EP2020977B1 - Bed with a pivoting device - Google Patents

Bed with a pivoting device Download PDFInfo

- Publication number

- EP2020977B1 EP2020977B1 EP07724956.3A EP07724956A EP2020977B1 EP 2020977 B1 EP2020977 B1 EP 2020977B1 EP 07724956 A EP07724956 A EP 07724956A EP 2020977 B1 EP2020977 B1 EP 2020977B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pivoting device

- bed

- sections

- gear

- frame

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C20/00—Head -, foot -, or like rests for beds, sofas or the like

- A47C20/04—Head -, foot -, or like rests for beds, sofas or the like with adjustable inclination

- A47C20/041—Head -, foot -, or like rests for beds, sofas or the like with adjustable inclination by electric motors

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C20/00—Head -, foot -, or like rests for beds, sofas or the like

- A47C20/04—Head -, foot -, or like rests for beds, sofas or the like with adjustable inclination

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C20/00—Head -, foot -, or like rests for beds, sofas or the like

- A47C20/08—Head -, foot -, or like rests for beds, sofas or the like with means for adjusting two or more rests simultaneously

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C27/00—Spring, stuffed or fluid mattresses or cushions specially adapted for chairs, beds or sofas

- A47C27/04—Spring, stuffed or fluid mattresses or cushions specially adapted for chairs, beds or sofas with spring inlays

- A47C27/045—Attachment of spring inlays to coverings; Use of stiffening sheets, lattices or grids in, on, or under spring inlays

- A47C27/0453—Attachment of spring inlays to outer layers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G7/00—Beds specially adapted for nursing; Devices for lifting patients or disabled persons

- A61G7/002—Beds specially adapted for nursing; Devices for lifting patients or disabled persons having adjustable mattress frame

- A61G7/015—Beds specially adapted for nursing; Devices for lifting patients or disabled persons having adjustable mattress frame divided into different adjustable sections, e.g. for Gatch position

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G7/00—Beds specially adapted for nursing; Devices for lifting patients or disabled persons

- A61G7/002—Beds specially adapted for nursing; Devices for lifting patients or disabled persons having adjustable mattress frame

- A61G7/018—Control or drive mechanisms

Definitions

- the invention relates to a bed, in particular hospital and / or nursing bed.

- a cushioning element or the like beds known from the prior art have a support structure, which provides a support surface for the mattress, the upholstery element or the like.

- a support structure may for example be formed by a mesh grid, a slatted frame or the like.

- slatted frames have proven to be a support structure for receiving a mattress, a cushion element or the like in everyday practice. They usually consist of a frame that carries the slats of the slatted base, which may be formed, for example, as a resilient slats made of plastic, wood or the like.

- bed frames In order to open the user of a bed the ability to adjust a desired sitting and / or lying position individually, bed frames are known from the prior art, which consist of individual relative to each other pivotally arranged sections. In general, these sections of a pivotally formed slatted frame of a Support frame worn (see eg WO 2004/107923 A1 ).

- adjustable trained slatted frame typically has a recorded from a support frame center or seat part. At this middle part, a head end is pivotally arranged at one end, which can be pivoted relative to the central part. At the other end, the middle part carries pivotably thereto a foot part, so that the slatted frame consists of a total of three sections. From the prior art, it is also known to subdivide the foot part in turn, two subsections which are arranged pivotable relative to each other. According to this embodiment, the slatted frame then consists of a total of four sections.

- the invention is therefore an object of the invention to provide a bed with a pivoting device, which requires a comparatively small installation space at the same time safe operation.

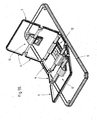

- Fig. 1 shows in a schematic perspective view of the support structure 2 of a bed 1.

- the support structure 2 is formed in the form of a slatted frame and provides a support surface 3, which serves to receive a mattress, a cushion element or the like.

- support structure 2 may be adjustable in height carried by a support frame, not shown, which in turn is on support rollers.

- the support structure 2 is itself formed as a slatted frame and has relatively mutually pivotally arranged sections 4, which are supported by a support frame 9.

- each subsection 4 consists of a frame 5.

- Each frame 5 in turn consists of frame parts 6, which are connected to one another by means of connectors 7.

- the slats 8 of the slatted frame are supported, the slats. 8 may be formed for example of wood, plastic or the like.

- the support frame 9 of the support structure 2 also consists of frame parts 10, which are interconnected by means of corresponding connector 11.

- both the frame parts 6 of the frame 5 and the frame parts 10 of the support frame 9 may be formed of aluminum, for example in the form of Aluminiumstrangpreß turnover.

- the frame parts 6 and 10 interconnecting connectors 7 and 11 are also made of aluminum. Likewise, it is possible to form the connectors 7 and 11, respectively, from plastic.

- the middle portion 4 that is, with respect to the leaf level Fig. 1 second section 4 from the left is fixedly connected to the holding frame 9.

- the front side of this section 4 is flanged on both sides of a closer to be described pivoting device 12 according to the invention.

- a second section 4 which can also be referred to as the head section.

- the serving as a head portion section 4 and serving as the middle section portion 4 are formed by means of the interposed pivoting device 12 relative to each other pivotable.

- each left side arranged portion 4 are arranged relative to this pivotally.

- Fig. 2 shows the support structure Fig. 1 in a schematic side view. Also from this representation, the individual sections 4 can be seen, which are formed relative to each other thanks to the respectively between two adjacent sections 4 respectively intermediate pivoting device 12.

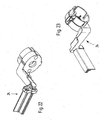

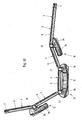

- a pivoting device 12 each have a drive device 13, which - as already on the basis of FIGS. 1 and 2 explained-frontally between two adjacent sections 4 is arranged.

- the drive means 13 comprises a motor 14 and a gear 15.

- the motor 14 and the gear 15 of the drive means 13 are housed in a housing 16, which is preferably formed in two parts and consists of plastic.

- a shaft 17 is flanged on the output side, according to the embodiment shown Fig. 3 is formed of two half-axes 18 and 19.

- the transmission 15 is arranged substantially centrally between the two half-axes 18 and 19.

- the half axles 18 and 19 each have a fastening flange 21 on one end, which serves to couple one of the two adjacent sections 4 with the pivoting device 12.

- the mounting flanges 21 are preferably formed as webs which can be inserted into the hollow frame parts 6 of a frame 5 of a section 4 and fastened there.

- the drive device 13 is how Fig. 3 further can be seen connected to a fixed support member 22.

- This support element 22 is formed from two sections 23, wherein the drive means 13 is arranged substantially centrally between the two sections 23.

- the subsections 23 preferably each form a housing 20, in which the respectively associated semiaxes 18 and 19 are arranged rotatably mounted.

- the subsections 23 each have an attachment flange 24 on one end, by means of which the swiveling device 12 can be arranged on a second subsection.

- the approach flanges 24 are preferably formed as web-shaped holder, which is inserted to arrange a portion 4 of the pivoting device 12 in the hollow frame parts of the associated frame 5 of the section 4 and can be fixed there.

- the pivoting device 12 serves to connect two sections 4 relatively pivotable with each other.

- the attachment flanges 21 serve to arrange the first section 4, whereas the attachment flanges 24 are provided for the arrangement of the second section 4.

- the mounting flanges 21 pivot relative to the shoulder flanges 24, whereby the portion 4 supported by the mounting flanges 21 is pivoted relative to the portion 4 carried by the shoulder flanges 24.

- the pivoting device 12 as in Fig. 3 is shown, is arranged frontally between two adjacent faces 4, as from the FIGS. 1 and 2 seen. In this way, a particularly space-saving design of the entire bed construction is achieved. In addition, there is no need for additional linkage, as these are known from the prior art.

- the pivoting device 12 is designed splash-proof.

- An operation of the drive device 13 is preferably carried out by means of a remote control, which may be cable-based or radio-based.

- a remote control which may be cable-based or radio-based.

- FIGS. 4, to 20 a first embodiment

- FIGS. 21 to 36 a second embodiment

- FIGS. 37 to 43 a third embodiment

- the Fig. 44 a fourth embodiment

- the Fig. 45 a fifth embodiment

- the FIGS. 46 to 50 a sixth embodiment

- the FIGS. 51 to 60 relate to a further embodiment.

- Identical reference numbers identify identical and / or similar parts and / or elements.

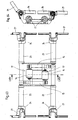

- Fig. 4 shows in a first embodiment, a drive device 13, which has a motor 14 and a transmission 15. Both the engine 14 and the transmission 15 are each housed in a housing.

- FIG. 5 A partially sectioned side view of the drive device 13 according to Fig. 4 along the section line VV to Fig. 4 , shows Fig. 5 , It is off Fig. 5 in particular, to recognize the structure of the transmission 15.

- FIG. 4 A perspective view of the drive device 13 according to Fig. 4 shows Fig. 6 , A side view of the drive device 13 after Fig. 4 , in the viewing direction with respect to the plane of the drawing Fig. 4 from the left is in Fig. 7 shown.

- Fig. 8 shows the drive device 13 in a detailed view Fig. 5 , wherein in particular the structure of the transmission 15 can be seen.

- the transmission 15 is a four-stage gear transmission.

- the transmission 15 comprises a ring gear 25 on the one hand and gear wheels 26 in engagement therewith on the other hand.

- the gears 26 form the transmission stages in a conventional manner.

- the ring gear 25 and the gears 26 are disposed within a transmission housing 27.

- a shaft 17 is provided which communicates with the gears 26 in a force-transmitting manner.

- the gear geometry of the transmission 15 is designed so that all gear stages have the same internal toothing.

- the ring gear 25 receives all components and serves as a housing.

- the geometry of the first three gear stages is identical.

- the sun gear profile is made by punching or lasering in the disk.

- the shaft is supported by means of an encapsulated rolling bearing 28 due to the following advantages: Low cost and small footprint; no axial forces and / or shear forces; extremely low output speed and the shaft 17 is additionally supported by the planetary gears.

- Fig. 9 shows in a perspective view the transmission 15 after Fig. 8 , In particular, the individual toothed wheels 26 as well as the toothed wheels separating from each other face plates 29 can be seen here.

- the ring gear 25 and an exemplary face plate 29 are shown in detail in the FIGS. 10, 11, 12 and 13 shown.

- FIG. 8 further reveals the gear 15 is closed by means of a motor 30 side cap 30.

- This cap 30 is in a detailed view in the FIGS. 14, 15 and 16 shown.

- Fig. 17 shows the to the transmission 15 after Fig. 8 flanged engine 14. It can be seen off Fig. 17 In particular, the formation of the motor-side pinion 31st

- FIGS. 18, 19 and 20 each show in a different view a planetary carrier 32, wherein the FIGS. 18 to 20 the planet carrier 32 of the last stage of the transmission 15 after Fig. 8 represent.

- Fig. 21 shows in exploded view a second embodiment of the invention, which differs from the embodiment according to the FIGS. 4 to 20 characterized in that a toothed belt is used as means for transmitting engine power.

- the timing belt itself is in Fig. 21 not shown.

- FIGS. 22, 23 . 24 and 25 shown.

- the with respect to the plane of the drawing Fig. 21 left mounting flange 21 is in a detailed view in the FIGS. 26, 27 and 28 played.

- connection part 33 For coupling the mounting flanges 21 to the respective associated half-axes 18 and 19 of the shaft 17 is used in the embodiment according to Fig. 21 a connection part 33, which in a detailed representation in the FIGS. 29, 30 . 31 and 32 is reproduced.

- the connecting part 33 consists of a pin-shaped extension 34 and a head 35.

- the head 35 carries circumferentially extending in the longitudinal direction ribs 36 which engage in the assembled state in a corresponding toothing of the respective associated mounting flanges 21, in particular Fig. 21 can be seen.

- a toothed belt gear 26, as in the embodiment according to Fig. 21 can be used as an example, is in the FIGS. 33, 34 . 35 and 36 shown.

- a third embodiment of the pivoting device 12 according to the invention show the FIGS. 37 to 43 .

- a motor 14 and a gear 15 are arranged in a housing 16, wherein the force deflection takes place on the shaft 17 by means of a gear arrangement 37.

- This gear assembly 37 is in a detailed view in Fig. 43 shown again.

- the gear assembly 37 consists of two gears 26, the front side engage with each other.

- FIG. 44 Another embodiment of the gear arrangement 37 shows Fig. 44 , which relates to a fourth embodiment of the invention.

- three bevel gears act together, each half axle 18 and 19 each end carries a bevel gear 38, which engage two bevel gears in a flanged on the gear 15 bevel gear 38.

- Fig. 45 shows a further embodiment of a gear arrangement 37 according to a fifth embodiment of the invention.

- a four-bar linkage in the form of a parallelogram is used for power transmission.

- a sixth embodiment of the invention is in the FIGS. 46 to 50 shown.

- the peculiarity of this embodiment results in particular from the compact design of the accommodated in the housing 16 drive means 13, in particular Fig. 50 recognize.

- the advantage of this embodiment is, in particular, that the drive device 13 with respect to the drawing plane after Fig. 50 down very little, which makes it possible in particular to use the pivoting device 12 according to the invention also for low-density beds.

- a spring 39 is provided which serves to provide a base load. The provision of such a spring allows advantageously, the entire drive means 13, that is, both the motor 14 and the gear 15 interpreted comparatively small dimensioned.

- the pivoting device according to the invention not only via a motor, but two motors, for example in the form of a double motor, has, which is especially in over-normal beds advantageous to provide the required adjustment can.

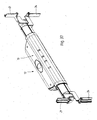

- FIGS. 51 to 60 Another embodiment is in the FIGS. 51 to 60 shown.

- a support structure 2 is also provided according to this embodiment, which consists of individual sections 4.

- the support structure 2 is supported by a holding frame 9 in the manner already described.

- the peculiarity of the embodiment according to the FIGS. 51 to 60 consists in the five relative to each other pivotally arranged sections 4, wherein three sections 4 are coupled to each other via a common pivoting device 12.

- the support structure 2 has a central portion 4, which is arranged in the final assembled state by means of two connecting rails 40 on the support frame 9, fixed, which means that the central portion 4 is not relative to the support frame 9 is pivotable.

- the middle section 4 sibling sections 4 are movable relative to the middle section 4.

- the to the movable sections 4 with respect to the plane of the drawing 51 On the right side or left side sibling sections 4 are in turn arranged to be movable to the movable sections 4. Due to this movable arrangement of the Subsections 4 resulting adjustment of the support structure 2, that is, the individual sections 4 relative to each other results, for example, from the FIGS. 55 . 56 and 58 to 60 , where the representation after Fig. 60 only the support structure 2, that does not show the support structure receiving the Auflagerkonstrutation in the final assembled state.

- FIGS. 61 to 68 show an embodiment of the invention, according to which at least with respect to a pivoting device 12, a double motor is used.

- a pivoting device 12 for which a double motor can be used, for example, the pivoting device 12 of a central portion 4, as exemplified in 51 shown.

- the pivoting device 12 has two motors 14. Each motor 14 is connected to an associated gear 15th flanged, which in turn is force-transmitting with an associated shaft 17 in conjunction.

- gear 15th flanged For power transmission between the transmission 15 on the one hand and shaft 17 on the other hand serves as a Gelenkkhebel 45th

- FIGS. 65 and 66 or 67 and 68 show a shoulder flange 24 and a mounting flange 21, respectively.

- the approach flange 24 has a connecting portion 42 which is placed in the final assembled state on the portion 23 of a support member 22, in particular Fig. 61 recognize.

- the approach flange 24 further has an angle part 43. This engages in the final assembled state in a hollow frame part 6 of a section 4, as already explained above.

- the mounting flange 21 has an angle portion 44, as from the FIGS. 67 and 68 seen.

Landscapes

- Health & Medical Sciences (AREA)

- Nursing (AREA)

- General Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Invalid Beds And Related Equipment (AREA)

- Chairs For Special Purposes, Such As Reclining Chairs (AREA)

Description

Die Erfindung betrifft ein Bett, insbesondere Krank - und/oder Pflegebett.The invention relates to a bed, in particular hospital and / or nursing bed.

Betten als solche sind aus dem Stand der Technik hinlänglich bekannt, weshalb es eines gesonderten druckschriftlichen Nachweises an dieser Stelle nicht bedarf.Beds as such are well known in the art, so there is no need for a separate documentary evidence at this point.

Zur bestimmungsgemäßen Aufnahme einer Matratze, eines Polsterelements oder dergleichen verfügen aus dem Stand der Technik bekannte Betten über eine Auflagerkonstruktion, die eine Auflagerfläche für die Matratze, das Polsterelement oder dergleichen bereitstellt. Eine solche Auflagerkonstruktion kann beispielsweise durch ein Netzgitter, einen Lattenrost oder dergleichen gebildet sein. Insbesondere Lattenroste haben sich als Auflagerkonstruktion zur Aufnahme einer Matratze, eines Polsterelements oder dergleichen im alltäglichen Praxiseinsatz bewährt. Sie bestehen in aller Regel aus einem Rahmen, der die Latten des Lattenrostes trägt, welche beispielsweise als federelastische Latten aus Kunststoff, Holz oder dergleichen gebildet sein können.For proper recording of a mattress, a cushioning element or the like beds known from the prior art have a support structure, which provides a support surface for the mattress, the upholstery element or the like. Such a support structure may for example be formed by a mesh grid, a slatted frame or the like. In particular slatted frames have proven to be a support structure for receiving a mattress, a cushion element or the like in everyday practice. They usually consist of a frame that carries the slats of the slatted base, which may be formed, for example, as a resilient slats made of plastic, wood or the like.

Um dem Verwender eines Bettes die Möglichkeit zu eröffnen, eine gewünschte Sitz- und/oder Liegeposition individuell einstellen zu können, sind aus dem Stand der Technik Lattenroste bekannt geworden, die aus einzelnen relativ zueinander verschwenkbar angeordneten Teilabschnitten bestehen. In der Regel werden diese Teilabschnitte eines verschwenkbar ausgebildeten Lattenrostes von einem Halterahmen getragen (siehe z.B.

Ein aus dem Stand der Technik bekannter, verstellbar ausgebildeter Lattenrost verfügt typischerweise über ein von einem Halterahmen aufgenommenes Mittel- oder Gesäßteil. An diesem Mittelteil ist einendseitig gelenkig ein Kopfteil angeordnet, welches relativ zum Mittelteil verschwenkt werden kann. Anderendseitig trägt das Mittelteil verschwenkbar hieran angeordnet ein Fußteil, so daß der Lattenrost aus insgesamt drei Teilabschnitten besteht. Aus dem Stand der Technik ist es ferner bekannt, das Fußteil in wiederum zwei Teilabschnitte zu untergliedern, die relativ zueinander verschwenkbar angeordnet sind. Gemäß dieser Ausgestaltungsform besteht der Lattenrost dann aus insgesamt vier Teilabschnitten.A known from the prior art, adjustable trained slatted frame typically has a recorded from a support frame center or seat part. At this middle part, a head end is pivotally arranged at one end, which can be pivoted relative to the central part. At the other end, the middle part carries pivotably thereto a foot part, so that the slatted frame consists of a total of three sections. From the prior art, it is also known to subdivide the foot part in turn, two subsections which are arranged pivotable relative to each other. According to this embodiment, the slatted frame then consists of a total of four sections.

Aus dem Stand der Technik ist es bekannt, die relativ zueinander verschwenkbar angeordneten Teilabschnitte eines Lattenrosts elektromotorisch relativ zueinander zu verschwenken. Zu diesem Zweck verfügen aus dem Stand der Technik vorbekannte Betten über unterhalb der Auflagerkonstruktion, das heißt des Lattenrosts angeordnete Elektromotoren, die vorzugsweise mittels kabelgestützter Fernsteuerung betätigbar sind. Die einzelnen Teilabschnitte der Auflagerkonstruktion, das heißt des Lattenrostes sind über entsprechende und unterhalb der Teilabschnitte angeordnete Gelenkgestänge mit den Elektromotoren gekoppelt, so daß bei einem Betrieb der Elektromotoren die Teilabschnitte mittels der dafür vorgesehenen Gelenkgestänge in ihrer relativen Lage zueinander wunschgemäß verschwenkt werden können.From the prior art it is known, the pivotally arranged relative to each other sections of a slatted frame to pivot by electric motor relative to each other. For this purpose, known from the prior art beds on below the support structure, that is, the slatted frame arranged electric motors, which are preferably actuated by means of cable-based remote control. The individual sections of the support structure, that is, the slatted base are coupled via corresponding and below the sections arranged linkage with the electric motors, so that during operation of the electric motors, the sections can be pivoted by means of the dedicated linkage in their relative position to each other as desired.

Die vorbeschriebene Konstruktion hat sich im alltäglichen Praxiseinsatz zwar bewährt, doch sie ist nicht frei von Nachteilen. So benötigen die unterhalb der Teilabschnitte angeordneten Elektromotoren und Gelenkgestänge in nachteiliger Weise einen gewissen Einbauraum, so daß die gesamte Bettkonstruktion in Höhenrichtung insgesamt ausladend groß ausfällt, was insbesondere dem Wunsch nach Niedrigbetten, die einen vereinfachten Einstieg ins Bett ermöglichen, entgegensteht. Ferner stellen die Gelenkgestänge ein gewisses Verletzungs- und damit Sicherheitsrisiko dar, weil Gegenstände und nicht zuletzt auch Gliedmaßen bei einer Verfahrbewegung zwischen den beweglichen Teilen eines Gelenkgestänges eingeklemmt werden können. Im übrigen sind die vorbekannten Konstruktionen nicht zuletzt optisch vergleichsweise unansehnlich, weil insbesondere im verschwenkten Zustand einiger Teilabschnitte die jeweils darunter angeordneten Gelenkgestänge für einen Betrachter optisch frei zugänglich sind.The construction described above has proven itself in everyday practice, but it is not free of disadvantages. Thus, the arranged below the sections electric motors and linkage disadvantageously require a certain installation space, so that the entire bed construction in height altogether expansively large fails, which in particular the desire for low beds, which allow a simplified entry into bed. Furthermore, the joint linkage is a certain risk of injury and thus safety, because objects and not least limbs can be trapped in a movement between the moving parts of a linkage. Moreover, the previously known constructions are visually comparatively unsightly, not least because, in particular in the pivoted state of some subsections, the respective articulated rods arranged underneath are visually freely accessible to a viewer.

Ausgehend vom Vorbeschriebenen liegt der Erfindung deshalb die Aufgabe zugrunde, ein Bett einer mit Verschwenkeinrichtung zu schaffen, die bei einem gleichzeitig sicheren Betrieb einen vergleichsweise geringen Einbauraum benötigt.Based on the above, the invention is therefore an object of the invention to provide a bed with a pivoting device, which requires a comparatively small installation space at the same time safe operation.

Zur Lösung dieser Aufgabe wird mit der Erfindung vorgeschlagen ein Bett mit einer Verschwenkeinrichtung entsprechend dem kennzeichnenden Teil des Patentanspruches 1 ausgebildet. Vorteilhafte Ausführungen und Weiterbildungen der Erfindung sind in den weiteren Ansprüchen umfasst.To solve this problem, a bed with a pivoting device according to the characterizing part of

Weitere Merkmale und Vorteile der Erfindung ergeben sich aus der Beschreibung anhand der nachfolgenden Fign. Dabei zeigen:

- Fig. 1

- in schematisch perspektivischer Darstellung ausschnittsweise ein Bett;

- Fig. 2

- die Darstellung nach

Fig. 1 in einer schematischen Seitenansicht; - Fig. 3

- in einer schematisch perspektivischen Darstellung die Verschwenkeinrichtung nach der Erfindung;

- Fign. 4 bis 20

- in zum Teil schematischer Darstellung eine erste Ausführungsform der erfindungsgemäßen Verschwenkeinrichtung;

- Fign. 21 bis 36

- in zum Teil schematischer Darstellung eine zweite Ausführungsform der erfindungsgemäßen Verschwenkeinrichtung;

- Fign. 37 bis 43

- in zum Teil schematischer Darstellung eine dritte Ausführungsform der erfindungsgemäßen Verschwenkeinrichtung;

- Fig. 44

- in schematischer Darstellung eine vierte Ausführungsform der erfindungsgemäßen Verschwenkeinrichtung;

- Fig. 45

- in schematischer Darstellung eine fünfte Ausführungsform der erfindungsgemäßen Verschwenkeinrichtung;

- Fign. 46 bis 50

- in zum Teil schematischer Darstellung eine sechste Ausführungsform der erfindungsgemäßen Verschwenkeinrichtung;

- Fign. 51 bis 60

- in zum Teil schematischer Darstellung eine weitere Ausführungsform der erfindungsgemäßen Verschwenkeinrichtung und

- Fign. 61 bis 68

- in zum Teil schematischer Darstellung eine Ausführungsform der Erfindung mit einem Doppelmotor.

- Fig. 1

- in a schematic perspective view a detail of a bed;

- Fig. 2

- the representation after

Fig. 1 in a schematic side view; - Fig. 3

- in a schematic perspective view of the pivoting device according to the invention;

- FIGS. 4 to 20

- in a partially schematic representation of a first embodiment of the pivoting device according to the invention;

- FIGS. 21 to 36

- in partly schematic representation of a second Embodiment of the pivoting device according to the invention;

- FIGS. 37 to 43

- in a partially schematic representation of a third embodiment of the pivoting device according to the invention;

- Fig. 44

- a schematic representation of a fourth embodiment of the pivoting device according to the invention;

- Fig. 45

- a schematic representation of a fifth embodiment of the pivoting device according to the invention;

- FIGS. 46 to 50

- in a partially schematic representation of a sixth embodiment of the pivoting device according to the invention;

- FIGS. 51 to 60

- in partly schematic representation of a further embodiment of the pivoting device according to the invention and

- FIGS. 61 to 68

- in a partially schematic representation of an embodiment of the invention with a double motor.

Die in

Der Halterahmen 9 der Auflagerkonstruktion 2 besteht gleichfalls aus Rahmenteilen 10, die mittels entsprechender Verbinder 11 miteinander verbunden sind. Dabei können sowohl die Rahmenteile 6 der Rahmen 5 als auch die Rahmenteile 10 des Halterahmens 9 aus Aluminium gebildet sein, beispielsweise in Form von Aluminiumstrangpreßteilen. Die die Rahmenteile 6 bzw. 10 miteinander verbindenden Verbinder 7 bzw. 11 bestehen gleichfalls aus Aluminium. Desgleichen ist es möglich, die Verbinder 7 bzw. 11 aus Kunststoff zu bilden.The

Der mittlere Teilabschnitt 4, das heißt der mit Bezug auf die Blattebene nach

An den als mittleren Abschnitt zu bezeichnenden Teilabschnitt 4 schließen sich mit Bezug auf die Zeichnungsebene nach

Die zwischen jeweils zwei Teilabschnitten 4 angeordnete Verschwenkeinrichtung 12 ist schematisch in

Wie

An das Getriebe 15 ist kraftausgangsseitig eine Welle 17 angeflanscht, die im gezeigten Ausführungsbeispiel nach

Die Halbachsen 18 und 19 tragen jeweils einendseitig einen Befestigungsflansch 21, der dazu dient, den einen der beiden benachbarten Teilabschnitte 4 mit der Verschwenkeinrichtung 12 zu koppeln. Dabei sind die Befestigungsflansche 21 bevorzugterweise als Stege ausgebildet, die in die hohl ausgebildeten Rahmenteile 6 eines Rahmens 5 eines Teilabschnittes 4 eingeschoben und dort befestigt werden können.The half axles 18 and 19 each have a

Die Antriebseinrichtung 13 ist, wie

Die Teilabschnitte 23 bilden bevorzugterweise jeweils ein Gehäuse 20 aus, in welchen die jeweils zugehörigen Halbachsen 18 bzw. 19 drehbar gelagert angeordnet sind.The

Die Teilabschnitte 23 tragen einendseitig jeweils einen Ansatzflansch 24, mittels welcher die Verschwenkeinrichtung 12 an einem zweiten Teilabschnitt angeordnet werden kann. Wie auch die Befestigungsflansche 21 sind die Ansatzflansche 24 bevorzugterweise als stegförmige Halter ausgebildet, die zur Anordnung eines Teilabschnittes 4 an der Verschwenkeinrichtung 12 in die hohl ausgebildeten Rahmenteile des zugehörigen Rahmens 5 des Teilabschnittes 4 eingeschoben und dort befestigt werden können.The

Die Verschwenkeinrichtung 12 dient dazu, zwei Teilabschnitte 4 relativ verschwenkbar miteinander zu verbinden. Dabei dienen die Befestigungsflansche 21 zur Anordnung des ersten Teilabschnitts 4, wohingegen die Ansatzflansche 24 zur Anordnung des zweiten Teilabschnitts 4 vorgesehen sind. Bei einer Betätigung der Verschwenkeinrichtung verschwenken die Befestigungsflansche 21 relativ gegenüber den Ansatzflanschen 24, wodurch der von den Befestigungsflanschen 21 getragene Teilabschnitt 4 relativ gegenüber dem von den Ansatzflanschen 24 getragenen Teilabschnitt 4 verschwenkt wird.The pivoting

Die Verschwenkeinrichtung 12, wie sie in

Dank der gekapselten Ausgestaltung der Verschwenkeinrichtung 12 ist diese spritzwassergeschützt ausgebildet. Eine Bedienung der Antriebseinrichtung 13 erfolgt vorzugsweise mittels einer Fernbedienung, die kabelgestützt oder funkbasiert ausgebildet sein kann. Bevorzugterweise ist einer der beiden Teilabschnitte 4, die über eine gemeinsame Verschwenkeinrichtung 12 miteinander gekoppelt sind, längsverschieblich zur Verschwenkeinrichtung 12 angeordnet, so daß mit Bezug auf die von den Teilabschnitten 4 bereitgestellte Auflagerfläche 3 eine Längenänderung möglich ist, so daß eine infolge einer Verschwenkbewegung auftretende Längenänderung der von der Auflagerfläche 3 aufgenommenen Matratze kompensiert werden kann.Thanks to the encapsulated embodiment of the pivoting

Mit den vorstehend erläuterten

Eine teilgeschnittene Seitenansicht der Antriebseinrichtung 13 nach

Eine perspektivische Darstellung der Antriebseinrichtung 13 nach

Bei dem Getriebe 15 nach der ersten Ausführungsform gemäß

Das Hohlrad 25 sowie die Zahnräder 26 sind innerhalb eines Getriebegehäuses 27 angeordnet. Kraftausgangsseitig ist eine Welle 17 vorgesehen, die mit den Zahnrädern 26 kraftübertragend in Verbindung steht.The

Die Verzahnungsgeometrie des Getriebes 15 ist so ausgelegt, daß alle Getriebestufen die gleiche Innenverzahnung besitzen. Das Hohlrad 25 nimmt alle Bauteile auf und dient als Gehäuse. Die Geometrie der ersten drei Getriebestufen ist identisch.The gear geometry of the

Bei dem Getriebe 15 nach

Das Hohlrad 25 sowie eine exemplarisch dargestellte Planscheibe 29 sind im Detail in den

Wie

Die

Aus

Zur Ankopplung der Befestigungsflansche 21 an die jeweils zugehörigen Halbachsen 18 bzw. 19 der Welle 17 dient in der Ausgestaltungsform nach

Eine dritte Ausführungsform der erfindungsgemäßen Verschwenkeinrichtung 12 zeigen die

Wie insbesondere der Darstellung nach

Eine andere Ausgestaltung der Zahnradanordnung 37 zeigt

Eine sechste Ausführungsform der Erfindung ist in den

Die vorstehenden Ausführungen sind lediglich beispielhaft und insofern nicht beschränkend zu verstehen. So kann beispielsweise vorgesehen sein, daß die erfindungsgemäße Verschwenkeinrichtung nicht nur über einen Motor, sondern über zwei Motoren, beispielsweise in Form eines Doppelmotors, verfügt, was insbesondere bei übernormal breiten Betten von Vorteil ist, um die benötigte Verstellkraft bereitstellen zu können.The above statements are merely exemplary and not limiting in this respect. Thus, for example, be provided that the pivoting device according to the invention not only via a motor, but two motors, for example in the form of a double motor, has, which is especially in over-normal beds advantageous to provide the required adjustment can.

Eine weitere Ausführungsform ist in den

Wie die Darstellung nach

Die Besonderheit der Ausführungsform nach den

Wie insbesondere die Darstellung nach den

Mit Bezug auf die Zeichnungsebene nach

Insbesondere aus den Abbildungen nach den

Aus den

Die

Wie insbesondere die

Die

Wie anhand der

Claims (7)

- A bed (1), in particular a sick bed and/or care bed, comprising a bearing construction (2) providing a bearing surface (3) for a mattress, an upholstered element or the like, wherein the bearing construction (2) is formed by sections (4) which are pivoting with respect to each other, wherein one pivoting device (12) is respectively arranged between two adjacent sections (4),

characterized in

that the pivoting device (12) comprises an electronic drive device (13), which drive device (13), for its part, comprises a motor (14) and a gear (15), that the pivoting device (12) comprises a shaft (17) that is flange-mounted on the gear (15) of the drive device (13), which shaft (17) is formed by two half-axes (18, 19), wherein the half-axes (18, 19) are each located in a housing (20), and that the pivoting device (12) comprises a supporting element (22) composed of two sections (23), wherein the two sections (23) are each formed by the housing (20) receiving the respective half-axis (18, 19). - A bed (1) according to claim 1, characterized in that the half-axes (18, 19) respectively carry a fastening flange (21) at one end, wherein the fastening flanges (21) serve to mount a first section (4) on the pivoting device (12).

- A bed (1) according to claim 2, characterized in that the sections (22) respectively carry a connecting flange (24) at one end, wherein the connecting flanges (24) serve to mount a second section (4) on the pivoting device (12).

- A bed (1) according to claim 1, characterized in that each section (4) is formed by a frame (5), which frame (5) is composed of hollow frame parts (6).

- A bed (1) according one of the preceding claims 1 through 4, characterized in that the fastening flanges (21) and the connecting flanges (24) are designed as web-shaped retainers which are inserted into the hollow frame parts (6) of the associated frame (5) of the section (4) and are fastened there for mounting a section (4) on the pivoting device (12).

- A bed (1) according to claim 1, characterized in that one of the sections (4) connected to the pivoting device (12) is arranged on the pivoting device (12) such that it can be relatively displaced into a transverse direction with respect to the longitudinal extension of the half-axes (18, 19) of the pivoting device (12).

- A bed (1) according to claim 1, characterized in that the drive device (13) comprises a housing (16) which receives the motor (14) and the gear (15).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200620008523 DE202006008523U1 (en) | 2006-05-26 | 2006-05-26 | Pivoting device for seat or bed, especially hospital or care bed, has electric motor drive arrangement between two adjacent sub-sections of seat or bed providing a supporting structure for mattress, upholstery element or similar |

| DE202006018156U DE202006018156U1 (en) | 2006-05-26 | 2006-11-28 | Pivoting device for pivoting a support surface of a mattress for a chair or bed comprises an electromotive drive unit arranged on the front side between neighboring partial sections |

| PCT/EP2007/004032 WO2007137678A1 (en) | 2006-05-26 | 2007-05-08 | Pivoting device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2020977A1 EP2020977A1 (en) | 2009-02-11 |

| EP2020977B1 true EP2020977B1 (en) | 2014-11-12 |

Family

ID=37833120

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07724956.3A Not-in-force EP2020977B1 (en) | 2006-05-26 | 2007-05-08 | Bed with a pivoting device |

Country Status (14)

| Country | Link |

|---|---|

| US (1) | US8312579B2 (en) |

| EP (1) | EP2020977B1 (en) |

| JP (1) | JP2009538163A (en) |

| KR (1) | KR101309941B1 (en) |

| CN (1) | CN101489515B (en) |

| AU (1) | AU2007267476B2 (en) |

| BR (1) | BRPI0712480A2 (en) |

| CA (1) | CA2653353C (en) |

| DE (1) | DE202006018156U1 (en) |

| MX (1) | MX2008015052A (en) |

| NO (1) | NO20085048L (en) |

| NZ (1) | NZ573364A (en) |

| RU (1) | RU2443405C2 (en) |

| WO (1) | WO2007137678A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202022103498U1 (en) | 2022-06-23 | 2023-10-10 | Hermann Bock Gmbh | Bed with a lifting device |

Families Citing this family (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20150059094A1 (en) | 2005-02-22 | 2015-03-05 | Roger P. Jackson | Patient positioning support structure |

| US9295433B2 (en) | 2005-02-22 | 2016-03-29 | Roger P. Jackson | Synchronized patient elevation and positioning apparatus for use with patient positioning support systems |

| US7565708B2 (en) | 2005-02-22 | 2009-07-28 | Jackson Roger P | Patient positioning support structure |

| US7739762B2 (en) | 2007-10-22 | 2010-06-22 | Mizuho Orthopedic Systems, Inc. | Surgery table apparatus |

| US9744087B2 (en) | 2005-02-22 | 2017-08-29 | Roger P. Jackson | Patient support apparatus with body slide position digitally coordinated with hinge angle |

| US9186291B2 (en) | 2005-02-22 | 2015-11-17 | Roger P. Jackson | Patient positioning support structure with trunk translator |

| US10869798B2 (en) | 2006-05-05 | 2020-12-22 | Warsaw Orthopedic, Inc. | Patient positioning support apparatus with virtual pivot-shift pelvic pads, upper body stabilization and fail-safe table attachment mechanism |

| DE202008008191U1 (en) | 2008-06-18 | 2008-09-18 | Bock, Klaus | drive system |

| DE202008016896U1 (en) | 2008-12-19 | 2009-03-05 | Spiroplex Gmbh | Couch surface facility for a bed |

| DE102008064096B4 (en) | 2008-12-19 | 2010-09-02 | Klaus Bock | Couch surface facility for a bed |

| JP5493742B2 (en) * | 2009-11-12 | 2014-05-14 | アイシン精機株式会社 | Movable sleeper |

| US8640284B2 (en) * | 2011-03-17 | 2014-02-04 | Jaume Casteras Farre | Articulated and/or jointed bed |

| DE202011100577U1 (en) * | 2011-05-12 | 2012-08-13 | Grass Gmbh | Furniture fitting for a movable furniture part and furniture |

| WO2013058806A1 (en) | 2011-10-17 | 2013-04-25 | Jackson Roger P | Patient positioning support structure |

| US9561145B2 (en) | 2012-02-07 | 2017-02-07 | Roger P. Jackson | Fail-safe release mechanism for use with patient positioning support apparati |

| CN102824254B (en) * | 2012-09-14 | 2014-05-14 | 天津科技大学 | Auxiliary nursing moving and taking device |

| US12011399B2 (en) | 2013-08-28 | 2024-06-18 | Warsaw Orthopedic, Inc. | Patient positioning support apparatus with fail-safe connector attachment mechanism |

| US9549863B2 (en) | 2014-07-07 | 2017-01-24 | Roger P. Jackson | Surgical table with pivoting and translating hinge |

| US9402775B2 (en) | 2014-07-07 | 2016-08-02 | Roger P. Jackson | Single and dual column patient positioning and support structure |

| CN206079823U (en) * | 2015-11-06 | 2017-04-12 | 上海信弘家具用品有限公司 | Electric bed mattress |

| US10506884B2 (en) * | 2016-02-24 | 2019-12-17 | Dreamwell, Ltd. | Adjustable foundation |

| US10813807B2 (en) * | 2016-06-29 | 2020-10-27 | Stryker Corporation | Patient support systems with hollow rotary actuators |

| US10864128B2 (en) | 2016-06-29 | 2020-12-15 | Stryker Corporation | Patient support systems with rotary actuators having cycloidal drives |

| US10765575B2 (en) | 2016-06-29 | 2020-09-08 | Stryker Corporation | Patient support systems with rotary actuators comprising rotation limiting devices |

| CN107928911A (en) * | 2017-12-05 | 2018-04-20 | 张艳艳 | A kind of multifunctional medicinal bed |

| CN112770706B (en) * | 2018-09-17 | 2022-08-19 | 艾尔高莫申公司 | Light-weight self-contained hinge assembly for bed frame mounting |

| CN109368542A (en) * | 2018-12-12 | 2019-02-22 | 常州工学院 | A kind of automatic controlling apparatus for height and method |

| WO2021245641A1 (en) * | 2020-06-03 | 2021-12-09 | Polyron Zikim Ach Ltd | Adjustable mattress frame and a method for adjusting the frame |

| TWI803397B (en) * | 2022-07-21 | 2023-05-21 | 施權航 | electric bed |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0408636A4 (en) | 1988-03-23 | 1992-01-02 | Robert Ferrand | Patient support system |

| US5063623A (en) * | 1990-10-15 | 1991-11-12 | Bathrick Leeland M | Power module for an ariculated bed |

| JPH0555937U (en) | 1992-01-06 | 1993-07-27 | 株式会社タカラユニオン | Backrest undulation device |

| FR2724882B1 (en) * | 1994-09-23 | 1997-01-10 | Faure Bertrand Equipements Sa | TUBULAR FRAME FOR AUTOMOBILE SEAT |

| US5711577A (en) * | 1995-12-01 | 1998-01-27 | Fisher Dynamics Corporation | Pivot assembly for a structured vehicle seat |

| US5926877A (en) * | 1997-10-23 | 1999-07-27 | Lin; Joe | Adjustable supporting table |

| DE29802384U1 (en) | 1998-02-12 | 1998-04-09 | Recticel Internationale Bettsysteme GmbH, 59439 Holzwickede | Seating / reclining furniture, especially slatted frame, with adjustable elements |

| US6058532A (en) * | 1998-03-30 | 2000-05-09 | Allen; Newton P. | Apparatus for elevating one end portion of a bed frame |

| RU2265764C2 (en) * | 1999-07-12 | 2005-12-10 | Лук Ламеллен Унд Купплюнгсбау Бетайлигунгс Кг | Driving gear |

| DK1217922T3 (en) | 1999-09-02 | 2004-11-01 | Linak As | Turning actuator, especially for adjustable furniture, including beds and bed bases |

| RU2200448C2 (en) * | 2000-12-14 | 2003-03-20 | Общество с ограниченной ответственностью "Арсен" | Transformable upholstered seating and lying furniture and rotary device for transformable upholstered furniture back |

| GB0100981D0 (en) | 2001-01-13 | 2001-02-28 | Smiths Group Plc | Surgical tables |

| DE20308887U1 (en) * | 2003-06-05 | 2004-10-07 | Cimosys Ag | Motorised adjustable support device for mattress has drive motor in driving connection through recess in side wall of first beam with parts of drive means mounted inside first beam |

| US7395568B2 (en) | 2003-09-12 | 2008-07-08 | Dreamwell, Ltd. | Self-contained articulated mattress |

| RU2261695C2 (en) * | 2003-09-22 | 2005-10-10 | Царёв Илья Львович | Functional bed |

| US6893092B1 (en) * | 2003-11-20 | 2005-05-17 | Fisher Dynamics Corporation | Inertia increasing vehicle seat adjustment mechanism |

| DE202004018913U1 (en) | 2004-04-01 | 2005-08-11 | Cimosys Ag | Modular power-operated furniture framework for support of seat upholstery has two parallel rails for sliding carriages hinged to longitudinal frame members carrying pockets for ends of slats |

| US7118171B2 (en) * | 2004-05-05 | 2006-10-10 | Lear Corporation | Seat assembly with folding head restraint and method for folding same |

-

2006

- 2006-11-28 DE DE202006018156U patent/DE202006018156U1/en not_active Expired - Lifetime

-

2007

- 2007-05-08 BR BRPI0712480-5A patent/BRPI0712480A2/en not_active IP Right Cessation

- 2007-05-08 JP JP2009511359A patent/JP2009538163A/en active Pending

- 2007-05-08 KR KR1020087031437A patent/KR101309941B1/en not_active IP Right Cessation

- 2007-05-08 CN CN2007800269571A patent/CN101489515B/en not_active Expired - Fee Related

- 2007-05-08 US US12/227,745 patent/US8312579B2/en not_active Expired - Fee Related

- 2007-05-08 CA CA2653353A patent/CA2653353C/en not_active Expired - Fee Related

- 2007-05-08 NZ NZ573364A patent/NZ573364A/en not_active IP Right Cessation

- 2007-05-08 MX MX2008015052A patent/MX2008015052A/en active IP Right Grant

- 2007-05-08 EP EP07724956.3A patent/EP2020977B1/en not_active Not-in-force

- 2007-05-08 AU AU2007267476A patent/AU2007267476B2/en not_active Ceased

- 2007-05-08 RU RU2008151373/12A patent/RU2443405C2/en not_active IP Right Cessation

- 2007-05-08 WO PCT/EP2007/004032 patent/WO2007137678A1/en active Application Filing

-

2008

- 2008-12-04 NO NO20085048A patent/NO20085048L/en not_active Application Discontinuation

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202022103498U1 (en) | 2022-06-23 | 2023-10-10 | Hermann Bock Gmbh | Bed with a lifting device |

Also Published As

| Publication number | Publication date |

|---|---|

| KR101309941B1 (en) | 2013-09-17 |

| DE202006018156U1 (en) | 2007-02-22 |

| NO20085048L (en) | 2009-02-06 |

| CN101489515A (en) | 2009-07-22 |

| KR20090021186A (en) | 2009-02-27 |

| EP2020977A1 (en) | 2009-02-11 |

| CN101489515B (en) | 2012-08-08 |

| MX2008015052A (en) | 2009-01-26 |

| BRPI0712480A2 (en) | 2012-08-28 |

| AU2007267476A1 (en) | 2007-12-06 |

| CA2653353C (en) | 2013-12-17 |

| RU2443405C2 (en) | 2012-02-27 |

| NZ573364A (en) | 2011-11-25 |

| US20090235456A1 (en) | 2009-09-24 |

| AU2007267476B2 (en) | 2012-07-12 |

| CA2653353A1 (en) | 2007-12-06 |

| WO2007137678A1 (en) | 2007-12-06 |

| JP2009538163A (en) | 2009-11-05 |

| RU2008151373A (en) | 2010-07-10 |

| US8312579B2 (en) | 2012-11-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2020977B1 (en) | Bed with a pivoting device | |

| EP1239755B1 (en) | Motor-driven, adjustable supporting device for the upholstery of seating and/or reclining furniture, for example of a mattress or of a bed | |

| EP2792277B1 (en) | Electric motor furniture drive | |

| EP1276406B1 (en) | Support device that can be adjusted by means of a motor and is used for the upholstery of a piece of furniture used for sitting and/or laying upon | |

| DE60012551T2 (en) | TURNING DRIVE, ESPECIALLY FOR ADJUSTABLE FURNITURE, SUCH AS BEDS AND BEDS | |

| EP2418984B1 (en) | Support device adjustable by an electric motor | |

| EP2418981B1 (en) | Support device adjustable by an electric motor | |

| EP1708595B1 (en) | Drive for furniture for adjusting a first furniture part in relation to a second part | |

| WO2004006725A1 (en) | Adjusting device and adjustable support device for beds, mattresses, armchairs and the like | |

| WO2004107924A1 (en) | Modular system for the assembly of power-adjusted supporting devices for the upholstery of seating and/or reclining furniture | |

| EP2418983B1 (en) | Support device adjustable by an electric motor | |

| EP2418982B1 (en) | Support device adjustable by an electric motor | |

| EP0794358A2 (en) | Electric adjustment drive for furnitures | |

| EP1416832B2 (en) | Drive for furniture for displacing parts of furniture in relation to one another | |

| EP0935937B1 (en) | Slatted bed base with adjustable head- and footpart of a furniture sitting or lying | |

| DE29720337U1 (en) | Drive arrangement of an electromotive height adjustment device | |

| DE202006008523U1 (en) | Pivoting device for seat or bed, especially hospital or care bed, has electric motor drive arrangement between two adjacent sub-sections of seat or bed providing a supporting structure for mattress, upholstery element or similar | |

| WO2014040728A1 (en) | Electromotive furniture drive | |

| WO2015049078A1 (en) | Actuator assembly for an adjustable piece of furniture for sitting or lying, and adjustable piece of furniture for sitting or lying | |

| EP4360506A1 (en) | Slatted base | |

| WO2002098262A1 (en) | Electromotive furniture drive for displacing parts of a piece of furniture in relation to each other | |

| DE102009036402A1 (en) | Drive device for seating and reclining furniture | |

| DE102009007149A1 (en) | Drive system for driving pivotable shaft of e.g. bed, has shaft associated to cable like holding device for electromotive linear drive such that additional force does not act on bearing of shaft and shaft is predominantly loaded in torsion |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20081201 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17Q | First examination report despatched |

Effective date: 20090403 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: HERMANN BOCK GMBH |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: BOCK, KLAUS |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20140616 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: BOCK, KLAUS |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 695296 Country of ref document: AT Kind code of ref document: T Effective date: 20141115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502007013566 Country of ref document: DE Effective date: 20150108 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20141112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150312 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150312 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150213 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20150515 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502007013566 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20150813 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20150508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150531 Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150508 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150531 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20160129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150508 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150601 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 695296 Country of ref document: AT Kind code of ref document: T Effective date: 20150508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150508 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502007013566 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20070508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141112 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230522 |