EP2980347A1 - Echelle telescopique comportant des tronçons d'echelle de densites differentes - Google Patents

Echelle telescopique comportant des tronçons d'echelle de densites differentes Download PDFInfo

- Publication number

- EP2980347A1 EP2980347A1 EP15178548.2A EP15178548A EP2980347A1 EP 2980347 A1 EP2980347 A1 EP 2980347A1 EP 15178548 A EP15178548 A EP 15178548A EP 2980347 A1 EP2980347 A1 EP 2980347A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- ladder

- section

- bar

- proximal end

- uprights

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 239000000463 material Substances 0.000 claims abstract description 34

- 229920000049 Carbon (fiber) Polymers 0.000 claims description 11

- 239000004917 carbon fiber Substances 0.000 claims description 11

- 238000004026 adhesive bonding Methods 0.000 claims description 2

- 229910000831 Steel Inorganic materials 0.000 description 5

- 239000002131 composite material Substances 0.000 description 5

- 238000010586 diagram Methods 0.000 description 5

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 5

- 239000010959 steel Substances 0.000 description 5

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 4

- 229910052782 aluminium Inorganic materials 0.000 description 4

- 230000005484 gravity Effects 0.000 description 4

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 2

- 229910052799 carbon Inorganic materials 0.000 description 2

- 230000003247 decreasing effect Effects 0.000 description 2

- 239000011152 fibreglass Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000010936 titanium Substances 0.000 description 2

- 229910052719 titanium Inorganic materials 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06C—LADDERS

- E06C5/00—Ladders characterised by being mounted on undercarriages or vehicles Securing ladders on vehicles

- E06C5/02—Ladders characterised by being mounted on undercarriages or vehicles Securing ladders on vehicles with rigid longitudinal members

- E06C5/04—Ladders characterised by being mounted on undercarriages or vehicles Securing ladders on vehicles with rigid longitudinal members capable of being elevated or extended ; Fastening means during transport, e.g. mechanical, hydraulic

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06C—LADDERS

- E06C7/00—Component parts, supporting parts, or accessories

- E06C7/18—Devices for preventing persons from falling

- E06C7/181—Additional gripping devices, e.g. handrails

- E06C7/183—Additional gripping devices, e.g. handrails situated along the ladder

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06C—LADDERS

- E06C1/00—Ladders in general

- E06C1/02—Ladders in general with rigid longitudinal member or members

- E06C1/04—Ladders for resting against objects, e.g. walls poles, trees

- E06C1/08—Ladders for resting against objects, e.g. walls poles, trees multi-part

- E06C1/12—Ladders for resting against objects, e.g. walls poles, trees multi-part extensible, e.g. telescopic

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06C—LADDERS

- E06C7/00—Component parts, supporting parts, or accessories

- E06C7/08—Special construction of longitudinal members, or rungs or other treads

Definitions

- the present invention relates to a telescopic ladder comprising ladder sections made of materials of different densities.

- the invention also relates to a vehicle on which is fixed such a telescopic ladder.

- telescopic ladder is meant a ladder composed of several sections that are movable relative to each other so as to vary the total length of the ladder by moving the sections relative to one another.

- One known type of telescopic ladder is a ladder extending between a proximal end attached to a vehicle and a distal end opposite the proximal end, the distal and proximal end being defined with respect to the vehicle.

- the distal end is remote from the proximal end by sliding the sections relative to each other so as to have them substantially end to end, while maintaining a portion of overlap between the sections.

- the scale can generally be rotated along a plurality of axes so as to further vary the position of the distal end of the scale.

- This type of telescopic ladder is used to carry out work at high heights or depths, particularly for personal assistance in a fire protection vehicle.

- a particular need for this type of telescopic ladder is to be able to perform work at low heights and depths but at a distance very far from the vehicle.

- the maximum distance separating the proximal and distal ends, projected on a horizontal axis must be as large as possible. This distance is more generally called the maximum range of the telescopic ladder.

- the present invention provides a telescopic ladder comprising a proximal end adapted to be fixed on a support, the ladder comprising between the proximal end and a distal end a plurality of sections movable relative to each other to deploy the scale, the stretch disposed at the level of the proximal end of the scale being made of a material having a density greater than the density of the material in which at least one other section of the scale is made.

- the present invention also relates to a vehicle comprising such a telescopic ladder.

- a telescopic ladder 10 fixed on a support at a proximal end 12 of the support.

- the support may be a vehicle, for example of the fire protection and / or personal assistance type, or a trailer to be coupled to a vehicle or more generally any means for supporting and / or transporting the ladder 10

- a vehicle 14 on which is disposed the telescopic ladder 10 described below.

- the scale 10 comprises between the proximal end 12 and a distal end 16, first, second, third and fourth sections 18 1 , 18 2 , 18 3 and 18 4 .

- the proximal and distal nature of the ends of the scale 10 is defined relative to the vehicle 14.

- the number of sections is not limited to four. Indeed, the scale 10 may comprise a number of sections 18 greater than or equal to two.

- the sections 18 are movable relative to each other to allow the ladder 10 to be deployed or folded. In particular, the sections slide one inside the other so that the ladder 10 can be arranged in a fully retracted position. , in which the sections 18 are arranged one inside the other, in a fully deployed position (position shown in FIG. figure 1 ), wherein the sections 18 are substantially arranged end-to-end.

- the sections overlap one by one so that a covering portion is formed between each of the sections.

- the distal end 16 of the scale 10 corresponds to the end of the scale 10 opposite the proximal end 12 when the scale 10 is in the fully deployed position. In other words, the distal end 16 of the scale 10 coincides with the end of the fourth section 18 4 furthest from the proximal end 12.

- the vehicle 14 comprises a turret 20 for moving the scale 10 in rotation about a vertical axis B relative to the vehicle 14 and cylinders (not shown) for tilting the scale 10 around a axis perpendicular to the vertical axis B and to a horizontal axis A.

- the range P of the scale 10 is defined as the distance, projected on the horizontal axis A, separating the proximal and distal ends 12 and 16.

- the scale 10 To allow the scale 10 to have a maximum range P greater than a telescopic scale having sections made of a material of the same density, the section disposed at the proximal end 12 of the scale 10 - this is -to say, the first section 18 1 - is made of a material having a density greater than the density of the material in which is made at least another portion 18 of the scale 10.

- the second, third and / or fourth sections 18 2 , 18 3 and 18 4 are made, in whole or in part, in a material having a density less than the material used to make the first section 18 1 so that, on the one hand, the mass of the scale 10 is decreased and, secondly, the center of gravity of the scale 10 is closer to the proximal end 12 with respect to a scale in which the second, third and fourth sections 18 2 , 18 3 and 18 4 are made of a material having the same density as the material used for the first section 18 1 .

- the terms "in whole” and "in part” are detailed below.

- the combination of the decrease in the mass of the scale 10 and the approximation of the center of gravity towards the proximal end 12 makes it possible, while guaranteeing the physical integrity of the scale 10, to reduce the minimum inclination of the scale 10 so that the maximum range P of the scale 10 is increased.

- the inclination of the scale 10 is defined as the angle formed between the scale 10 and the horizontal axis A, in the plane formed by the horizontal and vertical axes A and B.

- the scale 10 may also be arranged so that the distal end 16 is disposed at an altitude below ground level, or more generally at an altitude lower than the altitude where the vehicle is located 14. The aforementioned advantages also apply to this last case.

- the materials used to make the sections 18 are, for example, in decreasing order of density, steel, titanium, aluminum, composite materials based on fiberglass or composite materials based on carbon fiber.

- the first section 18 1 is made of steel

- at least one of the other sections 18 is made for example in aluminum, titanium or composite materials of fiberglass or carbon.

- the material whose density is less than the material used for the first section 18 1 is a material whose density is less than 5, preferably 3, preferably 2.

- Density - referred to as relative density - is defined as the ratio between the density of this material and the density of water at 4 ° C, at atmospheric pressure.

- the material used for the fourth section 18 4 is a material based on carbon fiber. preferably at least in part based on so-called "high modulus" carbon fiber, that is to say carbon fibers having a Young's modulus greater than 400 GPa.

- the material used for the first, second and third sections 18 1 , 18 2 and 18 3 is steel or aluminum so that the manufacturing cost of the scale 10 is limited.

- the composite material based on carbon fibers used for the uprights 22 may comprise additional folds of carbon fibers oriented in different directions and forming localized extra thicknesses to allow the uprights 22 to withstand stresses exerted in directions different.

- the pieces are fixed together by gluing.

- rivets are also used in combination with bonding.

- the maximum P range P of the scale 10 while having a manufacturing cost of the limited scale, only the section disposed at the distal end 16 - the fourth section 18 4 - is made of carbon fiber base.

- the maximum P range can be increased by up to 10% compared to a known type of telescopic ladder made entirely of steel.

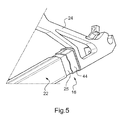

- the fourth section 18 4 comprises two uprights 22 extending parallel to one another to the distal end 16 of the scale 10.

- the fourth section 18 4 also comprises between the two uprights 22 a plurality of bars 26 allowing a user to advance along the fourth section 18 4 .

- the bars 26 extend substantially parallel to one another, each in a direction of extension C substantially perpendicular to the direction of extension of the uprights 22.

- the bars 26 comprise at each of their ends a fixing portion 38 of the bar 26 to an upright 22.

- This fixing portion 38 has a fixing surface of the bar 26 (not shown) intended to be brought into contact and fixed on a lateral surface 42 of an upright 22.

- Each bar 26 is formed, at a central portion 40, by a predetermined section perpendicular to the extension direction C of the bar 26, for example of rectangular shape.

- the bars 26 and the uprights 22 are arranged so that the area of the fixing surface of the bar 26 is greater than the area of the predetermined section at the of the central portion 40.

- the area of the predetermined section is defined by the area delimited by the outer envelope of the predetermined section.

- the attachment surface may be composed of one or more surfaces. In other words, the attachment surface may be continuous or discontinuous.

- the lateral surface 42 of the uprights 22 is inclined with respect to a plane perpendicular to the extension direction C of the bars 26.

- the lateral surface 42 is inclined at an angle of between 5 ° and 50 ° relative to the plane perpendicular to the extension direction C of a bar 26 This angle of inclination of the lateral surface 42 also corresponds to the angle formed between the fixing surface of the bar 26 and the plane perpendicular to the extension direction C of the bar 26.

- the combination of the flared shape of the ends of the bars 26 and the inclination of the lateral surfaces 42 allows the fourth section 18 4 to overcome the addition of reinforcing pieces - called struts - arranged between the bars 26 to guarantee the physical integrity of the known telescopic ladders, in particular in relation to the forces exerted by the side wind on the scale 10.

- the inclination of the lateral surfaces 42 also allows, for a constant distance between the two uprights 22 and a constant length of the surface on which the user bears, to increase the size of the section of the uprights 22 so that the uprights 22 have an increased mechanical strength.

- the fourth section 18 4 also comprises two rails 28 each extending along one of the two uprights 22, substantially parallel to the uprights 22.

- a plurality of support arms 30 - also called diagonals - are each fixed between the one of the uprights 22 and the rail 28 extending along this upright 22.

- the support arms 30 are arranged inclined relative to the extension direction of the uprights 22 and guardrails 28.

- each support arm 30 is formed together with another support arm 30 integrally to form a rail support 32 having substantially the shape of a V.

- Guardrail brackets 32 are arranged end to end between a post 22 and the rail 28 extending along this post 22 so that the bend of the V of a rail support 32 is fixed to the post 22 and the free ends of the V are fixed to the guardrail 28.

- each rail support 32 includes a base 34 for attaching the rail support 32 to an upper surface 23 of a post 22.

- the base 34 has an inclined portion 36 extending beyond the upper surface 23 of the post 22 to allow the base 34 to be also attached to the lateral surface 42 of the upright 22.

- the inclined portion 36 allows an increase in the contact area between the rail support 32 and the upright 22 so that the distribution of forces and therefore the mechanical strength of the fastener between the rail support 32 and the upright 22 are improved.

- the inclined portion 36 of the rail support 32 is suitable, when the base 34 of the railing support 32 is brought into contact with the upper surface 23 of an upright 22 and a bar 26 is disposed on the lateral surface 42 of the same upright 22 facing the railing support 32, to cover the fixing portion 38 of the bar 26.

- the inclined portion 36 is able to overlap the fixing portion 38 of the bar to allow the attachment of the inclined portion 36, the fixing portion 38 and the surface together. side of the amount.

- the inclined portion 36, the fixing portion 38 and the lateral surface 42 of the upright 22 can thus be riveted together to reinforce the attachment between the rail support 32, the bar 26 and the upright 22.

- the fourth section 18 4 also comprises at the distal end 16 an interface piece 24 for fixing a suspended nacelle (not shown) to the scale 10.

- the interface piece 24 is intended for be attached at one end to the scale 10 and, at another end, to a tilting device (not shown) on which is mounted the nacelle.

- the tilting device tilts the nacelle relative to the scale 10 so as to maintain the horizontality of the nacelle with respect to the ground.

- the interface piece 24 is fixed at the distal end 16 of the ladder 10 by sleeving, i.e. the pieces are threaded one inside the other.

- each upright 22 has at one end intended to be fixed to the interface piece 24 a portion of reduced section 25 so that a hollow portion 44 (shown in partial section) of the interface piece 24 in complementary form with the portion of reduced section 25 of the upright 22 can be housed and fit on the portion of reduced section 25.

- the guardrail 28 is fixed by sleeve to the interface piece 24, of similar to the attachment between the uprights 22 and the interface part 24. The fastening by sleeve allows a better distribution of the forces between the two parts fixed so that the fastener withstands greater stress than a fastener where the two parts are assembled end-to-end.

- a section 18 is made entirely of a material that at least the uprights 22, the rails 28, the bars 26 and the rail supports 32 are made of the same material.

- the expression "made entirely” does not exclude that the section comprises other parts, such as parts of assembly or fastening, made of another material, for example of higher density.

- a portion 18 is made in part of a material that at least one, but not all, of the uprights 22, the rails 28, the bars 26 and the supports of railing 32 are made of the same material.

- the fastening by sleeve between the interface piece 24 and the uprights 22 can be reversed, that is to say that the interface piece 24 comprises a portion whose section is reduced and the amounts 22 comprise a hollow portion complementarily shaped with the reduced section portion of the interface piece 24 so that the reduced section portion can fit and fit within the hollow portion.

- This fixing by reverse sleeve is also applicable to the attachment between the interface piece 24 and the guardrails 28.

- the section 18 which precedes it - the third section 18 3 - can also be made of a carbon fiber material for allow a greater reduction of the mass of the scale 10 and to bring the center of gravity closer to the scale 10 of the proximal end 12.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Ladders (AREA)

- Fire-Extinguishing By Fire Departments, And Fire-Extinguishing Equipment And Control Thereof (AREA)

- Steps, Ramps, And Handrails (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1457321A FR3024489B1 (fr) | 2014-07-29 | 2014-07-29 | Echelle telescopique comportant des troncons d'echelle de densites differentes |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP2980347A1 true EP2980347A1 (fr) | 2016-02-03 |

Family

ID=51726746

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP15178548.2A Withdrawn EP2980347A1 (fr) | 2014-07-29 | 2015-07-27 | Echelle telescopique comportant des tronçons d'echelle de densites differentes |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20160032649A1 (enExample) |

| EP (1) | EP2980347A1 (enExample) |

| JP (1) | JP2016031016A (enExample) |

| KR (1) | KR20160014555A (enExample) |

| CN (1) | CN105317367A (enExample) |

| FR (1) | FR3024489B1 (enExample) |

| HK (1) | HK1217220A1 (enExample) |

| RU (1) | RU2015131162A (enExample) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US12234135B2 (en) | 2014-11-24 | 2025-02-25 | Oshkosh Corporation | Fire apparatus |

| US10472889B1 (en) * | 2018-04-23 | 2019-11-12 | Oshkosh Corporation | Aerial ladder assembly |

| KR102134922B1 (ko) * | 2018-12-14 | 2020-07-17 | 이준호 | 인명구조용 소형 소방차 |

| CN110259370B (zh) * | 2019-06-20 | 2023-12-08 | 中交二航局第四工程有限公司 | 一种倾角可自适应调整且踏步始终保持水平的爬梯 |

| RU200222U1 (ru) * | 2020-03-13 | 2020-10-13 | Игорь Юрьевич Девятловский | Раздвижная лестница |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0000344A1 (en) * | 1977-07-06 | 1979-01-24 | Abru Aluminium Limited | Improvements in or relating to ladders |

| FR2473614A1 (fr) * | 1980-01-14 | 1981-07-17 | Kinziger Claude | Echelle telescopique |

| US4371055A (en) * | 1980-11-07 | 1983-02-01 | Little Giant Industries, Inc. | Method of manufacturing a fiberglass ladder |

| US20060032705A1 (en) * | 2004-08-16 | 2006-02-16 | Isham William R | Lightweight composite ladder rail having supplemental reinforcement in regions subject to greater structural stress |

| US20140102830A1 (en) * | 2012-10-16 | 2014-04-17 | Nasir U. Ahmed | Fiberglass Reinforced Plastic Lightweight Heavy-Duty Ladder and Method of Making Same |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2582520A (en) * | 1949-06-04 | 1952-01-15 | Mccabe Powers Auto Body Co | Ladder |

| FR2448028A1 (fr) * | 1979-01-30 | 1980-08-29 | Camiva | Structure d'echelle telescopique |

| US4540095A (en) * | 1984-02-23 | 1985-09-10 | Federal Motors, Inc. | Counterweighted aerial trailer |

| DE3625298A1 (de) * | 1986-04-26 | 1987-10-29 | Iveco Magirus | Leiteranordnung mit ausschiebbaren leiterteilen, insbesondere feuerwehrleiter |

| DE3640944A1 (de) * | 1986-11-29 | 1988-06-09 | Metz Feuerwehrgeraete Gmbh | Feuerwehrleiter |

| US4852690A (en) * | 1988-12-05 | 1989-08-01 | Simon Ladder Towers, Inc. | Aerial ladder tower with pretensioned truss members |

| US6342861B1 (en) * | 1989-04-26 | 2002-01-29 | Daniel A. Packard | Loop antenna assembly |

| US5211245A (en) * | 1991-07-01 | 1993-05-18 | Crash Rescue Equipment Service, Inc. | Vehicle mounted aerial lift |

| GB2387373A (en) * | 2002-04-12 | 2003-10-15 | Bamford Excavators Ltd | Composite boom for a load handling machine |

| US7201255B1 (en) * | 2004-01-23 | 2007-04-10 | Kreikemeier Robert D | Apparatus and method of forming a corrosion resistant coating on a ladder |

| CN201050290Y (zh) * | 2007-04-16 | 2008-04-23 | 王贞禄 | 塑胶制梯结构 |

| DE102008013203A1 (de) * | 2008-03-08 | 2009-09-17 | Terex-Demag Gmbh | Ausleger zur endseitigen Aufnahme von Lasten, Ausleger-Baugruppe mit mindestens zwei derartigen Auslegern sowie Verfahren zur Herstellung eines derartigen Auslegers |

| CN201276966Y (zh) * | 2008-08-07 | 2009-07-22 | 杨雅娟 | 一种可伸缩的梯子 |

| JP5543418B2 (ja) * | 2011-10-13 | 2014-07-09 | 株式会社小松製作所 | 作業車両の可動式ラダー装置 |

| ITMI20131680A1 (it) * | 2013-10-11 | 2015-04-12 | Cifa Spa | Dispositivo ausiliario per una gru e gru comprendente tale dispositivo ausiliario |

| CN203614016U (zh) * | 2013-12-24 | 2014-05-28 | 威海广泰空港设备股份有限公司 | 用于消防车的云梯伸缩机构 |

| US9410659B2 (en) * | 2014-02-10 | 2016-08-09 | The Boeing Company | Automated mobile boom system for crawling robots |

-

2014

- 2014-07-29 FR FR1457321A patent/FR3024489B1/fr not_active Expired - Fee Related

-

2015

- 2015-07-27 EP EP15178548.2A patent/EP2980347A1/fr not_active Withdrawn

- 2015-07-27 JP JP2015147414A patent/JP2016031016A/ja active Pending

- 2015-07-27 RU RU2015131162A patent/RU2015131162A/ru not_active Application Discontinuation

- 2015-07-28 US US14/810,834 patent/US20160032649A1/en not_active Abandoned

- 2015-07-29 KR KR1020150107108A patent/KR20160014555A/ko not_active Withdrawn

- 2015-07-29 CN CN201510455433.0A patent/CN105317367A/zh active Pending

-

2016

- 2016-05-06 HK HK16105180.1A patent/HK1217220A1/zh unknown

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0000344A1 (en) * | 1977-07-06 | 1979-01-24 | Abru Aluminium Limited | Improvements in or relating to ladders |

| FR2473614A1 (fr) * | 1980-01-14 | 1981-07-17 | Kinziger Claude | Echelle telescopique |

| US4371055A (en) * | 1980-11-07 | 1983-02-01 | Little Giant Industries, Inc. | Method of manufacturing a fiberglass ladder |

| US20060032705A1 (en) * | 2004-08-16 | 2006-02-16 | Isham William R | Lightweight composite ladder rail having supplemental reinforcement in regions subject to greater structural stress |

| US20140102830A1 (en) * | 2012-10-16 | 2014-04-17 | Nasir U. Ahmed | Fiberglass Reinforced Plastic Lightweight Heavy-Duty Ladder and Method of Making Same |

Also Published As

| Publication number | Publication date |

|---|---|

| FR3024489B1 (fr) | 2018-08-10 |

| HK1217220A1 (zh) | 2016-12-30 |

| KR20160014555A (ko) | 2016-02-11 |

| US20160032649A1 (en) | 2016-02-04 |

| RU2015131162A3 (enExample) | 2019-01-24 |

| JP2016031016A (ja) | 2016-03-07 |

| RU2015131162A (ru) | 2017-02-02 |

| FR3024489A1 (fr) | 2016-02-05 |

| CN105317367A (zh) | 2016-02-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2980347A1 (fr) | Echelle telescopique comportant des tronçons d'echelle de densites differentes | |

| FR2523072A1 (fr) | Aeronef pourvu d'une structure de sustentation a ailes superposees multiples | |

| FR2827235A1 (fr) | Poutre de pare-chocs de vehicule automobile et pare-chocs muni d'une telle poutre | |

| EP3174791A1 (fr) | Tube de structure de type hybride, notamment pour siège aéronautique | |

| EP1614622B1 (fr) | Plancher de cockpit pour aéronef | |

| FR2749561A1 (fr) | Train d'atterrissage a patins pour helicoptere | |

| CA2970373C (fr) | Dispositif de protection contre la chute d'objets | |

| FR2734787A1 (fr) | Pied pour siege d'aeronef, pietement incluant un tel pied et enfin, un siege d'aeronef incluant un tel pietement | |

| EP3767049B1 (fr) | Pergola qui comprend une structure de support et un élément d'ombrage pliable | |

| CA2500494C (fr) | Longeron de fuselage pour aeronef et caisson central equipe d'un tel longeron | |

| EP0716572A1 (fr) | Nappe de protection constituee de plaquettes assemblees par des anneaux et tabliers obtenus avec ce type de nappe | |

| WO1996002716A1 (fr) | Escalier a configuration variable | |

| FR2922830A1 (fr) | Dossier comprenant une ceinture integree de securite. | |

| EP0151591B1 (fr) | Greement, notamment pour planche a voile | |

| EP3279399A1 (fr) | Joint de chaussée pour ouvrage routier | |

| EP0814219A1 (fr) | Plateforme de travail individuelle roulante légère | |

| FR2992607A1 (fr) | Dispositif de couverture arriere d'un siege de vehicule automobile, siege, rangee et vehicule comprenant un siege equipe dudit dispositif | |

| EP1880074A1 (fr) | Echelle extensible repliable, avec montant central unique | |

| EP1647648B1 (fr) | Dispositif de liaison entre un poteau d'angle et deux éléments de remplissage d'un garde-corps | |

| EP4110683B1 (fr) | Véhicule avec structure montrant une troisième voie d'effort entre le berceau et un brancard avant, et procédé de montage d'un tel véhicule | |

| EP2501876B1 (fr) | Garde-corps constitué d'un ensemble de pièces détachées prêtes à être assemblées | |

| WO1988000152A1 (fr) | Aile pliable, notamment pour le vol de pente | |

| EP0323940A1 (fr) | Ecran paravent | |

| EP0026713A2 (fr) | Cadre de motocyclette à renfort de colonne de direction | |

| WO2013144368A1 (fr) | Abri comprenant des elements de toiture ayant une couverture composee modules coulissants |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| 17P | Request for examination filed |

Effective date: 20160727 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1217220 Country of ref document: HK |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20200201 |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: WD Ref document number: 1217220 Country of ref document: HK |