EP2414140B2 - Appareil de découpe de blocs de produits alimentaires en portions de poids identique - Google Patents

Appareil de découpe de blocs de produits alimentaires en portions de poids identique Download PDFInfo

- Publication number

- EP2414140B2 EP2414140B2 EP10714184.8A EP10714184A EP2414140B2 EP 2414140 B2 EP2414140 B2 EP 2414140B2 EP 10714184 A EP10714184 A EP 10714184A EP 2414140 B2 EP2414140 B2 EP 2414140B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- food

- block

- scanner

- slicing

- slicing machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 235000013305 food Nutrition 0.000 title description 260

- 230000005540 biological transmission Effects 0.000 claims description 52

- 238000005520 cutting process Methods 0.000 claims description 22

- 230000032258 transport Effects 0.000 description 38

- 238000001514 detection method Methods 0.000 description 27

- 238000000034 method Methods 0.000 description 14

- 230000005855 radiation Effects 0.000 description 11

- 235000013351 cheese Nutrition 0.000 description 5

- 238000010521 absorption reaction Methods 0.000 description 4

- 238000004458 analytical method Methods 0.000 description 4

- 238000005259 measurement Methods 0.000 description 4

- 230000000875 corresponding effect Effects 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 235000013580 sausages Nutrition 0.000 description 3

- 238000005303 weighing Methods 0.000 description 3

- 239000008280 blood Substances 0.000 description 2

- 210000004369 blood Anatomy 0.000 description 2

- 238000004364 calculation method Methods 0.000 description 2

- 238000011156 evaluation Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000004806 packaging method and process Methods 0.000 description 2

- 238000011144 upstream manufacturing Methods 0.000 description 2

- 208000034656 Contusions Diseases 0.000 description 1

- 241001237745 Salamis Species 0.000 description 1

- 230000002238 attenuated effect Effects 0.000 description 1

- 208000034526 bruise Diseases 0.000 description 1

- 230000002596 correlated effect Effects 0.000 description 1

- 238000011157 data evaluation Methods 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 229930014626 natural product Natural products 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 235000015175 salami Nutrition 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26D—CUTTING; DETAILS COMMON TO MACHINES FOR PERFORATING, PUNCHING, CUTTING-OUT, STAMPING-OUT OR SEVERING

- B26D5/00—Arrangements for operating and controlling machines or devices for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting

- B26D5/20—Arrangements for operating and controlling machines or devices for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting with interrelated action between the cutting member and work feed

- B26D5/30—Arrangements for operating and controlling machines or devices for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting with interrelated action between the cutting member and work feed having the cutting member controlled by scanning a record carrier

- B26D5/32—Arrangements for operating and controlling machines or devices for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting with interrelated action between the cutting member and work feed having the cutting member controlled by scanning a record carrier with the record carrier formed by the work itself

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26D—CUTTING; DETAILS COMMON TO MACHINES FOR PERFORATING, PUNCHING, CUTTING-OUT, STAMPING-OUT OR SEVERING

- B26D1/00—Cutting through work characterised by the nature or movement of the cutting member or particular materials not otherwise provided for; Apparatus or machines therefor; Cutting members therefor

- B26D1/01—Cutting through work characterised by the nature or movement of the cutting member or particular materials not otherwise provided for; Apparatus or machines therefor; Cutting members therefor involving a cutting member which does not travel with the work

- B26D1/12—Cutting through work characterised by the nature or movement of the cutting member or particular materials not otherwise provided for; Apparatus or machines therefor; Cutting members therefor involving a cutting member which does not travel with the work having a cutting member moving about an axis

- B26D1/14—Cutting through work characterised by the nature or movement of the cutting member or particular materials not otherwise provided for; Apparatus or machines therefor; Cutting members therefor involving a cutting member which does not travel with the work having a cutting member moving about an axis with a circular cutting member, e.g. disc cutter

- B26D1/143—Cutting through work characterised by the nature or movement of the cutting member or particular materials not otherwise provided for; Apparatus or machines therefor; Cutting members therefor involving a cutting member which does not travel with the work having a cutting member moving about an axis with a circular cutting member, e.g. disc cutter rotating about a stationary axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26D—CUTTING; DETAILS COMMON TO MACHINES FOR PERFORATING, PUNCHING, CUTTING-OUT, STAMPING-OUT OR SEVERING

- B26D5/00—Arrangements for operating and controlling machines or devices for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting

- B26D5/20—Arrangements for operating and controlling machines or devices for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting with interrelated action between the cutting member and work feed

- B26D5/26—Arrangements for operating and controlling machines or devices for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting with interrelated action between the cutting member and work feed wherein control means on the work feed means renders the cutting member operative

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26D—CUTTING; DETAILS COMMON TO MACHINES FOR PERFORATING, PUNCHING, CUTTING-OUT, STAMPING-OUT OR SEVERING

- B26D7/00—Details of apparatus for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting

- B26D7/06—Arrangements for feeding or delivering work of other than sheet, web, or filamentary form

- B26D7/0625—Arrangements for feeding or delivering work of other than sheet, web, or filamentary form by endless conveyors, e.g. belts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26D—CUTTING; DETAILS COMMON TO MACHINES FOR PERFORATING, PUNCHING, CUTTING-OUT, STAMPING-OUT OR SEVERING

- B26D7/00—Details of apparatus for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting

- B26D7/27—Means for performing other operations combined with cutting

- B26D7/30—Means for performing other operations combined with cutting for weighing cut product

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26D—CUTTING; DETAILS COMMON TO MACHINES FOR PERFORATING, PUNCHING, CUTTING-OUT, STAMPING-OUT OR SEVERING

- B26D2210/00—Machines or methods used for cutting special materials

- B26D2210/02—Machines or methods used for cutting special materials for cutting food products, e.g. food slicers

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T83/00—Cutting

- Y10T83/04—Processes

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T83/00—Cutting

- Y10T83/162—With control means responsive to replaceable or selectable information program

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T83/00—Cutting

- Y10T83/647—With means to convey work relative to tool station

Definitions

- the present invention relates to a slicing machine according to claim 1 for slicing a block of food into portions of exact weight.

- Food bars for example sausage, cheese and/or ham bars, often have to be cut into portions for sale, which consist of at least one, preferably several food slices.

- This cutting is usually done on so-called slicers, in which the respective block of food rests on a support that transports it continuously or intermittently in the direction of a cutting blade that separates food slices from the front end of the block of food.

- the thickness of each slice is preferably determined by the rate of feed in relation to the speed of rotation of the cutting blade.

- the slice(s) cut off is/are transported away in portions, whereby the weight of the packaging must comply with the finished packaging ordinance.

- the packs must be heavier than the specified minimum weight, particularly on average. This additional weight is known to those skilled in the art, for example, as a "give away" and is undesirable or should be kept as minimal as possible because it limits the profitability of food production.

- a generic slicing machine is known from the publication WO 2005/037501 A2 .

- the present invention aims at improved detection and tracking of the position of a block of food which is transported by one of several transport means of a slicing machine in the direction of the cutting knife.

- a food bar is preferably a sausage, cheese or ham bar. These food blocks often have an essentially constant cross-section. As a rule, the food blocks are elongated, like a sausage, i.e. their cross-section is significantly smaller than their length. As a rule, the food slices are cut perpendicular to the longitudinal axis. However, the food bar can also be a natural ham.

- the weight of the entire block of food is determined before it is sliced. This can be done with any scale familiar to a person skilled in the art. However, the determination of the weight within the meaning of the invention is not limited to weighing. If the density is known, the weight can also be determined on the basis of data from the transmission scanner, in which, for example, this delivers data about the external shape of the product. This weight W is transferred to a computer unit that stores the weight value. If the weight of the block of food is known, it can also be transferred directly to the computer unit without being weighed beforehand.

- the block of food is x-rayed slice by slice with a transmission scanner.

- This transmission scanner for example an X-ray scanner, has a radiation source and a photosensitive sensor, for example, which is located on opposite sides of the circumference of the block of food.

- This sensor is a line scan camera, for example.

- the radiation source emits radiation that enters on one side of the circumference of the block of food, penetrates the block of food over its entire width and is received by the sensor on the opposite side.

- This sensor measures the intensity of the received beams, which are attenuated when radiating through the block of food, the attenuation depending on the local condition of the block of food, for example its density. The irradiation takes place over the entire width of the product.

- the transmission scanner is preferred provided in a stationary manner and the block of food is transported through the transmission scanner, preferably along its longitudinal axis.

- the block of food rests, for example, on a conveyor belt that is arranged between the radiation source and the sensor.

- the block of food is irradiated slice by slice, with the slices preferably being arranged perpendicular to the longitudinal central axis of the block of food.

- the desired thickness of such a disk referred to below as “scanning disk” depends on the desired measurement accuracy.

- the thickness of the scan slice is preferably smaller than the food slice to be separated from the block of food.

- the thickness of the scanned slice is preferably ⁇ 1/5, particularly preferably ⁇ 1/10 of the thickness of the food slice actually cut off.

- the thickness of each scan slice is the same.

- the values measured by the sensor are stored in the computer unit, preferably depending on their respective position in the longitudinal direction of the block of food.

- the computer unit can be in the transmission scanner or in a downstream slicer or in another CPU. This storage can take place as individual values.

- a curve is preferably drawn through the measured values and this curve is stored.

- the computer unit therefore preferably knows which measured value was determined at which point along the longitudinal axis of the block of food.

- the respective thickness of the scan slice must also be registered and saved or taken into account when determining the curve.

- the sum P of all values determined by the sensor is formed. If the thickness of the scan slices is not uniform, it can be advantageous if a sum weighted with the slice thickness is formed. The sum is also saved.

- the food block is then transferred to a slicing machine in the same orientation in which it was x-rayed, which cuts it into portions.

- a specific length x N must be cut from the block of food, which corresponds to the desired target weight G of the respective portion, with a portion comprising at least one, preferably several, food slices.

- the cuts of the slicing machine are made essentially parallel to the transmission direction of the transmission scanner and are preferably arranged essentially perpendicular to the longitudinal center axis of the block of food. If this is not the case, a mathematical correction of the respective data set must be made.

- the initial position of the block of food when cutting open preferably corresponds as exactly as possible to the initial position when scanning, so that the longitudinal coordinates stored during scanning match the longitudinal coordinates when cutting open.

- a factor k is preferably first calculated by dividing the weight W of the block of food by the sum P of all measured signals from the scanning disks.

- the product length to be cut off per portion can also be calculated in a computer unit assigned to the slicer or in another CPU which receives data from the through-beam scanner and transmits data to the slicer.

- the computer unit knows which length x N is to be cut off from the block of food for the respective portion. This process is repeated for each portion until the food block is sliced open.

- the respective values are transferred from the computer unit to the slicing machine, which is controlled on the basis of this value.

- the product length to be cut off per portion can also be calculated in a computer unit assigned to the slicer or in another CPU which receives data from the through-beam scanner and transmits data to the slicer.

- the measured values are combined to form a curve.

- a number of integrals are calculated under the curve.

- the desired weight of the respective portion is specified and determined with the integral, which length (x N ) has to be cut off from the food block.

- the entire calculation for all portions of a food block is very particularly preferably carried out before it is sliced open.

- the length (x N ) to be severed from the block of food can be cut into a predetermined number of food slices. This then results in the thickness of the food slices to be separated for the respective portion

- a specific thickness of the food slices is predetermined.

- the computer unit then calculates how many of these food slices are cut off from the food block per portion.

- the scan slices all have the same thickness, it is sufficient to count the number of measured values determined per food block. This sum is then divided by a measured length of the food block and the thickness of a scanning disc is determined.

- the thickness of a scan slice can also be determined in any other manner familiar to a person skilled in the art.

- the transmission scanner preferably has a transport means, preferably a transport belt, with which the block of food is transported along the transmitter and receiver.

- the transmission scanner preferably has a means, preferably a detection means, which detects at least one point at the start of the block of food on the conveyor belt.

- the detection means can be arranged upstream or downstream of the transmission scanner.

- This detection means preferably starts the transmission scanner and/or the recording of the measured values of the transmission scanner.

- the measured values are preferably recorded as a function of the longitudinal axis of the product.

- the conveyor belt has an encoder that transmits the movement of the belt, in particular the path of the belt, to a data acquisition unit and/or the conveyor belt moves at a constant, known transport speed.

- the time is recorded and the distance covered by the product can be determined via an integration.

- the values from the X-ray scanner and the distance covered by the block of food are stored as pairs of values or as a curve. An interpolation between two or more values can also be calculated and preferably stored.

- the means preferably also starts the detection of the relative movement between the scanner and the block of food and/or the conveyor belt.

- the transmission scanner can also be movable while the product is stationary. In this case, the movement of the transmission scanner must be recorded.

- the time interval and/or the path that the product takes between being detected by the detection means and reaching the scanning plane, which preferably extends perpendicularly to the transport direction of the block of food, is preferably detected.

- this distance/path typically corresponds to the physical distance between the detection means and the scanning plane. In the case of natural products in particular, such as ham, this distance will usually deviate from the physical distance.

- This distance/distance is preferably forwarded to the slicing machine or a corresponding control unit/CPU so that this value can be used to synchronize the measured values with the slicing process, in particular with the movement of the block of food within the slicing device.

- several blocks of food are irradiated simultaneously, at least at times, with a transmission scanner.

- the blocks of food are preferably located next to one another and are preferably scanned along their longitudinal axis.

- a further aspect in the context of the present invention is therefore a radiation scanner with which several food blocks can be scanned in parallel at least at times.

- the scanner preferably has only one means of transport, preferably a conveyor belt.

- the transmission scanner preferably has only one transmitter and one receiver, the longitudinal axis of which preferably extends perpendicularly to the longitudinal axis of the product to be scanned.

- the length of the longitudinal axis of the transmitter and/or receiver preferably corresponds essentially to the width of the means of transport.

- the scanner preferably has a means for each block of food, preferably a detection means, which detects the beginning of the respective block of food on the conveyor belt.

- a reference point is preferably determined individually for each block of food and transmitted to a slicing machine and/or another control unit/CPU. This reference point can be different for each food bar.

- the distance between the center and the reference point is preferably determined for each block of food and transferred to the slicer or to another control unit/CPU.

- the subject of the present invention is a slicing machine according to claim 1.

- the means of transport is a plurality of conveyor belts, with the block of food preferably resting on one conveyor belt and being guided and/or transported at least in sections by another conveyor belt which is located above the block of food.

- the means includes a sensor.

- the agent may detect an initial point, line, or area of the product. Both the line and the surface can be curved. Based on this data, the position of the product on the conveyor of the slicer can be determined. Furthermore, this data can be used to adapt/synchronize the longitudinal coordinates determined during scanning to the path of the block of food in the slicing machine.

- the position of the block of food in the slicing machine is preferably detected without the block of food being appreciably lengthened or shortened in the process.

- the block of food is preferably fixed in the slicing device in such a way that it can at most perform a small movement relative to the transport means.

- the transport means includes a transmitter, for example an incremental transmitter, with which the movement, in particular the path covered by the conveyor belt, can be detected so that a controller knows at all times where the beginning of the product is and/or which longitudinal section of the product just being cut open.

- a transmitter for example an incremental transmitter, with which the movement, in particular the path covered by the conveyor belt, can be detected so that a controller knows at all times where the beginning of the product is and/or which longitudinal section of the product just being cut open.

- the slicing machine comprises several transport means. This makes it possible to cut several food blocks at the same time.

- the means of transport can be driven independently of one another and can therefore be operated at different speeds.

- Each means of transport has a means with which its movement, in particular its covered path, can be determined.

- This means is an encoder, for example an incremental encoder.

- each means of transport is provided with a means with which the position of the block of food on the respective means of transport can be determined and tracked in its direction of transport.

- the means recognizes the beginning of the respective block of food.

- the means is a sensor.

- the agent may detect an initial point, line, or area of the product. Both the line and the surface can be curved.

- each means of the slicing machine detects the beginning of the block of food in the same area as the means of the transmission scanner.

- the means(s) is/are located at the same height above the means of transport.

- the means(s) are preferably or particularly preferably arranged on the same latitude coordinates, so that they detect the start of the block of food at the same point as the means on the scanner.

- the slicing machine has a means, preferably per transport means, with which the orientation of the block of food on the conveyor belt can be determined.

- This means can be the same means used to identify the beginning of the product.

- This means it can be determined whether the bar was placed in the slicer in the correct orientation; i.e. whether the beginning of the block of food when scanning is also the beginning of the block of food when slicing and/or whether the block of food also rests with the same surface on the transport means of the slicer as it did during scanning. This is advantageous for cutting the block of food into portions with an exact weight and/or for classifying the cut food slices.

- the slicing machine preferably has a means with which the respective block of food can be individualized. This preferred embodiment makes it possible, in particular automatically possible, to assign the respective scan data record to the respective block of food.

- the slicing machine recognizes which food block it is and loads the associated data that is required for the weight-accurate portioning of the food block.

- the block of food can have a transponder or a barcode that is read by the slicing machine. This means can be the same means by which the beginning of the product is identified and/or by which the orientation of the product is determined.

- the path of a block of food is tracked between the transmission scanner and the slicing device and/or within the slicing device, preferably electronically. This can be done, for example, in the form of an electronic shift register. This preferred embodiment has the advantage that each data record can be clearly assigned to the respective block of food.

- the slicing machine preferably has a controller that automatically assigns a scan data set to the respective block of food. This ensures that the respective food block is portioned with exact weight. This preferred embodiment is also advantageous when several blocks of food are sliced open at the same time. The operator then does not have to pay attention to the order in which he inserts the food blocks into the slicing machine. The order in the radiographic scanner does not have to correspond to the order in which they were cut open.

- the slicing machine preferably has a gripper which grips the block of food at its end remote from the slicing surface and stabilizes the block of food in its position, in particular when the food bar has already been largely cut open.

- the block of food is only grasped when the slicing of the block of food has already begun.

- the block of food is preferably driven and/or guided in such a way that it does not compress the block of food when grasping and/or subsequently holding the end of the block of food. This preferred embodiment ensures that the longitudinal coordinates that are determined during scanning also match the longitudinal coordinates during cutting open.

- the data determined by the transmission scanner can also be used to determine quality features. For example, these values can be used to determine the area of the beginning and end of the block of food in which the diameter of the slices is smaller. Furthermore, areas of the food bar with a very high fat content, very large cavities (cheese) and/or so-called "blood spots" can be determined with the data. These areas with a reduced quality can then be sorted out and do not end up in the sliced portion. The sorting is also based on the measured data and a corresponding control of the slicing machine. Furthermore, the radiation allows foreign bodies to be detected in the food block. Food bars with foreign bodies are at least only partially cut open in order not to damage the knife or because they are unsuitable as food.

- This analysis is preferably carried out via an image evaluation.

- This image evaluation analyzes, preferably each, scan disk over its entire width; i.e. perpendicular to the direction of transport of the block of food.

- the transmission scanner or a connected CPU therefore preferably has image recognition software.

- the analysis is preferably carried out on the basis of a comparison, i.e. the data within one scan slice, the data before two more scan slices or the data from one or more scan slices and stored comparison data are compared with one another. As a result, local structural changes and foreign bodies can be detected.

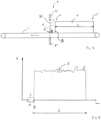

- figure 1 shows a slicing line in which food bars are cut into food slices and portions that are as precise in weight as possible are produced.

- a block of food 1 is conveyed with a feed belt through the transmission scanner 4, preferably an X-ray scanner. Before or after the scanning, the block of food is weighed, for example with scales 10. However, the weight of the respective block of food can also already be known.

- the product is scanned slice by slice in the scanner. The implementation of the scanning is explained in more detail using the Figures 2 - 5 explained.

- This feed belt can also include a buffer in which blocks of food that have already been scanned are waiting to be sliced.

- the data determined by the transmission scanner are either transferred directly to the slicing device or to another control unit/CPU, where they are further processed as required.

- the slicing process in the slicing device is now controlled using the data determined during scanning in such a way that the weight of the portions is as accurate as possible.

- food slices whose structure contains undesirable components are sorted out and food slices of different quality are classified into different product groups. After slicing, the respective food portions can be transferred to a weighing device 13 in order to check whether the desired weight has been maintained.

- This data can be used to calibrate the data evaluation of the transmission scanner and/or to control the slicing process.

- the scanner can also be arranged inside the slicing device 12, for example in the area of the product feed. Several blocks of food can be sliced at the same time in the slicing device.

- FIG. 1 shows a radiographic scanner which has a conveyor belt 5 on which the block of food 1 to be analyzed is located.

- the conveyor belt 5 has, for example, a drive 20 with a transmitter, so that the feed of the belt and/or its speed can be determined at any time. If the conveyor belt is operated at a constant, known speed, the path of the conveyor belt can also be determined from this.

- the transport direction of the conveyor belt is shown by the arrow.

- the radiation scanner has a detection means 6, for example a photocell, which detects a point or a line ⁇ of the beginning of the product.

- the detection means 6 is arranged at a distance ⁇ from the transmission scanner 4 .

- the detection means can be arranged upstream or downstream of the transmission scanner. This consists of a radiation source 4′ and a receiver 4′′, which span a scanning plane 22.

- the receiver 4′′ is preferably a line camera or any other means with which the block of food can be analyzed slice by slice.

- the weight of the entire food block can be determined before it is sliced. This can be done with any scale familiar to a person skilled in the art. However, the determination of the weight within the meaning of the invention is not limited to weighing. If the density is known, the weight can also be determined on the basis of data from the transmission scanner. This weight W is transferred to a computer unit that stores the weight value. If the weight of the block of food is known, it can also be transferred directly to the computer unit without being weighed beforehand. However, it can also be sufficient to merely determine the length of the block of food.

- the food block can be x-rayed slice by slice with a transmission scanner.

- This transmission scanner for example an X-ray scanner, has a radiation source 4' and a photosensitive sensor 4", for example, which are located on opposite sides of the circumference of the block of food 1.

- the radiation source emits rays which are on one side of the circumference of the block of food enter, penetrate the block of food and are received by the sensor on the opposite side.

- the block of food is irradiated over its entire width, which extends perpendicularly to the plane of the paper.

- the sensor 4" measures the intensity of the received rays, which are weakened when irradiated through the block of food , where the attenuation depends on the local nature of the food block, for example its density.

- the transmission scanner is preferably provided in a stationary manner and the block of food is transported through the transmission scanner, preferably along its longitudinal axis.

- the block of food is irradiated slice by slice, with the slices preferably being arranged perpendicular to the longitudinal central axis of the block of food.

- the desired thickness of such a disk referred to below as “scanning disk" depends on the desired measurement accuracy.

- the thickness of the scan slice is preferably smaller than the food slice to be separated from the block of food.

- the thickness of the scanned slice is preferably ⁇ 1/5, particularly preferably ⁇ 1/10 of the thickness of the food slice actually cut off.

- the thickness of each scan slice is the same.

- the values measured in each case by the sensor are stored in the computer unit, preferably as a function of their respective position in the longitudinal direction of the block of food, very particularly preferably as a curve of measured values.

- the computer unit can be assigned to the transmission scanner, the slicing machine or another control unit/CPU.

- the position of the scan values in the longitudinal direction is determined by the encoder on the conveyor belt.

- the computer unit accordingly shows which measured value was determined at which point along the longitudinal axis of the block of food. In the event that the thickness of the scan slices is not uniform, the respective thickness of the scan slice must also be registered and saved.

- the scan values can be determined as a function (as a function) of the thickness of the food block. However, for the weight-accurate portioning of the food block, it is usually sufficient if the measured scan values per scan slice are integrated over the thickness of the food product, ie one value per scan slice is sufficient.

- the food block is then transferred to a slicing machine in the same orientation in which it was x-rayed, which cuts it into portions.

- a certain length l must be cut off the food block per portion, which length corresponds to the desired target weight G of the respective portion, with a portion comprising at least one, preferably several food slices.

- the cuts of the slicing machine are made essentially parallel to the transmission direction of the transmission scanner and are preferably arranged essentially perpendicular to the longitudinal center axis of the block of food. If this is not the case, the scan values must be corrected mathematically accordingly.

- the slicing machine also has a detector, namely a sensor 15 (cf.

- FIG. 6 which preferably determines the same reference point/line ⁇ of the block of food as the detector 6 of the transmission scanner.

- the signal from this detector is used to determine the position of the block of food in the slicing device and/or to precisely synchronize the data from the scanning process with the slicing process of the product.

- the values determined by the transmission scanner can also be used to determine quality features. For example, these values can be used to determine the area of the beginning and end of the block of food in which the Diameter of the discs is smaller. Furthermore, areas of the food bar with a very high fat content, very large cavities (cheese) and/or so-called "blood spots" can be determined with the data. These areas with a reduced quality can then be sorted out and do not end up in the sliced portion. The sorting is also based on the measured values and a corresponding control of the slicing machine. Furthermore, the radiation allows foreign bodies to be detected in the food block. Food bars with foreign bodies are at least only partially cut open in order not to damage the knife or because they are unsuitable as food.

- the data determined for each scanned slice are preferably analyzed as a function of the thickness (perpendicular to the plane of the paper), ie in this case an integral consideration per scanned slice is generally not sufficient.

- a grayscale analysis is usually required here, which is carried out, for example, by image recognition software.

- the analysis of the determined data can lead to a food block being rejected in whole or in part. Partial areas of the block of food can be separated out during or after slicing. The rest can then be processed into "good portions”. Classification can also be carried out during or after slicing. The classification is preferably based on predetermined quality features.

- the signal of the transmission scanner is shown as a function of the signal of the transmitter from the conveyor belt 4. With a constant transport speed of the transport belt, the signal can also be plotted as a function of time.

- the scanner 4 After a distance/time interval of ⁇ , the distance/time difference between the detection of the start of the product by the X-ray scanner 4 and the detection of the reference point ⁇ by the detector 6, the scanner 4 first of all captures the start area 1' of the food 1. In the event that the detector 6 is arranged downstream of the x-ray scanner, the scanner first detects the initial region 1′ of the block of food 1 before the detector 6 detects the block of food.

- ⁇ corresponds exactly to the distance ⁇ between the detector 6 and the scanner 4. In the case of the in figure 2 product shown, this will probably not be the case.

- ⁇ ⁇ ⁇ because the product peak leads the reference point ⁇ .

- the value ⁇ is passed on to the slicing machine and is used to synchronize the scan values with the movement of the block of food in the slicing machine. In particular, the reference point is used to recalculate the correct start of the product. Since the food block in the present case is curved, the measured values slowly increase.

- a value is determined for each scanning disc 9 as a function of its position within the block of food.

- the measured values are summarized as curve 8.

- An interpolation can also take place between two or more measured values.

- Each measured value of the curve represents an integral over the thickness and the width of the respective scan slice.

- the scanner then records the further structure of the food block.

- the length of the block of food can be determined with the scan signal and the relative movement between the transmission scanner and the block of food. Based on the measured weight and/or the length L and the measured signals, the block of food is divided into portions each with a length l such that the desired weight of the portion is obtained in each case. The person skilled in the art recognizes that this length l can vary per portion.

- figure 4 essentially shows the arrangement according to FIG figure 2 , wherein in the present case the food block has a vertically arranged start or end area 1'. Accordingly, the in figure 5 shown measurement signal has a very steep beginning and end edge. In this case, the reference point ⁇ coincides with the beginning of the product. In this case, ⁇ and ⁇ are equal

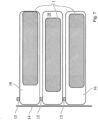

- FIG 6 shows a slicing machine not according to the invention.

- This has a transport means 16 with which a block of food 1 is transported in the direction of a rotating cutting blade 14 .

- the means of transport preferably has an encoder with which the movement of the means of transport and thus of the block of food can be tracked.

- This cutting blade 14 separates food slices from the food block, which are configured into portions from a plurality of food slices and are then transported away in this way.

- This slicing machine receives the data determined by the transmission scanner 4, as for example in the Figures 3 and 5 are shown in order to divide the block of food into portions that are as accurate as possible by weight or to classify the food slices.

- the slicing machine In order to synchronize the data transmitted by the scanner with the movement of the block of food in the slicing machine, the slicing machine also has a detection means 15 which is at a distance ⁇ from the slicing blade. As soon as this detection means detects the start of the block of food 1, the device can calculate when the start of the block of food 1 will be in the cutting plane of the cutting knife 14 and then correlate this point in time with the data transmitted by the scanner. For this purpose, the value ⁇ is preferably transmitted to the slicing machine. It is important that the detection means 15 detects the same area/point ⁇ of the front end of the food as the detection means 6 of the transmission scanner.

- the two detection means 6, 15 are therefore preferably arranged at the same height h, so that they detect the block of food at the same height. In the event that the detection takes place from above, the detection means 6, 15 must be provided on the same latitude coordinate. An at least almost identical arrangement of the detection means 6, 15 ensures that the cutting and the associated data are exactly correlated.

- the slicing machine can also have a stop against which the front end of the block of food rests, preferably without being compressed in the process. As a result, the position of the block of food in the slicing machine is clearly defined and its further path can be clearly traced. A control unit knows when the front end of the block of food will be in the cutting plane and will synchronize the scan data determined accordingly.

- FIG 7 shows an embodiment of a slicing machine according to the invention.

- the slicing machine according to the invention has a plurality of conveyor belts 16 with which the blocks of food can be transported at different speeds in the direction of the cutting knife.

- the blocks of food are cut into food slices.

- each means of transport 16 has a sensor with which the advance of each means of transport can be determined in each case.

- each transport means 16 has a detection means, namely a sensor, 15 with which the beginning of the respective block of food can be determined. Otherwise we go to the explanations figure 6 referred.

- figure 8 shows a food block which has 17 in the center in its initial region.

- the transport direction of the block of food is represented by the arrow marked "z".

- this means can be an orientation means with which it can be determined whether the beginning of the product 7 is actually arranged forward in the transport direction.

- the means 17 can receive information that allows the respective block of food to be identified. This makes it possible to assign the respective data set to the respective food block. This information can also be used to track production, so you know which portion was sliced from which food bar.

- the means 17 is preferably removed from the block of food prior to slicing.

- the means 17 also makes it possible to determine whether the block of food 1 is lying on the correct peripheral surface, here the peripheral surface 18′′′′, during scanning and/or during slicing. This can be important in particular when the block of food has an internal structure that is to be recognized during scanning.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Forests & Forestry (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Processing Of Meat And Fish (AREA)

- Analysing Materials By The Use Of Radiation (AREA)

- Formation And Processing Of Food Products (AREA)

- Manufacturing And Processing Devices For Dough (AREA)

Claims (2)

- Machine de découpe comprenant une lame de coupe (14) qui sépare des tranches d'aliment de l'extrémité avant (7) d'un aliment en barre (1), l'aliment en barre (1) étant transporté en direction de la lame de coupe (14) par un moyen de transport (16), à savoir une bande transporteuse, la machine de découpe comportant plusieurs moyens de transport (16), de sorte qu'il soit possible de découper plusieurs aliments en barre (1) simultanément,

caractérisée en ce que

chaque bande transporteuse est pourvue d'un moyen (15) avec lequel la position de l'aliment en barre sur la bande transporteuse dans sa direction de transport peut être identifiée et peut être suivie et la vitesse de transport de chaque bande transporteuse (16) est réglable individuellement, le moyen étant un capteur (15) et la bande transporteuse comportant un transmetteur, le moyen (15) reconnaissant le début de l'aliment en barre (1) et le moyen (15) détectant le début de l'aliment en barre (1) dans la même zone qu'un appareil de balayage radiographique. - Machine de découpe selon l'une des revendications précédentes, caractérisée en ce qu'elle possède un moyen (15), de préférence par moyen de transport (16), avec lequel l'orientation de l'aliment en barre sur la bande transporteuse peut être identifiée, le moyen de la machine de découpe détectant le début de l'aliment en barre dans la même zone qu'un moyen d'un appareil de balayage radiographique.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200910016096 DE102009016096A1 (de) | 2009-04-03 | 2009-04-03 | Verfahren zum Aufschneiden eines Lebensmittelriegels in gewichtsgenaue Portionen |

| DE102009060536 | 2009-12-23 | ||

| PCT/EP2010/002149 WO2010112239A2 (fr) | 2009-04-03 | 2010-04-06 | Procédé de découpe de blocs de produits alimentaires en portions de poids identique |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2414140A2 EP2414140A2 (fr) | 2012-02-08 |

| EP2414140B1 EP2414140B1 (fr) | 2019-11-27 |

| EP2414140B2 true EP2414140B2 (fr) | 2023-03-01 |

Family

ID=42313943

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10714184.8A Active EP2414140B2 (fr) | 2009-04-03 | 2010-04-06 | Appareil de découpe de blocs de produits alimentaires en portions de poids identique |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20120073415A1 (fr) |

| EP (1) | EP2414140B2 (fr) |

| ES (1) | ES2767175T3 (fr) |

| WO (1) | WO2010112239A2 (fr) |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2010112239A2 (fr) | 2009-04-03 | 2010-10-07 | CFS Bühl GmbH | Procédé de découpe de blocs de produits alimentaires en portions de poids identique |

| DE102011103863A1 (de) * | 2011-06-09 | 2012-12-13 | Weber Maschinenbau Gmbh Breidenbach | Verfahren zum Aufschneiden von Produkten |

| DE102011119719A1 (de) * | 2011-11-30 | 2013-06-06 | GEA CFS Bühl GmbH | Verfahren zum Aufschneiden eines Lebensmittelriegels unter Verwendung eines Schwingungssensors |

| DE102012018754A1 (de) * | 2012-09-21 | 2014-03-27 | Weber Maschinenbau Gmbh Breidenbach | Lebensmittelverarbeitungsvorrichtung und Verfahren zum sequentiellen Scannen von Lebensmittelprodukten |

| DE102013205043A1 (de) * | 2013-03-21 | 2014-09-25 | Gea Food Solutions Germany Gmbh | Linie ohne Kontrollwaage zwischen Aufschneide- und Verpackungsmaschine |

| EP2878203A1 (fr) * | 2013-11-29 | 2015-06-03 | Marel A/S | Appareil de coupe et procédé permettant de couper des produits alimentaires en produits plus petits |

| US20150208713A1 (en) * | 2014-01-28 | 2015-07-30 | Freshway Innovation, LLC | Agricultural Apparatus For Collecting, Cutting and/or Processing Produce and Methods Thereof |

| DE102015118202A1 (de) * | 2015-10-26 | 2017-04-27 | Textor Maschinenbau GmbH | Vorrichtung und verfahren zum aufschneiden von lebensmittelprodukten |

| DE102016101753A1 (de) * | 2016-02-01 | 2017-08-03 | Textor Maschinenbau GmbH | Aufschneiden von lebensmittelprodukten |

| EP3500410B1 (fr) | 2016-08-18 | 2022-09-14 | GEA Food Solutions Germany GmbH | Procédé de découpe de portions de poids exact |

| US10836065B2 (en) | 2017-01-04 | 2020-11-17 | Provisur Technologies, Inc. | Exposed load cell in a food processing machine |

| US10639798B2 (en) | 2017-01-04 | 2020-05-05 | Provisur Technologies, Inc. | Gripper actuating system in a food processing machine |

| US10160602B2 (en) | 2017-01-04 | 2018-12-25 | Provisur Technologies, Inc. | Configurable in-feed for a food processing machine |

| US9950869B1 (en) | 2017-01-04 | 2018-04-24 | Provisur Technologies, Inc. | Belt tensioner in a food processing machine |

| DE102018113618A1 (de) * | 2018-06-07 | 2019-12-12 | Weber Maschinenbau Gmbh Breidenbach | Vorrichtung und Verfahren zum Scannen von Lebensmittelriegeln mit verfahrbarer Scaneinheit |

| DE102019105309A1 (de) * | 2019-03-01 | 2020-09-03 | Wipotec Gmbh | Prüfvorrichtung |

| CN110686950B (zh) * | 2019-10-24 | 2024-09-13 | 云南昆船设计研究院有限公司 | 一种对不规则块状物料实现均匀分切的检测方法及系统 |

| BE1029404B1 (nl) * | 2021-12-23 | 2022-12-09 | Flanders Food Productions | Werkwijze voor het versnijden van kaas op industriële wijze |

| JP2024112156A (ja) * | 2023-02-07 | 2024-08-20 | 株式会社イシダ | 切断位置指定装置、切断位置指定方法、切断システム及びx線検査装置 |

| DE102023103990A1 (de) | 2023-02-17 | 2024-08-22 | Multivac Sepp Haggenmüller Se & Co. Kg | Aufschneide-Maschine sowie Verfahren zum Betreiben einer Aufschneide-Maschine |

| DE102023114662A1 (de) | 2023-04-20 | 2024-10-24 | Weber Food Technology Gmbh | Verfahren zur Steuerung einer Aufschneideeinheit und Verarbeitungslinie mit Aufschneideeinheit |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2335488A (en) † | 1998-03-16 | 1999-09-22 | Aew Int Ltd | Scanner for determining product size and/or shape using distance transducers |

Family Cites Families (33)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2965050A (en) | 1957-02-20 | 1960-12-20 | Industrial Nucleonics Corp | Measurement and controlling system for a dough machine |

| US4136504A (en) | 1976-09-10 | 1979-01-30 | Ihor Wyslotsky | Slicing method |

| AT349923B (de) | 1977-06-01 | 1979-05-10 | Kuchler Fritz | Aufschnittmaschine |

| IT1203196B (it) | 1978-08-16 | 1989-02-15 | Fata Fab App Sollevamento | Macchina per la preparazione automatica delle cariche di vari tipi di aucciu destinate a far parte di una mescola |

| US4428263A (en) * | 1981-10-08 | 1984-01-31 | Formax, Inc. | Food loaf slicing machine |

| US5042015A (en) | 1989-09-01 | 1991-08-20 | Quantronix, Inc. | Measuring method and apparatus |

| GB9307460D0 (en) | 1993-04-08 | 1993-06-02 | Thurne Eng Co Ltd | Packaging line |

| US5585603A (en) * | 1993-12-23 | 1996-12-17 | Design Systems, Inc. | Method and system for weighing objects using X-rays |

| DE4410596A1 (de) * | 1994-03-26 | 1995-10-05 | Holger Dr Ing Wente | Verfahren und Vorrichtung zur Bestimmung der Dichteverteilung eines inhomogenen Materials |

| US5974925A (en) | 1994-10-11 | 1999-11-02 | Formax, Inc. | Continuous feed for food loaf slicing machine |

| JPH08257982A (ja) * | 1995-03-22 | 1996-10-08 | Ryowa Kk | 食品スライス機 |

| DK199901596A (da) | 1999-11-04 | 2001-05-05 | Norfo As | Fremgangsmåde til opskæring af produkter samt apparat til udøvelse af fremgangsmåden |

| EP1332341A1 (fr) | 2000-09-28 | 2003-08-06 | Crisplant A/S | Systeme de pesee destine a un transporteur |

| US7832316B2 (en) * | 2000-11-03 | 2010-11-16 | Weber Maschinenbau Gmbh & Co. Kg | Apparatus for the slicing of food products having two cutter heads |

| DE10136980A1 (de) | 2001-03-14 | 2002-09-19 | Fritsch A Gmbh & Co Kg | Verfahren und Vorrichtung zur Bestimmung der Masse eines Teigbandabschnittes |

| US6635830B2 (en) | 2001-04-09 | 2003-10-21 | Formax, Inc. | Method of weight measurement using moving weigh conveyor |

| DE10135846B4 (de) * | 2001-07-23 | 2005-11-24 | Dipl.-Ing. Schindler & Wagner Gmbh & Co. Kg | Schneidmaschine |

| DE10226673A1 (de) | 2002-06-10 | 2004-01-08 | Bizerba Gmbh & Co. Kg | Vorrichtung zum Fördern und Bearbeiten von vereinzeltem Stückgut |

| US6763748B2 (en) | 2002-07-26 | 2004-07-20 | Formax, Inc. | Automatic draft length compensation for slicing machine system |

| US7055419B2 (en) * | 2003-01-10 | 2006-06-06 | Formax, Inc. | System and method for optimizing slices from slicing apparatus |

| US7153203B2 (en) * | 2003-07-21 | 2006-12-26 | Fmc Technologies, Inc. | Apparatus and method for portioning using automatic workpiece conveyance speed control |

| DE10342499B4 (de) * | 2003-09-12 | 2006-02-09 | Maschinenbau Heinrich Hajek Gmbh & Co. | Verfahren zum Portionieren von Lebensmitteln |

| US20070214969A1 (en) * | 2003-10-15 | 2007-09-20 | Peter Mueller | Method and Device for Slicing Food Bars |

| GB2418135A (en) | 2004-09-21 | 2006-03-22 | Key Country Foods Ltd | Food processing |

| IS7959A (is) | 2004-12-16 | 2006-06-17 | Skaginn Hf. | Athferth og bunathur vith sj βlfvirka beingarthst”ku, skurth meth vatni og snyrtingu β afurth |

| AU2005248942A1 (en) * | 2004-12-30 | 2006-07-20 | John Bean Technologies Corporation | Conveying conformable products |

| US7603936B2 (en) | 2005-03-05 | 2009-10-20 | Formax, Inc. | Loaf seam synchronization device for continuous loaf feed slicing machine |

| DE102005056848A1 (de) * | 2005-11-28 | 2007-05-31 | Reifenhäuser, Uwe, Dipl.-Ing. | Verfahren und Vorrichtung zum Schneiden eines Gutsstrangs in Scheiben |

| JP4623755B2 (ja) | 2006-02-20 | 2011-02-02 | 株式会社前川製作所 | 食肉ばら部位の肋骨位置検出方法及びその装置 |

| ATE526128T1 (de) | 2006-05-15 | 2011-10-15 | Lenz Appbau Ag | Vorrichtung zum schneiden von gemüse |

| DE102007021510A1 (de) | 2007-05-04 | 2008-11-06 | Maja-Maschinenfabrik Hermann Schill Gmbh & Co. Kg | Vorrichtung zum Schneiden eines Gegenstands in einzelne Portionen |

| US8336434B2 (en) * | 2007-10-22 | 2012-12-25 | Formax, Inc. | Food article end detection system for a food article slicing machine |

| WO2010112239A2 (fr) | 2009-04-03 | 2010-10-07 | CFS Bühl GmbH | Procédé de découpe de blocs de produits alimentaires en portions de poids identique |

-

2010

- 2010-04-06 WO PCT/EP2010/002149 patent/WO2010112239A2/fr active Application Filing

- 2010-04-06 US US13/262,504 patent/US20120073415A1/en not_active Abandoned

- 2010-04-06 ES ES10714184T patent/ES2767175T3/es active Active

- 2010-04-06 EP EP10714184.8A patent/EP2414140B2/fr active Active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2335488A (en) † | 1998-03-16 | 1999-09-22 | Aew Int Ltd | Scanner for determining product size and/or shape using distance transducers |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2010112239A3 (fr) | 2011-03-10 |

| ES2767175T3 (es) | 2020-06-16 |

| US20120073415A1 (en) | 2012-03-29 |

| WO2010112239A2 (fr) | 2010-10-07 |

| EP2414140B1 (fr) | 2019-11-27 |

| EP2414140A2 (fr) | 2012-02-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2414140B2 (fr) | Appareil de découpe de blocs de produits alimentaires en portions de poids identique | |

| EP2516118B1 (fr) | Procédé pour classer par ordre de qualité des tranches d'aliment découpées dans un pain d'aliment | |

| EP2315650B1 (fr) | Procédé et dispositif pour obtenir des données de commande pour un dispositif de coupe de produits alimentaires ainsi que pour obtenir de tranches constantes au niveau du poids de produits sur la base de lesdites données de commande | |

| DE102005010183B4 (de) | Verfahren und Vorrichtung zur Erzeugung von gewichtsgenauen Lebensmittelportionen | |

| EP2439029B1 (fr) | Procédé minimisant les restes pendant une découpe d'aliments | |

| EP2882296B1 (fr) | Procédé et dispositif de surveillance d'une machine de transformation de viande | |

| EP1820614B1 (fr) | Tranchage de produits alimentaires | |

| EP2711147B2 (fr) | Dispositif de traitement de produits alimentaires et procédé de balayage séquentiel de produits alimentaires | |

| EP2975945A2 (fr) | Ligne sans balance de vérification entre une machine de coupe et une machine d'emballage | |

| EP2691217B1 (fr) | Dispositif et procédé de surveillance automatique d'un dispositif de traitement de produits carnés | |

| DE10342499B4 (de) | Verfahren zum Portionieren von Lebensmitteln | |

| DE602004006079T2 (de) | Verfahren zur verarbeitung von filets, wie lachsfilets, und system zur durchführung des verfahrens | |

| DE102015221907A1 (de) | Verfahren zum Aufschneiden eines Lebensmittelriegels in gewichtsgenaue Portionen | |

| EP2047248B1 (fr) | Procédé et dispositif pour déterminer la teneur en graisse de morceaux de viande dans leur ensemble | |

| EP3730909B1 (fr) | Procédé et dispositif de pesage d'une partie de denrée alimentaire à détermination du poids | |

| EP1044770A1 (fr) | Procédé ainsi que dispositif pour découper des morceaux de jambon fumé de poids prédéterminé | |

| EP3500410B1 (fr) | Procédé de découpe de portions de poids exact | |

| DE102009016096A1 (de) | Verfahren zum Aufschneiden eines Lebensmittelriegels in gewichtsgenaue Portionen | |

| EP2090409A1 (fr) | Procédé de séparation d'aliments en forme de blocs | |

| DE102019122994A1 (de) | Käseteiler und Verfahren zum Messen einer Länge eines Käseprodukts |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20111103 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20161024 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 502010016388 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: B26D0005260000 Ipc: B26D0005020000 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B26D 1/143 20060101ALI20190417BHEP Ipc: B26D 5/02 20060101AFI20190417BHEP Ipc: B26D 5/26 20060101ALI20190417BHEP Ipc: B26D 7/30 20060101ALI20190417BHEP Ipc: B26D 7/06 20060101ALI20190417BHEP Ipc: B26D 5/32 20060101ALI20190417BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20190607 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: GEA FOOD SOLUTIONS GERMANY GMBH |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1206168 Country of ref document: AT Kind code of ref document: T Effective date: 20191215 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010016388 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200227 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200227 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200327 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2767175 Country of ref document: ES Kind code of ref document: T3 Effective date: 20200616 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200419 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502010016388 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: WEBER MASCHINENBAU GMBH BREIDENBACH Effective date: 20200813 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20200501 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200430 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200430 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200406 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20200430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200430 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20200406 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200406 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200406 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1206168 Country of ref document: AT Kind code of ref document: T Effective date: 20200406 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20210826 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200406 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200406 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200407 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20230301 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 502010016388 Country of ref document: DE |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230514 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240418 Year of fee payment: 15 |