EP2465802A2 - Garnwicklungsvorrichtung - Google Patents

Garnwicklungsvorrichtung Download PDFInfo

- Publication number

- EP2465802A2 EP2465802A2 EP11189514A EP11189514A EP2465802A2 EP 2465802 A2 EP2465802 A2 EP 2465802A2 EP 11189514 A EP11189514 A EP 11189514A EP 11189514 A EP11189514 A EP 11189514A EP 2465802 A2 EP2465802 A2 EP 2465802A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- yarn

- guide

- traverse

- bobbin

- unit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H54/00—Winding, coiling, or depositing filamentary material

- B65H54/02—Winding and traversing material on to reels, bobbins, tubes, or like package cores or formers

- B65H54/38—Arrangements for preventing ribbon winding ; Arrangements for preventing irregular edge forming, e.g. edge raising or yarn falling from the edge

- B65H54/388—Preventing the yarn from falling off the edge of the package

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H59/00—Adjusting or controlling tension in filamentary material, e.g. for preventing snarling; Applications of tension indicators

- B65H59/10—Adjusting or controlling tension in filamentary material, e.g. for preventing snarling; Applications of tension indicators by devices acting on running material and not associated with supply or take-up devices

- B65H59/36—Floating elements compensating for irregularities in supply or take-up of material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H54/00—Winding, coiling, or depositing filamentary material

- B65H54/02—Winding and traversing material on to reels, bobbins, tubes, or like package cores or formers

- B65H54/04—Winding and traversing material on to reels, bobbins, tubes, or like package cores or formers for making packages with closely-wound convolutions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H54/00—Winding, coiling, or depositing filamentary material

- B65H54/02—Winding and traversing material on to reels, bobbins, tubes, or like package cores or formers

- B65H54/28—Traversing devices; Package-shaping arrangements

- B65H54/30—Traversing devices; Package-shaping arrangements with thread guides reciprocating or oscillating with fixed stroke

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H59/00—Adjusting or controlling tension in filamentary material, e.g. for preventing snarling; Applications of tension indicators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H67/00—Replacing or removing cores, receptacles, or completed packages at paying-out, winding, or depositing stations

- B65H67/04—Arrangements for removing completed take-up packages and or replacing by cores, formers, or empty receptacles at winding or depositing stations; Transferring material between adjacent full and empty take-up elements

- B65H67/044—Continuous winding apparatus for winding on two or more winding heads in succession

- B65H67/048—Continuous winding apparatus for winding on two or more winding heads in succession having winding heads arranged on rotary capstan head

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/30—Handled filamentary material

- B65H2701/31—Textiles threads or artificial strands of filaments

- B65H2701/313—Synthetic polymer threads

- B65H2701/3132—Synthetic polymer threads extruded from spinnerets

Definitions

- the present invention relates to a yarn winding device which traverses yarns by a traverse unit and wind them onto a bobbin so as to form a package.

- a known yarn winding device has a traverse unit traversing yarns in the axial directions of bobbins and forms a package by winding yarns onto a bobbin while traversing the yarns.

- various methods of traversing yarns by the traverse unit of the yarn winding device have been known.

- Patent Document 1 Japanese Unexamined Patent Publication No.

- a cam drum traverse unit which is arranged to include a cam drum which is provided to be in parallel to the shaft of a bobbin and has a helical cam groove on the circumference and a traverse guide which reciprocates in the axial directions of the bobbin along the cam groove in response to the rotation of the cam drum.

- the traverse guide of this cam drum traverse unit moves so as to traverse yarns in the axial directions of the bobbin while sandwiching and binding the running yarns in the axial directions.

- Patent Document 2 Japanese Examined Patent Publication No. 3985/1979 ( Tokukosho 54-3985 ) ( Fig. 4 ) recites a rotating-blade-type traverse unit which has two blade-shaped traverse guides which are superposed onto each other and rotate in reverse directions.

- this traverse unit after a yarn is moved on one side in the axial directions of the bobbin by one traverse guide, the yarn is passed to the other traverse guide at the end point (i.e. an edge of the winding target range on the bobbin), and the yarn is moved to the other side in the axial directions of the bobbin by the other traverse guide.

- This Patent Document 2 aims at reducing the yarn accumulation (so-called saddle bag) at the end portions of the package.

- the technology recited in the document utilizes the yarn returning effect at the respective traversal ends, in a traverse unit which winds yarns such that a yarn guided by a traverse guide to a traversal end comes off from the traverse guide and is then engaged with another traverse guide and guided in a reverse direction.

- position regulation guides are provided at the traversal ends to arrange the speed of the yarn returning from a traversal end to be higher than the speed of the movement of the traverse guide, with the result that the yarn accumulation at the traversal ends is alleviated.

- a yarn Y is traversed while changing its form in the order of (3) ⁇ (2) ⁇ (1) ⁇ (2) ⁇ (3).

- a traverse guide 80 goes beyond the winding target range of a bobbin 81 and is reversed, the linear distance between the contact point Al of the running yarn Y with the traverse guide 80 and the contact point A2 of the running yarn Y with the bobbin 81 is short.

- the speed of winding onto the bobbin 81 i.e. the speed of supplying the yarn

- An object of the present invention is therefore to restrain the occurrence of yarn stitching by eliminating the slack in a yarn, which occurs between a bobbin and a traverse guide when the traverse guide is reversed.

- a yarn winding device of the present invention includes: a winding unit which winds a yarn onto a bobbin; a traverse unit which reciprocally moves the running yarn in axial directions of the bobbin; and a slack removal unit which removes the slack in the yarn running between the traverse guide and the bobbin, when the traverse guide is reversed.

- the yarn winding device of the present invention since the slack in a yarn running between the traverse guide and the bobbin is removed when the traverse guide is reversed, a yarn having a stable yarn form is wound at an edge of the winding target range of the bobbin, with the result that the occurrence of the yarn stitching is restrained.

- the yarn winding device is preferably arranged so that the slack removal unit is provided on a side upstream of the traverse guide in a direction in which the yarn runs, and is a resistance imparting unit which contacts the running yarn to impart, to the yarn, running resistance against the direction in which the yarn runs, when the traverse guide is reversed.

- the slack in the yarn is easily removed only by imparting running resistance against the running direction of the yarn when the traverse guide is reversed, as the tension on the yarn is increased on the side downstream of the resistance imparting unit.

- the yarn winding device preferably further includes: a fulcrum guide which is fixedly provided on the side upstream of the traverse guide in the direction in which the yarn runs; and a contact guide which is provided between the fulcrum guide and the traverse guide and functions as the resistance imparting unit, the contact guide externally contacting, in the axial directions of the bobbin, the yarn between the fulcrum guide and the traverse guide, on a line connecting the fulcrum guide with the traverse guide when the traverse guide reaches an edge of a winding target range of the bobbin.

- the yarn running between the traverse guide and the bobbin is maximally slackened when the direct distance between the contact point of the running yarn with the traverse guide and the contact point of the running yarn with the bobbin becomes the shortest, i.e., when the traverse guide reaches the edge of the winding target range of the bobbin.

- the contact guide contacts the yarn running between the fulcrum guide and the bobbin, on the line L2 (see Fig. 3 ) connecting the fulcrum guide with the traverse guide at the aforesaid position.

- the contact guide gets closer to the traversal center and away from the line L2, the angle of the yarn contacting and bended by the contact guide increases, and hence the damage onto the running yarn between the traverse guide and the bobbin becomes serious in comparison with the effect of removing the slack in the yarn.

- the contact guide contacts the yarn running between the fulcrum guide and the bobbin on the line L2, it is possible to effectively remove the slack in the yarn running between the traverse guide and the bobbin.

- the yarn winding device preferably further includes: a position change unit which changes a position of the contact guide in the axial directions of the bobbin; and a position control unit which controls the position change unit.

- the yarn winding device is preferably arranged so that the traverse unit is able to change a reversal position where the traverse guide is reversed, and the position control unit controls the position change unit so as to move the contact guide in accordance with a direction in which the reversal position of the traverse guide is changed, while the yarn is being wound onto the bobbin.

- the end faces of the package may be arranged to tilt axially outward.

- the reversal position of the traverse guide moves inward as the amount of wound yarns increases.

- the contact guide is moved inward. With this, the contact guide surely contacts the running yarn when the traverse guide is reversed, with the result that the yarn stitching is more effectively restrained.

- the yarn winding device preferably further includes: a winding control unit which controls a rotation speed of the bobbin rotated by the winding unit, the winding control unit controlling the winding unit so as to function as the slack removal unit which removes the slack in the yarn running between the traverse guide and the bobbin, by temporarily increasing the rotation speed of the bobbin when the traverse guide is reversed.

- the slack in the yarn running between the traverse guide and the bobbin is removed with less decrease in the quality of the yarn, as compared to the arrangement in which the slack is removed by imparting running resistance to the yarn.

- the yarn having the desired shape is wound at the edge of the winding target range on the bobbin, the occurrence of the yarn stitching is restrained.

- Fig. 1 is a profile of a yarn winding device according to First Embodiment of the present invention.

- Fig. 2 is a front elevation of the yarn winding device.

- a yarn winding device 1 successively receives a plurality of yarns Y from an unillustrated spinning machine provided above.

- the yarn winding device 1 is arranged to form a plurality of packages 10 by winding the yarns Y supplied from the spinning machine onto a plurality of bobbins 9.

- the yarn winding device 1 includes components such as a main body frame 2, an elevation frame 3 provided to the main body frame 2 to be vertically movable, a disc-shaped turret 4 rotatably provided to the main body frame 2, two bobbin holders 5 (winding units) each of which is supported by the turret 4 at one end and to which a plurality of bobbins 9 are attached, a traverse unit 6 which traverses the yarn Y which is to be wound onto the bobbin 9, a contact roller 7 which is able to contact the bobbins 9 attached to the bobbin holders 5, and a controller 8 which controls the overall operation by controlling the components.

- components such as a main body frame 2, an elevation frame 3 provided to the main body frame 2 to be vertically movable, a disc-shaped turret 4 rotatably provided to the main body frame 2, two bobbin holders 5 (winding units) each of which is supported by the turret 4 at one end and to which a plurality of bobbins 9 are

- the turret 4 is disc-shaped and is rotatably attached to the main body frame 2. At two positions which are symmetrical with respect to a shaft 4a which is the rotation center of the turret 4, ends of the two bobbin holders 5 are connected, respectively.

- the two bobbin holders 5 are rotatably protrude from the turret 4.

- the two bobbin holders 5 are arranged to rotate together with the turret 4.

- To each of the two bobbin holders 5, a plurality of bobbins 9 are attached in series in the axial directions of the bobbin holder 5.

- the turret 4 is rotated about the shaft 4a by a rotation motor 31. As the turret 4 is rotated, each of the two bobbin holders 5 moves between a winding position P1 at which the bobbin holder 5 contacts the contact roller 7 and yarns Y are wound onto the bobbins 9 and a standby position P2 which is below the winding position P1 and is point-symmetrical with the winding position P1 with respect to the shaft 4a of the turret 4.

- this bobbin holder 5 at the winding position P1 is switched to the standby position P2 whereas the bobbin holder 5 at the winding position P2 is switched to the winding position P1.

- Each of the two bobbin holders 5 supported by the turret 4 is rotated by the rotation motor 32.

- the bobbin holder 5 at the winding position P1 is rotated, the yarns Y are wound onto the bobbins 9 attached to this bobbin holder 5.

- the elevation frame 3 is a long frame extending in the axial directions of the bobbin holder 5, and supported by the main body frame 2 at its base end in the longitudinal direction.

- the elevation frame 3 is connected to a rod of an unillustrated cylinder fixed to the main body frame 2, and is vertically moved (i.e. moved in the direction away from the bobbin holder 5) with respect to the main body frame 2, as the cylinder is driven.

- the traverse unit 6 is provided on the elevation frame 3 and includes components such as fulcrum guides 19, a traverse cam 20, traverse guides 21, and a traverse motor 33.

- the fulcrum guides 19 are provided around the upper end of the elevation frame 3.

- the yarns Y supplied from the spinning machine are placed onto these fulcrum guides 19, and they function as the traversal fulcrums of the yarns Y.

- the traverse cam 20 is provided to be in parallel to the bobbin holder 5 and is rotatably supported by the elevation frame 3.

- the traverse cam 20 has a helical cam groove on its circumference, and is rotated by the traverse motor 33.

- the traverse guides 21 move along the cam groove as the traverse cam 20 is rotated, and reciprocate in the axial directions of the traverse cam 20 (bobbin holder 5).

- Each traverse guide 21 is arranged to sandwich a running yarn Y by two guide portions 21a in the axial directions of the bobbin holder 5.

- the traverse guide 21 guides the yarn Y running through the fulcrum guide 19 to the contact roller 7 while traversing, by using the fulcrum guide 19 as a fulcrum, the yarn Y in the axial directions (traversing directions) of the bobbin holder 5.

- yarn stitching restraining guides 50 are provided to be able to contact the yarns Y traversed by the traverse guide 21.

- Each yarn stitching restraining guide 50 is connected to the rod of the cylinder 34 fixed to the elevation frame 3. As the cylinder 34 is driven, the yarn stitching restraining guide 50 moves in the traversing directions with respect to the elevation frame 3.

- This yarn stitching restraining guide 50 will be detailed later. It is noted that, in First Embodiment, the yarn stitching restraining guides 50 may be fixed and immovable. On the other hand, the yarn stitching restraining guide 50 must be arranged to be movable in later-described Second Embodiment.

- the elevation frame 3 is connected to a supporting frame 11, and two supporting portions 11a rotatably supporting the contact roller 7 are provided at the respective longitudinal end portions of the supporting frame 11.

- the supporting frame 11 is long along the length of the elevation frame 3. Further, the supporting frame 11 is connected to the guide plate 12 at the longitudinal end portions of the supporting frame 11, and is arranged to be vertically movable with respect to the guide plate 12 (elevation frame 3) .

- the contact roller 7 is supported by the two supporting portions 11a of the supporting frame 11 to be in parallel to the bobbin holder 5. This contact roller 7 is arranged to be able to contact the outer circumferences of the bobbins 9 attached to the bobbin holder 5 at the winding position P1 or the packages 10 formed by winding the yarns Y onto the bobbins 9.

- the contact roller 7 is rotated by the rotation of the bobbin holder 5 while applying a predetermined contact pressure onto the packages 10, so as to adjust the shape of each package 10.

- the supporting frame 11 and the contact roller 7 are guided by the guide plate 12 to change their relative positions with respect to the elevation frame 3 in the direction to approach the bobbins 9 at the winding position P1 (i.e. downward direction) or in the direction away from these bobbins 9 (i.e. upward direction).

- the controller 8 performing the overall control of the yarn winding device 1 will be described.

- the controller 8 may include components such as a CPU (Central Processing Unit), a ROM (Read Only Memory) storing various programs and data for performing the overall control of the yarn winding device 1, and a RAM (Random Access Memory) temporarily storing data processed by the CPU, and perform below-described various controls as a program stored in the ROM is executed by the CPU.

- the controller 8 may be hardware composed by various circuits including an arithmetic circuit.

- the controller 8 includes a holder switching control unit 41, a winding control unit 42, a traverse control unit 43, and a contact position control unit 44.

- the holder switching control unit 41 drives the rotation motor 31 to rotate the turret 4, so as to switch the position of each of the two bobbin holders 5 between the winding position P1 and the standby position P2.

- the winding control unit 42 drives the rotation motor 32 to rotate the bobbin holder 5 at the winding position P1, so as to wind the yarns Y onto the bobbins 9 attached to the bobbin holder 5.

- the traverse control unit 43 drives the traverse motor 33 to rotate the traverse cam 20, so as to traverse the yarn Y sandwiched between the traverse guides 21 in the traversing directions by reciprocally moving the traverse guides 21 in the traversing directions.

- the contact position control unit 44 moves the cylinder 34 so as to change the positions of the yarn stitching restraining guides 50 in the traversing directions.

- the yarn stitching restraining guides 50 may be fixed as described above and the contact position control unit 44 may be unnecessary.

- the yarn stitching restraining guides 50 must be movable and the contact position control unit 44 is necessary.

- the controller 8 includes the contact position control unit 44 for this reason.

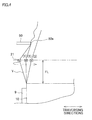

- Fig. 3 is used for illustrating the layout positions of the yarn stitching restraining guides. It is noted that the contact roller 7 is not illustrated in Fig. 3 . Furthermore, in reality, the yarn Y guided from the traverse guide 21 contacts the contact roller 7 first and then moves along its circumference and then contacts the bobbin 9. In this regard, for the sake of simplicity, the yarn Y guided from the traverse guide 21 is supposed to directly contact the bobbin 9 rather than the contact roller 7.

- Fig. 4 is used for illustrating the yarn forms of the yarn when the traverse guide is reversed. In Fig. 4 , the contact point between the yarn Y and the bobbin 9 gradually moves in a traversing direction when the traverse guide 21 is traversed. This movement, however, is ignored because it is very short in distance.

- two yarn stitching restraining guides 50 are provided for a single traverse unit 6 (i.e., a single yarn Y).

- An end face 50a of each of the two yarn stitching restraining guides 50 is positioned to be on the traversal center side of the line L1 connecting the traverse guide 21 at the reversal position with the fulcrum guide 19 and to be on the line L2 connecting the fulcrum guide 19 with the traverse guide 21 having reached the edge of the winding target range on the bobbin 9.

- an interval FL which is a free length of the yarn Y after the yarn Y on the traverse guide 21 is released from the traverse guide 21 and before the yarn Y contacts the bobbin 9.

- the tilt of the yarn Y in the free length interval FL is a synthetic vector of the rotation speed of the bobbin holder 5 (i.e., the speed of winding of the yarn Y onto the bobbin 9) and the traversing speed of the traverse guide 21.

- the traverse guide 21 traverses the yarn beyond the edge X1 of the winding target range of the wound yarns Y on the bobbin 9.

- the direct distance between the contact point where the running yarn Y contacts the traverse guide 21 and the contact point where the running yarn Y contacts the bobbin 9 becomes short for a moment.

- the distance becomes the shortest when the traverse guide 21 is at the same position as the edge X1 of the yarn Y wound onto the winding target range on the bobbin 9 in the axial directions of the bobbin 9 (i.e., (2) in Fig. 4 ).

- the form of the yarn Y is changed from the straight shape because the length of the yarn Y running in the free length interval between the traverse guide 21 and the bobbin 9 is unchanged, with the result that the yarn Y having an unpredictable shape is wound at the edge X1 of the winding target range on the bobbin 9 and hence the yarn stitching occurs.

- the yarn Y is traversed while changing its form in the order of (3) ⁇ (2) ⁇ (1) ⁇ (2) ⁇ (3) as shown in Fig. 4 .

- the traverse guide 21 is reversed, the running yarn Y contacts the yarn stitching restraining guide 50 and hence running resistance is imparted to the yarn Y.

- the tension on the yarn Y is increased on the downstream side (bobbin 9 side) of the part where the running resistance is imparted to the yarn Y, and consequently the slack in the yarn Y is easily removed.

- the yarn stitching restraining guide 50 can remove the slack in the yarn running between the traverse guide and the bobbin and restrain the occurrence of the yarn stitching as described above, when the yarn stitching restraining guide 50 is at least on the traversal center side of the line L1 connecting the traverse guide 21 at the reversal position (traversal end) with the fulcrum guide 19, i.e., on the traversal center side of the position where the yarn running at the traversal end starts to be slackened.

- the slack in the yarn running between the traverse guide and the bobbin is more effectively removed when the end face 50a of the yarn stitching restraining guide 50 is on the traversal center side of the line L1 and on the line L2 which connects the fulcrum guide 19 with the traverse guide 21 having reached the edge of the winding target range on the bobbin 9.

- the running resistance imparted to the yarn Y by the yarn stitching restraining guide 50 may be changed by changing the material of the guide and the surface roughness of the surface contacting the yarn Y, in addition to the layout position of the yarn stitching restraining guide 50.

- Second Embodiment of the present invention will be described.

- the yarn winding device 1 is arranged so that the yarn stitching restraining guides 50 which have been described in First Embodiment are movable.

- the positions of the yarn stitching restraining guides 50 are moved by the contact position control unit 44.

- the above-described cylinder 34 and contact position control unit 44 for moving the yarn stitching restraining guides 50 are prerequisite.

- the reversal position of the traverse guide 21 moves inward as the amount of wound yarns Y increases (L4 ⁇ L3).

- the cylinder 34 is controlled by the contact position control unit 44 so that the yarn stitching restraining guide 50 is moved inward (i.e., toward the center of the traversal width). With this, the yarn stitching restraining guide 50 surely contacts the running yarn Y when the traverse guide 21 is reversed, with the result that the yarn stitching is more effectively restrained.

- the yarn stitching is restrained by arranging the yarn stitching restraining guide 50 to be movable in accordance with the winding target range on the bobbin 9, it is possible to narrow the tapering angle to increase the total amount of the yarns wound in a single package 10, without increasing the diameter.

- the occurrence of the yarn stitching is restrained by the yarn stitching restraining guides 50.

- any arrangements may be adopted in place of the yarn stitching restraining guides 50 on condition that the slack in the yarn Y in the free length interval is removed.

- the rotation speed of the bobbin holder 5 is temporarily increased by controlling the winding control unit 42 by the rotation motor 32.

- the yarn stitching restraining guide 50 may be movably fixed to the elevation frame 3 by an unillustrated screw or the like, when it is unnecessary to move the yarn stitching restraining guide 50 during the winding of the yarns Y and the yarn stitching restraining guide 50 is moved only when, for example, the yarn type or the winding target range on the bobbin 9 is changed while the winding of the yarns Y is stopped. In this case, an operator loosens the screw, moves the yarn stitching restraining guide 50, and tightens the screw.

- the yarn stitching restraining guide 50 may be arranged to mechanically or electrically move in sync with a change in the traversal width of the traverse guide 21.

- An arm-type traverse unit is a device which reciprocally moves, in traversing directions, an arm member having a guide at its leading end by a drive motor.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Winding Filamentary Materials (AREA)

- Tension Adjustment In Filamentary Materials (AREA)

- Guides For Winding Or Rewinding, Or Guides For Filamentary Materials (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010277848A JP5730557B2 (ja) | 2010-12-14 | 2010-12-14 | 糸条巻取機 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2465802A2 true EP2465802A2 (de) | 2012-06-20 |

| EP2465802A3 EP2465802A3 (de) | 2013-08-21 |

| EP2465802B1 EP2465802B1 (de) | 2014-10-15 |

Family

ID=44992774

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP11189514.0A Active EP2465802B1 (de) | 2010-12-14 | 2011-11-17 | Garnwicklungsvorrichtung |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP2465802B1 (de) |

| JP (1) | JP5730557B2 (de) |

| KR (1) | KR101518978B1 (de) |

| CN (1) | CN102530640B (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023186549A1 (de) * | 2022-04-01 | 2023-10-05 | Oerlikon Textile Gmbh & Co. Kg | Aufwickelvorrichtung zum aufwickeln eines spinnfadens und verfahren zum aufwickeln eines spinnfadens |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015000777A (ja) * | 2013-06-13 | 2015-01-05 | 村田機械株式会社 | 糸巻取機 |

| KR101805824B1 (ko) * | 2016-04-14 | 2017-12-07 | 일진에이테크 주식회사 | 사 권취 장치 |

| CN112424100B (zh) * | 2018-08-09 | 2022-07-22 | 日本Tmt机械株式会社 | 丝线卷绕机 |

| JPWO2020075389A1 (ja) * | 2018-10-09 | 2021-09-02 | Tmtマシナリー株式会社 | 糸巻取機及びパッケージの生産方法 |

| DE102022001140A1 (de) * | 2022-04-01 | 2023-10-05 | Oerlikon Textile Gmbh & Co. Kg | Verfahren zum Aufwickeln eines Spinnfadens und Aufwickelvorrichtung zum Aufwickeln eines Spinnfadens |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS543985B1 (de) | 1970-07-24 | 1979-02-28 | ||

| JPH05238645A (ja) | 1992-02-28 | 1993-09-17 | Murata Mach Ltd | 糸条巻取方法および糸条巻取機 |

| JP2010163275A (ja) | 2009-01-19 | 2010-07-29 | Tmt Machinery Inc | 糸条巻取装置、この糸条巻取装置を用いた紡糸巻取機、糸条巻取方法、この糸条巻取方法を採用した紡糸巻取方法、及び、テーパエンドパッケージ |

| JP2010189127A (ja) | 2009-02-18 | 2010-09-02 | Tmt Machinery Inc | 糸条巻取機、及び糸条巻取方法 |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1130106A (fr) * | 1955-06-08 | 1957-01-31 | Rhodiaceta | Guide-fil |

| DE1560539A1 (de) * | 1963-07-03 | 1970-01-02 | Reiners Walter Dr Ing | Vorrichtung zur Vermeidung von Fadenabschlaegen bei Spulmaschinen |

| US4090676A (en) * | 1974-03-25 | 1978-05-23 | Kamitsu Seisakusho, Ltd. | Yarn or thread guiding device |

| GB1461884A (en) * | 1974-04-02 | 1977-01-19 | Bekaert Sa Nv | Winding apparatus |

| US4007885A (en) * | 1975-06-17 | 1977-02-15 | E. I. Du Pont De Nemours And Company | Flexible traverse guide assembly |

| JPS543985A (en) * | 1977-06-10 | 1979-01-12 | Masaaki Miyanaga | Core drill |

| US4961546A (en) * | 1989-09-29 | 1990-10-09 | Platt Saco Lowell Corporation | Strand tension compensator |

| JPH03158358A (ja) * | 1989-11-16 | 1991-07-08 | Toray Eng Co Ltd | 巻取機 |

| GB9024396D0 (en) * | 1990-11-09 | 1991-01-02 | Jeftex Limited | Thread package building |

| JPH11322192A (ja) * | 1998-05-14 | 1999-11-24 | Toray Ind Inc | 糸条の綾振り装置および糸条パッケージの製造方法 |

| JP3365975B2 (ja) * | 1999-05-28 | 2003-01-14 | 東レエンジニアリング株式会社 | 糸条巻取り方法 |

| EP1126058A3 (de) * | 2000-02-17 | 2002-11-27 | Schärer Schweiter Mettler AG | Vorrichtung zum Antreiben rotierbarer Organe einer OE-Spinnmaschine |

| DE10158975A1 (de) * | 2000-12-07 | 2002-06-13 | Barmag Barmer Maschf | Verfahren zum Aufwickeln eines Fadens zu einer Kreuzspule |

| JP4470338B2 (ja) * | 2001-03-22 | 2010-06-02 | 東レ株式会社 | 糸条巻取機のトラバース制御方法 |

| JP4395828B2 (ja) * | 2001-09-10 | 2010-01-13 | 村田機械株式会社 | 張力検出器を備える糸条巻取機 |

| EP1318097B1 (de) * | 2001-12-05 | 2010-02-24 | SSM Schärer Schweiter Mettler AG | Verfahren und Vorrichtung zur Regelung der Fadenspannung auf einer Textilmaschine sowie Anwendung des Verfahrens |

| JP4470487B2 (ja) * | 2003-01-09 | 2010-06-02 | 東レ株式会社 | 糸条トラバース装置および糸条巻き取り装置ならびに糸条パッケージの製造方法 |

| EP1520825B1 (de) * | 2003-10-04 | 2006-11-15 | Schärer Schweiter Mettler AG | Verfahren und Vorrichtung zur Regelung der Fadenspannung auf einer Spulmaschine, sowie Anwendung des Verfahrens |

| JP4523053B2 (ja) * | 2008-07-18 | 2010-08-11 | Tmtマシナリー株式会社 | 糸条巻取機 |

-

2010

- 2010-12-14 JP JP2010277848A patent/JP5730557B2/ja active Active

-

2011

- 2011-11-17 EP EP11189514.0A patent/EP2465802B1/de active Active

- 2011-11-18 KR KR1020110120705A patent/KR101518978B1/ko active Active

- 2011-12-01 CN CN201110392496.8A patent/CN102530640B/zh active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS543985B1 (de) | 1970-07-24 | 1979-02-28 | ||

| JPH05238645A (ja) | 1992-02-28 | 1993-09-17 | Murata Mach Ltd | 糸条巻取方法および糸条巻取機 |

| JP2010163275A (ja) | 2009-01-19 | 2010-07-29 | Tmt Machinery Inc | 糸条巻取装置、この糸条巻取装置を用いた紡糸巻取機、糸条巻取方法、この糸条巻取方法を採用した紡糸巻取方法、及び、テーパエンドパッケージ |

| JP2010189127A (ja) | 2009-02-18 | 2010-09-02 | Tmt Machinery Inc | 糸条巻取機、及び糸条巻取方法 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023186549A1 (de) * | 2022-04-01 | 2023-10-05 | Oerlikon Textile Gmbh & Co. Kg | Aufwickelvorrichtung zum aufwickeln eines spinnfadens und verfahren zum aufwickeln eines spinnfadens |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2012126484A (ja) | 2012-07-05 |

| EP2465802B1 (de) | 2014-10-15 |

| EP2465802A3 (de) | 2013-08-21 |

| KR20120066582A (ko) | 2012-06-22 |

| JP5730557B2 (ja) | 2015-06-10 |

| CN102530640B (zh) | 2016-02-24 |

| CN102530640A (zh) | 2012-07-04 |

| KR101518978B1 (ko) | 2015-05-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2465802B1 (de) | Garnwicklungsvorrichtung | |

| EP2548830B1 (de) | Spinnaufwickler | |

| US9315358B2 (en) | Spun yarn winding device and spun yarn winding facility | |

| EP2221265B1 (de) | Garnwickelmaschine und Garnwickelverfahren | |

| MXPA06001926A (es) | Dispositivo devanador de bobinas. | |

| EP3865441B1 (de) | Garnwicklungsmaschine | |

| KR100745498B1 (ko) | 탄성사용 권취시스템, 탄성사용 권취기 및 탄성사의권취방법 | |

| EP3363756B1 (de) | Garnwickler | |

| JP6436751B2 (ja) | 糸条巻取装置 | |

| EP3865442B1 (de) | Garnwickler und paketherstellungsverfahren | |

| KR101675813B1 (ko) | 보조 가이드를 이용한 권폭조정장치 | |

| EP4424623A1 (de) | Garnwickelmaschine | |

| JP7733594B2 (ja) | 糸巻取機 | |

| JP7130365B2 (ja) | クロス捲きパッケージを生産する繊維機械のワークステーションにおける綾振り三角形領域に配置された機械式糸貯留装置用糸ガイドプーリー | |

| JPS62275977A (ja) | タ−レツト型巻き取り機 | |

| EP3118148B1 (de) | Garnwickelvorrichtung | |

| JP2000095440A (ja) | 糸条の切替方法および装置 | |

| US3796383A (en) | Reciprocating yarn guide | |

| JPH10273268A (ja) | ターレット式糸条巻取機の糸切替え方法 | |

| JP2024038600A (ja) | 糸巻取機 | |

| JP2023143807A (ja) | 糸巻取機 | |

| JP2023135874A (ja) | 糸巻取機 | |

| HK1061007A1 (en) | Winder for elastomeric fibers | |

| HK1061007B (en) | Winder for elastomeric fibers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B65H 54/38 20060101ALI20130716BHEP Ipc: B65H 67/048 20060101AFI20130716BHEP |

|

| 17P | Request for examination filed |

Effective date: 20131227 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20140527 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 691550 Country of ref document: AT Kind code of ref document: T Effective date: 20141115 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602011010580 Country of ref document: DE Effective date: 20141127 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20141015 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 691550 Country of ref document: AT Kind code of ref document: T Effective date: 20141015 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150115 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150216 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150215 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150116 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602011010580 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141130 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141130 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20150731 |

|

| 26N | No opposition filed |

Effective date: 20150716 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141215 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20151117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141117 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20111117 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141015 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230426 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20251124 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20251120 Year of fee payment: 15 |