EP2220949B1 - Strangschneiden - Google Patents

Strangschneiden Download PDFInfo

- Publication number

- EP2220949B1 EP2220949B1 EP10152474.2A EP10152474A EP2220949B1 EP 2220949 B1 EP2220949 B1 EP 2220949B1 EP 10152474 A EP10152474 A EP 10152474A EP 2220949 B1 EP2220949 B1 EP 2220949B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rod

- circular blade

- strand

- axis

- cutting device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 241000208125 Nicotiana Species 0.000 claims description 17

- 235000002637 Nicotiana tabacum Nutrition 0.000 claims description 17

- 238000000034 method Methods 0.000 claims description 12

- 230000000694 effects Effects 0.000 claims 1

- 238000004519 manufacturing process Methods 0.000 description 5

- 238000011144 upstream manufacturing Methods 0.000 description 4

- 239000000463 material Substances 0.000 description 3

- 235000019504 cigarettes Nutrition 0.000 description 2

- 238000007493 shaping process Methods 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

- 230000001960 triggered effect Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24C—MACHINES FOR MAKING CIGARS OR CIGARETTES

- A24C5/00—Making cigarettes; Making tipping materials for, or attaching filters or mouthpieces to, cigars or cigarettes

- A24C5/14—Machines of the continuous-rod type

- A24C5/28—Cutting-off the tobacco rod

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24C—MACHINES FOR MAKING CIGARS OR CIGARETTES

- A24C5/00—Making cigarettes; Making tipping materials for, or attaching filters or mouthpieces to, cigars or cigarettes

- A24C5/14—Machines of the continuous-rod type

- A24C5/31—Machines of the continuous-rod type with special arrangements coming into operation during starting, slowing-down or breakdown of the machine, e.g. for diverting or breaking the continuous rod

Definitions

- the invention relates to a strand cutting device of the tobacco processing industry with a circular blade which is rotatable about an axis of rotation.

- the invention further relates to a method for cutting at least one strand of the tobacco processing industry, wherein a rotating circular blade is passed through the strand moving in a strand guide path.

- a corresponding strand cutting device is off EP 1 800 551 A2 known.

- the axis of rotation of the circular knife lies transversely to a strand which can be cut by the circular knife, the axis of rotation being arranged substantially horizontally during operation of the strand cutting device, and the strand cutting device being pivoted horizontally via a pivoting arm in order to engage the circular knife with the strand.

- US Pat. No. 3,380,329 shows a strand cutting device which is provided with a circular blade which is rotatable about a rotation axis.

- GB 321 067 A discloses a strand piercing apparatus having a circular blade which is rotatable about an axis of rotation.

- US 1 348 057 A also shows a corresponding strand cutting device with a rotating circular blade.

- a strand cutting device of the generic type and a corresponding method for cutting a strand of the tobacco processing industry educate such that a safe and fast cut through the strand is possible, the strand during cutting in particular not steered from its path and a clean cut should be possible.

- the strand cutting device according to the invention should also be applicable to machines which process a plurality of strands, in particular two strands.

- a Strand which is rotatable about an axis of rotation

- a circular blade guide device which moves the circular blade in operation linearly, the axis of rotation of the circular blade transverse, in particular perpendicular, to a strand guide track or is arranged to be cut in the operation of the circular blade strand.

- the circular knife guide device is preferably designed as a lifting device and / or linear movement device.

- the circular blade is guided linearly and preferably vertically through the strand.

- the axis of rotation is arranged substantially horizontally during operation of the strand cutting device.

- the axis of rotation is formed perpendicular to a longitudinal axis of a strand guide track.

- the strand guide path is the path in which the strand moves. In this case, a forced operation does not necessarily have to be provided.

- a strand guideway may also lead over a free distance, especially in air.

- the circular knife guide device causes a movement of the circular blade, which is parallel to the axis of rotation of the circular blade.

- a movement of the circular knife may be made possible, which is substantially perpendicular to a strand guide track or is substantially perpendicular to the movable strand of the tobacco processing industry to be cut through.

- the circular knife guide device may be provided with a hydraulic cylinder that generates the linear movement, or with motors that allow, for example via corresponding gears, the linear movement of the circular blade. In this case, a corresponding stroke for the circular blade is generated by the circular blade guide device, which is sufficiently large to cut through the strand or multiple strands.

- a strand guiding device which, in particular from below, is movable, in particular pivotable, or can be moved linearly to a strand or a strand guiding path.

- the strand guiding device may preferably be a kind of extension or supplement of a formatting device, wherein the strand guiding device has corresponding openings through which the strands can be moved. The openings may preferably be aligned with openings of a formatting device.

- the strand guiding device preferably serves as an abutment for the circular blade.

- the strand guiding device preferably has two guide openings, which can receive two mutually parallel and movable strands.

- the circular blade preferably experiences a linear stroke, which is greater than the distance between two parallel strands of the tobacco processing industry or two parallel strand guideways, due to the circular blade guide device.

- the distance is defined in the context of the invention so that the outer sides of the strands are each meant so that the stroke passes over both strands.

- the circular blade preferably has a corrugated or serrated surface at its cutting edge.

- the axis of rotation of the circular blade is at an angle of 85 ° to 90 ° to a movable and to be cut strand of the tobacco processing industry and / or at an angle of 0 ° to 5 ° to the linear movement of the circular blade.

- the 85 ° to 90 ° may also be relative to a corresponding strand guideway. It is preferable if the angle of the rotation axis of the circular blade to the strand guide track or the strand is at 90 ° or exactly 90 °. This then leads to relatively long diagonal cuts in the strand. To shorten this cut, especially at high strand speeds, the circular blade can be adjusted by a few degrees, so that the cut is improved at high strand speeds.

- a control which adjusts the corresponding angle of the circular blade to the strand guide track as a function of the strand speed.

- the circular blade is preferably rotated at a rotational speed of 1,000 to 3,000 revolutions per minute, more preferably at 2,000 revolutions per minute.

- the strand speed is usually in the range of 50 to 100 meters per minute, and the interface has a length of 12 to 20 mm.

- a rod making machine of the tobacco processing industry with a strand cutting device according to the invention for cutting at least one strand of the tobacco processing industry, wherein for starting the strand machine, the strand cutting device is arranged in a different position than strand-producing operation of the stranding machine, wherein between the two positions a strand guide path is arranged.

- the two strands or a plurality of strands between the two positions are preferably arranged.

- a very defined and controlled startup and shutdown of the stranding machine allows.

- the stranding machine To start the stranding machine this is driven from a low strand production speed to a high strand production speed, wherein initially the strand still carried away is and is therefore not intended for further processing.

- the strand After reaching a satisfactory strand or a predeterminable speed of the strand, the strand is or will be cut in the case of a two-line machine or a multi-strand machine, the strands with the device according to the invention.

- the upstream part of the strand, upstream relative to the cut enters the usual further processing of the stranding machine and is then correspondingly cut into desired lengths and further processed to filter cigarettes, for example.

- the strand may be a filter strand or a cigarette rod.

- the object is further achieved by a method for cutting at least one strand of the tobacco processing industry, wherein a rotating circular blade is passed through the strand moving in a strand guide path, wherein the circular blade is guided linearly through the strand, wherein the linear movement of the circular blade vertically to a strand longitudinal axis, wherein the linear motion of the circular blade is parallel to a rotational axis of the circular blade.

- the strand Due to the linear motion, the strand can be cut with a very short stroke, or the strands can be cut with a very short stroke, so that a very fast cut is possible.

- the device is then also very compact.

- an angle between the axis of rotation and the strand longitudinal axis may be provided, which is not equal to 90 °.

- the axis of rotation is preferably formed pivotable with respect to its angle to the strand longitudinal axis.

- the strand is guided in a strand guiding device, which serves as an abutment.

- the strand guiding device for cutting the strand to the strand in particular upwards, moves, in particular pivoted or moved linearly.

- a method for the controlled shutdown of an operating strand machine wherein in the presence of a stop signal, an inventive method for cutting at least one strand of the tobacco processing industry is performed.

- the stop signal may in this case be an automatically generated signal of the strand machine, for example if a strand burst was detected or else a signal which is triggered by an operator.

- Method is for the first time possible to perform a controlled shutdown of an operating strand machine so that defined strand material is cut and defined further processing steps on the cut strand material, which is downstream of the cut, can be performed.

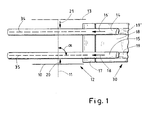

- Fig. 1 schematically shows a plan view of a part of a strand machine 30. It is a double-strand machine, for example, a double filter strand machine. Correspondingly, two filter strands 14 and 15 are shown, which move in the conveying direction 16 or 16 '. This may be strands 14 and 15 covered with a wrapping material. The wrapping and shaping of the filter strands 14 and 15 is done in a format of which the sub-format 18 is shown here. There are also corresponding strand guideways 19 and 19 ⁇ shown in which the strands 14 and 15 are guided. These are in the area of the lower format 18 to appropriately trained tracks.

- the strand guide tracks 19 and 19 'according to the invention are thus in particular a track in which a corresponding strand is arranged or moved. This can also be at least partially without a fixed limit.

- a circular blade 10 indicated that rotates about the axis of rotation 11.

- the circular blade may be corrugated or serrated at its cutting edge.

- Fig. 1 for illustration below the position "start" 12 place for an operator and above the position "operation” 13 a part of the strand machine.

- Fig. 1 In the upper area of Fig. 1 , ie above the position 13, for example, motors, gears, etc. are arranged in the strand machine.

- the circular blade 10 is located in Fig. 1 in position 12, ie in the position start.

- the axis of rotation 11 is perpendicular to the longitudinal axes 34, 35 of the strands 14 and 15.

- the angle ⁇ has an amount of 90 °.

- the blade 10 is moved from the "operating" position 13 in the circular blade movement direction 21 through the strands 14 and 15 and cuts the strands 14 and 15, respectively.

- the upstream portions of the strands 14 and 15 relative to that cut then become excluded from further processing, whereas the downstream parts of this cut can be further processed. This happens, as far as any intended sensors do not recognize that these parts of the strands are no longer suitable for further processing.

- a strand guiding device 17 which has two openings 25 and 26 for guiding the strands 14, 15.

- the openings 25, 26 are in the Figures 2 and 3 better to recognize.

- the strand guiding device 17 is pivoted from below the strands for cutting the strands thereto. This too is in the Figures 2 and 3 better to recognize.

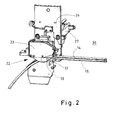

- FIG. 2 3 shows a schematic representation of a strand cutting device 22 according to the invention which has a housing 23 and the circular blade 10. It is shown in FIG Fig. 2 the strand guiding device 17 with the two openings 25 and 26 shown. The strand guiding device 17 is in Fig. 2 to the strands 14, 15 and swung in Fig. 3 pivoted away.

- FIG. 2 the operating state of the strand machine is shown when starting, ie the circular blade 10 is in the position 12 from Fig. 1 , This is remote from the machine wall 24, so that the strands 14, 15 are arranged between the circular blade 10 and the machine wall 24. It is also in Fig. 2 and Fig. 3 a lifting device 27 is shown, which allows the linear stroke of the strand cutting device 22 and thus of the circular blade 10.

- Fig. 4 is yet another schematic plan view of a part of a stranding machine shown.

- Fig. 4 shows in comparison to Fig. 1 a circular blade 10, which is opposite the strand guideways 19 and 19 'or in the strand guideways 19 and 19' arranged filter strands 14, 15, which are not shown, with the strand longitudinal axes 34, 35, which are also not shown, inclined.

- an angle ⁇ which may be between 0 ° and 5 °. In particular, at low speeds, it may make sense to increase the angle ⁇ or set not equal to 0 °.

- control of the angle ⁇ takes place as a function of the strand speed.

Landscapes

- Manufacturing Of Cigar And Cigarette Tobacco (AREA)

- Cigarettes, Filters, And Manufacturing Of Filters (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL10152474T PL2220949T3 (pl) | 2009-02-24 | 2010-02-03 | Cięcie pasma |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102009010090A DE102009010090A1 (de) | 2009-02-24 | 2009-02-24 | Strangschneiden |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2220949A1 EP2220949A1 (de) | 2010-08-25 |

| EP2220949B1 true EP2220949B1 (de) | 2013-06-05 |

Family

ID=42173045

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10152474.2A Active EP2220949B1 (de) | 2009-02-24 | 2010-02-03 | Strangschneiden |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP2220949B1 (enExample) |

| JP (1) | JP2010193886A (enExample) |

| CN (1) | CN101811308B (enExample) |

| DE (1) | DE102009010090A1 (enExample) |

| PL (1) | PL2220949T3 (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2729025A1 (de) * | 2011-07-07 | 2014-05-14 | Hauni Maschinenbau AG | Längsfördereinrichtung für produkte der tabak verarbeitenden industrie |

| CN116268555B (zh) * | 2023-04-23 | 2025-10-03 | 龙岩烟草工业有限责任公司 | 烟支导向装置、分切装置、接装机以及调节间隙的方法 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1348057A (en) * | 1918-11-04 | 1920-07-27 | Comas Cigarette Machine Compan | Cutting attachment for cigarette-machines |

| GB321067A (en) * | 1928-11-10 | 1929-10-31 | American Mach & Foundry | Improvements in cut-off devices for cigarette making machines |

| GB1021741A (en) * | 1963-05-20 | 1966-03-09 | Michael Aren Pym | Improvements in or relating to continuous rod making machines |

| US3380329A (en) * | 1966-04-06 | 1968-04-30 | Philip Morris Inc | Continuous rod cutter |

| DE2746915A1 (de) * | 1977-10-19 | 1979-04-26 | Hauni Werke Koerber & Co Kg | Vorrichtung zum fuehren von werkzeugen an tabakverarbeitenden maschinen |

| US4554931A (en) * | 1982-10-15 | 1985-11-26 | Hauni-Werke Korber & Co. Kg | Apparatus for severing rod-shaped articles of the tobacco processing industry |

| IT1208281B (it) * | 1987-04-17 | 1989-06-12 | Sasib Spa | Dispositivo deviatore troncatore del baco in confezionatrici di sigarette |

| DE3813786C2 (de) | 1988-04-23 | 2000-02-17 | Hauni Werke Koerber & Co Kg | Vorrichtung zum Abschneiden eines Stranges der tabakverarbeitenden Industrie |

| JP3274882B2 (ja) * | 1992-05-08 | 2002-04-15 | 日本たばこ産業株式会社 | シガレット製造機のたばこロッド走行案内装置 |

| IT1279717B1 (it) * | 1995-12-21 | 1997-12-16 | Gd Spa | Dispositivo di taglio per bachi continui di sigaretta |

| DE502004009212C5 (de) * | 2003-11-07 | 2024-02-22 | Körber Technologies Gmbh | Vorrichtung und Verfahren zum Herstellen von mindestens zwei Fasersträngen der Tabakverarbeitenden Industrie |

| DE102005062644A1 (de) | 2005-12-23 | 2007-07-26 | Hauni Maschinenbau Ag | Schneidvorrichtung und Strangmaterialabfördervorrichtung der Tabak verarbeitenden Industrie |

| DE102006042238A1 (de) * | 2006-09-06 | 2008-03-27 | Hauni Maschinenbau Ag | Einrichtung zum Fördern von stabförmigen Artikeln |

| ITBO20060664A1 (it) * | 2006-09-28 | 2006-12-28 | Gd Spa | Unita' di taglio per almeno un baco continuo |

-

2009

- 2009-02-24 DE DE102009010090A patent/DE102009010090A1/de not_active Ceased

-

2010

- 2010-02-03 PL PL10152474T patent/PL2220949T3/pl unknown

- 2010-02-03 EP EP10152474.2A patent/EP2220949B1/de active Active

- 2010-02-23 JP JP2010037205A patent/JP2010193886A/ja not_active Withdrawn

- 2010-02-24 CN CN201010136504.8A patent/CN101811308B/zh active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN101811308A (zh) | 2010-08-25 |

| JP2010193886A (ja) | 2010-09-09 |

| EP2220949A1 (de) | 2010-08-25 |

| PL2220949T3 (pl) | 2013-11-29 |

| CN101811308B (zh) | 2014-06-18 |

| DE102009010090A1 (de) | 2010-09-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2848380B1 (de) | Vorrichtung zum Aufschneiden von Lebensmittelprodukten und Verfahren zum Bereitstellen von Zwischenblättern | |

| EP2543452B1 (de) | Biegevorrichtung für stabförmige Werkstücke | |

| EP2524608B2 (de) | Schneideinrichtung für eine Strangmaschine der Tabak verarbeitenden Industrie und Verfahren zum Einstellen der Position der oder jeder Schleifscheibe einer Schleifvorrichtung in einer Schneideinrichtung für eine Strangmaschine der Tabak verarbeitenden Industrie | |

| EP2258522B1 (de) | Vorrichtung zum Schneiden eines kontinuierlich geführten Strangs in strangförmige Artikel variabler Länge sowie Strangmaschine mit einer solchen Vorrichtung | |

| EP2471391A2 (de) | Schneideinrichtung für eine Strangmaschine der Tabak verarbeitenden Industrie und Verfahren zum Einstellen der Position eines Schleifscheibenhalters einer Vorrichtung zum Schleifen in einer Schneideinrichtung für eine Strangmaschine der Tabak verarbeitenden Industrie | |

| EP2364596B1 (de) | Vorrichtung und Verfahren zum Trennen von Wurstketten | |

| DD201972A5 (de) | Vorrichtung zum gleichzeitigen durchtrennen von zwei fortlaufenden zigarettenstraengen | |

| EP2220949B1 (de) | Strangschneiden | |

| EP1625799B1 (de) | Anordnung zur Herstellung wenigstens eines Filterstrangs | |

| EP1741353B1 (de) | Formatbildungseinrichtung der Tabak verarbeitenden Industrie | |

| EP1800551B1 (de) | Strangdurchschneidvorrichtung und Strangmaterialabfördervorrichtung der Tabak verarbeitenden Industrie, sowie Verfahren zum Betrieb einer Strangmaschine der Tabak verarbeitenden Industrie | |

| EP2481303A1 (de) | Schneideinrichtung für eine Strangeinrichtung der Tabak verarbeitenden Industrie und Verfahren zur Regelung des Messervorschubs in einer Schneideinrichtung für eine Strangmaschine der Tabak verarbeitenden Industrie | |

| DE3813786C2 (de) | Vorrichtung zum Abschneiden eines Stranges der tabakverarbeitenden Industrie | |

| EP2241204A1 (de) | Trimmeinrichtung und Verfahren zur Steuerung einer Trimmeinrichtung | |

| EP3894206B1 (de) | Vorrichtung mit guillotine-ablängvorrichtung zum fertigen eines verpackungsmaterialerzeugnisses aus einem faserausgangsmaterial und verfahren zum fertigen eines verpackungsmaterialerzeugnisses | |

| DE102013208307B4 (de) | Plattenaufteilanlage | |

| EP2449898A2 (de) | Vorrichtung zur Herstellung von Koaxialfiltern für stabförmige Rauchartikel | |

| EP2449896A1 (de) | Vorrichtung zur Herstellung von Koaxialfiltern für stabförmige Rauchartikel | |

| DE19547193C2 (de) | Verfahren und Vorrichtung zum Einschneiden eines Baumstammes | |

| DE19854662B4 (de) | Tabakschneidverfahren und -vorrichtung | |

| EP3620054B1 (de) | Teigband-erzeugungsvorrichtung sowie betriebsverfahren hierfür | |

| EP2449895A2 (de) | Vorrichtung zur Herstellung von Koaxialfiltern für stabförmige Rauchartikel | |

| DE1801479A1 (de) | Verfahren und Vorrichtung zur automatischen Produktion von Ziegel im Steifpressverfahren | |

| DE102019102404B4 (de) | Vorrichtung zum Schneiden eines mit einem Verstärkungselement versehenen Schlauchs | |

| DE2542112C2 (de) | Verfahren und Vorrichtung zum Ablängen von Seitenware |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA RS |

|

| 17P | Request for examination filed |

Effective date: 20110114 |

|

| TPAC | Observations filed by third parties |

Free format text: ORIGINAL CODE: EPIDOSNTIPA |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: A24C 5/28 20060101AFI20130103BHEP Ipc: A24C 5/31 20060101ALI20130103BHEP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: HARTMANN, FRANZ Inventor name: STUDT, STEPHAN Inventor name: GLOGASA, JOACHIM |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 615109 Country of ref document: AT Kind code of ref document: T Effective date: 20130615 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010003523 Country of ref document: DE Effective date: 20130801 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130906 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130905 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130916 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130905 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131005 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131007 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: G.D S.P.A. Effective date: 20140305 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502010003523 Country of ref document: DE Effective date: 20140305 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| BERE | Be: lapsed |

Owner name: HAUNI MASCHINENBAU A.G. Effective date: 20140228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140203 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20140203 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140228 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140228 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20141031 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140203 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140228 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140228 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140203 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R100 Ref document number: 502010003523 Country of ref document: DE |

|

| PLCK | Communication despatched that opposition was rejected |

Free format text: ORIGINAL CODE: EPIDOSNREJ1 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 615109 Country of ref document: AT Kind code of ref document: T Effective date: 20150203 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150203 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 |

|

| PLBN | Opposition rejected |

Free format text: ORIGINAL CODE: 0009273 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION REJECTED |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150203 |

|

| 27O | Opposition rejected |

Effective date: 20151204 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502010003523 Country of ref document: DE Owner name: HAUNI MASCHINENBAU GMBH, DE Free format text: FORMER OWNER: HAUNI MASCHINENBAU AG, 21033 HAMBURG, DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20100203 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: PD Owner name: HAUNI MASCHINENBAU GMBH; DE Free format text: DETAILS ASSIGNMENT: VERANDERING VAN EIGENAAR(S), VERANDERING VAN DE JURIDISCHE ENTITEIT; FORMER OWNER NAME: HAUNI MASCHINENBAU AG Effective date: 20160809 |

|

| PGRI | Patent reinstated in contracting state [announced from national office to epo] |

Ref country code: IT Effective date: 20161122 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130605 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20190224 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20200301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200203 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502010003523 Country of ref document: DE Owner name: KOERBER TECHNOLOGIES GMBH, DE Free format text: FORMER OWNER: HAUNI MASCHINENBAU GMBH, 21033 HAMBURG, DE |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230608 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250225 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250226 Year of fee payment: 16 |