EP2678552B1 - Procédé et appareil de commande pour régler une température d'une bougie-crayon de préchauffage - Google Patents

Procédé et appareil de commande pour régler une température d'une bougie-crayon de préchauffage Download PDFInfo

- Publication number

- EP2678552B1 EP2678552B1 EP12704047.5A EP12704047A EP2678552B1 EP 2678552 B1 EP2678552 B1 EP 2678552B1 EP 12704047 A EP12704047 A EP 12704047A EP 2678552 B1 EP2678552 B1 EP 2678552B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- glow plug

- resistance

- temperature

- difference

- determined

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02P—IGNITION, OTHER THAN COMPRESSION IGNITION, FOR INTERNAL-COMBUSTION ENGINES; TESTING OF IGNITION TIMING IN COMPRESSION-IGNITION ENGINES

- F02P19/00—Incandescent ignition, e.g. during starting of internal combustion engines; Combination of incandescent and spark ignition

- F02P19/02—Incandescent ignition, e.g. during starting of internal combustion engines; Combination of incandescent and spark ignition electric, e.g. layout of circuits of apparatus having glowing plugs

- F02P19/021—Incandescent ignition, e.g. during starting of internal combustion engines; Combination of incandescent and spark ignition electric, e.g. layout of circuits of apparatus having glowing plugs characterised by power delivery controls

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02P—IGNITION, OTHER THAN COMPRESSION IGNITION, FOR INTERNAL-COMBUSTION ENGINES; TESTING OF IGNITION TIMING IN COMPRESSION-IGNITION ENGINES

- F02P19/00—Incandescent ignition, e.g. during starting of internal combustion engines; Combination of incandescent and spark ignition

- F02P19/02—Incandescent ignition, e.g. during starting of internal combustion engines; Combination of incandescent and spark ignition electric, e.g. layout of circuits of apparatus having glowing plugs

- F02P19/025—Incandescent ignition, e.g. during starting of internal combustion engines; Combination of incandescent and spark ignition electric, e.g. layout of circuits of apparatus having glowing plugs with means for determining glow plug temperature or glow plug resistance

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02P—IGNITION, OTHER THAN COMPRESSION IGNITION, FOR INTERNAL-COMBUSTION ENGINES; TESTING OF IGNITION TIMING IN COMPRESSION-IGNITION ENGINES

- F02P19/00—Incandescent ignition, e.g. during starting of internal combustion engines; Combination of incandescent and spark ignition

- F02P19/02—Incandescent ignition, e.g. during starting of internal combustion engines; Combination of incandescent and spark ignition electric, e.g. layout of circuits of apparatus having glowing plugs

- F02P19/021—Incandescent ignition, e.g. during starting of internal combustion engines; Combination of incandescent and spark ignition electric, e.g. layout of circuits of apparatus having glowing plugs characterised by power delivery controls

- F02P19/023—Individual control of the glow plugs

Definitions

- the invention relates to a method for adjusting a temperature of a glow plug, in particular for igniting a fuel-air mixture in an internal combustion engine, wherein the temperature of the glow plug is adjusted in response to a resistance of the glow plug by means of a control, and a control device for carrying out the method ,

- Glow plugs which are used in internal combustion engines to ignite a fuel-air mixture are preheated in a cold state before their temperature is so high that it is sufficient for the ignition of the fuel-air mixture.

- the glow plug has for this purpose a heater, which acts on the cold glow plug in a short period of 1 to 2 seconds with an excessive heating voltage, so that the glow plug is overstressed at this time.

- the tip of the glow plug After completion of this so-called push phase, the tip of the glow plug has reached a temperature of about 1000 ° C, while the remaining part of the glow plug still has a temperature which is well below this temperature of 1000 ° C.

- the temperature of the glow plug that is obtained in the preheating phase represents an input variable for a control with which the temperature of the glow plug is adjusted, such as in EP 1 936 183 A2 is described. However, since this input variable for the control is determined during a transient process, this leads to errors in the subsequent control.

- the invention is therefore an object of the invention to provide a method for controlling the temperature of a glow plug in which the occurring during the preheating temperature overshoot is reliably prevented, although the glow plug is subjected to an excessive heating voltage.

- the object is achieved in that the temperature in a preheating the glow plug, in which an overvoltage is applied to the glow plug, is regulated.

- the advantage of the invention is that the annealing temperature over the entire annealing of the glow plug is now modulated with high quality and the control of the annealing temperature at each time the annealing phase, advantageously also in the preheating (push phase) takes place, in which the heater of the Glow plug, the cold glow plug in a short period of 1 to 2 seconds applied to an excessive heating voltage. This allows better control of the preheat phase both at the key start and during long startup phases.

- a resistance difference which at the end of the preheating phase results in a measured resistance, is determined with the aid of a physical model during the preheating phase.

- the temperature in the preheat phase in which an overvoltage is applied to the glow plug, is controlled by means of the predictive model.

- the preheating phase of the glow plug is more robust, since no or only small temperature overshoot occur and there are provided accurate input values for the control in the further course of the glow plug glow.

- the control is already aligned closely to the desired temperature setpoint in the preheating phase.

- the input variable of the resistor for the control is initialized and the time at the first energization of the glow plug is taken into account. Furthermore, the development effort is reduced because no application for a controlled preheating is necessary and the input parameters are determined only once and maintained for the life of the glow plug.

- the measured resistance of the glow plug is added to the resistance difference and fed the sum of the control formed from the measured resistance and the resistance difference. Thereby, the measured resistance is increased by an anticipated certain amount, which corresponds to the temperature actually occurring during the preheating phase in the glow plug.

- Erindungsillet is determined from a characteristic curve, which is determined individually for each glow plug in the heated, steady operation of the glow plug, based on the sum of the measured resistance and the resistance difference, a Temperaturistwert which is subtracted from the temperature setpoint, wherein the thus determined temperature difference of the control is determined from which a drive voltage for the glow plug to set the desired temperature setpoint.

- the integration of the resistance difference in the determination of the temperature actual value means that even during the rapid preheating phase, a regulation of the temperature of the glow plug can be ensured.

- the resistance difference consists of several, in particular summed, partial resistance differences, wherein each partial resistance difference is determined as a function of at least one operating parameter of the glow plug.

- a first partial resistance difference is determined as a function of an energy content of the glow plug which it has at the time of starting the annealing process.

- the energy content of the glow plug is characterized by an initial resistance, an initial amount of heat or an initial power.

- the heat balance of the cold glow plug is considered before Clearbestromung. For example, since in a cold glow plug the initial resistance is very small, while in a glow plug, which was once heated, the initial resistance is greater, it ensures that always the correct input variable is used in determining the resistance difference.

- a second partial resistance difference is determined as a function of a temperature setpoint of the glow plug, which it should have at the end of the annealing process.

- a third partial resistance difference is determined as a function of an output temperature of the glow plug which it has at the time of starting the annealing process. Since the glow plug has a different behavior at different temperatures at the first start, this output temperature of the glow plug is also taken into account in order to model the correct behavior of the glow plug.

- the starting temperature corresponds to an ambient temperature of the glow plug at the time of starting the annealing process.

- the ambient temperature of the glow plug is easy to determine, since motor vehicles in whose internal combustion engines the glow plugs are installed have an outside temperature display. Thus, it is possible to dispense with further hardware for determining the ambient temperature.

- a fourth partial resistance difference is determined as a function of an annealing process of the glow plug that is directly preceded by the start of the annealing process.

- the state of the glow plug is taken into account, which has the glow plug when the ignition of the engine, which pulls a heating of the glow plug by itself, has taken place, but this short time later turned off again and was activated within a few moments again.

- the immediately preceding annealing process is characterized by its annealing duration or annealing energy, wherein a factor is determined in dependence on an initial resistance of the glow plug, which is multiplied by the fourth partial resistance difference and added to the resistance difference.

- the annealing time which corresponds to the duty cycle of the glow plug, allows conclusions about how much energy is still stored in the glow plug.

- the fourth partial resistance difference which was determined in dependence on the start of the annealing preceding annealing time, added to the resistance difference.

- a development of the invention relates to a control device for adjusting a temperature of a glow plug according to claim 10.

- the invention allows numerous embodiments. One of them will be explained in more detail with reference to the figures shown in the drawing.

- Cold internal combustion engines in particular diesel engines, require a start-up aid for ignition of the fuel-air mixture introduced into the diesel engine at ambient temperatures of ⁇ 40 ° C.

- glow systems used which consist of glow plugs, a Glühzeit Kunststoff réelle and annealing software, which is stored in an engine control unit or the Glühzeit Kunststoff réelle consist.

- annealing systems are also used to improve the emission of the vehicle. Further fields of application of the glow system are the burner exhaust system, the auxiliary heating, the preheating of fuel (flex fuel) or the preheating of the cooling water.

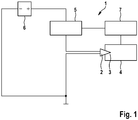

- FIG. 1 A glow plug 2 protrudes into the combustion chamber 3 of the diesel engine 4.

- the glow plug 2 is on the one hand connected to the Glühzeit Kunststoff réelle 5 and on the other hand leads to a battery 6, which controls the glow plug 2 with the rated voltage of, for example, 11 volts.

- the Glühzeit Kunststoff réelle 5 is connected to the engine control unit 7, which in turn leads to the diesel engine 4.

- the glow plug 2 is preheated by the application of an overvoltage in a, also referred to as a push phase preheating, which lasts 1 to 2 seconds.

- the electrical energy that is supplied to the glow plug 2 is thus converted into heat in a heating coil, not shown, which is why the temperature at the top of the glow plug 2 rises steeply.

- the heating power of the heating coil is adjusted via the electronic Glühzeit Kunststoff 5 to the requirement of the respective diesel engine 4.

- the fuel-air mixture is conducted past the hot tip of the glow plug 2 and heats up. Associated with an intake air heating during the compressor stroke of the diesel engine 4, the ignition temperature of the fuel-air mixture is achieved.

- the glow plug 2 has different glow phases. As already stated, in a preheating phase, which takes 1 to 2 seconds, the cold glow plug 2 is supplied with an overvoltage, which is above the rated voltage of the glow plug 2. During this short period of time, the tip of the glow plug is heated to approximately 1000 ° C, while the remaining part of the glow plug 2 is still below this temperature, thereby forming a transient temperature profile within the glow plug 2.

- This preheating phase is followed by a heating phase of the glow plug 2, in which the transient temperature distribution compensates for a steady temperature distribution over the entire glow plug 2. Such a heating phase usually takes approximately 30 seconds.

- the resistance difference is adjusted dynamically in the heating phase. This is followed by the annealing phase, in which a steady temperature distribution over the entire glow plug is ensured.

- FIG. 2 a schematic diagram for the temperature modeling of the glow plug 2 during the rapid preheat phase is shown, which is integrated as software in the engine control unit 7 or the Glühzeit Kunststoff Technology 5 and is taken into account in a temperature control of the glow plug.

- a temperature setpoint T DES is provided by the engine control unit 7.

- a resistance R m of the glow plug is measured, which represents a value for the current temperature at the glow plug 2. This measured resistance R m is determined at each Bestromungsvorgang, which takes place at regular intervals.

- this measured resistance R m is added to a resistance difference ⁇ R, which is determined by means of a predictive model 8.

- This predictive model 8 models the temperature of the glow plug 2 in the rapid preheat phase.

- This initial resistance R 01 is determined.

- This initial resistance R 01 is fed to a characteristic curve 9, which was determined during stationary operation of the glow plug. From this characteristic curve 9, a first partial resistance difference ⁇ R1 is determined on the basis of the measured initial resistance R 01 .

- the temperature setpoint T DES is provided which characterizes the end temperature of the glow plug 2 to be reached.

- This temperature setpoint T DES is also given to a further characteristic curve 10 as input variable, from which a second partial resistance difference ⁇ R2 is determined.

- the thus determined partial resistance differences ⁇ R1 and ⁇ R2 are added in block 14.

- the third partial resistance difference ⁇ R3 is determined by means of a third characteristic 11.

- the third partial resistance difference ⁇ R3 is added to the first and the second partial resistance difference ⁇ R1 and ⁇ R2.

- an annealing time / annealing energy E U * 1 * t

- E U * 1 * t

- the resistor R 01 is another characteristic thirteenth which as a result yields a factor F which is multiplied in block 22 by the fourth partial resistance difference ⁇ R4.

- the factor F is selected so that when the time measured initial resistance R is greater than a predetermined threshold value of the resistor R 01 01, this is equal to the first The factor F tends towards the value zero, when the initial resistance R 01 is less than the predetermined threshold value of the resistor R 01.

- the fourth partial resistance difference ⁇ R4 is added in block 16 to the above-described partial resistance difference ⁇ R1, ⁇ R2 and ⁇ R3, resulting in a resistance difference ⁇ R corresponding to a predetermined temperature occurring at the end of the preheating operation on the glow plug 2.

- the determined in the predictive model 8 resistance difference ⁇ R is added in block 17 to the measured resistance R m .

- This sum of the resistance difference .DELTA.R and the measured resistance R m is supplied to a characteristic curve 18, in which the resistance is plotted against the temperature.

- This characteristic curve 18 is a characteristic determined individually for each glow plug 2 at a steady-state temperature distribution, since glow plugs have an independent transfer function due to production tolerances.

- a base temperature T BAS of the glow plug 2 is determined.

- This base temperature T BAS is compared in block 19 with a heat conduction model, which takes into account the extent to which there is a temperature difference between the interior of the heater of the glow plug 2 and the surface temperature of the glow plug 2.

- a temperature difference is supplied in block 19 to the base temperature T BAS , the sum of which results in the actual temperature T ACT of the glow plug 2.

- This actual temperature T ACT is now used in the control cycle, where it is subtracted from the temperature setpoint T DES in block 20.

- the difference between the temperature setpoint T DES and the actual temperature T ACT is supplied to a controller 21, which determines a voltage U GOV which is supplied to the glow plug 2, in particular the heater of the glow plug 2, for rapid adjustment of the temperature setpoint T DES .

- FIG. 3 shows two temperature-time diagrams in which the measured temperature Tm once without predictive modeling ( FIG. 3a ) and once with predictive modeling ( FIG. 3b ) is shown.

- FIG. 3a It can be seen that the measured temperature Tm, which is to be matched to the temperature set point T Des, shortly after the beginning of the annealing process has a temperature overshoot which is approaching the temperature setpoint T Des only after a time of about 30 seconds.

- the mathematically FIG. 2 modeled temperature Tmo is shown without model 8, which after the preheating phase, approximately after 5 seconds, reaches and regulates the level of the temperature setpoint T Des .

- FIG. 3b shows the course of the measured temperature Tm in the consideration of the predictive determined by means of the predictive temperature model 8 resistance difference .DELTA.R.

- the measured temperature Tm shows no temperature overshoot, but approaches immediately after the Preheating phase of the modeled temperature Tm.

- the temperature setpoint T Des is reached by means of this control and is regulated by this.

- a temperature control of the glow plug 2 not only during stationary operation, in which no more resistance-temperature fluctuations, but also in transient operation, preferably in the rapid preheating at the beginning of the annealing process and during to carry out the heating phase.

- the temperature modeling of the glow plug 2 in the rapid preheating phase it is modeled how large the resistance difference .DELTA.R will be at the end of the preheating process, this difference in resistance .DELTA.R being supplied as input to the control process.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Combined Controls Of Internal Combustion Engines (AREA)

- Ignition Installations For Internal Combustion Engines (AREA)

- Resistance Heating (AREA)

- Control Of Resistance Heating (AREA)

Claims (10)

- Procédé d'ajustement d'une température d'une bougie-crayon de préchauffage, en particulier pour l'allumage d'un mélange air-carburant dans un moteur à combustion interne, dans lequel la température (Tm) de la bougie-crayon de préchauffage (2) est ajustée en fonction d'une résistance (Rm) de la bougie-crayon de préchauffage (2) au moyen d'un réglage, la température (Tm) étant réglée dans une phase de préchauffage dans laquelle une surtension est appliquée à la bougie-crayon de préchauffage (2), caractérisé en ce que pour le réglage de la température (Tm) de la bougie-crayon de préchauffage (2), dans la phase de préchauffage, une différence de résistance (ΔR) qui existe à la fin de la phase de préchauffage par rapport à une résistance mesurée (Rm) est déterminée de manière anticipée à l'aide d'un modèle physique (8) pendant la phase de préchauffage, en ce que la résistance mesurée (Rm) de la bougie-crayon de préchauffage (2) est ajoutée à la différence de résistance (ΔR) et la somme formée de la résistance mesurée (Rm) et de la différence de résistance (ΔR) est acheminée au réglage, en ce qu'à partir d'une courbe caractéristique (18) qui est déterminée individuellement pour chaque bougie-crayon de préchauffage (2) pendant le fonctionnement chauffé stationnaire de la bougie-crayon de préchauffage (2), on détermine, à l'aide de la somme constituée de la résistance mesurée (Rm) et de la différence de résistance (ΔR), une valeur réelle de température (TACT) qui est soustraite d'une valeur de consigne de température (TDes) de la bougie-crayon de préchauffage, la différence de température ainsi déterminée étant acheminée au réglage, à partir duquel une tension de commande (UGOV) pour la bougie-crayon de préchauffage (2) est déterminée.

- Procédé selon la revendication 1, caractérisé en ce que la différence de résistance (ΔR) se compose de plusieurs différences de résistance partielles (ΔR1, ΔR2, ΔR3, ΔR4), en particulier additionnées, chaque différence de résistance partielle (ΔR1, AR2, ΔR3, ΔR4), étant déterminée en fonction d'au moins un paramètre de fonctionnement (R01, TDes, TC, E, R02) de la bougie-crayon de préchauffage (2).

- Procédé selon la revendication 2, caractérisé en ce qu'une première différence de résistance partielle (ΔR1) est déterminée en fonction d'un niveau d'énergie que présente la bougie-crayon de préchauffage (2) au moment du démarrage de l'opération de préchauffage.

- Procédé selon la revendication 3, caractérisé en ce que le niveau d'énergie de la bougie-crayon de préchauffage (2) est caractérisé par une résistance initiale (R01), une quantité de chaleur initiale, ou une puissance initiale de la bougie-crayon de préchauffage (2).

- Procédé selon la revendication 2, 3 ou 4, caractérisé en ce qu'une deuxième différence de résistance partielle (ΔR2) est déterminée en fonction d'une valeur de consigne de température (TDes) que présente la bougie-crayon de préchauffage (2) à la fin de l'opération de préchauffage.

- Procédé selon au moins l'une quelconque des revendications 2 à 5, caractérisé en ce qu'une troisième différence de résistance partielle (ΔR3) est déterminée en fonction d'une température initiale (Tc) que présente la bougie-crayon de préchauffage (2) au moment du démarrage de l'opération de préchauffage.

- Procédé selon la revendication 5, caractérisé en ce que la température initiale (TC) correspond à une température de l'environnement de la bougie-crayon de préchauffage (2) au moment du démarrage de l'opération de préchauffage.

- Procédé selon au moins l'une quelconque des revendications précédentes 2 à 7, caractérisé en ce qu'une quatrième différence de résistance partielle (ΔR4) est déterminée en fonction d'une opération de préchauffage de la bougie-crayon de préchauffage (2) précédant immédiatement le démarrage de l'opération de préchauffage.

- Procédé selon la revendication 8, caractérisé en ce que l'opération de préchauffage immédiatement précédente est caractérisée par la durée de son préchauffage ou par son énergie de préchauffage (E), un facteur (F) étant déterminé notamment en fonction de la résistance initiale (R01) de la bougie-crayon de préchauffage (2), lequel facteur est multiplié par la quatrième différence de résistance partielle (ΔR4) et est ajouté à la différence de résistance (ΔR).

- Appareil de commande pour ajuster une température d'une bougie-crayon de préchauffage, en particulier pour l'allumage d'un mélange air-carburant dans un moteur à combustion interne, qui ajuste la température (Tm) de la bougie-crayon de préchauffage (2) en fonction d'une résistance (Rm) de la bougie-crayon de préchauffage (2) au moyen d'un réglage, des moyens (8, 21) étant prévus, lesquels règlent la température (Tm) dans une phase de préchauffage dans laquelle une surtension est appliquée à la bougie-crayon de préchauffage (2), caractérisé en ce que des moyens pour régler la température (Tm) de la bougie-crayon de préchauffage (2) dans la phase de préchauffage sont réalisés de telle sorte qu'ils déterminent de manière anticipée une différence de résistance (ΔR) qui existe à la fin de la phase de préchauffage par rapport à une résistance mesurée (Rm) à l'aide d'un modèle physique (8) pendant la phase de préchauffage, qu'ils ajoutent la résistance mesurée (Rm) de la bougie-crayon de préchauffage (2) à la différence de résistance (ΔR) et acheminent au réglage la somme formée de la résistance mesurée (Rm) et de la différence de résistance (ΔR), qu'ils déterminent, à l'aide de la somme constituée de la résistance mesurée (Rm) et de la différence de résistance (ΔR), à partir d'une courbe caractéristique (18) qui est déterminée individuellement pour chaque bougie-crayon de préchauffage (2) pendant le fonctionnement chauffé stationnaire de la bougie-crayon de préchauffage (2), une valeur réelle de température (TACT) et la soustraient d'une valeur de consigne de température (TDes) de la bougie-crayon de préchauffage, et acheminent la différence de température ainsi déterminée au réglage, à partir duquel une tension de commande (UGOV) pour la bougie-crayon de préchauffage (2) est déterminée.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102011004514A DE102011004514A1 (de) | 2011-02-22 | 2011-02-22 | Verfahren und Steuergerät zur Einstellung einer Temperatur einer Glühstiftkerze |

| PCT/EP2012/052212 WO2012113653A1 (fr) | 2011-02-22 | 2012-02-09 | Procédé et appareil de commande pour régler une température d'une bougie-crayon de préchauffage |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2678552A1 EP2678552A1 (fr) | 2014-01-01 |

| EP2678552B1 true EP2678552B1 (fr) | 2018-04-18 |

Family

ID=45607241

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12704047.5A Active EP2678552B1 (fr) | 2011-02-22 | 2012-02-09 | Procédé et appareil de commande pour régler une température d'une bougie-crayon de préchauffage |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US10132288B2 (fr) |

| EP (1) | EP2678552B1 (fr) |

| JP (1) | JP5815752B2 (fr) |

| CN (1) | CN103380293B (fr) |

| DE (1) | DE102011004514A1 (fr) |

| WO (1) | WO2012113653A1 (fr) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102011085435A1 (de) * | 2011-10-28 | 2013-05-02 | Robert Bosch Gmbh | Verfahren und Vorrichtung zur Bestimmung einer Oberflächentemperatur einer Glühstiftkerze in einem Verbrennungsmotor |

| DE102012102013B3 (de) * | 2012-03-09 | 2013-06-13 | Borgwarner Beru Systems Gmbh | Verfahren zur Regelung der Temperatur einer Glühkerze |

| DE102016114315A1 (de) * | 2016-08-03 | 2018-02-08 | Eberspächer Climate Control Systems GmbH & Co. KG | Verfahren zum Betreiben eines brennstoffbetriebenen Fahrzeugheizgerätes |

| DE102017109071B4 (de) * | 2017-04-27 | 2022-10-20 | Borgwarner Ludwigsburg Gmbh | Verfahren zum Regeln der Temperatur von Glühkerzen |

| DE102017115946A1 (de) * | 2017-07-14 | 2019-01-17 | Borgwarner Ludwigsburg Gmbh | Verfahren zum Regeln der Temperatur einer Glühkerze |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2829700A1 (de) * | 1978-07-06 | 1980-01-17 | Bosch Gmbh Robert | Verfahren zum vorwaermen von brennkraftmaschinen der diesel- o.ae. bauart mittels gluehkerzen |

| DE3502966A1 (de) * | 1984-06-01 | 1985-12-05 | Robert Bosch Gmbh, 7000 Stuttgart | Einrichtung zur steuerung und regelung der temperatur einer gluehkerze |

| JPS61268874A (ja) * | 1985-05-22 | 1986-11-28 | Nippon Denso Co Ltd | デイ−ゼルエンジンの予熱制御装置 |

| JPS61268875A (ja) * | 1985-05-22 | 1986-11-28 | Nippon Denso Co Ltd | デイ−ゼルエンジンの予熱制御装置 |

| JPS6433477A (en) * | 1987-07-29 | 1989-02-03 | Sanyo Electric Co | Absorption heat pump device |

| ES2048187T3 (es) * | 1987-11-09 | 1994-03-16 | Siemens Ag | Procedimiento para la regulacion de la temperatura de bujias de arranque en motores diesel y disposicion de circuito para la realizacion del procedimiento. |

| JP3155084B2 (ja) * | 1992-09-25 | 2001-04-09 | マツダ株式会社 | エンジンのグロープラグ制御装置 |

| DE10147675A1 (de) | 2001-09-27 | 2003-04-30 | Beru Ag | Verfahren zum Aufheizen eines elektrischen Heizelementes, insbesondere einer Glühkerze für eine Brennkraftmaschine |

| DE10311898B4 (de) * | 2003-03-18 | 2005-04-21 | Webasto Ag | Heizgerät f∢r ein Fahrzeug |

| DE10348391B3 (de) * | 2003-10-17 | 2004-12-23 | Beru Ag | Verfahren zum Glühen einer Glühkerze für einen Dieselmotor |

| EP1929151A1 (fr) | 2005-09-21 | 2008-06-11 | Beru Aktiengesellschaft | Procede de commande d'un groupe de bougies de prechauffage d'un moteur diesel |

| CN1991654B (zh) * | 2005-12-31 | 2013-05-22 | 博奥生物有限公司 | 不需要温度传感器的精密加热温度控制装置及方法 |

| DE102006025834B4 (de) | 2006-06-02 | 2010-05-12 | Beru Ag | Verfahren zum Steuern einer Glühkerze in einem Dieselmotor |

| DE102006060632A1 (de) | 2006-12-21 | 2008-06-26 | Robert Bosch Gmbh | Verfahren zur Regelung der Temperatur einer Glühkerze einer Brennkraftmaschine |

| FR2910564B1 (fr) * | 2006-12-22 | 2013-05-10 | Renault Sas | Procede de pilotage de l'alimentation electrique d'une bougie de pre-chauffage de moteur a combustion interne |

| DE102007031613B4 (de) * | 2007-07-06 | 2011-04-21 | Beru Ag | Verfahren zum Betreiben von Glühkerzen in Dieselmotoren |

| US8183501B2 (en) * | 2007-12-13 | 2012-05-22 | Delphi Technologies, Inc. | Method for controlling glow plug ignition in a preheater of a hydrocarbon reformer |

| DE102008007393A1 (de) | 2008-02-04 | 2009-08-06 | Robert Bosch Gmbh | Verfahren und Vorrichtung zum Ermitteln der Temperatur von Glühstiftkerzen in einem Brennkraftmotor |

| DE102008040971B4 (de) * | 2008-08-04 | 2012-12-27 | Robert Bosch Gmbh | Verfahren und Vorrichtung zum Regeln der Temperatur von Glühstiftkerzen in einer Brennkraftmaschine |

| JP5037464B2 (ja) * | 2008-09-12 | 2012-09-26 | 株式会社オートネットワーク技術研究所 | グロープラグ制御装置、制御方法及びコンピュータプログラム |

| DE102009024138B4 (de) * | 2009-06-04 | 2012-02-02 | Beru Ag | Verfahren zur Regelung der Temperatur einer Glühkerze |

| US8912470B2 (en) * | 2009-07-01 | 2014-12-16 | Robert Bosch Gmbh | Method and device for controlling a glow plug |

| GB2471889B (en) | 2009-07-17 | 2014-03-26 | Gm Global Tech Operations Inc | A glow plug for a diesel engine |

-

2011

- 2011-02-22 DE DE102011004514A patent/DE102011004514A1/de not_active Withdrawn

-

2012

- 2012-02-09 EP EP12704047.5A patent/EP2678552B1/fr active Active

- 2012-02-09 WO PCT/EP2012/052212 patent/WO2012113653A1/fr not_active Ceased

- 2012-02-09 JP JP2013554842A patent/JP5815752B2/ja active Active

- 2012-02-09 US US14/001,072 patent/US10132288B2/en active Active

- 2012-02-09 CN CN201280009834.8A patent/CN103380293B/zh active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2014506656A (ja) | 2014-03-17 |

| US20140054279A1 (en) | 2014-02-27 |

| EP2678552A1 (fr) | 2014-01-01 |

| CN103380293A (zh) | 2013-10-30 |

| US10132288B2 (en) | 2018-11-20 |

| JP5815752B2 (ja) | 2015-11-17 |

| WO2012113653A1 (fr) | 2012-08-30 |

| DE102011004514A1 (de) | 2012-08-23 |

| CN103380293B (zh) | 2016-08-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1528253A1 (fr) | Méthode pour le recuit d'une bougie à incandescence d'un moteur Diesel | |

| EP2678552B1 (fr) | Procédé et appareil de commande pour régler une température d'une bougie-crayon de préchauffage | |

| DE2925351C2 (de) | Steuervorrichtung für die Glühkerzen einer Diesel-Brennkraftmaschine | |

| EP2122157A1 (fr) | Procédé et dispositif de commande d'excitation de bougie de préchauffage | |

| EP1936183A2 (fr) | Procédé destiné à la régulation de la température d'une bougie de préchauffage d'un moteur à combustion interne | |

| DE102009046438B4 (de) | Verfahren zur Regelung oder Steuerung der Temperatur einer Glühstiftkerze | |

| EP2162608B1 (fr) | Procédé et dispositif pour commander une température de post-chauffage dans un moteur à combustion interne diesel | |

| DE19729101A1 (de) | System zum Betreiben einer Brennkraftmaschine insbesondere eines Kraftfahrzeugs | |

| EP2080888B1 (fr) | Reconnaissance automatique de carburant | |

| DE102006005710A1 (de) | Vorrichtung und Verfahren zur Steuerung wenigstens einer Glühkerze eines Kraftfahrzeugs | |

| DE10135880A1 (de) | Verfahren und Vorrichtung zum Steuern der Aufheizung der Glühkerzen eines Dieselmotors | |

| DE10038565C2 (de) | Kraftstoffversorgungssystem für eine Brennkraftmaschine insbesondere eines Kraftfahrzeugs | |

| EP1420207B1 (fr) | Méthode de commande d'un élément d'allumage par incandescence pour un appareil de chauffage | |

| EP2596233A1 (fr) | Procédé et dispositif de commande du comportement d'incandescence d'une bougie-crayon incandescente d'un moteur à combustion interne | |

| DE102010042364B4 (de) | Verfahren und Vorrichtung zur Ermittlung einer Aktortemperatur eines Kraftstoffinjektors für eine Brennkraftmaschine | |

| DE102011086445A1 (de) | Verfahren und Vorrichtung zur Regelung der Temperatur einer Glühstiftkerze in einer Brennkraftmaschine | |

| EP2542775A1 (fr) | Procédé et dispositif pour commander ou régler une température d'une bougie-crayon de préchauffage sur un moteur à combustion d'un véhicule automobile | |

| EP2025540B1 (fr) | Procédé de fonctionnement d'un appareil de chauffage combustible | |

| DE102010001662B4 (de) | Verfahren und Vorrichtung zum Betreiben einer Glühkerze in einer Brennkraftmaschine eines Kraftfahrzeuges | |

| DE102005052879A1 (de) | Verfahren zum Betreiben einer Brennkraftmaschine und Brennkraftmaschine | |

| EP0809021A2 (fr) | Méthode et dispositif de commande de préchauffage des bougies de réchauffage d'un moteur diesel | |

| DE102012206224A1 (de) | Verfahren und Vorrichtung zur Regelung einer Temperatur einer Glühstiftkerze in einer Brennkraftmaschine | |

| WO2009074375A1 (fr) | Procédé et unité de commande servant à la commande électrique d'un actionneur d'une soupape d'injection | |

| EP1674794A1 (fr) | Procédé de mise en marche d'un dispositif de chauffage de véhicule et dispositif de chauffage de véhicule | |

| DE19708430A1 (de) | Verfahren und Vorrichtung zur Steuerung des Glühvorgangs einer Glühkerze eines Dieselmotors |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20130923 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20171127 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 990765 Country of ref document: AT Kind code of ref document: T Effective date: 20180515 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502012012550 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20180418 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180718 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180718 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180719 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180820 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502012012550 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 |

|

| 26N | No opposition filed |

Effective date: 20190121 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190209 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190228 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190228 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190209 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 990765 Country of ref document: AT Kind code of ref document: T Effective date: 20190209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180818 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20120209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180418 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250219 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250228 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250422 Year of fee payment: 14 |