EP2139773B1 - Bag filling method on a forming, filling and sealing machine - Google Patents

Bag filling method on a forming, filling and sealing machine Download PDFInfo

- Publication number

- EP2139773B1 EP2139773B1 EP08734811A EP08734811A EP2139773B1 EP 2139773 B1 EP2139773 B1 EP 2139773B1 EP 08734811 A EP08734811 A EP 08734811A EP 08734811 A EP08734811 A EP 08734811A EP 2139773 B1 EP2139773 B1 EP 2139773B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- bag

- filling

- relative movement

- weight

- phase

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B1/00—Packaging fluent solid material, e.g. powders, granular or loose fibrous material, loose masses of small articles, in individual containers or receptacles, e.g. bags, sacks, boxes, cartons, cans, or jars

- B65B1/30—Devices or methods for controlling or determining the quantity or quality or the material fed or filled

- B65B1/32—Devices or methods for controlling or determining the quantity or quality or the material fed or filled by weighing

- B65B1/34—Adjusting weight by trickle feed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B1/00—Packaging fluent solid material, e.g. powders, granular or loose fibrous material, loose masses of small articles, in individual containers or receptacles, e.g. bags, sacks, boxes, cartons, cans, or jars

- B65B1/04—Methods of, or means for, filling the material into the containers or receptacles

- B65B1/10—Methods of, or means for, filling the material into the containers or receptacles by rotary feeders

- B65B1/12—Methods of, or means for, filling the material into the containers or receptacles by rotary feeders of screw type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B43/00—Forming, feeding, opening or setting-up containers or receptacles in association with packaging

- B65B43/42—Feeding or positioning bags, boxes, or cartons in the distended, opened, or set-up state; Feeding preformed rigid containers, e.g. tins, capsules, glass tubes, glasses, to the packaging position; Locating containers or receptacles at the filling position; Supporting containers or receptacles during the filling operation

- B65B43/46—Feeding or positioning bags, boxes, or cartons in the distended, opened, or set-up state; Feeding preformed rigid containers, e.g. tins, capsules, glass tubes, glasses, to the packaging position; Locating containers or receptacles at the filling position; Supporting containers or receptacles during the filling operation using grippers

- B65B43/465—Feeding or positioning bags, boxes, or cartons in the distended, opened, or set-up state; Feeding preformed rigid containers, e.g. tins, capsules, glass tubes, glasses, to the packaging position; Locating containers or receptacles at the filling position; Supporting containers or receptacles during the filling operation using grippers for bags

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B43/00—Forming, feeding, opening or setting-up containers or receptacles in association with packaging

- B65B43/42—Feeding or positioning bags, boxes, or cartons in the distended, opened, or set-up state; Feeding preformed rigid containers, e.g. tins, capsules, glass tubes, glasses, to the packaging position; Locating containers or receptacles at the filling position; Supporting containers or receptacles during the filling operation

- B65B43/54—Means for supporting containers or receptacles during the filling operation

- B65B43/56—Means for supporting containers or receptacles during the filling operation movable stepwise to position container or receptacle for the reception of successive increments of contents

- B65B43/58—Means for supporting containers or receptacles during the filling operation movable stepwise to position container or receptacle for the reception of successive increments of contents vertically movable

Definitions

- the invention relates to a method for producing, filling and sealing of plastic bags with dusty or granular bulk material and for closing the filled bags.

- Such a method is for example from the DE 93 01 355 U known.

- a device for producing, filling and closing unilaterally open preferably provided with gusseted bags of thermoplastic described in which a first welding and separation station to form the bag with bottom seam, a filling station and a second welding station for closing the bag available.

- these filling machines are classified in the FFS ( F orm F ill and S eal) category.

- the filling of dusty goods according to the known filling method described usually leads to a significantly inflated product volume or to a significant reduction in bulk density, since the product accumulates heavily in the free fall with air. This, in turn, leads to bottling the product initially much more packaging material is needed. In addition, the air must be able to escape from the bag again, otherwise it can not be stacked or stored.

- a film tube can be unwound from a settlement.

- the invention makes use of the fact that less dust is formed when the mouth of the Be colllorgans is below the Be colllgutsaustrittsö réelle of the metering. It is surprising that meaningful signals can be obtained with load cells, while there is mechanical contact of the filling material in the bag and the metering device.

- the filling member mainly generates higher-frequency interference signals, which can be eliminated by filtering the signals.

- Another measure that can increase filling speed and quality of measurement is a relative movement of dosing and bag during the filling process. When this relative movement is uniform, spurious signals are limited. This is especially true when the sack is moved uniformly.

- the measured values obtained during the submillar filling can advantageously be used as weight measured values for checking or regulating the bag weight during filling.

- This definition implies that, based on the weight measurements, the time at which the bag filling ends is determined. It also includes that a control of the filling speed and / or the speed of the relative movement between the bag and Be Pavllorgan is made.

- the filling speed that is, the weight increase per unit time or the first derivative of the weight after the time, can be used to detect errors that occur during the filling process.

- Such flaws can include a sack crack, which usually results in a rapid decrease in weight gain.

- the outlined procedure is believed to work best when the control unit emits a warning signal as the weight gain moves out of a desired range.

- the warning signal can be used by the control unit and / or the machine personnel to correct the error.

- monitoring the first derivative of weight gain over time provides insights into the quality of the filling process and early fault detection.

- a measurement with a radiation sensor can also be used to determine the Be Glallgutstandes.

- a radiation can be used which penetrates the bag material, but not the filling material.

- On the side facing away from the radiation emitter side of the bag radiation can only be collected by a suitable sensor when the transmitter and receiver are located above the Gregutspiegels.

- the speed with which the product level rises and the speed of the relative movement between the bag and the filling device should be matched to one another. At exactly the same speed, the distance between the mouth and Medgutapt remains constant, which may be desirable.

- This warning signal which of course can also lead manually (by the machine operator) or automatically (by a control device) to a control process, can reveal or expose a whole series of errors or failure mechanisms.

- This teaching also appears to be advantageous for non-dusty filling goods.

- the second period may overlap with the first period in which the weight gain is controlled. It may be shorter, longer, or the same as or the first, and may be before, during, or after the first one.

- volumetric weight determination means for example, that a measured or known number of screw revolutions is multiplied or otherwise mathematically linked to a known product delivery rate per revolution, so that the weight or volume of the material conveyed into the bag at one time is determined or included can be estimated with sufficient accuracy.

- the load cells can again assume the provision of measured values.

- load cells for the purposes of this document covers all suitable weight sensors such as scales and just the load cells themselves.

- load cells those weight sensors that contain electrical resistances arranged in the form of a Wheatstone bridge.

- the resistors change their ohmic resistance when deformed.

- the resistors are mounted on an element that deforms as the weight changes. Accordingly, the electrical output values of the Wheatstone bridge, which underlie the weight measurement change.

- empirical weight measurement is a measure or estimate that is only or largely due based on empirical values (eg, during a time T, a volume V of a particular filling material is filled).

- Explicit use can also be made in a fourth period of time, which can again be configured in position and duration as desired at the other time periods. This fourth period of time is advantageous at the end of the filling process.

- the filling can be carried out for the benefit of the overall process, while the outlet of the filling element is located above the filling material level.

- This phase of filling for example, can also be found at the end of the filling process and used to enable a sensitive and accurate dosing of the filling material.

- the filling is advantageously carried out with a method according to the invention, among other cement, titanium dioxide and all kinds of plastic dusts into consideration.

- the expert should understand under dusty goods bulk goods that just can not be filled on an FFS machine, unless a special filling process that often uses screws to guide the bulk material, is used.

- Devices for carrying out the method according to the invention are generally controlled and / or regulated by control devices which are loaded with stored command sequences which arrange and / or monitor the methods described above.

- These control programs are stored either on components of the control device or on other data carriers such as CDs or DVDs. It is also possible to send parts or the entirety of such programs.

- data set is used in the context of this application. This term also includes the sending of the relevant electronic information via networks, for example by e-mail.

- the closed at the lower end empty bag 11 is a horizontally displaceable transport, such as a gripper 18, passed and transported to the filling station.

- the filling station takes over a further transport 4, which consists of 3,4,5, the bag section.

- the empty bag is now opened with a suction system 16.

- the gripper 4 or be moved in the Z direction (sackeinafter).

- the connecting piece of the transport system 3 is moved into the bag and protects the sack inner surfaces from contamination by possible product adherence to the metering tube 2,21.

- the opened bag is pulled by the transport system 3,4,5 on the metering tube 2,21 until the lower end of the bag is approximately equal to the Gregutaustrittsö réelle 31.

- the bag bottom support device 32,33,34 is driven in the embodiment shown below the sack floor.

- a bag bottom support device 32, 33, 34 is not absolutely necessary. Rather, the relative movement of the bag relative to the Be Stirllorgan 2,21 mainly caused by the fact that the frame 5 along the guide 6 moves. This is represented by the double arrow 35. In this embodiment of the invention, therefore, the bag is moved relative to the Be refhapllorgan 2,21.

- the closure tube 21 is lifted and releases the product outlet opening 31.

- the product / bulk material 24 is filled in the bag. Meanwhile, the transport system 3,4,5 lowers the bag in such a way that the product outlet opening 31 is always below the filling level. However, even before the end of the metering of the product / bulk material 24, the product outlet opening 31 may be located at least once above the filling level 38.

- the closure tube 21 is lowered and closes the product outlet opening 31 by making contact with the closure 20.

- the connecting piece is pulled out of the bag.

- the gripper (s) 4 of the transport system 3, 4, 5 is or will now be moved counter to the Z direction (out of the bag) and tightens the opening area at the upper edge 25 of the previously opened bag.

- vibration generators / beaters 29 This effect of product compaction can be enhanced by the additional use of vibration generators / beaters 29. It is advantageous here to set the dosing tube 2, 21 in vibration by means of a vibration generator 29, since it is located within the product at least with parts of its lateral surface during filling. The vibrations are transmitted from the dosing 2.21 to the filling material 24, in which then takes place a compression. Another advantage of the "vibrating metering tube" 2.21 is that the formation of product adherence to the metering 2.21 is thereby largely avoided.

- the vibrator 29 could also be arranged on the "Sackêtunterstützungsvortechnisch" 34!

- a particularly advantageous embodiment of the carriage is the frame 5 together with the neck 3, transport 4 and the absorption 16 to sensors to store.

- the sensors send their signal to a weighing electronics, which ultimately controls the dosing process.

- the metering or pipe 2 In the metering or pipe 2 is a screw 7, can be promoted with the filling material 24 from the hopper 1 without much dust in the bag 8.

- the various sensors 26 (in particular weighing sensors or load cells) indicate advantageous locations for attaching such sensors.

- the conveyor belt 27 transports the filled bags (8). In the vicinity thereof, the checkweigher 30 and the vibration generator 29 are mounted.

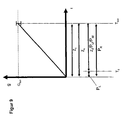

- FIGS. 3 to 5 show the time course of the bag weight in three embodiments of the invention. With respect to these figures, the terms previously used with respect to monitoring the filling rate g / t are used.

- FIGS. 7 to 9 show the same embodiments and use the terms already used above with respect to the UnterLitebe colllung with simultaneous generation of measurement signals. This distinction increases the clarity and facilitates the distinction between inventive and non-inventive filling method.

- FIG. 3 the time course of the weight increase of a bag in the execution of a bag filling process is shown.

- the bag weight g is plotted on the vertical axis and the time t on the horizontal axis.

- Interference signals are caused here mainly by the Be Schollorgan 2,21 whose Basal Bachsö réelle 31 is yes in the period Z 3 , which coincides here with the phase 1 and time Z 2 , below the Be Schollgutapts 38 is located.

- the filling element will be at the beginning of the filling above the filling material level 38, since there is still no or too little filling material in the bag 8. This circumstance is taken into account here by the fact that the time period Z 3 does not begin at time 0 but at time T 2 .

- the phase P 2 of the bag filling begins.

- this point in time will be regarded as having been attained if, on the basis of the volumetric measurement or estimation of the bag weight, it can be assumed that a certain proportion G 1 of the bag target weight G target has been reached. This percentage can be 95%.

- some parameters of the bag filling change The bag weight is actually monitored by the evaluation of the load cell signals and the filling takes place while the Be Glallorgan 2,21 is located entirely above the Gregutapt 38. This improves the quality of the weight measurements.

- the monitoring of the weight increase is carried out during the entire filling process in this embodiment.

- the filling process ends when the target weight G target is reached.

- the termination is performed automatically by the control device, not shown, when the load cells 26 report the desired signals to the control device.

- the filling rate is lower in Phase 2 than in Phase 1.

- FIG. 4 Another variant of this procedure is in FIG. 4 illustrated. It is sufficient at this point, the differences to the in FIG. 3 To be mentioned embodiment:

- the period Z 4 in which the signals of the load cells are also used to control / regulate the bag weight, lasts during the entire filling process. There is no volumetric weight control. It is advantageous if the interference signals, which arise in particular during the submillar filling (Z 3 ), are eliminated by filters on the measuring signals.

- FIG. 5 is dispensed with different phases of the filling process.

- the weight of the bag is used for weight control (period Z 4 ).

- the Submirror method filled (period Z 3 ).

- a reduction of the bag speed does not occur.

- FIG. 6 shows how the in FIG. 5 illustrated embodiment, the first derivative of the weight after the time g / t during the filling operation behaves. It is constant.

- the curly bracket S indicates the desired range. This does not necessarily have to be symmetrical about the setpoint G / T nominal .

- the target range S has a lower S U and an upper S O limit.

- the arrows 36, 37 indicate that the value g / t can leave the target range if an error occurs.

- a course of the weight change according to the arrow 36 can occur as a result of a blind crack.

- an alarm is triggered, which can trigger measures of the machine personnel and / or the control device.

- FIG. 7 shows again the same embodiment as FIG. 3 but additionally uses the terms introduced in relation to the measurement of the bag weight during the filling of the lower mirror.

- the phase P U in which the submirror process is filled is equivalent to the third time period Z 3 .

- This period is preceded here by the phase P L , in which the mouth 31 of the Be Glallorgans 2 is not below the level of contents 38, since the mouth 31 is a minimum distance AM above the bottom of the bag 39 and there is not enough good in the bag 8 to to cover the mouth 31.

- the relative velocity v R between the sack 8 and the metering device 2 is set so that it is slower than the speed v F , with which the filling material rises in the bag.

- v R can also be zero here.

- the filling material level 38 "overtakes" the mouth 31 until a desired distance A setpoint between the level of contents 38 and the mouth 31 is reached. From this point in time T 2 , the speeds v R and v F are adjusted, so that the distance A target is maintained.

- the phase P M in which the measured values are utilized in any desired form while being filled in the submirror process, thus lasts between the times T 2 and T 1 during the entire submirror filling.

- the overlap between the periods P R and P L indicates that there is still a relative velocity greater than zero in the phase P L (slowed relative movement v R between the sack 8 and the metering element 2).

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Quality & Reliability (AREA)

- Basic Packing Technique (AREA)

- Package Closures (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

- Containers And Plastic Fillers For Packaging (AREA)

Abstract

Description

Die Erfindung betrifft ein Verfahren zum Herstellen, Befüllen und Verschließen von Kunststoffsäcken mit staubigem oder auch körnigem Schüttgut sowie zum Verschließen der befüllten Säcke.The invention relates to a method for producing, filling and sealing of plastic bags with dusty or granular bulk material and for closing the filled bags.

Eine derartiges Verfahren ist beispielsweise aus der

Bei der Abfüllung staubiger Schüttgüter auf Maschinen der genannten Kategorie über Schwerkraft bzw. durch den freien Fall muss die vom Produkt verdrängte, staubige Luft aus dem Sack entweichen können. Bei dem Entweichen der Luft kommt es oft zu Kontaminationen in den oberen Randbereichen des Sackes. Bedingt durch die Kontamination mit Produktstaub kann der Sack mittels der bei dieser Art Verpackung im Allgemeinen üblichen Verschweißung nicht sicher verschlossen werden. Darüber hinaus belastet der Staub die Umwelt und muss gesondert abgesaugt werden.When filling dusty bulk materials on machines of the named category by gravity or by free fall, the dusty air displaced by the product must be able to escape from the bag. The escape of air often leads to contamination in the upper edge areas of the bag. Due to the contamination with product dust, the bag can not be securely closed by means of the welding which is generally customary in this type of packaging. In addition, the dust pollutes the environment and must be separately extracted.

Ferner führt die Abfüllung staubiger Güter nach dem beschriebenen bekannten Abfüllverfahren in der Regel zu einem deutlich überhöhten Produktvolumen bzw. zu einer deutlichen Reduzierung des Schüttgewichtes, da sich das Produkt durch den freien Fall stark mit Luft anreichert. Dieses wiederum führt dazu, dass zur Abfüllung des Produkts zunächst deutlich mehr Verpackungsmaterial gebraucht wird. Darüber hinaus muss die Luft auch wieder aus dem Sack entweichen können, da er sich sonst nicht stapeln bzw. lagern lässt.Furthermore, the filling of dusty goods according to the known filling method described usually leads to a significantly inflated product volume or to a significant reduction in bulk density, since the product accumulates heavily in the free fall with air. This, in turn, leads to bottling the product initially much more packaging material is needed. In addition, the air must be able to escape from the bag again, otherwise it can not be stacked or stored.

Da das Entweichen der Luft in der Regel sehr lange dauert, kann die Entlüftung nicht bereits vor dem Verschließen des Sackes stattfinden. Der Sack muss daher eine Perforation aufweisen. Dieses belastet zusätzlich die Umwelt, da durch die Perforation der Verpackung die feinkörnigen, staubigen Produkte zum Teil nach außen gelangen können.Since the escape of air usually takes a long time, the venting can not take place before closing the bag. The bag must therefore have a perforation. This additionally pollutes the environment, as the fine-grained, dusty products can partially escape through the perforation of the packaging.

Mit der Zeit nimmt das Volumen des Schüttgutes wieder ab. Die Sackverpackung ist nun, gemessen am verpackten Schüttgutvolumen, deutlich zu groß. Solcherart befüllte Säcke lassen sich nur schlecht auf Paletten stapeln, da sie zu instabil sind. Die

In beiden vorgenannten Druckschriften werden Dosierorgane vorgestellt, die Schnecken enthalten. Diese Schnecken fördern das Befüllgut in die Säcke. Die bevorzugte Förderrichtung in diesen Schnecken entspricht der Wirkrichtung der Schwerkraft. Durch die Schnecken unterbleibt ein freier Fall des Befüllguts in den Sack. Daher werden Schnecken oft zur Absackung von staubigen Befüllgütern verwendet. Ihre Verwendung ist jedoch - auch in Bezug auf die vorliegende Erfindung - keineswegs zwingend.In both of the aforementioned publications Dosierorgane are presented which contain screws. These screws transport the filling material into the bags. The preferred conveying direction in these screws corresponds to the effective direction of gravity. Due to the screws, there is no free fall of the filling material in the bag. Therefore, screws are often used for bagging dusty filling goods. However, their use is by no means mandatory - also in relation to the present invention.

Neben der vorgenannten mechanischen Ausgestaltung der Sackbefüllungsorgane steht bei der Konzeption von FFS-Maschinen, die insbesondere staubige Güter abfüllen, der Wiegeprozess im Zentrum des Interesses. Bei FFS-Maschinen des Standes der Technik (siehe zum Beispiel

Ein anderer Nachteil, der sich insbesondere bei der Befüllung staubiger Befüllgüter zeigt, liegt in der Begrenzung der Befüllgeschwindigkeit. Die staubigen Güter entwickeln eben zu viel Staub, wenn sie schnell abgefüllt werden. Da ein Vorverwiegen des für einen Sack gedachten Befüllgutes nicht in Frage kommt, stellt sich auch die Frage, wie überhaupt das Sackgewicht während des Befüllens geregelt werden soll.Another disadvantage, which manifests itself in particular when filling dusty filling goods, is the limitation of the filling speed. The dusty goods just develop too much dust if they are bottled quickly. Since pre-weighing of the filling material intended for a sack is not an option, the question arises as to how the sack weight should be regulated during filling.

Daher lässt sich die Aufgabenstellung der vorliegenden Erfindung folgendermaßen zusammenfassen: Es soll ein möglichst schneller Abfüllprozess bei geringer Staubentwicklung vorgeschlagen werden, bei dem das Gewicht des Sackes möglichst genau geregelt werden kann. Die Aufgabe wird durch Anspruch 1 gelöst.Therefore, the task of the present invention can be summarized as follows: It should be as fast as possible filling process proposed at low dust, in which the weight of the bag can be controlled as accurately as possible. The problem is solved by

In aller Regel wird der Befüllung des Sackes die Sackbildung - oft aus einem Schlauchstück - unmittelbar vorausgehen. Zur Bildung der Schlauchstücke kann ein Folienschlauch von einer Abwicklung abgewickelt werden.As a rule, the filling of the bag, the bag formation - often directly from a piece of tubing - immediately precede. To form the pieces of hose, a film tube can be unwound from a settlement.

Die Erfindung macht sich zunutze, dass weniger Staub entsteht, wenn die Mündung des Befüllorgans sich unterhalb der Befüllgutsaustrittsöffnung des Dosierorgans befindet. Es ist überraschend, dass sich mit Wägezellen sinnvolle Signale gewinnen lassen, während ein mechanischer Kontakt des Befüllgutes im Sack und dem Dosierorgan besteht.The invention makes use of the fact that less dust is formed when the mouth of the Befüllorgans is below the Befüllgutsaustrittsöffnung of the metering. It is surprising that meaningful signals can be obtained with load cells, while there is mechanical contact of the filling material in the bag and the metering device.

Es ist von Vorteil, diese Signale zu filtern. Hierbei hat sich gezeigt, dass das Befüllorgan vor allem höherfrequente Störsignale erzeugt, die durch eine Filterung der Signale beseitigt werden können.It is an advantage to filter these signals. In this case, it has been shown that the filling member mainly generates higher-frequency interference signals, which can be eliminated by filtering the signals.

Eine weitere Maßnahme, die Abfüllgeschwindigkeit und Messgüte steigern kann, ist eine Relativbewegung von Dosierorgan und Sack während des Befüllvorganges. Wenn diese Relativbewegung gleichförmig ist, werden Störsignale begrenzt. Dies gilt insbesondere, wenn der Sack gleichförmig bewegt wird.Another measure that can increase filling speed and quality of measurement, is a relative movement of dosing and bag during the filling process. When this relative movement is uniform, spurious signals are limited. This is especially true when the sack is moved uniformly.

Die während der Unterspiegelbefüllung gewonnenen Messwerte können vorteilhafterweise als Gewichtsmesswerte zur Kontrolle beziehungsweise Regelung des Sackgewichts während der Befüllung eingesetzt werden. Diese Definition schließt ein, dass aufgrund der Gewichtsmesswerte der Zeitpunkt, zu dem die Sackbefüllung endet, bestimmt wird. Sie schließt außerdem ein, dass eine Steuerung der Abfüllgeschwindigkeit und/oder der Geschwindigkeit der Relativbewegung zwischen Sack und Befüllorgan vorgenommen wird.The measured values obtained during the submillar filling can advantageously be used as weight measured values for checking or regulating the bag weight during filling. This definition implies that, based on the weight measurements, the time at which the bag filling ends is determined. It also includes that a control of the filling speed and / or the speed of the relative movement between the bag and Befüllorgan is made.

Die Abfüllgeschwindigkeit, das heißt die Gewichtszunahme pro Zeiteinheit oder auch die erste Ableitung des Gewichts nach der Zeit, kann dazu benutzt werden, Fehler, die bei dem Abfüllvorgang auftreten, zu erkennen. Zu solchen Fehlern kann ein Sackriss, der in der Regel zu einem schnellen Sinken der Gewichtszunahme führt, zählen. Das skizzierte Verfahren dürfte am Besten funktionieren, wenn die Steuereinheit ein Warnsignal auswirft, wenn sich die Gewichtszunahme aus einem Sollbereich heraus bewegt. Das Warnsignal kann von der Steuereinheit und/oder vom Maschinenpersonal zur Korrektur des Fehlers genutzt werden.The filling speed, that is, the weight increase per unit time or the first derivative of the weight after the time, can be used to detect errors that occur during the filling process. Such flaws can include a sack crack, which usually results in a rapid decrease in weight gain. The outlined procedure is believed to work best when the control unit emits a warning signal as the weight gain moves out of a desired range. The warning signal can be used by the control unit and / or the machine personnel to correct the error.

Auch die Überwachung der ersten Ableitung der Gewichtszunahme nach der Zeit ermöglicht Einblicke in die Güte des Abfüllverfahrens und eine frühe Fehlererkennung.Also, monitoring the first derivative of weight gain over time provides insights into the quality of the filling process and early fault detection.

Bei allen erfindungsgemäßen Verfahren und auch anderen Verfahren, die auf Maschinen durchgeführt werden, die die Relativposition zwischen Sack und Befüllorgan ändern (die Druckschriften

- der Abstand zwischen der Mündung des Befüllorgans und dem Sackboden wird auf einen Mindestabstand eingestellt,

- die Sackbefüllung beginnt, wobei Befüllgut durch die Mündung des Befüllorgans in den Sack strömt,

- der Befüllgutspiegel steigt, wobei entweder keine Steigerung des Abstandes zwischen der Mündung und dem Sackboden durch eine Relativbewegung vorgenommen wird oder diese Relativbewegung langsamer ist als die Geschwindigkeit, mit der der Füllgutpegel steigt,

- ein Beginn oder eine Steigerung der Geschwindigkeit der Relativbewegung zu einem Zeitpunkt, nachdem der Füllgutpegel über der Mündung liegt.

- the distance between the mouth of the filling device and the bottom of the bag is set to a minimum distance,

- the bag filling begins, with filling material flowing through the mouth of the filling member into the bag,

- the Befüllgutspiegel increases, either no increase in the distance between the mouth and the bag bottom is made by a relative movement or this relative movement is slower than the speed at which the Füllgutpegel increases,

- a start or an increase in the speed of the relative movement at a time after the level of contents is above the mouth.

Durch diese Maßnahmen kann vor allem die Staubbildung reduziert werden.By these measures, especially the dust formation can be reduced.

Wenn, ergänzend zu den vorstehenden Maßnahmen, der Beginn oder die Steigerung der Geschwindigkeit der Relativbewegung vorgenommen wird, nachdem der Füllgutstand über der Mündung liegt, wenn ein Sollabstand zwischen der Mündung und dem Füllgutstand erreicht ist, ist gewährleistet, dass die Mündung des Befüllorgans nicht zu weit unter dem Befüllgutstand zurückbleibt. Außerdem führt die beschleunigte Relativbewegung dazu, dass die Möglichkeit besteht, das.Gewicht des Sackes und nicht den Fülldruck des Befüllgutes, das aus der Mündung dringt, zu messen.If, in addition to the above measures, the beginning or the increase in the speed of the relative movement is made after the Füllgutstand is above the mouth, when a desired distance between the mouth and the Füllgutstand is reached, it is ensured that the mouth of the Befüllorgans not remains far below the Befüllgutstand. In addition, the accelerated relative movement leads to the possibility of measuring the weight of the bag and not the filling pressure of the filling material that comes out of the mouth.

Das Erreichen des Sollabstandes kann wieder durch eine Gewichtsmessung, d. h. durch die Auswertung von Wägezellensignalen verifiziert werden, da man sicherlich aufgrund der Kenntnis der Dichte des Befüllstoffes und dem Sackvolumen oder einfach aufgrund empirischer Werte in der Lage ist, einem Sackgewicht einen Befüllgutstand zu zuordnen. Ähnliches gilt bei der Messung der Abfüllgeschwindigkeit.The achievement of the desired distance can again by a weight measurement, d. H. be verified by the evaluation of load cell signals, since it is certainly due to the knowledge of the density of the Befüllstoffes and the bag volume or simply due to empirical values in a position to assign a Sackgewicht a Befüllgutstand. The same applies when measuring the filling speed.

Eine Messung mit einem Strahlungssensor kann jedoch auch zur Feststellung des Befüllgutstandes herangezogen werden. So kann eine Strahlung verwendet werden, die das Sackmaterial, nicht aber das Befüllgut durchdringt. Auf der dem Strahlungsemittent abgewandten Seite des Sackes kann nur dann Strahlung von einem geeigneten Sensor aufgefangen werden, wenn sich Sender und Empfänger oberhalb des Füllgutspiegels befinden.However, a measurement with a radiation sensor can also be used to determine the Befüllgutstandes. Thus, a radiation can be used which penetrates the bag material, but not the filling material. On the side facing away from the radiation emitter side of the bag radiation can only be collected by a suitable sensor when the transmitter and receiver are located above the Füllgutspiegels.

Wenn der Sollabstand zwischen Mündung des Befüllorgans und Füllgutspiegel erreicht ist, sollten die Geschwindigkeit, mit der der Füllgutspiegel steigt, und die Geschwindigkeit der Relativbewegung zwischen Sack und Befüllorgan aneinander angeglichen werden. Bei einer exakt gleichen Geschwindigkeit bleibt der Abstand zwischen Mündung und Befüllgutspiegel konstant, was erwünscht sein kann.When the nominal distance between the mouth of the filling element and the product level has been reached, the speed with which the product level rises and the speed of the relative movement between the bag and the filling device should be matched to one another. At exactly the same speed, the distance between the mouth and Füllgutspiegel remains constant, which may be desirable.

Zu der zusätzlichen Beobachtung der Gewichtszunahme des Sackes pro Zeiteinheit ist folgendes zu sagen: Liegt diese Gewichtszunahme außerhalb eines Ziel- oder Toleranzbereiches, so wird ein Warnsignal ausgegeben.For the additional observation of the weight increase of the bag per unit of time, the following can be said: If this increase in weight is outside a target or tolerance range, a warning signal is output.

Dieses Warnsignal, das natürlich auch manuell (durch den Maschinenbediener) oder automatisch (durch eine Steuereinrichtung) zu einem Regelvorgang führen kann, kann eine ganze Reihe von Fehlern oder Fehlermechanismen aufzeigen oder entlarven. Diese Lehre erscheint auch bei nicht staubigen Befüllgütern vorteilhaft anwendbar.This warning signal, which of course can also lead manually (by the machine operator) or automatically (by a control device) to a control process, can reveal or expose a whole series of errors or failure mechanisms. This teaching also appears to be advantageous for non-dusty filling goods.

Die folgende Tabelle enthält Beispiele dafür, welche Messwerte oder welcher Messwertverlauf auf welche Fehler schließen lassen:

Bei der optionalen Verwendung einer Schnecke zur Abfüllung des Befüllgutes treten unter anderem folgende Fehlercharakterisika hinzu:

Da die Kontrolle oder Regelung des Sackgewichtes während der zweiten Zeitspanne eben nicht durch eine Auswertung der Signale der Wägezellen erfolgt, ist es vorteilhaft, dieses volumetrisch oder empirisch zu ermitteln. Hierbei ist unter volumetrischer Gewichtsbestimmung beispielsweise zu verstehen, dass eine gemessene oder bekannte Zahl von Schneckenumdrehungen mit einer bekannten Füllgutförderrate pro Umdrehung multipliziert oder sonst wie mathematisch verknüpft wird, so dass das Gewicht oder das Volumen des zu einem Zeitpunkt in den Sack geförderten Materials ermittelt oder mit hinreichender Genauigkeit abgeschätzt werden kann. Am Ende einer solchen zweiten Zeitspanne mit volumetrischer Messung können die Wägezellen wieder die Bereitstellung von Messwerten übernehmen. Übrigens deckt der Begriff Wägezellen für die Zwecke dieser Druckschrift alle geeigneten Gewichtssensoren wie Waagen und eben die Wägezellen selber ab. Im Allgemeinen versteht der Fachmann unter Wägezellen solche Gewichtssensoren, die elektrische Widerstände, die in Form einer Wheatstonebrücke angeordnet sind, enthalten. Die Widerstände ändern ihren ohmschen Widerstand, wenn sie verformt werden. Die Widerstände sind auf einem Element angebracht, das sich bei einer Gewichtsänderung verformt. Dementsprechend ändern sich die elektrischen Ausgangswerte der Wheatstonebrücke, die der Gewichtsmessung zugrunde liegen.Since the control or regulation of the bag weight during the second period of time is not carried out by an evaluation of the signals of the load cells, it is advantageous to determine this volumetrically or empirically. Volumetric weight determination means, for example, that a measured or known number of screw revolutions is multiplied or otherwise mathematically linked to a known product delivery rate per revolution, so that the weight or volume of the material conveyed into the bag at one time is determined or included can be estimated with sufficient accuracy. At the end of such a second period of time with volumetric measurement, the load cells can again assume the provision of measured values. Incidentally, the term load cells for the purposes of this document covers all suitable weight sensors such as scales and just the load cells themselves. Generally, those skilled in the art will understand as load cells those weight sensors that contain electrical resistances arranged in the form of a Wheatstone bridge. The resistors change their ohmic resistance when deformed. The resistors are mounted on an element that deforms as the weight changes. Accordingly, the electrical output values of the Wheatstone bridge, which underlie the weight measurement change.

Im Vergleich zu der volumetrischen Gewichtsmessung ist eine empirische Gewichtsmessung eine Messung oder Abschätzung, die nur oder größtenteils auf empirischen Werten beruht (z. B. während einer Zeit T wird ein Volumen V eines bestimmten Befüllmaterials abgefüllt).Compared to volumetric weight measurement, empirical weight measurement is a measure or estimate that is only or largely due based on empirical values (eg, during a time T, a volume V of a particular filling material is filled).

Es ist vorteilhaft, wenn die Mündung des Befüllorgans während einer dritten Zeitspanne unterhalb des Befüllgutspiegels liegt. In der Regel wird dies ganz zu Beginn des Befüllprozesses (leerer Sack) nicht der Fall sein können. Tests haben jedoch gezeigt, dass diese Maßnahme (die Unterspiegelbefüllung) die Nebelbildung beim Befüllen des Sackes zurückführt. Eine Überschneidung zwischen zweiter (keine Gewichtsregelung nach Wägezellensignalen) und dritter Zeitspanne (Unterspiegelbefüllung) ist vorteilhaft. Die Relativbewegung von Befüllorgan und Befüllgut ist geeignet, bei der Unterspiegelbefüllung die Gewichtsmessung zu stören. Diese Störungen unterbleiben jedoch in einer zweiten Zeitspanne nach der obigen Definition, da während einer solchen Zeitspanne die Gewichtsmessung eben nicht zur Gewichtskontrolle oder -regelung herangezogen wird. Eine Alternative zu dieser Maßnahme ist die Ausblendung der Störsignale durch einen geeigneten Filter. Es hat sich gezeigt, dass die Störsignale, die von dem Befüllorgan erzeugt werden, relativ hochfrequent sind, so dass diese Maßnahme vorteilhaft ist.It is advantageous if the mouth of the Befüllorgans is below the Füllgutgutspiegels during a third period of time. As a rule, this will not be the case at the beginning of the filling process (empty bag). However, tests have shown that this measure (the sub-level filling), the mist formation during filling of the bag leads back. An overlap between the second (no weight control according to load cell signals) and the third time span (bottom mirror filling) is advantageous. The relative movement of Befüllorgan and Befüllgut is suitable to interfere with the Unterspiegelbefüllung the weight measurement. However, these disturbances cease for a second period of time as defined above, because during such a period the weight measurement is not used for weight control. An alternative to this measure is the suppression of interference by a suitable filter. It has been found that the interference signals generated by the Befüllorgan are relatively high frequency, so that this measure is advantageous.

Eine explizite Nutzung auch kann in einer vierten Zeitspanne, die wieder in Lage und Dauer beliebig zu den anderen Zeitspannen gestaltet sein kann, vorgenommen werden. Vorteilhaft ist diese vierte Zeitspanne am Ende des Befüllprozesses.Explicit use can also be made in a fourth period of time, which can again be configured in position and duration as desired at the other time periods. This fourth period of time is advantageous at the end of the filling process.

In einer fünften Zeitspanne, die wieder in Lage und Dauer beliebig zu den anderen Zeitspannen gestaltet sein kann, kann zum Vorteil des Gesamtprozesses die Befüllung vorgenommen werden, während sich der Ausgang des Befüllorgans oberhalb des Befüllgutspiegels befindet. Diese Phase der Befüllung kann zum Beispiel ebenfalls am Ende des Befüllprozesses stehen und dazu genutzt werden, eine feinfühlige und genaue Dosierung des Befüllgutes zu ermöglichen.In a fifth period of time, which can again be designed as desired in position and duration at the other time intervals, the filling can be carried out for the benefit of the overall process, while the outlet of the filling element is located above the filling material level. This phase of filling, for example, can also be found at the end of the filling process and used to enable a sensitive and accurate dosing of the filling material.

Als staubige Güter, deren Abfüllung vorteilhafterweise mit einem erfindungsgemäßen Verfahren vorgenommen wird, kommen unter anderem Zement, Titandioxid und alle möglichen Kunststoffstäube in Betracht. Allgemein dürfte der Fachmann unter staubigen Gütern Schüttgüter verstehen, die sich an einer FFS-Maschine eben nicht abfüllen lassen, wenn nicht ein spezielles Abfüllverfahren, das sich oft Schnecken zur Führung des Schüttgutes bedient, verwendet wird.As dusty goods, the filling is advantageously carried out with a method according to the invention, among other cement, titanium dioxide and all kinds of plastic dusts into consideration. In general, the expert should understand under dusty goods bulk goods that just can not be filled on an FFS machine, unless a special filling process that often uses screws to guide the bulk material, is used.

Vorrichtungen zur Durchführung des erfindungsgemässen Verfahrens werden in der Regel von Steuervorrichtungen gesteuert und/oder geregelt, die mit gespeicherten Befehlsfolgen, die die vorstehend beschriebenen Verfahren anordnen und/oder überwachen, beaufschlagt sind. Diese Steuerprogramme sind entweder auf Bestandteilen der Steuervorrichtung oder auf anderen Datenträgern wie CDs oder DVDs gespeichert. Auch eine Versendung von Teilen oder der Gesamtheit solcher Programme erscheint möglich. Für alle vorstehend genannten und bekannten Möglichkeiten oder Medien, Daten und Befehlsfolgen zu speichern und/oder zu transportieren, wird im Rahmen dieser Anmeldung der Begriff "Datenset" gebraucht. Dieser Begriff umschließt auch die Versendung der betreffenden elektronisierten Informationen über Netzwerke, zum Beispiel per E-Mail.Devices for carrying out the method according to the invention are generally controlled and / or regulated by control devices which are loaded with stored command sequences which arrange and / or monitor the methods described above. These control programs are stored either on components of the control device or on other data carriers such as CDs or DVDs. It is also possible to send parts or the entirety of such programs. For all of the abovementioned and known possibilities or media to store and / or transport data and command sequences, the term "data set" is used in the context of this application. This term also includes the sending of the relevant electronic information via networks, for example by e-mail.

Weitere Ausführungsbeispiele der Erfindung gehen aus der gegenständlichen Beschreibung und den Ansprüchen hervor.Further embodiments of the invention will become apparent from the description and the claims.

Die einzelnen Figuren zeigen:

- Fig. 1

- Seitenansicht einer FFS-Maschine

- Fig. 2

Detailansicht von Figur 1 - Fig. 3

- den Verlauf des Sackgewichtes, gegen die Zeit aufgetragen (1. Ausführungsbeispiel)

- Fig. 4

- den Verlauf des Sackgewichtes, gegen die Zeit aufgetragen (2. Ausführungsbeispiel)

- Fig. 5

- den Verlauf des Sackgewichtes, gegen die Zeit aufgetragen (3. Ausführungsbeispiel)

- Fig. 6

- der Verlauf der Sackgewichtszunahme, gegen die Zeit aufgetragen (3. Ausführungsbeispiel)

- Fig. 7

- den Verlauf des Sackgewichtes, gegen die Zeit aufgetragen (1. Ausführungsbeispiel, Nomenklatur in Bezug auf die Unterspiegelbefüllung)

- Fig. 8

- den Verlauf des Sackgewichtes, gegen die Zeit aufgetragen (2. Ausführungsbeispiel, Nomenklatur in Bezug auf die Unterspiegelbefüllung)

- Fig. 9

- den Verlauf des Sackgewichtes, gegen die Zeit aufgetragen (3. Ausführungsbeispiel, Nomenklatur in Bezug auf die Unterspiegelbefüllung)

- Fig. 1

- Side view of a FFS machine

- Fig. 2

- Detail view of

FIG. 1 - Fig. 3

- the course of the bag weight, plotted against time (1st embodiment)

- Fig. 4

- the course of the bag weight, plotted against time (2nd embodiment)

- Fig. 5

- the course of the bag weight, plotted against time (3rd embodiment)

- Fig. 6

- the course of the bag weight increase, plotted against time (3rd embodiment)

- Fig. 7

- the course of the bag weight, plotted against time (1st embodiment, nomenclature with respect to the Unterspiegelbefüllung)

- Fig. 8

- the course of the bag weight, plotted against time (2nd embodiment, nomenclature with respect to the Unterspiegelbefüllung)

- Fig. 9

- the course of the bag weight, plotted against time (3. Exemplary embodiment, nomenclature with respect to the lower mirror filling)

Eine Schlauchfolienbahn 15, vorzugsweise mit eingelegten Seitenfalten, wird zunächst von einem Vorzugrollensystem 9 in ein horizontal bewegliches Transportmittel, beispielsweise ein Greiferpaar 18 gefördert.A

Die Folienbahn 15 wird, nachdem der Vorzug den Abschnitt entsprechend der gewünschten Sacklänge vorgezogen hat, vom Messer 17 durchgeschnitten. Gleichzeitig erfolgt die Bodenschweißung 13. Der am unteren Ende verschlossene Leersack 11 wird einem horizontal verschieblichen Transportmittel, beispielsweise einem Greifer 18, übergeben und zur Füllstation transportiert.The

In der Füllstation übernimmt ein weiteres Transportmittel 4, welches aus 3,4,5 besteht, den Sackabschnitt. Der Leersack wird nun mit einem Saugersystem 16 geöffnet. Dazu wird der bzw. werden die Greifer 4 in Z-Richtung (sackeinwärts) bewegt. Der Anschlussstutzen des Transportsystems 3 wird in den Sack bewegt und schützt die Sackinnenflächen vor der Verschmutzung durch eventuelle Produktanhaftungen am Dosierrohr 2,21.In the filling station takes over a

Der geöffnete Sack wird vom Transportsystem 3,4,5 über das Dosierrohr 2,21 gezogen, bis sich das untere Ende des Sackes ungefähr in Höhe der Füllgutaustrittsöffnung 31 befindet. Die Sackbodenunterstützungseinrichtung 32,33,34 wird bei dem gezeigten Ausführungsbeispiel unter den Sackboden gefahren. Eine Sackbodenunterstützungseinrichtung 32,33,34 ist jedoch nicht unbedingt erforderlich. Vielmehr wird die Relativbewegung des Sackes gegenüber dem Befüllorgan 2,21 hauptsächlich dadurch hervorgerufen, dass der Rahmen 5 entlang der Führung 6 fährt. Dies wird durch den Doppelpfeil 35 dargestellt. Bei diesem Ausführungsbeispiel der Erfindung wird also der Sack gegenüber dem Befüllorgan 2,21 bewegt. Denkbar ist es natürlich auch, die Relativbewegung zwischen Sack 8 und Dosierorgan 2 durch eine Bewegung des Dosierorgans 2 oder gar durch eine Bewegung von Sack 8 und Dosierorgan 2 herbeizuführen. In der Regel ist es hierbei ausreichend, wenn der Sack hierbei durch greiferartige Transportmittel 4 an seinem oberen Ende gehalten wird. Die erwähnte Sackbodenunterstützungseinrichtung 32,33,34 bietet optionalen, zusätzlichen Schutz vor einem Riss des gerade geschweißten Sackbodens.The opened bag is pulled by the

Das Verschlussrohr 21 wird angehoben und gibt die Produktaustrittsöffnung 31 frei. Das Produkt/Schüttgut 24 wird in den Sack gefüllt. Währenddessen senkt das Transportsystem 3,4,5 den Sack in der Weise ab, dass sich die Produktaustrittsöffnung 31 jederzeit unterhalb des Füllspiegels befindet. Noch vor dem Ende der Dosierung des Produktes/Schüttguts 24 kann sich die Produktaustrittsöffnung 31 jedoch zumindest einmal oberhalb des Füllspiegels 38 befinden. Nach Ende der Befüllung wird das Verschlussrohr 21 abgesenkt und verschließt die Produktaustrittsöffnung 31, indem sie Kontakt mit dem Verschluss 20 aufnimmt. Der Anschlussstutzen wird aus dem Sack gezogen. Der bzw. die Greifer 4 des Transportsystems 3,4,5 wird bzw. werden nun entgegen der Z-Richtung (sackauswärts) bewegt und zieht den Öffnungsbereich am oberen Rand 25 des zuvor geöffneten Sacks stramm. Ein weiteres Transportmittel übernimmt den befüllten Sack 8. Mittels der Verschließeinrichtung 14 wird nun der obere Rand des Sacks 25 verschlossen. Zusammen mit dem Dosiervorgang kann bei Bedarf durch den im Verschlussrohr 21 integrierten Filter abgesaugt werden. Das erforderliche Vakuum wird über den Stutzen 23 eingeleitet. Die Integration des Filters in das Verschlussrohr erlaubt eine sehr kompakte Bauform, die es ermöglicht, auch relativ kleine Säcke abzufüllen. Das Absaugen der Luft führt gewissermaßen zu einer Verdichtung des Schüttguts. Hierdurch kann eine der Produktmenge angemessene Sackgröße gewählt werden.The

Dieser Effekt der Produktverdichtung kann durch den zusätzlichen Einsatz von Vibrationserzeugern/ Klopfern 29 noch verstärkt werden. Hier ist es vorteilhaft, das Dosierrohr 2,21 mittels eines Vibrationserzeugers 29 in Schwingung zu versetzen, da es sich während der Befüllung zumindest mit Teilen seiner Mantelfläche innerhalb des Produktes befindet. Die Schwingungen werden vom Dosierrohr 2,21 an das Befüllgut 24 übertragen, in dem dann eine Verdichtung stattfindet. Ein weiterer Vorteil des "vibrierenden Dosierrohrs" 2,21 ist, dass die Bildung von Produktanhaftungen am Dosierrohr 2,21 dadurch weitgehend vermieden wird. Der Rüttler 29 könnte auch an der "Sackbodenunterstützungsvorrichtung" 34 angeordnet sein!This effect of product compaction can be enhanced by the additional use of vibration generators /

Eine besonders vorteilhafte Ausführung des Verfahrschlittens ist es, den Rahmen 5 mitsamt Stutzen 3, Transportmittel 4 sowie der Aufsaugung 16 auf Sensoren zu lagern. Die Sensoren senden ihr Signal an eine Wägeelektronik, welche letztendlich den Dosiervorgang steuert.A particularly advantageous embodiment of the carriage is the

Zu erwähnen ist noch die Führung bzw. Stütze 6, die den Rahmen 5 und damit die Transportmittel 4 trägt. In dem Dosierorgan beziehungsweise Rohr 2 befindet sich eine Schnecke 7, mit der Befüllmaterial 24 aus dem Trichter 1 ohne große Staubbildung in den Sack 8 gefördert werden kann. Die verschiedenen Sensoren 26 (v. a. Wägesensoren beziehungsweise Wägezellen) deuten vorteilhafte Orte zum Anbringen solcher Sensoren an. Das Transportband 27 transportiert die befüllten Säcke (8). In der Umgebung desselben sind die Kontrollwaage 30 und der Vibrationserzeuger 29 angebracht.To mention is still the guide or

Die

Die in

In

Mit dem Erreichen des Zeitpunktes T1 beginnt die Phase P2 der Sackbefüllung. In der Regel wird man bei diesem Ausführungsbeispiel diesen Zeitpunkt als erreicht ansehen, wenn man aufgrund der volumetrischen Messung oder Abschätzung des Sackgewichtes davon ausgehen kann, dass ein bestimmter Anteil G1 des Sacksollgewichtes GSoll erreicht ist. Dieser Anteil kann 95 % sein. Im vorliegenden Ausführungsbeispiel (nach

Eine andere Variante dieses Verfahrens wird in

Die Zeitspanne Z4, in der die Signale der Wägezellen auch zur Kontrolle/Regelung des Sackgewichts genutzt werden, dauert während des gesamten Befüllvorgangs an. Es findet keine volumetrische Gewichtskontrolle statt. Es ist vorteilhaft, wenn die Störsignale, die insbesondere während der Unterspiegelbefüllung (Z3) entstehen, durch Filter auf den Messsignalen beseitigt werden.The period Z 4 , in which the signals of the load cells are also used to control / regulate the bag weight, lasts during the entire filling process. There is no volumetric weight control. It is advantageous if the interference signals, which arise in particular during the submillar filling (Z 3 ), are eliminated by filters on the measuring signals.

In

In

Allgemein haben Tests gezeigt, dass noch weitere technische Merkmale in allen erfindungsgemäßen Vorrichtungen und/oder Verfahren vorteilhaft einsetzbar sind:

- a) Das Sollgewicht GSoll sollte erreicht werden, während die Relativbewegung zwischen

Sack 8und Dosierorgan 2 noch andauert. Wie bereits mehrfach ausgeführt kann diese Relativbewegung durch eine Bewegung eines oder beider dieser beiden Elemente 2, 8 herbeigeführt werden. Es ist auch möglich, dass die Relativbewegung bereits unmittelbar nach dem Zeitpunkt verlangsamt oder beendet wird, an dem das letzte wirklich noch verwertete Messsignal der Wägezellen zustande kommt. Dieses kann vor dem Erreichen des Sollgewichtes sein, und die Zeitspanne zwischen diesem letzten Messsignal und dem Abbruch der Sackbefüllung bei Erreichen des Sollgewichts GSoll kann aus der Kenntnis der Abfüllgeschwindigkeit allein durch Zeitmesssung und Berechnung gewonnen werden. Alternativ kommt wieder eine kurze volumetrische Messphase Z2 in Betracht. Wichtig ist, dass gerade die wichtigen letzten Messwerte der Wägezellen nicht durch das Abbrechen der Bewegung, die ja positive oder negative Beschleunigungen hervorruft, verfälscht werden. Schließlich ist die Gewichtsmessung nach der Formel F=gm eine Kraftmessung und die Kraft ist mit der Beschleunigung über das Grundgesetz der Mechanik F=ma verknüpft. Trotz dieser Ausführung erscheint es möglich, insbesondere bei einer Überspiegelbefüllung, auch oben eine Relativbewegung gut zu messen. - b) Die

Relativbewegung zwischen Sack 8und Dosierorgan 2 sollte während der Befüllung gleichförmig sein. Alternativ ist es auch möglich, wenn zu Beginn des Befüllprozesses eine Beschleunigungsphase stattfindet. Wichtig ist, dass die Relativbewegung gleichförmig ist, während die Wägezellensignale zur Gewichtskontrolle ausgewertet werden (Zeitspanne Z4). Bei gleichförmigen Bewegungen treten eben keine Beschleunigungen des teilweise befüllten Sackes 8 auf, die die Gewichtsmessung verfälschen würden. Eine Alternative zu dieser Vorgehensweise besteht darin, die Relativgeschwindigkeit aufzuzeichnen, etwaige Beschleunigungen zu ermitteln und die durch diese Beschleunigungen entstehenden Fehler gemäß der Formel F=ma aus dem Messwert herauszurechnen. Hierzu sollte auch das augenblickliche Gewicht des Sackes bekannt sein.

- a) The target weight G target should be achieved while the relative movement between the

bag 8 andmetering 2 is still ongoing. As already stated several times, this relative movement can be brought about by a movement of one or both of these twoelements - b) The relative movement between

bag 8 andmetering 2 should be uniform during filling. Alternatively, it is also possible if an acceleration phase takes place at the beginning of the filling process. Importantly, the relative motion is uniform while the load cell signals are evaluated for weight control (time Z4). With uniform movements just no accelerations of the partially filledbag 8 occur, which would distort the weight measurement. An alternative to this procedure is to record the relative speed, to determine any accelerations and to calculate the errors resulting from these accelerations according to the formula F = ma from the measured value. For this purpose, the instantaneous weight of the bag should be known.

Wie erwähnt wird in der Phase PU im Unterspiegelverfahren befüllt. Wie bereits zu

In

Claims (10)

- Method for producing a bag, filling the latter with pulverulent or granular contents and closing said bag, in which at least the following measures occur:- a bag (8) is filled using a filling element (2),- there is relative movement between the filling element and the bag while the bag is being filled,- parts of the filling element (2) at least occasionally dip below the contents level (38) during a first phase (PU) while the bag is being filled,- the outlet opening of the filling element is at least occasionally above the contents level (38) during the phase (P2),- the load cells (26) providing measurement signals at least during a second phase (PM) which comprises at least parts of the first phase (PU),- and these signals being used by the control device to control and/or regulate the filling operation,characterized in that

the filling speed of the contents is lower in the phase (P2) than in the phase (PU) - Method according to Claim 1,

characterized in that

the control apparatus filters the signals provided by the load cells (26), in particular during the second phase (PM). - Method according to Claim 2,

characterized in that

higher frequency signals are removed during filtering. - Method according to one of the preceding claims, characterized in that

a relative movement (vR) takes place between the bag (8) and the metering element (2) at least during a third period of time (PR) which comprises at least parts of the second period of time (PM). - Method according to the preceding claim, characterized in that

the relative movement (vR) is at least occasionally a uniform movement. - Method according to one of the preceding claims, characterized in that

the control device uses the measured values from the load cells (26) at least in one of the following ways or only in one of the following ways:- as measured values for monitoring or regulating the weight (g),- as measured values of the weight gain (g/t) for detecting an error in the filling process,- as a first derivative of the weight gain after the time (g/t2). - Method according to one of the preceding claims, characterized in that

the control device controls the relative movement between the bag (8) and the metering element (2) and the filling operation as follows:- the distance between the mouth (31) of the filling element (2) and the bottom (39) of the bag is set to a minimum distance (AM),- the bag filling operation begins, contents flowing into the bag (8) through the mouth (31) of the filling element (2),- the contents level rises, either the distance between the mouth (31) and the bottom (39) of the bag not being increased by a relative movement or this relative movement being slower than the speed (vF) at which the contents level (38) rises,- the relative movement begins or the speed (vR) of the relative movement is increased at a point in time after the contents level (38) is above the mouth (31). - Method according to the preceding claim, characterized in that the relative movement begins or the speed (vR) of the relative movement is increased after the contents level (38) is above the mouth (31) if a desired distance (ASoll) between the mouth (31) and the contents level (38) has been reached.

- Method according to the preceding claim, characterized in that the reaching of the desired distance (ASoll) is verified using one of the following methods:- a weight measurement (g) by evaluating load cell signals,- a measurement of the filling speed (g/t),- a measurement using an optical sensor,- a volumetric measurement.

- Method according to one of the three preceding claims,

characterized in that

the speed (vR) of the relative movement and the speed (vF) at which the contents level (38) rises are matched to one another.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102007014892A DE102007014892A1 (en) | 2007-03-26 | 2007-03-26 | Sack filling process on a form, fill and seal machine |

| PCT/EP2008/002429 WO2008116653A1 (en) | 2007-03-26 | 2008-03-21 | Bag filling method on a forming, filling and sealing machine |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2139773A1 EP2139773A1 (en) | 2010-01-06 |

| EP2139773B1 true EP2139773B1 (en) | 2010-07-21 |

Family

ID=39590666

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08734811A Not-in-force EP2139773B1 (en) | 2007-03-26 | 2008-03-21 | Bag filling method on a forming, filling and sealing machine |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP2139773B1 (en) |

| AT (1) | ATE474774T1 (en) |

| DE (2) | DE102007014892A1 (en) |

| ES (1) | ES2348992T3 (en) |

| WO (1) | WO2008116653A1 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5336412B2 (en) * | 2010-04-01 | 2013-11-06 | 東洋自動機株式会社 | Package filling apparatus and filling method in bag filling and packaging machine |

| CN102390552B (en) * | 2011-07-26 | 2013-02-20 | 广州市锐嘉包装设备有限公司 | Regular particle material combination quantitative filling machine |

| CN108528833A (en) * | 2018-04-27 | 2018-09-14 | 丁涛 | Accurately control the drug granule packing machine and method of discharge quantity |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB579529A (en) * | 1943-06-18 | 1946-08-07 | Quaker Oats Co | Improvements in or relating to the packaging of materials |

| DE9301355U1 (en) | 1992-10-26 | 1993-11-25 | Windmöller & Hölscher, 49525 Lengerich | Device for filling and closing bags open on one side |

| DE4447051C2 (en) * | 1994-12-29 | 2002-07-04 | Rovema Gmbh | Process for dispensing bulk goods in portions |

| DE19920478C2 (en) | 1999-05-04 | 2001-05-03 | Windmoeller & Hoelscher | Device for producing and preferably also for filling and closing bags made of thermoplastic material |

| ES2251901T3 (en) | 2000-10-24 | 2006-05-16 | WINDMOLLER & HOLSCHER | DEVICE FOR MANUFACTURING AND, PREFERIBLY, ALSO TO FILL AND CLOSE SACKS OF THERMOPLASTIC SYNTHETIC MATERIAL. |

| ITMI20030519A1 (en) | 2003-03-18 | 2004-09-19 | Concetti Spa | EQUIPMENT FOR FILLING BAGS WITH MATERIAL |

| WO2006002876A2 (en) * | 2004-06-30 | 2006-01-12 | Haver & Boecker Ohg | Filling plant |

| DE102004038323B4 (en) * | 2004-08-06 | 2006-10-26 | Khs Ag | Method for the lower layer filling of bottles or similar containers and filling machine for carrying out the method |

| DE102005037916B4 (en) | 2004-11-11 | 2018-08-02 | Windmöller & Hölscher Kg | Machine for forming, filling and closing sacks and method of operating same |

-

2007

- 2007-03-26 DE DE102007014892A patent/DE102007014892A1/en not_active Ceased

-

2008

- 2008-03-21 ES ES08734811T patent/ES2348992T3/en active Active

- 2008-03-21 EP EP08734811A patent/EP2139773B1/en not_active Not-in-force

- 2008-03-21 WO PCT/EP2008/002429 patent/WO2008116653A1/en active Application Filing

- 2008-03-21 DE DE502008000997T patent/DE502008000997D1/en active Active

- 2008-03-21 AT AT08734811T patent/ATE474774T1/en active

Also Published As

| Publication number | Publication date |

|---|---|

| DE102007014892A1 (en) | 2008-10-02 |

| ATE474774T1 (en) | 2010-08-15 |

| ES2348992T3 (en) | 2010-12-21 |

| EP2139773A1 (en) | 2010-01-06 |

| WO2008116653A1 (en) | 2008-10-02 |

| DE502008000997D1 (en) | 2010-09-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1819596B1 (en) | Machine for forming, filling and closing bags with a bag lifting device | |

| EP2785594B1 (en) | Packaging machine and method for filling pouches | |

| EP2006203B1 (en) | Packing machine and delivery device for a packing machine | |

| EP2621814B1 (en) | Apparatus and method for dosing a bulk good | |

| DE69031542T2 (en) | Device for measuring the draw resistance of filter cigarettes | |

| EP2707286B1 (en) | Packing machine and method for filling open sacks | |

| WO2008151978A1 (en) | Method and device for packaging polycrystalline bulk silicon | |

| EP1975073B1 (en) | Machine for filling and closing sacks | |

| EP2139772B1 (en) | Weighing method for a forming, filling and sealing machine | |

| EP2139773B1 (en) | Bag filling method on a forming, filling and sealing machine | |

| EP2896571B1 (en) | Metering device and method for metering | |

| EP3477037A1 (en) | Device and method for filling a spacing frame or distance frame | |

| AT508312B1 (en) | FORM FAULT DETECTION | |

| EP0273254B1 (en) | Method and device for pouring bulk material, especially coffee | |

| WO2008138689A1 (en) | Tubular bag machine and method for testing a tubular bag seam | |

| DE102011075431A1 (en) | Method for optimizing the conveyance of a packaging material web in the region of a tube forming device of a tubular bag machine | |

| WO2022128371A1 (en) | Method for operating a bagging machine | |

| DE102021129545A1 (en) | Test procedure for suction unit and suction unit for carrying out the procedure | |

| WO2022253504A2 (en) | Method for operating a tubular-bag machine | |

| DE4215089A1 (en) | Rotary filling machine with scales for valve sacks - has sack breaker to destroy underweight sacks and return contents for refilling | |

| EP3531089A1 (en) | Method for testing a system consisting of a conveyor belt for the transport of bulk materials and a belt weigher allocated to the conveyor belt |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20091026 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 502008000997 Country of ref document: DE Date of ref document: 20100902 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Effective date: 20101209 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20100721 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20101021 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20101121 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20101021 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20101022 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 |

|

| 26N | No opposition filed |

Effective date: 20110426 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502008000997 Country of ref document: DE Effective date: 20110426 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110331 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20111130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120321 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120331 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120321 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110321 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100721 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 474774 Country of ref document: AT Kind code of ref document: T Effective date: 20130321 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130321 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160321 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160321 |

|

| PGRI | Patent reinstated in contracting state [announced from national office to epo] |

Ref country code: IT Effective date: 20170710 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20190321 Year of fee payment: 12 Ref country code: DE Payment date: 20190331 Year of fee payment: 12 |

|