely freeing the mineral from the seam, not provided for in groups E21C25/00 - E21C33/00, E21C37/00 or E21C39/00

Definitions

- the invention relates to a milling machine, in particular road milling machine, stabilizer, recycler or surface miner, with a drive device which is designed such that the milling machine performs on the ground translational and / or rotational movements, and a working device which is designed such that the soil is being worked on. Moreover, the invention relates to a method for operating such a milling machine.

- ground milling machines which include in particular the road milling machines, stabilizers, recyclers or surface miners.

- the known milling machines are characterized by a drive device for executing translational and / or rotational movements of the machine on the ground and a working device for working the soil.

- the drive device has at least one module that executes a specific machine function as a function of drive parameters

- the working device has at least one module that executes a specific machine function as a function of operating parameters.

- the individual components of the drive device and working device can in turn comprise a plurality of components.

- a drive device is understood as meaning all components of the road milling machine which are intended or suitable for moving the machine

- a working device is understood as meaning all components of the road milling machine which are intended or suitable for use in the processing of the soil

- the drive device and working device can also have common components.

- a common component of the drive and working device may be an engine, in particular an internal combustion engine.

- the drive power of the internal combustion engine can be transmitted via a pump distributor gearbox to hydraulic pumps in order to supply hydraulic motors provided in the drives of the milling machine with hydraulic fluid.

- the drive device then includes the internal combustion engine, the pump distributor gear, the hydraulic pumps and the drives with the hydraulic motors.

- the feed rate of the milling machine can be controlled continuously at different speeds of the engine by a corresponding adjustment of the hydraulic pump.

- An essential component of the working device is the milling / cutting roller, which is arranged in the known milling machines in a Fräswalzengephaseuse.

- the milling / cutting roller is generally driven by the single drive machine of the milling machine, wherein the drive power of the drive machine is transmitted via a mechanical transmission to the milling / cutting roller.

- the speed of the milling / cutting roller is thus determined by the speed of the internal combustion engine and the transmission ratio of the transmission.

- the milling / cutting roller can for example also be driven hydraulically, wherein the speed is controlled by a corresponding adjustment of the hydraulic pumps.

- the working device may also comprise further assemblies which cooperate for the processing of the soil with the milling / cutting roller.

- these include, for example, an adjustable in height relative to the ground hold-down, which is arranged in the working direction of the milling machine in front of the milling / cutting roller, or in height relative to the ground adjustable and resting with a predetermined contact force on the ground scraper, in the working direction the milling machine is arranged behind the cutting / milling roller, or an edge protection that is adjustable in height relative to the floor and resting on the floor with a predetermined bearing force, which is arranged in the longitudinal direction of the milling machine.

- Milling machines have a central control and processing unit, which is configured such that the assemblies of the drive device are controlled such that a specific machine function is performed, and the assemblies of the Worker be controlled so that a specific machine function is performed.

- the execution of a specific machine function is dependent on certain operating parameters, which are specified by the machine operator.

- the operating parameters which are taken into account in the control of the assemblies of the drive device referred to as drive parameters and among the parameters that are taken into account in the control of the components of the working device, as working parameters.

- milling machines To input the drive and working parameters, milling machines have an operating unit that can be designed differently.

- the operating unit may, for example, have buttons or switches, slides, control sticks or be designed as a touch screen.

- the operation of a milling machine is a complex task for the machine operator.

- the machine operator must specify all drive and working parameters in such a way that the desired milling result is achieved.

- the machine operator must take into account that the specification of one operating parameter can directly influence another parameter. Because when operating the milling machine, the interaction of all parameters is decisive for the quality of the milling pattern. Therefore, the operation of a milling machine requires a great deal of experience of the machine operator.

- the invention has for its object to provide a milling machine with a simplified operation for the machine operator. Moreover, it is an object of the invention to provide a method of operating a milling machine which simplifies the operation of the machine.

- the milling machine according to the invention has an operating unit for inputting operating parameters for controlling the drive device and the working device.

- the operating unit allows the machine operator to enter all parameters relevant to the project.

- the operator can, for example, adjust the engine power of the drive machine, the feed rate of the milling machine, the milling depth or the speed of the milling drum.

- the setting of all drive and working parameters is not required for the respective milling task.

- the operating unit is characterized by a selection unit for selecting an operating mode from a plurality of operating modes. Consequently, the operator only needs to select one operating mode for the project. For example, if the task is fine milling to achieve a fine milling pattern, the operator only needs to select the fine milling operation mode. For fine milling, depending on the particular milling task, several operating modes can also be provided in which the required working time or the wear of the milling tools can be taken into account

- the control and computing unit has a memory in which for each operating mode of the plurality of operating modes at least two predetermined operating parameters, which are assigned to the operating mode, are stored.

- the relevant operating parameters therefore need not be set by the machine operator, but can be read out of the memory.

- the control and computing unit is configured in such a way that at least one module is actuated in dependence on the at least two operating parameters which are stored in the memory for the operating mode selected with the selection unit such that the respective machine function is executed.

- each assembly may be driven based on an operating parameter of the at least two operating parameters. Consequently, the milling machine is controlled with the operating parameters assigned to the operating mode selected by the operator. The assignment of the parameters therefore does not need to be made by the operator, so that the operator is relieved. Only with the selection of the operating mode thus an optimal milling result is achieved.

- the operating parameters include drive parameters and operating parameters, wherein the drive device has at least one module that executes a specific machine function as a function of drive parameters, and the operating device has at least one module which performs a specific machine function as a function of operating parameters, and in which Memory for each operating mode of the plurality of operating modes at least two predetermined operating parameters that are assigned to the operating mode are stored.

- the control and computing unit is configured such that at least one assembly of the working device is controlled in dependence on the at least two working parameters, which are stored in the memory for the operating mode selected with the selection unit such that the respective machine function is performed ,

- the feed rate is a drive parameter, which can preferably be specified by the machine operator himself and can also be changed by the machine operator during operation of the construction machine. Therefore, in a preferred embodiment, the feed rate is an input with the control unit for controlling the drive device drive parameter. However, it can also be provided that the machine operator specifies working parameters, for example the milling depth.

- the milling machine according to the invention can furthermore provide that, for each operating mode of the plurality of operating modes, at least one function describing the dependency of an operating parameter of an assembly on at least one operating parameter of at least one other assembly is stored.

- a function is understood to mean all information which describes a relationship between the one parameter and the other parameter.

- This function can also be a characteristic field, for example.

- the control and computation unit is further configured such that, based on the dependence of an operating parameter of an assembly on at least one operating parameter at least one other assembly descriptive function, which is stored in the memory selected for the selected operation mode in the memory, at least one assembly of the working device or drive means so controlled that the respective machine function is performed. Consequently, in the control of the milling machine not only a predetermined operating parameter of a module, but also a relationship between predetermined parameters of different modules can be considered.

- control and computation unit may be configured such that based on the dependence of a working parameter of an assembly on at least one drive parameter of at least one other assembly descriptive function or on the basis of the dependence of a drive parameter Assembly of at least one working parameter of at least one other assembly descriptive function, which is stored for the selected with the selection unit operating mode in the memory, at least one assembly of the working device or drive means is controlled such that the respective machine function is performed.

- an assembly of the drive means comprises motor driven drives on which the construction machine stands, a drive parameter being the feed speed of the milling machine, and an assembly of the working means comprises a motor driven milling / cutting roller, a working parameter being the speed of the milling / cutting.

- Cutting roller is.

- a function describing the dependence of a working parameter of an assembly on a drive parameter of another assembly is a function describing the dependence of the speed of the milling / cutting roll on the feed rate of the milling machine.

- the control and processing unit is configured in this embodiment, that on the Based on the function of the speed of the milling / cutting roller of the feed rate of the milling machine descriptive function, which is stored for the selected with the selection unit operating mode in the memory, for a given feed speed, the speed of the cutting / cutting roller is set. Alternatively, with manual change of the speed of the milling / cutting roller, the feed speed of the machine can be adjusted.

- the adjustment of the associated speed of the cutting / cutting roller, which is a working parameter then automatically depending on the feed speed.

- Different dependencies can be specified for different milling tasks, so that an optimal setting is made for the selected milling task.

- An embodiment may provide that the plurality of operation modes selectable with the selection unit have at least one fine milling mode for a finer milling pattern at a smaller milling depth of the milling / cutting drum and a rough milling mode for a coarser milling pattern at a larger milling depth of the milling / cutting drum wherein, for the fine milling operating mode, a function is stored in the memory which, at a given feed rate for the fine milling operating mode, provides a higher rotational speed of the milling / cutting roller than for the rough milling operating mode.

- the machine operator can also be offered a selection of milling operating modes that differ in the quality of the milling pattern.

- an assembly of the working device is a device for supplying water into a milling / cutting roller housing accommodating the milling / cutting roller with a motor-driven pumping device, wherein a working parameter is the delivery rate of the pumping device.

- a working parameter stored at a predetermined feed rate for the Feinfräs operating mode specifies a lower flow rate of the pumping device than for the rough milling operating mode.

- an assembly of the working device is a motor-driven conveying device for conveying material removed with the milling / cutting roller, wherein a working parameter is the delivery rate of the conveying device.

- a working parameter may be stored in the memory which, at a given feed rate for the fine milling operating mode, provides a lower delivery rate of the conveyor than for the rough milling operating mode.

- An assembly of the working device can also be a height adjustable relative to the ground and resting with a predetermined contact force on the ground hold-down, which is arranged in the direction of the milling machine in front of the milling / cutting roller, or adjustable in height relative to the ground and with a predetermined contact force on the floor resting scraper, which is arranged in the working direction of the milling machine behind the cutting / milling roller, or adjustable in height relative to the ground and resting with a predetermined contact force on the ground edge protection, which is arranged in the longitudinal direction of the milling machine , include.

- the working parameter is the height adjustment or bearing force of the blank holder or the height adjustment or contact force of the scraper or the height adjustment or bearing force of the edge protection.

- the method according to the invention is preferably characterized in that an assembly of the drive device comprises motor-driven drives on which the construction machine stands, wherein a drive parameter is the feed speed of the milling machine, and an assembly of the working device comprises a motor-driven milling / cutting roller, wherein a working parameter the speed of the milling / cutting roller is.

- the method according to the invention is preferably characterized characterized in that the feed rate for controlling the drive means is input to an input unit, wherein a function describing the dependence of a work parameter of an assembly on a drive parameter of another assembly is a function describing the dependence of the speed of the milling / cutting roll on the feed rate of the milling machine, and on the basis of the function describing the dependence of the speed of the milling / cutting roller on the feed rate of the milling machine, which is read from the memory for the selected operating mode, the speed of the cutting / cutting roller is set.

- the method according to the invention is preferably characterized in that a function is read out of the memory for a first operating mode of the plurality of selectable operating modes, which specifies a higher speed of the milling / cutting roller at a predetermined feed rate than for a second operating mode of the plurality of modes of operation.

- an assembly of the milling machine comprises a device for supplying water into a milling / cutting roller housing receiving the milling / cutting roller with a motor-driven pumping device, wherein a working parameter is the delivery rate of the pumping device.

- the method according to the invention is preferably characterized in that a function is read out of the memory for a first operating mode of the plurality of selectable operating modes, which specifies a larger delivery rate of the pumping device at a predetermined feed rate than for a second operating mode of the plurality of operating modes.

- an assembly of the working device comprises a motor-driven conveying device for conveying material removed by the milling / cutting roller, wherein a working parameter is the delivery rate of the conveying device.

- the method according to the invention is preferably characterized in that a function is read out of the memory for a first operating mode of the plurality of operating modes selectable with the selection unit, which predetermines a larger delivery rate of the conveyor at a predetermined feed rate than for a second operating mode of the plurality modes of operation.

- the method according to the invention is preferably characterized in that an assembly of the working device a in height to the ground adjustable and resting with a predetermined contact force on the ground down holding device, which is arranged in the working direction of the milling machine in front of the milling / cutting roller, or a adjustable in height above the ground and resting with a predetermined contact force on the ground scraper, which is arranged in the working direction of the milling machine behind the cutting / milling, or adjustable in height relative to the ground and resting with a predetermined contact force on the ground Edge protection, which is arranged in the longitudinal direction of the milling machine comprises, wherein a working parameter is the height adjustment or bearing force of the blank or Abstreifers or edge protection.

- Fig. 1 shows a side view of a road milling machine as an example of a milling machine in a simplified schematic representation.

- the milling machine can also be a recycler, stabilizer or surface miner.

- the milling machine has a chassis 1 supported by a machine frame 2 with a control station 3.

- the chassis 1 of the milling machine may comprise four drives 4, 5, which are arranged on the rear and front sides on both sides of the machine frame 2.

- the steerable drives 4, 5, in particular chain drives that allow translational and / or rotational movements of the milling machine, are attached to lifting cylinders 6, 7, which are attached to the machine frame 1, so that the machine frame is height adjustable.

- the drives 4, 5 can be chain drives. Instead of crawler wheels and wheels can be provided.

- the milling machine has an engine 16 arranged on the machine frame, in particular an internal combustion engine.

- the drive power of the internal combustion engine is transmitted via a pump distributor gearbox to hydraulic pumps in order to supply hydraulic motors provided in the drives 4, 5 of the milling machine with hydraulic fluid.

- the milling machine has a milling / cutting roller 8, which is arranged in a Fräswalzengephase 9.

- the milling drum 8 is driven by the single drive machine, wherein the drive power of the drive machine 16 is transmitted via a mechanical gear 32 to the milling / cutting roller 8.

- a device, not shown, for supplying water into the milling drum housing is provided, which has a pumping device, not shown.

- the milling machine also has other assemblies that work together for the processing of the soil with the milling / cutting roller.

- These only suggestively illustrated assemblies are in the Height relative to the ground adjustable and resting with a predetermined contact force on the ground down device 10, which is arranged in the working direction of the milling machine in front of the milling / cutting roller 8, a height adjustable relative to the ground and resting with a predetermined contact force on the ground scraper 11, which is arranged in the working direction A of the milling machine behind the cutting / milling roller 8, and on each longitudinal side of the cutting / cutting roller 8 in height relative to the ground adjustable and resting with a predetermined contact force on the ground edge protection 12, the extends in the longitudinal direction of the milling machine.

- the individual assemblies may in turn comprise a plurality of different components, for example actuators, sensors, etc., which, however, are likewise not shown, since they are generally known to the person skilled in the art.

- a conveyor 13 with a conveyor belt 14 is provided.

- the operator For the control of the milling machine, the operator with an operating unit 15, which may be provided on the control station 3, enter various operating parameters.

- the control of the respective components of the individual modules is carried out in the present embodiment with a central control and processing unit. But it can also be provided several individual control and computing units.

- the control and processing unit may include, for example, a general purpose processor, a digital signal processor (DSP) for continuous processing of digital signals, a microprocessor, an application specific integrated circuit (ASIC), a logic element integrated circuit (FPGA), or other integrated circuits (IC). or hardware components to perform the individual process steps.

- DSP digital signal processor

- ASIC application specific integrated circuit

- FPGA logic element integrated circuit

- IC integrated circuits

- a data processing program software can be run on the hardware components to carry out the method steps. It is also possible a plurality or combination of the various components.

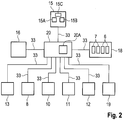

- Fig. 2 shows a simplified block diagram with the essential components of the milling machine.

- the drive device comprises the drive machine 16 and the drives, not shown, each having a hydraulic motor.

- the working device comprises in addition to the drive machine 16 as a common component with the drive means the milling / cutting roller 8, the down in the direction of the milling / cutting roller hold-down 10, the scraper 11 behind the milling / cutting roller and the edge protection 12 on both sides of the milling / cutting roller.

- Another assembly of the working device is the device 18 for height adjustment of the machine frame 1, which has the four lifting columns 6, 7, so that the milling depth can be adjusted.

- the working device has the device 19 for supplying water with the pumping device and the conveyor 13 with the conveyor belt 14.

- the individual modules are connected via control lines 33 to the central control and computing unit 20.

- the rotational speed of the prime mover 16 determines the rotational speed n of the milling / cutting roller 8, which is driven by the prime mover via the mechanical gear 32, while the feed rate v is adjusted by appropriately adjusting the hydraulic pumps for the hydraulic motors.

- the operating unit 15 has an input unit 15A, which may have, for example, buttons, switches, sliders, a keyboard or a touch screen in order to enter certain parameters manually.

- the input unit 15A may also include a joystick for controlling the machine, especially the steerable drives.

- the operating unit has a display unit 15B, for example a screen.

- the operating unit 15 has a selection unit 15C, which however can also be part of the input unit, for example, can be designed as a touch screen together with the input unit.

- the selecting unit 15C allows the operator to select an operating mode M x from a plurality of operating modes M 1 to M n .

- the selection unit can have buttons, switches or buttons assigned to the individual operating modes M 1 to M n on a touchscreen.

- Another Possible embodiment is a rotary switch with the operating modes associated rotational positions.

- micro-milling I micro-milling II, fine milling I, fine milling II, standard milling I, standard milling II, standard milling III, rough milling (rough milling), whereby different milling tasks can be selected for the individual milling types.

- the individual milling tasks are designated by the index "I", "II” or "III”.

- the milling tasks can be different milling patterns, which can differ in the roughness of the surface. It can also be considered different conditions, for example, the type of substrate (concrete or asphalt), or whether the fastest possible or low-wear processing of the soil should be done.

- Each operating mode is assigned a data record which is stored in a memory 20A of the control and computing unit 20.

- Each record contains the drive and work parameters that are considered optimal for the task at hand.

- the record does not have to contain all the parameters that need to be set to complete the task.

- Individual operating parameters in particular those parameters that should be changed by the machine operator during operation of the milling machine, can not be included in the data record. These parameters can be entered manually by the operator using the control unit.

- the present embodiment provides an additional check routine.

- the used milling / cutting roller is characterized by a marking, for example a bar code, which is read by a reading device, not shown.

- the record that is the operating mode "Finishing I" contains a list of markings of different milling / cutting rolls that can be used to perform the milling job, such as milling tools for fine milling.

- the control and computing unit 20 checks whether the marking of the used milling / cutting roller is entered in the list (block 22: "Compatibility with roller?"). If this is the case, it is concluded that the milling machine is equipped with the correct milling drum type for "fine milling I". Thereafter, the drive and operating parameters are read out of the memory 20A, which are assigned to the operating mode "fine milling I" (block 23: “read operating parameters”). At this time the machine is not yet in operation, ie the machine is standing still and the milling / cutting roller is not lowered (block 24: "Machine in operation?).

- the next step queries whether the milling operation should be started (block 25: "Start milling operation?"). If this is the case, the "fine milling I" data set becomes For the start of the milling operation required drive and working parameters of the further control is based (block 26: "setting the operating parameters for starting the machine”.)

- a speed n A for the milling machine is preset, for example, at 1600 rpm, so that sufficient power is available for the application

- the milling depth is not specified for the setting as a working parameter, since the milling / cutting roller 8 by the operator by operating the lifting columns 5, 6 is manually lowered to the desired depth (Block 27: “Lower to Fr After lowering the milling / cutting roller 8, ie setting the milling depth, the machine operator sets the drives 4, 5 in motion (block 28: "start”). This sets the milling machine in operation (block 24: "Mill

- the individual modules of the milling machine are controlled by the control and processing unit 20 such that the modules execute the respective machine functions on the basis of the drive and working parameters of the operating mode "fine milling I" (block 29: setting the operating parameters for In the following, with reference to block 29, the method steps performed in consideration of the selected operating mode will be described in detail.

- the control and computing unit 20 sets for the milling operation as an operating parameter, for example, the engine speed n, which may be a different speed than when preparing the cutting / cutting roller.

- This engine speed n can also be included as a fixed predefined variable in the "fine milling I" data set.

- the data set "fine milling II” may differ from the data set "fine milling I” in that the working parameter of the engine speed n for "fine milling II" is greater or smaller than the working parameter of the engine speed n for "fine milling I".

- the engine speed as an example of a working parameter u. a. influences the milling drum speed, which determines the quality of the milling pattern.

- the milling pattern is also determined by the feed speed v of the milling machine, which can change the machine operator during operation of the machine.

- a higher feed rate v requires a higher milling drum speed and thus a higher engine speed n.

- the feed rate v and the engine speed n are therefore related.

- a fixed value is not specified for the engine speed n, but a value dependent on the feed rate v.

- different functions which may differ from one another, for example in the constant k, are stored in the memory 20A of the control and arithmetic unit 20.

- the relationship between feed rate v and engine speed n may also be a non-linear relationship.

- the engine speed is controlled in discrete steps. For example, may be provided min -1 for the milling engine speeds of 1200 min-1, 1600 min-1, 1800 min -1 and 2100th In this case, it is particularly preferred to keep the ratio v / n between feed and engine speed within a certain range.

- the engine speed can be adjusted when exceeding or falling below limit values for the feed rate.

- different functions can be stored in the memory 20A of the control and arithmetic unit 20, which differ, for example, in the predetermined ranges in which the relationship between feed and engine speed should be different.

- the arithmetic and evaluation unit calculates with the function stored for "fine milling I” the required motor speed n, which can be a different speed for "fine milling I” than, for example, for the operating mode “fine milling II “or” rough milling ".

- the control and computing unit 20 continuously monitors which feed rate the machine operator has specified. When the operator has changed the feed rate, the control and computation unit 20 calculates the new engine speed using the function stored for the selected operating mode and then sets the new engine speed (Block 29: Setting the Mill Operating Parameters).

- the feed rate v can be calculated and set with the function even after specification of an engine speed n. Consequently, when driving the individual modules, a drive parameter can determine a working parameter or vice versa.

- the operating parameters for controlling the other assemblies of the working device are read out for the milling operation to control actuators or other drive devices of these modules.

- These parameters include in particular, the height h of the blank holder 10, scraper 11 and edge protection 12 and their bearing force on the ground.

- the height of the blank holder 10, scraper 11 and edge protector 12 is particularly dependent on the height of the machine frame 1 relative to the surface of the soil, which in turn determines the milling depth.

- the control and computing unit 20 sets hold-down device 10, wiper 11 and edge protector 12 to the height specified by the parameters or their contact force.

- the control and computing unit 20 also controls the pumping means of the means 19 for supplying water into the Fräswalzengepuruse 9 such that the amount of water is supplied, which dictates the corresponding working parameter for the operating mode "fine milling 1".

- This amount of water may be smaller than the amount of water that sets the appropriate working parameters for standard milling I, II, III, which in turn may be smaller than the amount of water for rough milling.

- the control and computing unit 20 can also control the conveyor 13 present on milling machines on the basis of a further working parameter, since, for example, the "fine milling" operating mode requires the setting of a smaller flow rate than "rough milling".

- the above-mentioned operating parameters may not only be fixed predefined quantities, but also variables which are dependent on other operating parameters, as is the case, for example, for the rotational speed of the milling / cutting roller.

- the actuation of the assemblies described above can therefore also be carried out on the basis of the function describing the dependency of an operating parameter of an assembly on at least one operating parameter of at least one other assembly, which function is stored in the memory for the operating mode selected with the selection unit.

- a predetermined value can initially be set for the start of the milling operation as a function of the operating mode and then varied during the milling operation as a function of at least one operating parameter.

- the above operating parameters may also depend on several other operating parameters.

- the engine speed n can be regulated not only as a function of the feed rate v, but also as a function of the power requirement of the loads driven by the drive unit. Consequently, different specifications can be made for the different operating modes.

- the engine speed can for example be a dependent of the feed function in which a given feed speed a certain minimum motor rotation speed is operatively associated with, for example, 1600 min -1 at a feed rate of 15 m / min.

- the motor speed is increased independently of the feed rate. If the feed is then increased, this can lead to a further increase in the engine speed, depending on the above-mentioned functional relationship, if the minimum engine speed determined as a function of the feed is above the currently set engine speed.

- the setting of the delivery rate of the pumping means of the means 19 for supplying water into the milling drum housing 9, for example, may be read from the memory based on a predetermined function stored in the memory 20C and for the selected operating mode depending on at least one Operating parameters of a module or multiple modules are set.

- the function can describe the dependence of the delivery rate on the feed rate (drive parameters) and the milling depth (working parameters), whereby the delivery rate should increase with increasing feed rate and should increase with increasing milling depth.

- the previously specified and adjusted operating parameters are continuously monitored, whereby the control and computing unit 20 continuously checks whether the operating parameters previously read from the memory 20A, on the basis of which the control is currently taking place, have been changed (block 31). "Modification If the parameters have been changed, the new parameter sets are polled, if not, the machine control is continued based on the previous parameters.

Landscapes

- Engineering & Computer Science (AREA)

- Mining & Mineral Resources (AREA)

- Mechanical Engineering (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Geology (AREA)

- Road Repair (AREA)

- Numerical Control (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102016010390.6A DE102016010390A1 (de) | 2016-08-30 | 2016-08-30 | Fräsmaschine und Verfahren zum Betrieb einer Fräsmaschine |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3290586A1 true EP3290586A1 (fr) | 2018-03-07 |

| EP3290586B1 EP3290586B1 (fr) | 2020-10-14 |

Family

ID=59745707

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17186317.8A Active EP3290586B1 (fr) | 2016-08-30 | 2017-08-15 | Fraiseuse et procédé de fonctionnement d'une fraiseuse |

Country Status (4)

| Country | Link |

|---|---|

| US (3) | US10378350B2 (fr) |

| EP (1) | EP3290586B1 (fr) |

| CN (1) | CN107780329B (fr) |

| DE (1) | DE102016010390A1 (fr) |

Families Citing this family (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102016113251A1 (de) * | 2015-10-27 | 2017-04-27 | Wirtgen Gmbh | Fräsmaschine und Verfahren zum Betrieb einer Fräsmaschine |

| DE102016010390A1 (de) * | 2016-08-30 | 2018-03-01 | Wirtgen Gmbh | Fräsmaschine und Verfahren zum Betrieb einer Fräsmaschine |

| US10309066B2 (en) * | 2016-11-04 | 2019-06-04 | Caterpillar Paving Products Inc. | Control system for cold planer and apparatus and method thereof |

| US10386866B2 (en) * | 2017-11-20 | 2019-08-20 | Caterpillar Paving Products Inc. | Automatic control of plunge velocity based on depth of cut |

| DE102017010919B4 (de) * | 2017-11-24 | 2023-08-03 | Bomag Gmbh | Verfahren zum Steuern einer Höhenverstellung eines Abstreifschildes einer Bodenfräsmaschine und Bodenfräsmaschine |

| US10733991B2 (en) * | 2017-12-21 | 2020-08-04 | Deere & Company | Construction machine mode switching with voice services |

| US10621982B2 (en) | 2017-12-21 | 2020-04-14 | Deere & Company | Construction machines with voice services |

| CN108677670A (zh) * | 2018-07-02 | 2018-10-19 | 江阴澄云机械有限公司 | 一种铣刨机 |

| CN111287059A (zh) * | 2020-02-19 | 2020-06-16 | 徐州徐工筑路机械有限公司 | 一种冷再生施工自动化系统 |

| DE102021114397A1 (de) * | 2021-06-03 | 2022-12-08 | Bomag Gmbh | Verfahren zur Steuerung einer Straßenfräsmaschine und Straßenfräsmaschine |

| CN113463477A (zh) * | 2021-08-13 | 2021-10-01 | 李维维 | 一种微表处摊铺机及施工方法 |

| CN113463469A (zh) * | 2021-08-13 | 2021-10-01 | 李维维 | 一种微表处摊铺机及施工方法 |

| CN113564992A (zh) * | 2021-08-13 | 2021-10-29 | 李维维 | 一种微表处摊铺机及施工方法 |

| DE102021133306A1 (de) * | 2021-12-15 | 2023-06-15 | Wirtgen Gmbh | Verfahren zur Aufwands-Abschätzung einer geplanten Fräsaufgabe, die mit einer Straßenfräsmaschine durchgeführt wird oder durchgeführt werden soll |

| DE102022122472B4 (de) * | 2022-09-05 | 2024-03-28 | Wirtgen Gmbh | Selbstfahrende Bodenbearbeitungsmaschine mit Zwillingsmotoren und einem deren Leistung unterschiedlich übertragenden Arbeitsgetriebe |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4929121A (en) * | 1989-09-05 | 1990-05-29 | Caterpillar Paving Products Inc. | Control system for a road planer |

| EP2722441A1 (fr) * | 2012-10-19 | 2014-04-23 | Wirtgen GmbH | Engin automoteur et procédé de fonctionnement d'un engin automoteur |

| EP2840183A1 (fr) * | 2013-08-23 | 2015-02-25 | Wirtgen GmbH | Engin autopropulsé et procédé de fonctionnement d'un engin automoteur |

| DE102014001885A1 (de) * | 2014-02-12 | 2015-08-13 | Bomag Gmbh | Verfahren zur Optimierung einer Betriebsfunktion einer Bodenfräsmaschine und Bodenfräsmaschine |

| EP3208382A1 (fr) * | 2016-02-16 | 2017-08-23 | Wirtgen GmbH | Engin automobile et procédé de fonctionnement d'un engin automobile |

Family Cites Families (38)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2311891A (en) | 1941-04-17 | 1943-02-23 | Tyson Harry | Road grooving machine |

| DE1917670C3 (de) | 1969-04-05 | 1973-01-04 | Eimer, Manfred, Dipl.Ing., Dr., 3400 Grone | Einrichtung zur selbsttätigen Regelung des Dreschprozesses bei einem Mähdrescher |

| US3750762A (en) | 1971-08-19 | 1973-08-07 | Omsteel Ind Inc | Speed control system for vehicle mounting a work performing device |

| US4043402A (en) | 1975-03-24 | 1977-08-23 | Koehring Company | Soil stabilizer machine with detachable hydraulic motor structure driving rotatably mounted cutting elements |

| US4549610A (en) | 1979-06-05 | 1985-10-29 | Lely Cornelis V D | Vehicle with front and rear steerable wheels individually driven by hydraulic motors |

| US4270801A (en) * | 1979-08-14 | 1981-06-02 | Cmi Corporation | Steering and cutter drum positioning in a paved roadway planing machine |

| US4277898A (en) | 1979-12-26 | 1981-07-14 | J. I. Case Company | Hydraulic control system for excavating machine |

| US4333685A (en) | 1980-06-09 | 1982-06-08 | Federal-Mogul Corporation | Road surfacing apparatus |

| US4343513A (en) | 1980-08-25 | 1982-08-10 | Gomaco, Inc. | Method and power transmission system for operating a road planar machine |

| US4588231A (en) | 1982-01-27 | 1986-05-13 | Concrete Safety Equipment, Inc. | Pavement surfacing machine |

| HU195345B (en) | 1984-02-24 | 1988-04-28 | Mem Mueszaki Intezet | Method and regulator for controlling load of machine and speed of a mobile straw cutter |

| US4655634A (en) | 1985-09-23 | 1987-04-07 | Dresser Industries, Inc. | Road planer control and safety system |

| IT1205549B (it) | 1986-07-11 | 1989-03-23 | Elda Barbieri | Macchina frantumatrice mobile semovente |

| US5190398A (en) | 1991-03-12 | 1993-03-02 | Swisher Jr George W | Apparatus for preparing a road bed |

| US5318378A (en) | 1992-09-28 | 1994-06-07 | Caterpillar Paving Products Inc. | Method and apparatus for controlling a cold planer in response to a kickback event |

| US5415495A (en) | 1993-07-19 | 1995-05-16 | Surface Preparation Technologies, Inc. | Cutting machine and a method for its use |

| US6186248B1 (en) | 1995-12-12 | 2001-02-13 | Boart Longyear Company | Closed loop control system for diamond core drilling |

| US5879056A (en) | 1997-04-25 | 1999-03-09 | Caterpillar Inc. | Kickback protection device and method of use |

| US6050770A (en) | 1997-05-30 | 2000-04-18 | Schaeff Incorporated | Stabilization system for load handling equipment |

| US6338281B1 (en) | 1997-08-13 | 2002-01-15 | Reliance Electric Technologies, Llc | Bearing apparatus having integrated load sensing arrangement |

| GB9912108D0 (en) | 1999-05-25 | 1999-07-28 | Rolls Royce Plc | Bearing load control |

| US6558072B2 (en) | 2001-05-15 | 2003-05-06 | Caterpillar Paving Products Inc. | Speed control system for a work machine |

| DE10203732A1 (de) | 2002-01-30 | 2003-08-21 | Wirtgen Gmbh | Baumaschine |

| DE10213017A1 (de) | 2002-03-22 | 2003-10-09 | Wirtgen Gmbh | Verfahren zum Optimieren eines Schneidprozesses bei Straßenfräsmaschinen, sowie Fräsmaschine zum Bearbeiten von Straßendecken |

| US6921230B2 (en) | 2002-12-24 | 2005-07-26 | Diamond Products, Limited | Closed loop control system for pavement surfacing machine |

| US7066555B2 (en) * | 2003-08-26 | 2006-06-27 | Asphalt Zipper, Inc. | Reinforced concrete milling/cutting mandrel |

| DE102006024123B4 (de) | 2006-05-22 | 2010-02-25 | Wirtgen Gmbh | Selbstfahrende Baumaschine, sowie Verfahren zum Bearbeiten von Bodenoberflächen |

| US8465105B2 (en) | 2007-01-18 | 2013-06-18 | Cmi Terex Corporation | Control system for cutter drum |

| WO2008115560A1 (fr) * | 2007-03-20 | 2008-09-25 | Volvo Construction Equipment Ab | Fraiseuse avec commande de vitesse de tambour porte-couteaux |

| DE102008008260B4 (de) * | 2008-02-08 | 2010-09-09 | Wirtgen Gmbh | Steuerung einer Gewinnungsmaschine und Gewinnungsmaschine |

| US8128177B2 (en) | 2010-02-08 | 2012-03-06 | Wirtgen Gmbh | Adaptive advance drive control for milling machine |

| CN202838001U (zh) * | 2012-09-25 | 2013-03-27 | 三一重工股份有限公司 | 一种路面施工机群及其配合引导系统 |

| US8989968B2 (en) * | 2012-10-12 | 2015-03-24 | Wirtgen Gmbh | Self-propelled civil engineering machine system with field rover |

| WO2015042226A1 (fr) * | 2013-09-20 | 2015-03-26 | Surface Preparation Technologies Llc | Procédé et appareil pour découper une rainure sinusoïdale dans une surface routière |

| DE102015002743A1 (de) | 2014-12-23 | 2016-06-23 | Wirtgen Gmbh | Selbstfahrende Baumaschine und Verfahren zum Betreiben einer selbstfahrenden Baumaschine |

| DE102015002426A1 (de) | 2014-12-30 | 2016-06-30 | Bomag Gmbh | Bodenfräsmaschine und Verfahren zum Verstellen des Abstreiferschildes einer Bodenfräsmaschine |

| US10094078B2 (en) * | 2016-03-03 | 2018-10-09 | Caterpillar Paving Products Inc. | Cold planer rear door and sliding plates sealing design |

| DE102016010390A1 (de) * | 2016-08-30 | 2018-03-01 | Wirtgen Gmbh | Fräsmaschine und Verfahren zum Betrieb einer Fräsmaschine |

-

2016

- 2016-08-30 DE DE102016010390.6A patent/DE102016010390A1/de active Pending

-

2017

- 2017-08-15 EP EP17186317.8A patent/EP3290586B1/fr active Active

- 2017-08-16 CN CN201710702628.XA patent/CN107780329B/zh active Active

- 2017-08-17 US US15/679,199 patent/US10378350B2/en active Active

-

2019

- 2019-08-08 US US16/535,407 patent/US11203929B2/en active Active

-

2021

- 2021-12-14 US US17/550,829 patent/US12312955B2/en active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4929121A (en) * | 1989-09-05 | 1990-05-29 | Caterpillar Paving Products Inc. | Control system for a road planer |

| EP2722441A1 (fr) * | 2012-10-19 | 2014-04-23 | Wirtgen GmbH | Engin automoteur et procédé de fonctionnement d'un engin automoteur |

| EP2840183A1 (fr) * | 2013-08-23 | 2015-02-25 | Wirtgen GmbH | Engin autopropulsé et procédé de fonctionnement d'un engin automoteur |

| DE102014001885A1 (de) * | 2014-02-12 | 2015-08-13 | Bomag Gmbh | Verfahren zur Optimierung einer Betriebsfunktion einer Bodenfräsmaschine und Bodenfräsmaschine |

| EP3208382A1 (fr) * | 2016-02-16 | 2017-08-23 | Wirtgen GmbH | Engin automobile et procédé de fonctionnement d'un engin automobile |

Also Published As

| Publication number | Publication date |

|---|---|

| US11203929B2 (en) | 2021-12-21 |

| EP3290586B1 (fr) | 2020-10-14 |

| US20220170367A1 (en) | 2022-06-02 |

| US10378350B2 (en) | 2019-08-13 |

| US20180058214A1 (en) | 2018-03-01 |

| US20200072049A1 (en) | 2020-03-05 |

| DE102016010390A1 (de) | 2018-03-01 |

| US12312955B2 (en) | 2025-05-27 |

| CN107780329B (zh) | 2019-11-15 |

| CN107780329A (zh) | 2018-03-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3290586B1 (fr) | Fraiseuse et procédé de fonctionnement d'une fraiseuse | |

| EP2558645B1 (fr) | Procédé pour faire fonctionner une fraiseuse à découper les sols munie d'un cylindre de fraisage réglable en hauteur | |

| EP3483341B1 (fr) | Engin de chantier automoteur et procédé de fonctionnement d'un engin de chantier automoteur | |

| DE102014001885A1 (de) | Verfahren zur Optimierung einer Betriebsfunktion einer Bodenfräsmaschine und Bodenfräsmaschine | |

| DE112008000646T5 (de) | Fräsmaschine mit Schneidtrommel-Geschwindigkeitssteuerung | |

| EP3299523B1 (fr) | Procédé et dispositif pour le traitement d'un sol de fondation | |

| EP3115507A1 (fr) | Machine de travail du sol et procede de fonctionnement optimise contre l'usure d'une machine de travail du sol | |

| EP2722441A1 (fr) | Engin automoteur et procédé de fonctionnement d'un engin automoteur | |

| DE102017110146A1 (de) | Fräsmaschine | |

| DE102019108759B4 (de) | Bodenbearbeitungsmaschine | |

| DE2857550C2 (fr) | ||

| DE3818159A1 (de) | Verfahren und vorrichtung zur steuerung des betriebs von hon- oder schleifmaschinen | |

| EP3208382B1 (fr) | Engin automobile et procédé de fonctionnement d'un engin automobile | |

| EP3587668B1 (fr) | Engin de construction automoteur et procédé de traitement des revêtements de sol | |

| DE112009004293T5 (de) | Adaptive Unterdrehzahlsteuerung | |

| DE112021007705T5 (de) | Werkzeugmaschinensteuerungsvorrichtung und Werkzeugmaschinensteuerungssystem | |

| DE112012004044T5 (de) | Rotor/Motordrehzahlsteuerung für eine Kaltfräse | |

| DE102018117969A1 (de) | Parametereinstellungsunterstützungsvorrichtung | |

| WO2024208738A1 (fr) | Système de transport pour des pièces à travailler et procédé permettant de faire fonctionner un système de transport | |

| DE19811316A1 (de) | Lageregelung für eine Kombinationsfräsmaschine mit innen angeordneter Schleifscheibe | |

| DE102022126170A1 (de) | System und verfahren zur materialentleerung in fräskammer | |

| WO2022156948A1 (fr) | Procédé et machine de génie civil pour travaux de sol | |

| EP3842667A1 (fr) | Engin de construction autonome et procédé de commande d'un engin de construction autonome | |

| EP4330519B1 (fr) | Tunnelier et procédé pour creuser un tunnel au moyen d'un tunnelier | |

| DE102021133306A1 (de) | Verfahren zur Aufwands-Abschätzung einer geplanten Fräsaufgabe, die mit einer Straßenfräsmaschine durchgeführt wird oder durchgeführt werden soll |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20180905 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20190718 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20200424 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1323687 Country of ref document: AT Kind code of ref document: T Effective date: 20201015 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502017007721 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20201014 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210115 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210114 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210215 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210114 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210214 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502017007721 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 |

|

| 26N | No opposition filed |

Effective date: 20210715 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20210831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210831 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210214 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210815 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210815 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20170815 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230525 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1323687 Country of ref document: AT Kind code of ref document: T Effective date: 20220815 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220815 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20201014 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250819 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250829 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20250822 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250827 Year of fee payment: 9 |