EP2492414B1 - Modulares Geländer mit Regulierungsvorrichtung - Google Patents

Modulares Geländer mit Regulierungsvorrichtung Download PDFInfo

- Publication number

- EP2492414B1 EP2492414B1 EP12156201.1A EP12156201A EP2492414B1 EP 2492414 B1 EP2492414 B1 EP 2492414B1 EP 12156201 A EP12156201 A EP 12156201A EP 2492414 B1 EP2492414 B1 EP 2492414B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- handrail

- bars

- vertical

- strip

- support bar

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000000295 complement effect Effects 0.000 claims description 3

- 230000000903 blocking effect Effects 0.000 claims 3

- 208000031968 Cadaver Diseases 0.000 description 4

- 238000009434 installation Methods 0.000 description 4

- 238000012986 modification Methods 0.000 description 4

- 230000004048 modification Effects 0.000 description 4

- 230000007547 defect Effects 0.000 description 3

- 230000001681 protective effect Effects 0.000 description 2

- 240000008042 Zea mays Species 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 210000000003 hoof Anatomy 0.000 description 1

- 230000003100 immobilizing effect Effects 0.000 description 1

- 239000005340 laminated glass Substances 0.000 description 1

- 239000002650 laminated plastic Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F11/00—Stairways, ramps, or like structures; Balustrades; Handrails

- E04F11/18—Balustrades; Handrails

- E04F11/181—Balustrades

- E04F11/1836—Handrails of balustrades; Connections between handrail members

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F11/00—Stairways, ramps, or like structures; Balustrades; Handrails

- E04F11/18—Balustrades; Handrails

- E04F11/181—Balustrades

- E04F11/1812—Details of anchoring to the wall or floor

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F11/00—Stairways, ramps, or like structures; Balustrades; Handrails

- E04F11/18—Balustrades; Handrails

- E04F11/181—Balustrades

- E04F11/1812—Details of anchoring to the wall or floor

- E04F11/1814—Covers for the base portions of the balustrade posts

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F11/00—Stairways, ramps, or like structures; Balustrades; Handrails

- E04F11/18—Balustrades; Handrails

- E04F11/181—Balustrades

- E04F11/1817—Connections therefor

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F11/00—Stairways, ramps, or like structures; Balustrades; Handrails

- E04F11/18—Balustrades; Handrails

- E04F11/181—Balustrades

- E04F11/1851—Filling panels, e.g. concrete, sheet metal panels

- E04F11/1853—Glass panels

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F11/00—Stairways, ramps, or like structures; Balustrades; Handrails

- E04F11/18—Balustrades; Handrails

- E04F11/181—Balustrades

- E04F11/1817—Connections therefor

- E04F2011/1819—Connections therefor between balustrade posts and horizontal or sloping balustrade members

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F11/00—Stairways, ramps, or like structures; Balustrades; Handrails

- E04F11/18—Balustrades; Handrails

- E04F11/181—Balustrades

- E04F11/1817—Connections therefor

- E04F2011/1819—Connections therefor between balustrade posts and horizontal or sloping balustrade members

- E04F2011/1821—Connections therefor between balustrade posts and horizontal or sloping balustrade members between balustrade posts and handrails

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F11/00—Stairways, ramps, or like structures; Balustrades; Handrails

- E04F11/18—Balustrades; Handrails

- E04F11/181—Balustrades

- E04F11/1817—Connections therefor

- E04F2011/1831—Connections therefor between balustrade filling members, e.g. panels, and balustrade posts

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F11/00—Stairways, ramps, or like structures; Balustrades; Handrails

- E04F11/18—Balustrades; Handrails

- E04F2011/1868—Miscellaneous features of handrails not otherwise provided for

- E04F2011/187—Miscellaneous features of handrails not otherwise provided for lengthwise adjustable, e.g. telescopic

Definitions

- the present invention relates, in a general manner, to the technical field of guardrails intended, in the building sector, to be installed at the edge of slabs of balconies or terraces. More particularly, this invention is concerned with a railing of modular structure, provided with an adjusting device.

- the railings of balconies or terraces are, usually, made with support bars at more or less important intervals, the tops of the support bars being interconnected by a horizontal handrail, while at intermediate heights these support bars are also interconnected by one or more horizontal rails.

- the smooth can be sufficiently close together to constitute by themselves a protective barrier.

- These rails may also remain relatively spaced, in which case they receive between them full or perforated filling elements such as panels of metal or laminated glass or plastic, or they are interconnected by a series of vertical bars sufficiently closer together.

- the bases of the support bars are fixed at ground level, for example near the edge of a balcony slab, by means of hooves.

- Each shoe is itself fixed on the slab by means of a screw, advantageously with the interposition of a wedge allowing adjustment of inclination of the support bar.

- the railings do not include any other height adjustment device.

- irregularities or inclinations of the edge of the slab echo to the top of the support bars, creating a lack of horizontality smooth and especially the handrail.

- This problem is posed not only in case of a construction defect on the front edge of the slab, but also in case of desired inclination of a side edge of the slab to facilitate the flow and evacuation of water rain by gravity.

- Guardrails have already been designed with independent adjustment means for the rails and the handrail. This should theoretically allow a horizontal setting of the rails and the handrail.

- Such a solution requires manual interventions at multiple points, at the time of installation of the railing, without guarantee the horizontality and parallelism of the rails and the handrail. This can result in a visual defect of the guardrail, or even a difficulty of setting up a filling panel between two smooth.

- each support bar has at its base a shoe, on which are guided and immobilized two vertical sections to which are fixed the rails and the handrail. It is thus possible to vertically adjust the position of the rails and the handrail, maintaining their spacing and their parallelism, before immobilizing the assembly by means of a locking flange screwed on the shoe and simultaneously tightened against the bases of the two vertical profiles.

- such a railing embodiment does not allow an easy height adjustment and independent of the two sections, since it provides a common locking flange to these two sections.

- the embodiment according to the aforementioned document eliminates any fixed and rigid support bar extending over the height of the railing, replacing such a support bar by two profiles to be fixed on the same low height shoe. This results in a mechanical weakness of the assembly, due to the fact that the guiding of the sections relative to the shoe is made over a very small length, and also to a risk of insufficient tightening of the locking flange against these profiles.

- the handrail is composed of successive elements, of length equal to that of a module.

- the present invention aims to overcome the disadvantages described above, and therefore aims to provide a railing with improved adjustment device, which allows a vertical as well as longitudinal adjustment, maintaining the spacing and parallelism of smooth and handrail, while avoiding to weaken the parts that participate in the mechanical strength of the railing and that undergo and transmit the efforts.

- the invention relates to a modular railing with adjusting device, according to claim 1.

- the two support bars of each module each comprise a lateral vertical groove into which a complementary part belonging to the associated bar is introduced and guided.

- each bar in the set vertical position, comprise at least one locking screw, screwed into a corresponding threaded hole of the bar and adapted to be clamped against the bottom of the groove of the support bar.

- the fastening means of the handrail consist of a connecting piece mounted at the top of each bar, the connecting piece covering the top of the associated support bar in the entire vertical adjustment range of the bar relative to the bar -support.

- a railing formed modules in which the rails and the handrail are integral, these modules giving the possibility of adjusting the horizontality of the handrail by lifting more or less each bar.

- the rails being fixed between the bars, the vertical adjustment thus carried out preserves the spacing and the parallelism between the rails and the handrail.

- the constitution of the railing in initially independent modules, nevertheless interconnected by a common handrail to these modules allows easy longitudinal adjustment at the time of installation of the railing, spacing more or less two adjacent support bars belonging to two consecutive modules, with a large adjustment range which, however, shall not exceed the maximum deviation set by the applicable standards or other safety requirements.

- the guardrail design object of the invention, retains an important and rigid fixed structure constituted by the support bars fixed on the slab by means of the shoes, and it provides a "long" guide of the bars by the grooves extending over the entire height of the support bars, which provides significant mechanical strength, the support bars can absorb and transmit significant effort.

- each single-bar support bar allows vertical adjustment and individual tightening of all the bars, facilitating the installation of the railing, possibly with the use of appropriate shims to temporarily maintain a set position.

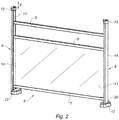

- the guardrail installed on a balcony slab 2 is made from independent modules 3, in the illustrated example several modules 3 placed one after another the along the front edge 4 of the slab 2, and another module 3 placed on a lateral edge 5 of this slab 2.

- the railing comprises vertical support bars 6, horizontal rails 7, 8 and 9 which interconnect the support bars 6 at intermediate heights, and a handrail 10 interconnecting them the vertices of these support bars 6.

- three rails 7, 8 and 9 are provided, with a lower rail 7, an intermediate rail 8, and a top rail 9.

- Filling panels 11 of shape rectangular are mounted between the lower rail 7 and the intermediate rail 8, while the upper rail 9 forms a simple protective bar.

- the bases of the support bars 6 are fixed on the slab 2 by means of shoes 12.

- a module 3 as represented on the figure 2 , comprises two support bars 6 with their respective fixing shoes 12, the three rails 7, 8 and 9 connecting these two support bars 6, and the filling panel 11 which is mounted between the two rails 7 and 8.

- the bars -supports 2 are provided at their vertex respective connecting pieces 13, provided for the attachment of the handrail 10 which is common to all of the modules 3 and therefore does not belong to a particular module.

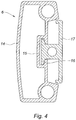

- each support bar 6 comprises a main section 14 which constitutes the body of this support bar, the main section 14 comprising a single vertical lateral groove 15.

- a complementary "T" part 16 belonging to a vertical secondary profile, designated as a bar 17.

- each support bar 6 At the base of each support bar 6, and as shown in detail in the figure 5 , the lower end of the main section 14 is secured to the fixing shoe 12.

- the latter is intended to be clamped on the slab 2, with the interposition of a setting pad 18 with a toric surface, by means of a screw fixation 19.

- a cover 20 covers the fixing shoe 12, in particular to conceal and protect the fixing screw 19 (the cover 20 having been shown spaced from the shoe 12 for clarity of the drawing).

- the different rails 7, 8 and 9 are all connected, by their ends, to the two bars 17 of a module 3, these two bars 17 being located vis-à-vis.

- the connection between the rails 7, 8, 9 and the bars 17 is made by means of screws (not shown), according to a technique known per se.

- the connecting pieces 13 provided for fixing the handrail 10 are mounted at the top of the bars 17.

- the figure 7 represents the connecting piece 13 spaced from the top of the main profile 14 of the support bar 6, it being understood that in final configuration this connecting piece 13 covers the top of the main section 14.

- the two bars 17 of a module 3 are slid into the grooves 15 of the main profiles 14 of the two support bars 6, and these bars 17 come to a low abutment on the fixing shoes 12 of the support bars 6.

- Each module 3 thus prepared is placed on the slab 2, and is fixed thereto by tightening the fixing screws 19.

- the modules 3 are thus fixed one after the other, the support bar 6 right of a module 3 being located near the support bar 6 left of the next module 3.

- the spacing e between the vertical axis of the right-hand support bar 6 of a module 3 and the vertical axis of the left-hand support bar 6 of the next module 3 is adjustable by the simple choice of the position of installation and fixing of the respective shoes 12 of these two support bars 6.

- the railing is thus adaptable to the length of the slab 2, to compensate for inaccuracies in the length of this slab.

- the connecting pieces 13 are mounted at the top of the bars 17 (unless they have already been previously), and the handrail 10 is itself fixed on these 13.

- the horizontality of the handrail 10 above each module 3, by raising more or less strongly each bar 17 relative to the fixing shoe 12 by sliding of this bar 17 in the vertical groove 15 of the associated main section 14.

- the locking screw 21 is screwed into a corresponding threaded hole 22 of the bar 17, and tightly against the bottom of the groove 15.

- This height adjustment operation makes it possible in particular to compensate for the defects in horizontality or other irregularities of the front edge 4 of the slab 2, but also to compensate for a slight intentional inclination of this slab 2 and its lateral edge 4, inclination to favor the flow and evacuation of rainwater.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Steps, Ramps, And Handrails (AREA)

Claims (4)

- Modulares Schutzgeländer mit Einstellvorrichtung, Trägerstangen (6) umfassend, die in Intervallen angeordnet sind, deren höchste Punkte durch einen Handlauf (10) miteinander verbunden sind, und die auch auf Zwischenhöhen durch horizontale Stangen (7, 8, 9) miteinander verbunden sind, die zwischen sich Füllelemente (11) oder eine Reihe von vertikalen Stangen aufnehmen können, dadurch gekennzeichnet, dass das Schutzgeländer aus ursprünglich unabhängigen Modulen (3) gebildet wird, die dennoch durch den Handlauf (10) miteinander verbunden sind, jedes bestehend aus:- zwei im Abstand angeordneten vertikalen Trägerstangen (6, 14), die jeweils an ihrer Basis mit einem Befestigungssockel (12) versehen sind,- zwei vertikalen Stegen (17), die jeweils vertikal über die beiden Trägerstangen (6, 14) geführt werden, wobei die beiden Stege (17) einander gegenüber angeordnet sind,- zumindest zwei horizontalen Stangen (7, 8, 9), welche die beiden Stege (17) miteinander verbinden,- Befestigungsmittel (13) für den Handlauf (10), die von den jeweiligen höchsten Punkten der beiden Stege (17) getragen werden, und- Arretiermittel (21, 22) für jeden Steg (17) im Verhältnis zur zugeordneten Trägerstange (6, 14) in einer gewünschten vertikalen Position,wobei der Handlauf (10) für eine Einheit von Modulen (3) derselbe ist, und zu keinem Modul im Besonderen gehört.

- Modulares Schutzgeländer nach Anspruch 1, dadurch gekennzeichnet, dass die beiden Trägerstangen (6, 14) eines jeden Moduls (3) jeweils eine laterale vertikale Nut (15) umfassen, in die ein ergänzender Abschnitt (16) eingeführt und darin geführt wird, welcher zum zugeordneten Steg (17) gehört.

- Modulares Schutzgeländer nach Anspruch 2, dadurch gekennzeichnet, dass die Arretiermittel für jeden Steg (17) in der eingestellten vertikalen Position zumindest eine Blockierschraube (21) umfassen, die in ein entsprechendes Gewindeloch (22) für den Steg (17) geschraubt wird, und dafür vorgesehen ist, am Grund der Nut (15) der Trägerstange (6, 14) festgezogen zu werden.

- Modulares Schutzgeländer nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, dass die Befestigungsmittel des Handlaufes (10) durch ein Verbindungsteil (13) gebildet werden, das am höchsten Punkt eines jeden Stegs (17) montiert wird, wobei das Verbindungsteil (13) den höchsten Punkt der zugeordneten Trägerstange (6, 14) im gesamten vertikalen Einstellbereich des Stegs (17) im Verhältnis zur Trägerstange (6, 14) abdeckt.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1151418A FR2971805B1 (fr) | 2011-02-22 | 2011-02-22 | Garde-corps modulaire avec dispositif de reglage, et module constitutif d'un tel garde-corps |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2492414A1 EP2492414A1 (de) | 2012-08-29 |

| EP2492414B1 true EP2492414B1 (de) | 2017-04-19 |

Family

ID=45581795

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12156201.1A Active EP2492414B1 (de) | 2011-02-22 | 2012-02-20 | Modulares Geländer mit Regulierungsvorrichtung |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP2492414B1 (de) |

| FR (1) | FR2971805B1 (de) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108222388B (zh) * | 2018-02-01 | 2019-11-12 | 温州市旭阳艺术装饰工程有限公司 | 一种便于安装的装饰护栏 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2741903B1 (fr) | 1995-12-01 | 1998-02-20 | Mollard Pierre | Portion de palissade et palissade comprenant au moins deux de ces portions |

| NL1007638C2 (nl) * | 1997-11-27 | 1999-06-09 | Straatman Bv | Hekwerk. |

| FR2857395B1 (fr) | 2003-07-08 | 2005-09-02 | Technal | Pietement de support pour un poteau vertical de garde-corps |

-

2011

- 2011-02-22 FR FR1151418A patent/FR2971805B1/fr not_active Expired - Fee Related

-

2012

- 2012-02-20 EP EP12156201.1A patent/EP2492414B1/de active Active

Also Published As

| Publication number | Publication date |

|---|---|

| FR2971805A1 (fr) | 2012-08-24 |

| FR2971805B1 (fr) | 2016-07-01 |

| EP2492414A1 (de) | 2012-08-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA1260211A (fr) | Corniche pour ouvrage d'art | |

| EP3492675B1 (de) | Vorrichtung zum befestigen von lamellen an einem starren gitterpaneel, lamellenbefestigungskit an einem starren gitterpaneel und sichtschutzzaun, der mit diesem kit ausgestattet ist | |

| FR3047260B1 (fr) | Garde-corps autoporte | |

| EP0651112B1 (de) | Modulaires Geländer mit horizontalen oder geneigten Holmen | |

| EP2492414B1 (de) | Modulares Geländer mit Regulierungsvorrichtung | |

| FR2800768A1 (fr) | Dispositif pour le montage et l'immobilisation de consoles de support sur une facade de batiment ou analogue | |

| EP0774032A1 (de) | Variabel gestaltete treppe | |

| FR3078086A1 (fr) | Systeme de platelage comportant des moyens de fixation d'un bandeau peripherique vertical. | |

| FR2937353A1 (fr) | Procede et dispositif pour l'installation de panneaux photovoltaiques, et couverture photovoltaique de toiture en faisant application | |

| FR2935406A1 (fr) | Abri telescopique guide en partie haute | |

| FR3002253A1 (fr) | Toiture pour construction de preference modulaire | |

| EP2299027B1 (de) | Gerüststruktur, insbesondere Fassadengerüst | |

| FR3116291A1 (fr) | Garde-corps comprenant un dispositif d’obturation d’un espace libre | |

| EP0158755B1 (de) | Modularer Laufsteg, insbesondere zur Überwachung von Kabeltragrollen-Pendelgestellen von Schwebebahninstallationen | |

| FR2738862A1 (fr) | Barriere modulable | |

| FR2637635A1 (fr) | Rambarde perfectionnee et dispositif permettant sa fixation au sol | |

| EP1640529A1 (de) | Sicherheitsgeländer | |

| FR2516142A1 (fr) | Renvoi d'angle pour echafaudage | |

| EP2149649A2 (de) | Vorrichtung zum Befestigen einer Geländerhalterung an einem Bauwerk | |

| EP0731236A1 (de) | Befestigungsvorrichtung am Deckenunterbau für tragende Geländerpfosten | |

| FR2844537A1 (fr) | Dispositif de liaison des marches aux montants d'un escalier, notamment d'une passerelle pour pietons et escalier ou passerelle pour pietons ainsi equipes | |

| FR2934001A1 (fr) | Potelet de garde-corps de securite et garde-corps de securite comprenant au moins un tel potelet | |

| FR2970018A1 (fr) | Garde-corps reglable | |

| FR2935451A1 (fr) | Ferrure d'assemblage multifonction | |

| FR2671574A1 (fr) | Etrier d'echafaudage suspendu et module d'echafaudage comportant ledit etrier. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| 17P | Request for examination filed |

Effective date: 20130218 |

|

| 17Q | First examination report despatched |

Effective date: 20160406 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20161123 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 886119 Country of ref document: AT Kind code of ref document: T Effective date: 20170515 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602012031230 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170419 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 886119 Country of ref document: AT Kind code of ref document: T Effective date: 20170419 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170719 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170720 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170719 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170819 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602012031230 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 |

|

| 26N | No opposition filed |

Effective date: 20180122 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20171229 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180220 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180220 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180220 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180220 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602012031230 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20120220 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170419 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170419 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250131 Year of fee payment: 14 |