EP2455544A2 - Machine de fraisage de sol ou de revêtement routier et procédé de fraisage de sols ou de revêtement routier - Google Patents

Machine de fraisage de sol ou de revêtement routier et procédé de fraisage de sols ou de revêtement routier Download PDFInfo

- Publication number

- EP2455544A2 EP2455544A2 EP20110189602 EP11189602A EP2455544A2 EP 2455544 A2 EP2455544 A2 EP 2455544A2 EP 20110189602 EP20110189602 EP 20110189602 EP 11189602 A EP11189602 A EP 11189602A EP 2455544 A2 EP2455544 A2 EP 2455544A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- milling

- milling device

- travel

- hood

- machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000003801 milling Methods 0.000 title claims abstract description 157

- 239000002689 soil Substances 0.000 title claims abstract description 46

- 238000000034 method Methods 0.000 title claims abstract description 14

- 230000002441 reversible effect Effects 0.000 claims abstract description 16

- 238000002156 mixing Methods 0.000 claims abstract description 13

- 239000000203 mixture Substances 0.000 claims description 22

- 238000003971 tillage Methods 0.000 claims description 21

- 239000000463 material Substances 0.000 claims description 16

- 238000009825 accumulation Methods 0.000 claims description 7

- 230000001360 synchronised effect Effects 0.000 claims description 4

- 230000000630 rising effect Effects 0.000 claims description 3

- 238000003754 machining Methods 0.000 claims description 2

- 230000003247 decreasing effect Effects 0.000 claims 1

- 230000035508 accumulation Effects 0.000 description 6

- 230000033001 locomotion Effects 0.000 description 6

- 230000006870 function Effects 0.000 description 3

- 239000011230 binding agent Substances 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 238000005056 compaction Methods 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000011049 filling Methods 0.000 description 2

- 230000013011 mating Effects 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 239000003381 stabilizer Substances 0.000 description 2

- 239000000725 suspension Substances 0.000 description 2

- 239000010426 asphalt Substances 0.000 description 1

- 238000009412 basement excavation Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000007730 finishing process Methods 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 238000010298 pulverizing process Methods 0.000 description 1

- 238000004064 recycling Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01C—CONSTRUCTION OF, OR SURFACES FOR, ROADS, SPORTS GROUNDS, OR THE LIKE; MACHINES OR AUXILIARY TOOLS FOR CONSTRUCTION OR REPAIR

- E01C21/00—Apparatus or processes for surface soil stabilisation for road building or like purposes, e.g. mixing local aggregate with binder

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01C—CONSTRUCTION OF, OR SURFACES FOR, ROADS, SPORTS GROUNDS, OR THE LIKE; MACHINES OR AUXILIARY TOOLS FOR CONSTRUCTION OR REPAIR

- E01C23/00—Auxiliary devices or arrangements for constructing, repairing, reconditioning, or taking-up road or like surfaces

- E01C23/06—Devices or arrangements for working the finished surface; Devices for repairing or reconditioning the surface of damaged paving; Recycling in place or on the road

- E01C23/065—Recycling in place or on the road, i.e. hot or cold reprocessing of paving in situ or on the traffic surface, with or without adding virgin material or lifting of salvaged material; Repairs or resurfacing involving at least partial reprocessing of the existing paving

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01C—CONSTRUCTION OF, OR SURFACES FOR, ROADS, SPORTS GROUNDS, OR THE LIKE; MACHINES OR AUXILIARY TOOLS FOR CONSTRUCTION OR REPAIR

- E01C23/00—Auxiliary devices or arrangements for constructing, repairing, reconditioning, or taking-up road or like surfaces

- E01C23/06—Devices or arrangements for working the finished surface; Devices for repairing or reconditioning the surface of damaged paving; Recycling in place or on the road

- E01C23/08—Devices or arrangements for working the finished surface; Devices for repairing or reconditioning the surface of damaged paving; Recycling in place or on the road for roughening or patterning; for removing the surface down to a predetermined depth high spots or material bonded to the surface, e.g. markings; for maintaining earth roads, clay courts or like surfaces by means of surface working tools, e.g. scarifiers, levelling blades

- E01C23/085—Devices or arrangements for working the finished surface; Devices for repairing or reconditioning the surface of damaged paving; Recycling in place or on the road for roughening or patterning; for removing the surface down to a predetermined depth high spots or material bonded to the surface, e.g. markings; for maintaining earth roads, clay courts or like surfaces by means of surface working tools, e.g. scarifiers, levelling blades using power-driven tools, e.g. vibratory tools

- E01C23/088—Rotary tools, e.g. milling drums

Definitions

- the invention relates to a soil cultivation machine for milling soil or traffic surfaces according to the preamble of claim 1 or a method for milling soil or traffic areas with a soil cultivation machine according to the preamble of claim 10.

- Such construction machines are used for material processing, namely, for example, the stabilization of unsuitable soils, the pulverization of asphalt floors, or the recycling of bound or unbound road surfaces.

- a powdery binder into the soil in order to increase its ability to be installed and its carrying capacity.

- the known tillage machines have a rotating in a mixing chamber milling drum, which is arranged vertically adjustable under the milling drum enclosing, fixed to the machine frame hood.

- the tillage machine can be self-propelled. Examples of such machines are in the WO 96/24725 , of the WO 2005/054578 or the EP 2218823 A described.

- the necessary processes take place, adapted to the respective application, such as e.g. Removal and crushing of the milled roadway material, addition of binders, mixing and distribution of added materials, etc.

- Such machines are often equipped with a closed control station.

- the control station is preferably arranged forward in the direction of travel, in newer machines even on or in front of the front axle. Due to the position of the control station an observation of the milling device from the driver's station is not possible, especially because the hood completely surrounds the milling device and rests on the ground surface.

- the mix is swirled around in the mixing chamber, so that when stopping the milling drum each settles a larger amount of mix before and behind the milling drum.

- a recess approximately 40% deep of the milling drum diameter remains at the location where the milling drum was located and over the entire length of the milling drum , according to the working width of the tillage machine extends.

- the invention is therefore an object of the invention to provide a soil tillage machine for milling of soils, as well as a method for milling of soils in which at the end of the milling process, the processed soil surface can be left in a substantially flat state.

- the invention advantageously provides that a control for terminating the milling operation controls the milling depth of the milling device with simultaneous coordinated forward or reverse travel along a predetermined trajectory, whereby the milling device can be moved out into the out-of-ground upper position, without any of the Retracting the milling device resulting recess in the processed soil surface remains.

- the lifting movement for reducing the cutting depth is controlled synchronized with the driving movement that the mixed material volume located in the direction of travel before the milling device is pushed by the hood into the recess, wherein together with the supplied by the rotary movement of the milling device from the mixing chamber Mischgutvolumen the depression in the is gradually completely filled by the lifting movement of the milling device gradually released space.

- the recess which is released when the milling device is moved out should be filled with the mixture. It is understandable that an absolute flatness is not achievable, but the well is filled with mix so that no significant bumps remain.

- the driver Upon completion of the milling operation, the driver issues a signal to the controller, which then controls the milling depth of the milling device while simultaneously advancing or reversing the tillage machine along a predetermined trajectory to complete the milling operation.

- the trajectory can be stored, for example, in the controller and coordinates the retraction of the milling device while driving the soil tillage machine in such a way that the milling device can be moved into the upper position out of the ground engaging while at the same time when moving out the milling device freed depression is closed in the processed soil surface.

- the height adjustment of the milling device takes place simultaneously with forward or reverse travel, such that the Mischgutanophenouracil located in front and behind the milling in the direction of travel are successively conveyed into the increasingly released by the retraction of the milling depression.

- the predetermined by the controller trajectory when lifting the milling device can be determined empirically and possibly deposited for different soil conditions in the controller in a memory. Therefore, the controller according to the invention causes the vehicle driver does not have to worry about retracting the milling device, but only tells the controller when the milling is to be stopped, so that the driver can focus solely on driving and steering the tillage machine.

- the operation of the soil tillage machine is facilitated for the driver, because it can focus on the driving and a possible position change of the machine, without having to coordinate the excavation of the milling device at the same time.

- the control along the trajectory means that e.g. the axis of rotation of the milling device or, alternatively, the deepest point of engagement of the milling device when lifting such a trajectory follows.

- control controls the milling depth of the milling device along a predetermined trajectory depending on the direction of travel of the machine frame trajectory.

- the controller synchronizes the path of the height adjustment of the milling device with the path in the direction of travel.

- Such a control has the advantage that it is independent of the driving speed and ensures that the trajectory for the height adjustment of the milling device is maintained at each driving speed.

- control for terminating the milling operation additionally controls the position of at least one hood flap.

- the amount of mixed material can be controlled, which is subtracted to close the released by moving out of the milling device recess.

- the flap position of the trailing flap in the direction of travel hood flap can be controlled to a height that takes into account the increase in volume of the mix due to its loosening during milling.

- the milling of the soil causes a loosening, which leads to an increase in volume of the mixed material, so that the trailing hood flap, which acts as a scraper, can not be moved to the original height of the soil surface, but preferably with a distance from the ground, the Volume increase of the mix taken into account.

- control can, as already stated, depending on the nature of the ground hold different trajectories for selection by the driver, which also contain material-dependent control values for the position of the hood flaps whose lower edge determines the wiping height above the ground.

- the predetermined trajectory of the control to terminate the milling and the successive reduction of the milling depth can be degressive rising.

- the predetermined trajectory of the control for terminating the milling operation essentially has the course of an asymptotic function, in particular an arctan function.

- the tillage machine may be provided with a height-adjustable machine frame. It can additionally be provided that the controller additionally raises the machine frame after completion of the finishing process of the milling, so that the tillage machine receives more ground clearance and can be easily moved to another processing point.

- the machinist reverses the direction of travel of the machine frame to complete the milling operation.

- the controller registers the selected direction of travel and controls the correct, depending on the direction of travel. the rear in the direction of travel or the trailing hood flap.

- the now in the direction of travel rear hood flap is used as a scraper whose Abstreifiere is adjustable by the controller.

- the invention also relates to a method for milling soil with a soil cultivation machine having the features of claim 10.

- the method according to the invention provides i.a. Also, to close the remaining with moving out of the milling device depression with mixed material on the one hand from the direction in the rear hood flap smeared mix and on the other hand of the moved along along the predetermined by the control trajectory milling device removed and conveyed into the recess mix is used.

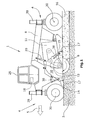

- Fig. 1 shows the tillage machine 1 for milling floors and roads with a supported by trolleys 4 machine frame 6 and consisting of a cab 26 control station.

- the driver's cab 26 is displaceable on the machine frame transversely to the direction of travel.

- the seat in the control station can be turned 180 ° for reversing.

- Fig. 1 apparent tillage machine 1 is from the WO 96/24725 known.

- the technical solutions described in the context of this application are also applicable to stabilizers or recyclers, as for example from the WO 2005/054578 or the EP 2218823 A are known.

- the trolleys 4 have at the front and rear end of the machine frame 6 two common or optionally individually steerable suspension axles 30.

- Each wheel of the chassis 4 is provided with a lifting column 28, so that the height of the machine frame 6 and possibly its inclination is exactly adjustable to working or transport height.

- hood 10 which surrounds the milling device 8, in particular a milling drum, and forms a mixing chamber 12 for the processed mix 16 between the milling device 8 and hood 10 ,

- the milling device 8 can be lowered by means of a height adjustment device 20 to a set milling depth or be moved out of the processed soil 2 after completion of the milling.

- the hood 10 may be fixedly attached to the machine frame 6 and has at its front and rear in the direction of travel 5 via actuators 36,38 pivotable hood flaps 14,15, which complete the mixing chamber 12 of the hood 10 against the bottom surface 3 of the bottom 2 as needed ,

- the hood may be suspended from chains on the machine frame, i. In operation, the hood 10 slides on the chains hanging over the ground. If you drive the milling drum to zero milling depth, then the hood 10 is still on the bottom surface 3. If you drive the milling drum even higher, then it takes the hood 10 and thus lifts the hood 10 from the ground.

- the pivotable hood flaps 14, 15 may be additionally provided, for sealing and sealing with respect to the floor surface 3, by a flexible strip 17, e.g. a rubber lip, be provided.

- the milling drum 8 is mounted in a pivoting device 11 which is pivotally mounted on the machine frame 6, wherein the Fräswalzenachse 32 and the output axis of the Fräswalzenantriebs can be pivoted in a slot 19 in the side walls of the hood 10 to allow the routing depth adjustment.

- the height adjustment of the milling device 8 can also be done in other ways, eg as in the WO 2005/054578 described.

- the milling drum drive is preferably a mechanical drive, e.g. is driven by a combustion engine via a belt transmission.

- Fig. 2 schematically shows the situation when counter-milling in forward drive 5.

- mix 16 is formed both before and behind the milling drum 8 a accumulation of material 19,21 of mix 16. Since the mix 16 against the Floor 2 is loosened, have the Mischgutophenouracil 19,21 before and behind the milling device 8 slightly more volume than the recess 22 in which the milling device 8 operates during milling.

- How out Fig. 2 can be raised when driving forward 5, the front hood flap 14 and the rear hood in the direction of travel 15 be lowered to strip the recycled mix 16 at a preset height.

- the soil working machine 1 has a control 18, which automatically controls the cutting depth of the milling device 8 with simultaneous forward or reverse travel 5,7 to complete the milling.

- the driver only has to give an appropriate command to the controller 18, so that the controller 18 can control the height adjustment device 20 to finish the milling.

- the control takes place along a predetermined trajectory 24, which may be stored in the controller 18, so that the Milling device 8 in the out-of-ground upper position 9 in Fig. 3 can be moved out without a resulting from the retraction of the milling device 8 recess 22 remains in the processed soil surface 3.

- the trajectory 24 is in Fig. 3 as a connecting line of the positions of the axis of rotation 32 of the milling device designed as a milling 8 is shown.

- the controller 18 can also control the position of the hood flaps 14,15 in addition to the milling depth.

- Fig. 3 shows a degressively rising curve for the trajectory 24th Fig. 3 shows the situation in which the tillage machine 1 in forward drive 5 in the in Fig. 2 has been shown and then issued a command to stop the milling to the controller 18.

- the milling device 9 then makes the in Fig. 3 apparent movement corresponding to the trajectory 24 in reverse 7, the then trailing hood flap 14 is used as stripping, the Abstreifschreib is set by the controller 18, so that the rear now in the direction of travel hood flap 14 Mischgutanphaseufitch 19 pushes into the recess 22.

- the front hood flap 15 in the direction of travel is, as already in Fig. 2 shown raised to the dashed position, so that it does not form a new accumulation in reverse 7, but it allows the milling drum milled off this accumulation 21 during the reverse drive 7 and thus spends in the recess 22.

- the trajectory 24 may also be in the form of an asymptote, e.g. in the form of an arctan function, however, the shape of the trajectory 24 is not limited thereto.

- the controller 18 synchronizes the path of the height adjustment via the height adjustment device 20 with the path in the direction of travel (forward drive 5 or reverse drive 7).

- the trajectories 24 for filling the recess 22 in the case of synchronous milling or when moving out in forward travel 5 run differently than in Fig. 3 shown. If the milling device 8, the recess 22 in forward motion leaves, then the rear flap in the direction of travel 15 assumes the predetermined by the controller 18 Abstreiffunktion, as in Fig. 4 shown.

- the path that is required to fill the recess 22 is about 1 to 3 diameter of the milling drum.

- Different trajectories 24 may be stored in the controller 18 for different ground materials and for retracting forward or reverse travel.

- each trailing hood flap 14,15 can be adjusted by the controller 18 via actuators 36,38 to a level that takes into account the increase in volume of the mix 16 due to its loosening during milling.

- These control values can also be stored in the controller 18 in a material-specific manner together with the trajectory 24.

- the recess 22 is filled with mix 16 with the same degree of loosening, as it has arisen during the entire milling of a milling track.

- the milling can be completed without leaving depressions 22 and mixed material accumulations 19, 21 and without leaving any differences in the degree of loosening in the machined surface.

- This is essential for the subsequent processing of the soil surface 3 with compaction machines, as well as for the later road surface application machines that apply a road or road surface on the compacted soil surface 3. Namely, if there are significant density differences in the recycled mix 16, these will be e.g. possibly even enhanced by the subsequent compaction machines, so that a subsequently applied road surface has unevenness at the corresponding points.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Mining & Mineral Resources (AREA)

- Mechanical Engineering (AREA)

- Road Repair (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102010051551A DE102010051551A1 (de) | 2010-11-18 | 2010-11-18 | Bodenbearbeitungsmaschine sowie Verfahren zum Fräsen von Böden oder Verkehrsflächen |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2455544A2 true EP2455544A2 (fr) | 2012-05-23 |

| EP2455544A3 EP2455544A3 (fr) | 2014-06-18 |

| EP2455544B1 EP2455544B1 (fr) | 2016-06-08 |

Family

ID=45318818

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP11189602.3A Active EP2455544B1 (fr) | 2010-11-18 | 2011-11-17 | Machine de fraisage de sol ou de revêtement routier et procédé de fraisage de sols ou de revêtement routier |

Country Status (5)

| Country | Link |

|---|---|

| US (2) | US8485755B2 (fr) |

| EP (1) | EP2455544B1 (fr) |

| CN (2) | CN202347408U (fr) |

| AU (1) | AU2011250734B2 (fr) |

| DE (1) | DE102010051551A1 (fr) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103437269A (zh) * | 2013-08-29 | 2013-12-11 | 徐州徐工筑路机械有限公司 | 一种冷再生机转子运动机构 |

| EP2840183A1 (fr) * | 2013-08-23 | 2015-02-25 | Wirtgen GmbH | Engin autopropulsé et procédé de fonctionnement d'un engin automoteur |

| EP2977514A1 (fr) | 2014-07-23 | 2016-01-27 | Wirtgen GmbH | Machine de travail du sol et procede de fraisage de sols ou de voies de circulation |

| US10294086B2 (en) | 2016-04-06 | 2019-05-21 | Oshkosh Corporation | Dual actuator assembly |

| US11767645B2 (en) | 2021-04-01 | 2023-09-26 | Wirtgen Gmbh | Self-propelled construction machine and method for operating a self-propelled construction machine |

Families Citing this family (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102010051551A1 (de) * | 2010-11-18 | 2012-05-24 | Wirtgen Gmbh | Bodenbearbeitungsmaschine sowie Verfahren zum Fräsen von Böden oder Verkehrsflächen |

| DE102012012395A1 (de) * | 2012-06-25 | 2014-01-02 | Wirtgen Gmbh | Straßenfräsmaschine |

| DE102012016173A1 (de) * | 2012-08-16 | 2014-02-20 | Wirtgen Gmbh | Selbstfahrende Baumaschine und Verfahren zum Betreiben einer Baumaschine |

| DE102012215013A1 (de) | 2012-08-23 | 2014-02-27 | Wirtgen Gmbh | Selbstfahrende Fräsmaschine, sowie Verfahren zum Abladen von Fräsgut |

| DE102013208645B4 (de) * | 2013-05-10 | 2018-01-11 | Wirtgen Gmbh | Vorrichtung, insbesondere Kleinfräse, zum Bearbeiten von Straßenoberflächen |

| CN103437268B (zh) * | 2013-08-29 | 2016-04-27 | 徐州徐工筑路机械有限公司 | 一种路面冷再生机转子机构 |

| DE102013016515A1 (de) * | 2013-10-07 | 2015-04-09 | Wirtgen Gmbh | Vorrichtung sowie Verfahren zum Bearbeiten von Böden oder Fahrbahnen |

| US9103079B2 (en) * | 2013-10-25 | 2015-08-11 | Caterpillar Paving Products Inc. | Ground characteristic milling machine control |

| DE102015002426A1 (de) * | 2014-12-30 | 2016-06-30 | Bomag Gmbh | Bodenfräsmaschine und Verfahren zum Verstellen des Abstreiferschildes einer Bodenfräsmaschine |

| US20160326701A1 (en) * | 2015-05-07 | 2016-11-10 | Caterpillar Paving Products Inc. | Rotary Mixer with Automated Control Functions |

| DE102015014573B4 (de) | 2015-11-12 | 2020-03-19 | Wirtgen Gmbh | Selbstfahrende Bodenfräsmaschine und Verfahren zum Bearbeiten einer Verkehrsfläche |

| US9797100B1 (en) | 2016-05-23 | 2017-10-24 | Caterpillar Paving Products Inc. | Milling machine |

| CA3044842A1 (fr) * | 2016-11-23 | 2018-05-31 | Garlon J. Maxwell | Tambour de lissage a nivellement de precision pour le lissage de surfaces de revetement |

| US10151071B1 (en) * | 2017-06-13 | 2018-12-11 | Caterpillar Paving Products Inc. | Anti-slab height control system for a cold planer |

| DE102019104218A1 (de) | 2019-02-19 | 2020-08-20 | Wirtgen Gmbh | Arbeitszug, umfassend eine Bodenbearbeitungsmaschine und ein weiteres Fahrzeug sowie eine automatisierte Abstandsüberwachung |

| DE102019135867A1 (de) | 2019-12-30 | 2021-07-01 | Wirtgen Gmbh | Abtragendes Bodenbearbeitungsverfahren mit bezüglich der Vortriebsrichtung schräg angestelltem abtragendem Werkzeug und zur Ausführung des Verfahrens ausgebildete Bodenbearbeitungsmaschine |

| US11136732B2 (en) * | 2020-01-28 | 2021-10-05 | Caterpillar Paving Products Inc. | Milling machine having pivot arms offset from engine output shaft |

| US11203841B2 (en) | 2020-04-01 | 2021-12-21 | Caterpillar Paving Products Inc. | Machine, system, and method for automated milling exit cut operation |

| DE102020120243B4 (de) * | 2020-07-31 | 2022-02-17 | Wirtgen Gmbh | Baumaschine |

| CN112663462B (zh) * | 2020-12-22 | 2022-06-10 | 广西北部湾投资集团有限公司沿海高速公路分公司 | 一种基于精铣刨打磨的旧路面处理装置及施工方法 |

| US20230050075A1 (en) | 2021-08-04 | 2023-02-16 | Midwest Industrial Supply, Inc. | Method and composition for constructing scientifically engineered and constructed unpaved runways |

| DE102021134623A1 (de) * | 2021-12-23 | 2023-06-29 | Wirtgen Gmbh | Baumaschine |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3865195A (en) | 1972-07-05 | 1975-02-11 | Koehring Co | Self-propelled soil stabilizer machine |

| WO1996024725A1 (fr) | 1995-02-12 | 1996-08-15 | Wirtgen Gmbh | Engin pour travaux routiers |

| JP2003301410A (ja) | 2002-04-10 | 2003-10-24 | Komatsu Ltd | 地盤改良機 |

| WO2005054578A1 (fr) | 2003-12-04 | 2005-06-16 | Wirtgen Gmbh | Machine automotrice servant a realiser des voies de circulation |

| DE102006024123A1 (de) | 2006-05-22 | 2007-11-29 | Wirtgen Gmbh | Selbstfahrende Baumaschine, sowie Verfahren zum Bearbeiten von Bodenoberflächen |

| DE202008016935U1 (de) | 2008-12-23 | 2010-06-10 | Wirtgen Gmbh | Baumaschine, insbesondere Stabilisierer oder Recycler |

| EP2218823A2 (fr) | 2009-02-14 | 2010-08-18 | Wirtgen GmbH | Stabilisateur ou recycleur |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3921875A1 (de) * | 1989-07-04 | 1991-01-17 | Bomag Gmbh | Bodenverfestigungsgeraet |

| DE10241067B3 (de) * | 2002-09-05 | 2004-04-22 | Wirtgen Gmbh | Vorrichtung zum Bearbeiten von Böden oder Fahrbahnen |

| CN1209530C (zh) * | 2003-05-16 | 2005-07-06 | 长沙中联重工科技发展股份有限公司 | 可实现铣刨机排料速度自适应控制的方法及装置 |

| CN100465387C (zh) | 2003-12-01 | 2009-03-04 | 日本植生株式会社 | 砂浆或混凝土喷涂装置及使用该装置的砂浆或混凝土喷涂方法 |

| WO2008077963A1 (fr) * | 2006-12-22 | 2008-07-03 | Wirtgen Gmbh | Fraiseuse routière et procédé permettant d'obtenir le parallélisme du bâti de machine par rapport au sol |

| US7585128B2 (en) * | 2007-02-13 | 2009-09-08 | Hall David R | Method for adding foaming agents to pavement aggregate |

| DE102007038677B4 (de) * | 2007-08-15 | 2009-09-17 | Wirtgen Gmbh | Abstreifeinrichtung, sowie Baumaschine |

| US8177456B2 (en) * | 2007-12-21 | 2012-05-15 | Asphalt Zipper, Inc. | Pavement milling assembly |

| CN201280682Y (zh) * | 2008-10-20 | 2009-07-29 | 三一重工股份有限公司 | 一种具有积料清除装置的铣刨机 |

| DE102010051551A1 (de) * | 2010-11-18 | 2012-05-24 | Wirtgen Gmbh | Bodenbearbeitungsmaschine sowie Verfahren zum Fräsen von Böden oder Verkehrsflächen |

-

2010

- 2010-11-18 DE DE102010051551A patent/DE102010051551A1/de not_active Ceased

-

2011

- 2011-11-11 AU AU2011250734A patent/AU2011250734B2/en active Active

- 2011-11-17 EP EP11189602.3A patent/EP2455544B1/fr active Active

- 2011-11-17 US US13/298,377 patent/US8485755B2/en active Active

- 2011-11-18 CN CN201120462891.4U patent/CN202347408U/zh not_active Withdrawn - After Issue

- 2011-11-18 CN CN201110369936.8A patent/CN102465486B/zh active Active

-

2013

- 2013-06-12 US US13/915,844 patent/US8764341B2/en active Active

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3865195A (en) | 1972-07-05 | 1975-02-11 | Koehring Co | Self-propelled soil stabilizer machine |

| WO1996024725A1 (fr) | 1995-02-12 | 1996-08-15 | Wirtgen Gmbh | Engin pour travaux routiers |

| DE19504495A1 (de) | 1995-02-12 | 1996-08-22 | Wirtgen Gmbh | Maschine zur Erneuerung von Fahrbahnen |

| JP2003301410A (ja) | 2002-04-10 | 2003-10-24 | Komatsu Ltd | 地盤改良機 |

| WO2005054578A1 (fr) | 2003-12-04 | 2005-06-16 | Wirtgen Gmbh | Machine automotrice servant a realiser des voies de circulation |

| DE102006024123A1 (de) | 2006-05-22 | 2007-11-29 | Wirtgen Gmbh | Selbstfahrende Baumaschine, sowie Verfahren zum Bearbeiten von Bodenoberflächen |

| DE202008016935U1 (de) | 2008-12-23 | 2010-06-10 | Wirtgen Gmbh | Baumaschine, insbesondere Stabilisierer oder Recycler |

| EP2218823A2 (fr) | 2009-02-14 | 2010-08-18 | Wirtgen GmbH | Stabilisateur ou recycleur |

Non-Patent Citations (4)

| Title |

|---|

| "CAT BODENSTABILISIERER", ZEPPELIN CAT, April 2008 (2008-04-01), XP003035235, Retrieved from the Internet <URL:HTTPS://WEB.ARCHIVE.ORG/WEB/20080404020648/HTTP://WWW.ZEPPELIN-CAT.AT/CAT_BODENSTABILISIERER> |

| CATERPILLAR: "RM-500 BODENSTABILISIERER", CAT BROCHURE, April 2006 (2006-04-01), pages 1 - 15, XP003035234 |

| F.J. STETTER BODENVERBESSERUNG: "ZU VERKAUFEN CAT BODENSTABILISIERER RM 500", STETTERSERVICE PRODUCT SHEET, August 2009 (2009-08-01), XP003035236 |

| FOLEY EQUIPMENT: "CAT RM500 ROAD RECLAIMER", YOUTUBE, 21 April 2014 (2014-04-21), XP054975948, Retrieved from the Internet <URL:HTTPS://WWW.YOUTUBE.COM/WATCH?V=EAQZPD4DGA4> |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2840183A1 (fr) * | 2013-08-23 | 2015-02-25 | Wirtgen GmbH | Engin autopropulsé et procédé de fonctionnement d'un engin automoteur |

| US9322139B2 (en) | 2013-08-23 | 2016-04-26 | Wirtgen Gmbh | Self-propelled construction machine and method for operating a self-propelled construction machine |

| US9644330B2 (en) | 2013-08-23 | 2017-05-09 | Wirtgen Gmbh | Self-propelled construction machine and method for operating a self-propelled construction machine |

| CN103437269A (zh) * | 2013-08-29 | 2013-12-11 | 徐州徐工筑路机械有限公司 | 一种冷再生机转子运动机构 |

| EP2977514A1 (fr) | 2014-07-23 | 2016-01-27 | Wirtgen GmbH | Machine de travail du sol et procede de fraisage de sols ou de voies de circulation |

| DE102014214436A1 (de) | 2014-07-23 | 2016-01-28 | Wirtgen Gmbh | Bodenbearbeitungsmaschine, sowie Verfahren zum Fräsen von Boden- oder Verkehrsflächen |

| US9879392B2 (en) | 2014-07-23 | 2018-01-30 | Wirtgen Gmbh | Ground working machine, as well as method for milling ground surfaces or traffic surfaces |

| US10494778B2 (en) | 2014-07-23 | 2019-12-03 | Wirtgen Gmbh | Ground working machine, as well as method for milling ground surfaces or traffic surfaces |

| US10294086B2 (en) | 2016-04-06 | 2019-05-21 | Oshkosh Corporation | Dual actuator assembly |

| US11767645B2 (en) | 2021-04-01 | 2023-09-26 | Wirtgen Gmbh | Self-propelled construction machine and method for operating a self-propelled construction machine |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2455544B1 (fr) | 2016-06-08 |

| CN102465486B (zh) | 2014-07-02 |

| AU2011250734A1 (en) | 2012-06-07 |

| US8485755B2 (en) | 2013-07-16 |

| AU2011250734B2 (en) | 2013-05-02 |

| CN102465486A (zh) | 2012-05-23 |

| EP2455544A3 (fr) | 2014-06-18 |

| US8764341B2 (en) | 2014-07-01 |

| DE102010051551A1 (de) | 2012-05-24 |

| US20130309009A1 (en) | 2013-11-21 |

| US20120128419A1 (en) | 2012-05-24 |

| CN202347408U (zh) | 2012-07-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2455544B1 (fr) | Machine de fraisage de sol ou de revêtement routier et procédé de fraisage de sols ou de revêtement routier | |

| EP2886717B1 (fr) | Machine de post-traitement et procédé destiné au post-traitement d'une couche de béton fraîchement réalisée | |

| EP2735650B2 (fr) | Procédé de traitement de couches, un engin de construction et un engin auxiliaire de construction | |

| EP2953844A1 (fr) | Véhicule | |

| DE112016000713B4 (de) | Auto-Kalibrierung eines automatischen Nivelliersteuersystems in einer Arbeitsmaschine | |

| DE6905815U (de) | Vorrichtung zum abtragen verschlissener strassendecken. | |

| DE2856635C2 (de) | Maschine zum Beschichten von abgefrästen oder abgeschälten Straßendecken | |

| DE2330548A1 (de) | Vorrichtung, die waehrend ihrer vorwaertsbewegung ein band aus einem formbaren plastischen gemisch legt | |

| WO2008098383A1 (fr) | Engin de terrassement | |

| DE202008016935U1 (de) | Baumaschine, insbesondere Stabilisierer oder Recycler | |

| DE102018006688A1 (de) | Bodenfräsmaschine und Verfahren zum Betrieb einer Bodenfräsmaschine | |

| DE102012024769A1 (de) | Baumaschine zum Einmischen wenigstens eines schüttgutartigen Zuschlagstoffs in den Bodenuntergrund, insbesondere Bodenstabilisierer und/oder Recycler | |

| EP3301223B1 (fr) | Dispositif d'assainissement et de profilage de revêtements routiers endommagés liés à l'eau | |

| EP4108831A1 (fr) | Procédé de commande d'un engin de fraisage de chaussée et engin de fraisage de chaussée | |

| EP1073798B1 (fr) | Dispositif de traitement de chaussees | |

| DE102021212736A1 (de) | Verfahren zum betrieb einer selbstfahrenden bodenfräsmaschine sowie bodenfräsmaschine mit einer steuereinrichtung | |

| DE3031688A1 (de) | Verfahren und vorrichtung zum formgiessen insbesondere von beton | |

| EP2568079B1 (fr) | Dispositif d'asphaltage à froid | |

| DE2248577C2 (de) | Gerät zum Bearbeiten der unteren Tragschicht für eine Fahrbahn | |

| DE20000148U1 (de) | Fertiger im Containermaß | |

| DE8315139U1 (de) | Fraesmaschine | |

| DE1658563A1 (de) | Vorrichtung zum Einfuellen und Einebnen von Schuettgut in an verfestigte Fahrbahnen angrenzenden Laengsstreifen | |

| DE102022128413A1 (de) | Fräsmaschinen, systeme und zugehörige verfahren | |

| EP1799910B1 (fr) | Dispositif pour construire une voie ou similaire | |

| EP2982803B1 (fr) | Engin avec appareil niveleur associé et procédé de nivellement avec cet engin |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E01C 21/00 20060101AFI20140515BHEP Ipc: E01C 23/088 20060101ALI20140515BHEP |

|

| 17P | Request for examination filed |

Effective date: 20141014 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| TPAC | Observations filed by third parties |

Free format text: ORIGINAL CODE: EPIDOSNTIPA |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160111 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 805349 Country of ref document: AT Kind code of ref document: T Effective date: 20160715 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502011009906 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20160608 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160908 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160909 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161008 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161010 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161130 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502011009906 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20170309 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161130 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161130 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161117 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 805349 Country of ref document: AT Kind code of ref document: T Effective date: 20161117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161117 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20161130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20111117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160608 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230525 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20231123 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20231123 Year of fee payment: 13 Ref country code: IT Payment date: 20231130 Year of fee payment: 13 Ref country code: FR Payment date: 20231124 Year of fee payment: 13 Ref country code: DE Payment date: 20231120 Year of fee payment: 13 |