EP1983161A1 - Safety device for protection of a rotor of a fluid flow engine installed at right angles to the horizontal plane against overturning and mounting device - Google Patents

Safety device for protection of a rotor of a fluid flow engine installed at right angles to the horizontal plane against overturning and mounting device Download PDFInfo

- Publication number

- EP1983161A1 EP1983161A1 EP20070007681 EP07007681A EP1983161A1 EP 1983161 A1 EP1983161 A1 EP 1983161A1 EP 20070007681 EP20070007681 EP 20070007681 EP 07007681 A EP07007681 A EP 07007681A EP 1983161 A1 EP1983161 A1 EP 1983161A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rotor

- securing device

- horizontal plane

- foundation

- support surface

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/60—Mounting; Assembling; Disassembling

- F04D29/64—Mounting; Assembling; Disassembling of axial pumps

- F04D29/644—Mounting; Assembling; Disassembling of axial pumps especially adapted for elastic fluid pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D25/00—Component parts, details, or accessories, not provided for in, or of interest apart from, other groups

- F01D25/28—Supporting or mounting arrangements, e.g. for turbine casing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/26—Rotors specially for elastic fluids

- F04D29/28—Rotors specially for elastic fluids for centrifugal or helico-centrifugal pumps for radial-flow or helico-centrifugal pumps

- F04D29/284—Rotors specially for elastic fluids for centrifugal or helico-centrifugal pumps for radial-flow or helico-centrifugal pumps for compressors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/60—Assembly methods

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/70—Disassembly methods

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2240/00—Components

- F05D2240/20—Rotors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2240/00—Components

- F05D2240/90—Mounting on supporting structures or systems

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/37—Impeller making apparatus

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/4932—Turbomachine making

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/4932—Turbomachine making

- Y10T29/49321—Assembling individual fluid flow interacting members, e.g., blades, vanes, buckets, on rotary support member

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49826—Assembling or joining

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49826—Assembling or joining

- Y10T29/49828—Progressively advancing of work assembly station or assembled portion of work

Definitions

- Safety device for securing a transversely mounted against a horizontal plane rotor of a turbomachine against tipping and mounting device

- the invention relates to a mounting device for assembling and disassembling a composed of rotor disks rotor of a turbomachine, which rotor disks are clamped together by at least one tie rod comprising a mounted on a foundation turning block and a securing device which pivotally mounted on the turning block, relative to a horizontal plane of the Foundation cross-mounted rotor against tipping secures. Furthermore, the invention relates to a securing device as a part of the mounting device.

- a rotor variant comprises a plurality of adjacent elements, which are braced by a tie rod extending centrally through the elements.

- these elements are rotor disks and, on the other hand, pipe sections, so-called hollow shafts, which can rest on the rotor disks.

- the clamping of the rotor disks and the hollow shafts is carried out with each end screwed onto the tie rod nuts, often the compressor side provided screw is designed as a hollow shaft.

- the face-to-face flat rotor disks usually carry at their outer peripheries the blades of the turbine and the compressor. Instead of a central tie rod, it is also known to use several decentralized tie rods.

- an assembly tool which in Essentially comprises two bearing blocks.

- the two bearing blocks are placed at a distance from each other and the rotor is placed on them.

- One of the two bearing blocks - the so-called turning block - is equipped with a joint arranged between foot and bearing surface, which is fastened to one end of the rotor.

- the rotor is thus placed so that its example compressor side end can be attached directly to the joint of the turning block.

- the other bearing block then supports the rotor from the turbine side.

- the hinge attached to the reversing link serves to relocate the rotor from the horizontal position to a vertical position. For this purpose, a trailer nut is screwed onto the tie rod at the turbine end of the rotor.

- a rope of a crane is attached to the hanger by means of a shackle.

- the compressor end rotates about the pivot point of the joint.

- the lifting process is completed when the rotor has reached a vertical position.

- this is secured by means of a fuse, which is also provided on the turning block against tipping over.

- this backup includes a locking pin, which is provided on the turning block above the joint and blocks the return movement of the rotor from the vertical. Then the trailer nut is dismantled, after which the actual work can be done on the vertical rotor (or tie rod).

- the tie rod is set up vertically and then the individual rotor disks are threaded successively from above onto the tie rod by means of a crane.

- the rotor nut arranged on the turbine side is removed, after which the individual rotor disks can be removed from the tie rod.

- the object of the present invention is to provide a new assembly device for assembling and disassembling a rotor composed of rotor disks of a turbomachine specify that an earthquake-resistant support of the vertical rotor is achieved.

- Another object of the invention is to provide a securing device for securing a transverse to a horizontal plane erected rotor of a turbomachine against tipping, in which the rotor is particularly easy to align in the vertical.

- the first object is achieved by a mounting device with the features of claim 9.

- the problem solved by the safety device is solved by a safety device having the features of claim 1.

- the invention is based on the recognition that an earthquake-proof mounting device can be obtained if the turning block and the securing device can be fastened separately from the foundation against overturning. So far, the safety device was also provided on the turning block. Because of this arrangement, only a comparatively weak securing of the vertical rotor was possible, which could no longer ensure safe support of the vertically erected for mounting or dismounting rotor in areas where smaller earthquakes occur relatively frequently - for example in California or New Zealand. Due to this requirement, the distance between the central attachment point of the rotor on the turning block and the point of its lateral support, which prevents tipping of the rotor about the axis of rotation of the joint has been significantly increased according to the invention.

- the invention thus provides a particularly secure and reliable mounting device for assembling and disassembling a rotor composed of rotor disks of a turbomachine.

- the invention proceeds from the recognition that a particularly simple alignment of the rotor positioned approximately perpendicularly with respect to the horizontal plane into the perpendicular can be achieved if the at least one support surface of the securing device against which the rotor bears can be displaced.

- the forces acting on the securing device transversely to the normal force from the rotor are comparatively small, so that the securing device can be adapted accordingly.

- the vertical rotor allows a particularly simple threading or removal of rotor disks on the tie rod.

- the already already approximately vertical rotor can be aligned so that only balance forces must be absorbed by the securing device.

- the total weight of the rotor is in this case then carried by the reversing jack and directed into the foundation.

- the support surface is arranged on a ring composed of at least two ring segments.

- the support surface can thereby create a part of the lateral surface of the rotor, in particular on the lateral surface of a hollow shaft or a rotor disk.

- the support surface is the inner cylindrical surface of the ring, wherein the ring attached to the rotor is also provided as mechanical protection.

- the ring can either be attached to the still located in the horizontal rotor, so even before the erection of the rotor in the vertical. Or, the ring is already preassembled in the framework-like securing device and opened so far that the rotor section, which is to be inserted into the ring, can be introduced.

- one of the two ring segments is pivotally mounted relative to the other ring segment. This allows a particularly simple mounting of the ring on the rotor carried out, regardless of whether the ring is pre-assembled on the horizontal rotor or whether the ring is secured to the securing device in advance.

- a plurality of screw connections or a plurality of hydraulic cylinders are provided which each extend parallel or nearly parallel to the horizontal plane and which have parallel or nearly parallel to the horizontal plane movable elements such as screws or hydraulic pistons.

- at least three screw connections or hydraulic cylinders are provided in such a way to displace the rotor, which is positioned approximately vertically, in such a way that it is brought into the perpendicular from an approximately vertical position can be.

- more than three, in particular preferably eight or nine screw connections or hydraulic cylinders are provided in order to ensure a particularly secure lateral support and a particularly exact alignment. This is particularly required for heavy duty gas turbines used in commercial power generation, since their rotor weight can be several tens of thousands of kilograms.

- the screw or hydraulic cylinder of the securing device are arranged like a beam around a virtual center.

- the securing device and the turning block are to be aligned and fastened to one another on the foundation in such a way that, in the vertical, the projection of the virtual center coincides with a central rotor support point on the turning block.

- the central rotor support point is the point on the axis of rotation of the joint, on which the center of gravity of the rotor is to be placed.

- At least one eccentric disc may be provided, in which the support surface is arranged. So that by means of the support surface of the approximately vertically positioned rotor can be adjusted in any position relative to the Rotorabstütztician the turning block, preferably two nested eccentric discs are provided, of which the inner eccentric disc has the support surface. This also makes it possible to achieve a particularly simple alignment of the approximately vertically positioned rotor in the vertical.

- this has above the foundation a jacked up on several supports and struts platform or platform on.

- the platform serves, for example, as a work platform for fitters, who make the alignment of the rotor in the vertical.

- the support surface is provided at the height of the platform.

- the one or more support surfaces may then be connected to the platform via the fittings or the hydraulic cylinder.

- the distance between the joint of the turning block and the supporting surface arranged above about 2 - 3 m.

- FIG. 1 is a stored on two trestles 11 rotor 13 a heavy stationary gas turbine shown.

- the rotor 13 includes a tie rod 15 which extends centrally through a plurality of turbine disks 17 and compressor disks 19.

- the compressor-side end of the rotor 13 is shown on the left.

- the turbine disks 17 and the compressor disks 19 are rotor disks 21 and wear at their outer ends blades, which are a compressible flow medium of the gas turbine exposed.

- a front hollow shaft 22 is screwed onto the tie rod 15 at the compressor-side end 33 of the rotor 13.

- a nut 24 is provided.

- a mounting device 23 is provided in addition to the two bearing blocks 11, which is arranged rotorend perfume.

- the mounting device 23 comprises a turning bracket 27 which is mounted on a foundation 29.

- the turning block 27 is set up in alignment with the two bearing blocks 11 and has at its tip a joint 31 which is connected to the compressor-side end 33 of the rotor 13.

- the rotor 13 is rotatable about an axis of rotation parallel to the horizontal plane 47 of the joint 31.

- the joint 31 comprises a roller-mounted receptacle for a rotatable about a vertical axis 35 turntable 37. On the vertical axis 35 is also the Rotorabstütztician.

- a trailer nut 41 is mounted on the means of a shackle the rope of a crane can be struck.

- the mounting device 23 further comprises a securing device 45 designed as a frame 43, which is anchored separately in the foundation 29 by the turning block 27.

- the framework 43 comprises a platform 49 or work platform jacked up on four vertical supports 64.

- further struts 65 extending transversely to the supports 64 are provided on each side edge of the framework 43, which additionally connect the foundation-side ends of the supports 64 to the platform 49.

- part of the platform 49 and the struts 65 arranged underneath can be moved out of the pivoting range of the rotor 13.

- the platform 49 and the securing device 45 then have an opened receptacle (cf. FIG. 3 ).

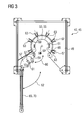

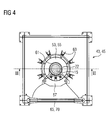

- FIG. 3 The plan view of the platform 49 of the securing device 45 show the Figures 3 and 4 , in which FIG. 3 the open to receive the rotor 13 platform 49 shows and FIG. 4 the closed platform 49 with centrally arranged tie rod 15 and front hollow shaft 22 according to the sectional view IV-IV of FIG. 2 ,

- a centrally disposed opening 51 is provided, in which an axial portion of the hollow shaft 22 can be inserted.

- the opening 51 is enclosed by a segmented ring 53, whose first segment 55 comprises a segmental arc of approximately 270 ° and whose second segment 57 comprises a segmental arc of approximately 90 °.

- the second ring segment 57 is pivotable relative to the first ring segment 55 about an axis of rotation 59, which serves for easy and quick closing and opening of the ring 53 (see. FIG. 4 ). Both segments 55, 57 each have an inwardly directed support surface 61, which can each be applied to a portion of the lateral surface of the rotor 13 and the tie rod 15.

- the ring 53 lies in a plane parallel to the horizontal plane 47, ie parallel to the foundation 29, and can be displaced by means of an auxiliary device supporting it within this plane for vertical alignment of the rotor 13.

- the auxiliary device comprises, for example, a plurality of screw connections 63 fastened to the platform 49.

- Each of these screw connections 63 has a screw axis 67, which likewise lies in the plane parallel to the horizontal plane 47.

- the screw 63 are arranged radially with a closed ring 53, so that their screw axes 67 meet in a virtual center 66.

- screw 63 can also be provided in each case a hydraulic arrangement with a movable piston rod to laterally support the ring 53 and thereby align the rotor 13 (or tie rod 15) relative to the turn block 27 such that of this from an approximately vertical orientation in a vertical alignment can be shifted.

- the ring 53 may be mounted in a double-nested eccentric, so that the opening 51 relative to the axis 35 of the turning block 27 is arbitrarily alignable.

- the ring 53 is only optional.

- the lateral support of the rotor 13 it is also possible for the lateral support of the rotor 13 to take place directly from the screw connections 63 or directly from the piston rods of the hydraulic cylinders.

- the support surfaces 61 would then be arranged on the inwardly projecting free ends 69 of the screw 63 or the inwardly projecting free ends of the piston rods of the hydraulic cylinders, which would then be applied directly to the lateral surface of the rotor 13.

- the ring 53 and the platform 49 must first be opened.

- the second segment 57 of the ring 53 is pivotable about the rotation axis 59 according to the arrow 60 from a closed position to an open position (shown).

- those are in the FIG. 3 shown below struts 65 and the railing 70 of the platform of the platform 49 according to the arrow 62 folded away, so that a total of the receptacle is opened.

- FIG. 4 shows the top view of the securing device 45 with the almost completely closed ring 53.

- the ring 53 surrounds the hollow shaft 22 so that the support surfaces 61 abut the lateral surface of the hollow shaft 22.

- the ring 53 is displaceable over the individual screw 63 in the plane parallel to the foundation 29, so that the center of the ring 53 and thus the center of the tie rod 15 relative to the turn block 27 and thus relative to the central Rotorabstütztician is slightly displaced to the rotor thirteenth in a vertical orientation.

- the latter larger, outgoing from the rotor forces and moments and forward into the foundation as a backup device, which is mounted directly on the turning block. Larger forces can occur, for example, with comparatively smaller earthquakes, so that now the device according to the invention satisfies earthquake requirements to a certain extent.

- the scaffolding can also serve as a working platform, so that the alignment of the rotor can be performed in a perpendicular much easier by fitters.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Abstract

Description

Sicherungsvorrichtung zur Sicherung eines quer gegenüber einer Horizontalebene aufgestellten Rotors einer Strömungsmaschine gegen Umkippen sowie MontagevorrichtungSafety device for securing a transversely mounted against a horizontal plane rotor of a turbomachine against tipping and mounting device

Die Erfindung betrifft eine Montagevorrichtung zum Zusammensetzen und Zerlegen eines sich aus Rotorscheiben zusammensetzenden Rotors einer Strömungsmaschine, welche Rotorscheiben von mindestens einem Zuganker miteinander verspannt sind, umfassend einen auf einem Fundament befestigten Wendebock und eine Sicherungsvorrichtung, welche einen am Wendebock schwenkbar gelagerten, gegenüber einer Horizontalebene des Fundaments quer aufgestellten Rotor gegen Umkippen sichert. Des Weiteren betrifft die Erfindung eine Sicherungsvorrichtung als ein Teil der Montagevorrichtung.The invention relates to a mounting device for assembling and disassembling a composed of rotor disks rotor of a turbomachine, which rotor disks are clamped together by at least one tie rod comprising a mounted on a foundation turning block and a securing device which pivotally mounted on the turning block, relative to a horizontal plane of the Foundation cross-mounted rotor against tipping secures. Furthermore, the invention relates to a securing device as a part of the mounting device.

Gasturbinen sowie deren struktureller Aufbau sind allgemein bekannt. Die Rotoren von Gasturbinen können dabei in unterschiedlicher Art und Weise aufgebaut und zusammengesetzt sein. Eine Rotorvariante umfasst eine Vielzahl von aneinanderliegenden Elementen, welche über einen sich zentral durch die Elemente erstreckenden Zuganker verspannt sind. Diese Elemente sind einerseits Rotorscheiben und andererseits Rohrabschnitte, so genannte Hohlwellen, die an den Rotorscheiben anliegen können. Das Verspannen der Rotorscheiben und der Hohlwellen erfolgt mit jeweils endseitig auf dem Zuganker aufgeschraubten Schraubenmuttern, wobei häufig die verdichterseitig vorgesehene Schraubenmutter als Hohlwelle ausgebildet ist. Die stirnseitig flächig aneinander liegenden Rotorscheiben tragen in der Regel an ihren Außenumfängen die Laufschaufeln der Turbine und des Verdichters. Anstelle eines zentralen Zugankers ist es auch bekannt, mehrere dezentrale Zuganker zu verwenden.Gas turbines and their structural design are well known. The rotors of gas turbines can be constructed and assembled in different ways. A rotor variant comprises a plurality of adjacent elements, which are braced by a tie rod extending centrally through the elements. On the one hand, these elements are rotor disks and, on the other hand, pipe sections, so-called hollow shafts, which can rest on the rotor disks. The clamping of the rotor disks and the hollow shafts is carried out with each end screwed onto the tie rod nuts, often the compressor side provided screw is designed as a hollow shaft. The face-to-face flat rotor disks usually carry at their outer peripheries the blades of the turbine and the compressor. Instead of a central tie rod, it is also known to use several decentralized tie rods.

Um einen derartigen mehrteiligen Rotor zusammenzusetzen und zu zerlegen ist ein Montagewerkzeug bekannt, welches im Wesentlichen zwei Lagerböcke umfasst. Die beiden Lagerböcke werden zueinander beabstandet aufgestellt und der Rotor wird auf ihnen abgelegt. Einer der beiden Lagerböcke - der so genannte Wendebock - ist dabei mit einem zwischen Fuß und Auflagefläche angeordnetem Gelenk ausgestattet, welches mit einem Ende des Rotors befestigt wird. Der Rotor wird also so platziert, dass sein beispielsweise verdichterseitiges Ende unmittelbar an dem Gelenk des Wendebocks befestigt werden kann. Der andere Lagerbock stützt dann den Rotor turbinenseitig ab. Das am Wendebock befestigte Gelenk dient zur Umlagerung des Rotors aus der waagerechten Lage in eine dazu senkrechte Position. Dazu wird am turbinenseitigen Ende des Rotors eine Anhängemutter auf den Zuganker aufgeschraubt. An die Anhängemutter wird mittels eines Schäkels ein Seil eines Krans befestigt. Während der Kran das turbinenseitige Ende des Rotors anhebt, dreht sich das verdichterseitige Ende um den Drehpunkt des Gelenks. Der Anhebevorgang ist abgeschlossen, wenn der Rotor in einer senkrechten Position angelangt ist. Dann wird dieser mittels einer Sicherung, welche auch am Wendebock vorgesehen ist, gegen Umkippen gesichert. In der Regel umfasst diese Sicherung einen Blockierbolzen, der am Wendebock oberhalb des Gelenks vorgesehen ist und das Zurückbewegen des Rotors aus der Senkrechten blockiert. Anschließend wird die Anhängemutter demontiert, wonach dann die eigentlichen Arbeiten am senkrecht aufgestellten Rotor (oder Zuganker) erfolgen können.To assemble and disassemble such a multi-part rotor, an assembly tool is known, which in Essentially comprises two bearing blocks. The two bearing blocks are placed at a distance from each other and the rotor is placed on them. One of the two bearing blocks - the so-called turning block - is equipped with a joint arranged between foot and bearing surface, which is fastened to one end of the rotor. The rotor is thus placed so that its example compressor side end can be attached directly to the joint of the turning block. The other bearing block then supports the rotor from the turbine side. The hinge attached to the reversing link serves to relocate the rotor from the horizontal position to a vertical position. For this purpose, a trailer nut is screwed onto the tie rod at the turbine end of the rotor. A rope of a crane is attached to the hanger by means of a shackle. As the crane lifts the turbine end of the rotor, the compressor end rotates about the pivot point of the joint. The lifting process is completed when the rotor has reached a vertical position. Then this is secured by means of a fuse, which is also provided on the turning block against tipping over. In general, this backup includes a locking pin, which is provided on the turning block above the joint and blocks the return movement of the rotor from the vertical. Then the trailer nut is dismantled, after which the actual work can be done on the vertical rotor (or tie rod).

Zur Montage des Rotors wird der Zuganker senkrecht aufgestellt und anschließend die einzelnen Rotorscheiben mittels eines Krans nacheinander von Oben auf den Zuganker aufgefädelt. Bei der Demontage eines vollständig montierten Rotors wird die turbinenseitig angeordnete Rotormutter entfernt, wonach die einzelnen Rotorscheiben dem Zuganker entnommen werden können.To mount the rotor, the tie rod is set up vertically and then the individual rotor disks are threaded successively from above onto the tie rod by means of a crane. During disassembly of a fully assembled rotor, the rotor nut arranged on the turbine side is removed, after which the individual rotor disks can be removed from the tie rod.

Aufgabe der vorliegenden Erfindung ist es, eine neue Montagevorrichtung zum Zusammensetzen und zum Zerlegen eines sich aus Rotorscheiben zusammensetzenden Rotors einer Strömungsmaschine anzugeben, mit der eine erdbebensichere Abstützung des senkrecht aufgestellten Rotors erreicht wird. Weitere Aufgabe der Erfindung ist die Bereitstellung einer Sicherungsvorrichtung zur Sicherung eines quer gegenüber einer Horizontalebene aufgestellten Rotors einer Strömungsmaschine gegen Umkippen, bei der der Rotor besonders einfach in die Lotrechte ausrichtbar ist.The object of the present invention is to provide a new assembly device for assembling and disassembling a rotor composed of rotor disks of a turbomachine specify that an earthquake-resistant support of the vertical rotor is achieved. Another object of the invention is to provide a securing device for securing a transverse to a horizontal plane erected rotor of a turbomachine against tipping, in which the rotor is particularly easy to align in the vertical.

Die erstgenannte Aufgabe wird durch eine Montagevorrichtung mit den Merkmalen des Anspruchs 9 gelöst. Die auf die Sicherungsvorrichtung gelöste Aufgabe wird durch eine Sicherungsvorrichtung mit den Merkmalen des Anspruchs 1 gelöst.The first object is achieved by a mounting device with the features of claim 9. The problem solved by the safety device is solved by a safety device having the features of claim 1.

Die Erfindung geht von der Erkenntnis aus, dass eine erdbebensichere Montagevorrichtung erhalten werden kann, wenn der Wendebock und die Sicherungsvorrichtung gegen Umkippen getrennt voneinander am Fundament befestigbar sind. Bisher war die Sicherungsvorrichtung auch am Wendebock vorgesehen. Aufgrund dieser Anordnung war nur eine vergleichsweise schwache Sicherung des senkrecht stehenden Rotors möglich, die in Gebieten, bei denen kleinere Erdbeben vergleichsweise häufig auftreten - beispielsweise in Kalifornien oder Neuseeland -, eine sichere Abstützung des zur Montage oder Demontage senkrecht aufgestellten Rotors nicht mehr gewährleisten konnte. Aufgrund dieser Anforderung ist erfindungsgemäß der Abstand zwischen dem zentralen Befestigungspunkt des Rotors am Wendebock und dem Punkt seiner seitlichen Abstützung, welches ein Umkippen des Rotors um die Drehachse des Gelenks verhindert, signifikant vergrößert worden. Es wurde des Weiteren erkannt, dass die Abstützkräfte bzw. die Abstützmomente aufgrund des signifikant vergrößerten Abstandes nun nicht mehr vom Wendebock ins Fundament übertragen werden konnten. Folglich wurde erkannt, dass die die Befestigung des Rotors am Wendebock und die seitliche Abstützung des Rotors von zwei getrennt am Fundament befestigten Vorrichtungen erfolgen musste: dem am Fundament befestigten Wendebock und der davon separat befestigten gerüstartigen Sicherungsvorrichtung.The invention is based on the recognition that an earthquake-proof mounting device can be obtained if the turning block and the securing device can be fastened separately from the foundation against overturning. So far, the safety device was also provided on the turning block. Because of this arrangement, only a comparatively weak securing of the vertical rotor was possible, which could no longer ensure safe support of the vertically erected for mounting or dismounting rotor in areas where smaller earthquakes occur relatively frequently - for example in California or New Zealand. Due to this requirement, the distance between the central attachment point of the rotor on the turning block and the point of its lateral support, which prevents tipping of the rotor about the axis of rotation of the joint has been significantly increased according to the invention. It was further recognized that the support forces and the Abstützmomente could not be transferred from the turning block to the foundation due to the significantly increased distance now. Consequently, it was recognized that the attachment of the rotor to the turning block and the lateral support of the rotor had to be carried out by two separately attached to the foundation devices: attached to the foundation turning bridge and the separately attached scaffold-like safety device.

Durch die Trennung von Abstützung des Rotors im Wendebock und der Sicherung des Rotors gegen Umkippen mittels der Sicherungsvorrichtung können nun von dem Rotor ausgehende größere Kräfte und Momente, welche beispielsweise bei einem vergleichsweise schwächeren Erdbeben auftreten, von der Sicherungsvorrichtung aufgenommen und in das Fundament abgeleitet werden, ohne dass dabei der senkrecht aufgestellte Rotor umzukippen droht oder tatsächlich umkippt. Die Aufnahme der Kräfte zur seitlichen Abstützung erfolgt dabei auf eine Höhe - bezogen auf die Fundamentebene - welche wesentlich größer ist als die Höhe der Drehachse des Gelenks des Wendebocks.By separating support of the rotor in the turning block and securing the rotor against tipping by means of the securing device, larger forces and moments emanating from the rotor, which occur, for example, in a comparatively weaker earthquake, can now be absorbed by the securing device and discharged into the foundation, without causing the vertical rotor threatens to tip over or actually overturn. The absorption of the forces for lateral support is carried out at a height - based on the foundation level - which is substantially greater than the height of the axis of rotation of the pivot of the turning block.

Durch die Erfindung kann somit eine besonders sichere und zuverlässige Montagevorrichtung zum Zusammensetzen und Zerlegen eines sich aus Rotorscheiben zusammensetzenden Rotors einer Strömungsmaschine angegeben werden.The invention thus provides a particularly secure and reliable mounting device for assembling and disassembling a rotor composed of rotor disks of a turbomachine.

Des Weiteren geht die Erfindung von der Erkenntnis aus, dass ein besonders einfaches Ausrichten des annähernd senkrecht gegenüber der Horizontalebene aufgestellten Rotors in die Lotrechte erreicht werden kann, wenn die mindestens eine Abstützfläche der Sicherungsvorrichtung, an welcher der Rotor anliegt, verlagerbar ist. Insbesondere, wenn der Rotor in die Lotrechte ausgerichtet werden soll, sind die vom Rotor auf die Sicherungsvorrichtung quer zur Normalkraft einwirkenden Kräfte vergleichsweise gering, so dass die Sicherungsvorrichtung dementsprechend angepasst dimensioniert werden kann. Des Weiteren ermöglicht der lotrecht stehende Rotor eine besonders einfache Auf- bzw. Abfädelung von Rotorscheiben auf den Zuganker.Furthermore, the invention proceeds from the recognition that a particularly simple alignment of the rotor positioned approximately perpendicularly with respect to the horizontal plane into the perpendicular can be achieved if the at least one support surface of the securing device against which the rotor bears can be displaced. In particular, when the rotor is to be aligned in the perpendicular, the forces acting on the securing device transversely to the normal force from the rotor are comparatively small, so that the securing device can be adapted accordingly. Furthermore, the vertical rotor allows a particularly simple threading or removal of rotor disks on the tie rod.

Sofern die Abstützfläche, an welcher sich der Rotor anlegt, in einer Ebene annähernd parallel zur Horizontalebene verlagerbar ist, kann der bereits schon annähernd senkrecht stehende Rotor so ausgerichtet werden, dass lediglich Balancekräfte von der Sicherungsvorrichtung aufgenommen werden müssen. Die gesamte Gewichtskraft des Rotors wird in diesem Fall dann von dem Wendebock getragen und in das Fundament geleitet.If the support surface on which the rotor rests, in a plane approximately parallel to the horizontal plane is displaced, the already already approximately vertical rotor can be aligned so that only balance forces must be absorbed by the securing device. The total weight of the rotor is in this case then carried by the reversing jack and directed into the foundation.

Vorteilhafte Ausgestaltungen sind in den Unteransprüchen angegeben.Advantageous embodiments are specified in the subclaims.

In einer bevorzugten Ausgestaltung ist die Abstützfläche an einem sich aus mindestens zwei Ringsegmenten zusammensetzenden Ring angeordnet. Die Abstützfläche kann sich dabei an einem Teil der Mantelfläche des Rotors, insbesondere an der Mantelfläche einer Hohlwelle oder einer Rotorscheibe, anlegen. Vorzugsweise ist die Abstützfläche die innere zylindrische Fläche des Rings, wobei der an dem Rotor befestigte Ring auch als mechanischer Schutz vorgesehen ist. Der Ring kann entweder an dem noch in der waagerechten befindlichen Rotor befestigt werden, also noch vor dem Aufstellen des Rotors in die Senkrechte. Oder, der Ring ist in der gerüstartigen Sicherungsvorrichtung bereits vormontiert und so weit geöffnet, dass der Rotorabschnitt, welcher in den Ring eingelegt werden soll, einbringbar ist.In a preferred embodiment, the support surface is arranged on a ring composed of at least two ring segments. The support surface can thereby create a part of the lateral surface of the rotor, in particular on the lateral surface of a hollow shaft or a rotor disk. Preferably, the support surface is the inner cylindrical surface of the ring, wherein the ring attached to the rotor is also provided as mechanical protection. The ring can either be attached to the still located in the horizontal rotor, so even before the erection of the rotor in the vertical. Or, the ring is already preassembled in the framework-like securing device and opened so far that the rotor section, which is to be inserted into the ring, can be introduced.

Um den Rotor besonders einfach und schnell in einer Sicherungsvorrichtung zu befestigen, ist eines der beiden Ringsegmente gegenüber dem anderen Ringsegment schwenkbar befestigt. Hierdurch kann eine besonders einfach Montage des Rings am Rotor erfolgen, unabhängig davon, ob der Ring am waagerechten Rotor vormontiert wird oder ob der Ring an der Sicherungsvorrichtung vorab befestigt ist.In order to fix the rotor particularly easily and quickly in a securing device, one of the two ring segments is pivotally mounted relative to the other ring segment. This allows a particularly simple mounting of the ring on the rotor carried out, regardless of whether the ring is pre-assembled on the horizontal rotor or whether the ring is secured to the securing device in advance.

Um die Abstützflächen zu verlagern, sind mehrere Verschraubungen oder mehrere Hydraulikzylinder vorgesehen, welche sich jeweils parallel oder nahezu parallel zur Horizontalebene erstrecken und welche parallel oder nahezu parallel zur Horizontalebene bewegbare Elemente wie Schrauben oder Hydraulikkolben aufweisen. Dabei sind mindestens drei Verschraubungen bzw. Hydraulikzylinder vorgesehen, um den annähernd senkrecht aufgestellten Rotor derartig zu verlagern, dass dieser aus einer annähernd senkrechten Position in die Lotrechte gebracht werden kann. Vorzugsweise sind jedoch mehr als drei, insbesondere vorzugsweise acht oder neun Verschraubungen bzw. Hydraulikzylinder vorgesehen, um eine besonders sichere seitliche Abstützung und um eine besonders exakte Ausrichtung zu gewährleisten. Dies ist insbesondere für Rotoren von schweren, zur kommerziellen Stromerzeugung genutzten Gasturbinen erforderlich, da deren Rotorgewicht mehrere zehntausend Kilogramm betragen können.In order to displace the support surfaces, a plurality of screw connections or a plurality of hydraulic cylinders are provided which each extend parallel or nearly parallel to the horizontal plane and which have parallel or nearly parallel to the horizontal plane movable elements such as screws or hydraulic pistons. In this case, at least three screw connections or hydraulic cylinders are provided in such a way to displace the rotor, which is positioned approximately vertically, in such a way that it is brought into the perpendicular from an approximately vertical position can be. Preferably, however, more than three, in particular preferably eight or nine screw connections or hydraulic cylinders are provided in order to ensure a particularly secure lateral support and a particularly exact alignment. This is particularly required for heavy duty gas turbines used in commercial power generation, since their rotor weight can be several tens of thousands of kilograms.

Die Verschraubungen oder Hydraulikzylinder der Sicherungsvorrichtung sind dabei strahlenartig um einen virtuellen Mittelpunkt angeordnet. Die Sicherungsvorrichtung und der Wendebock sind darüber hinaus derartig am Fundament gegeneinander auszurichten und zu befestigen, dass in der Senkrechten die Projektion des virtuellen Mittelpunkts mit einem zentralen Rotorabstützpunkt am Wendebock zusammenfällt. Der zentrale Rotorabstützpunkt ist dabei der auf der Drehachse des Gelenks liegende Punkt, auf dem der Schwerpunkt des Rotors platziert werden soll. Insbesondere hierdurch kann das lotrechte Ausrichten des Rotors vergleichsweise schnell erfolgen bei vergleichsweise geringem Aufwand.The screw or hydraulic cylinder of the securing device are arranged like a beam around a virtual center. In addition, the securing device and the turning block are to be aligned and fastened to one another on the foundation in such a way that, in the vertical, the projection of the virtual center coincides with a central rotor support point on the turning block. The central rotor support point is the point on the axis of rotation of the joint, on which the center of gravity of the rotor is to be placed. In particular, as a result, the vertical alignment of the rotor can be done comparatively quickly with relatively little effort.

Anstelle von mehreren Verschraubungen oder mehreren Hydraulikzylindern kann in einer alternativen Ausgestaltung der Sicherungsvorrichtung mindestens eine Excenterscheibe vorgesehen sein, in welcher die Abstützfläche angeordnet ist. Damit mittels der Abstützfläche der annähernd senkrecht aufgestellte Rotor in jede beliebige Position gegenüber dem Rotorabstützpunkt des Wendebocks verstellt werden kann, sind vorzugsweise zwei ineinander geschachtelte Excenterscheiben vorgesehen, von denen die innere Excenterscheibe die Abstützfläche aufweist. Auch hierdurch ist eine besonders einfache Ausrichtung des annähernd senkrecht aufgestellten Rotors in die Lotrechte möglich.Instead of a plurality of screw connections or a plurality of hydraulic cylinders, in an alternative embodiment of the safety device at least one eccentric disc may be provided, in which the support surface is arranged. So that by means of the support surface of the approximately vertically positioned rotor can be adjusted in any position relative to the Rotorabstützpunkt the turning block, preferably two nested eccentric discs are provided, of which the inner eccentric disc has the support surface. This also makes it possible to achieve a particularly simple alignment of the approximately vertically positioned rotor in the vertical.

In einer vorteilhaften Ausgestaltung der Sicherungsvorrichtung weist diese oberhalb des Fundamentes eine auf mehreren Stützen und Streben aufgebockte Plattform oder Arbeitsbühne auf. Die Plattform dient beispielsweise als Arbeitsplattform für Monteure, welche die Ausrichtung des Rotors in die Lotrechte vornehmen. Insbesondere dann ist es von Vorteil, wenn die Abstützfläche auf der Höhe der Plattform vorgesehen ist. Die eine oder mehrere Abstützflächen können dann mit der Plattform über die Verschraubungen oder der Hydraulikzylinder verbunden sein. Vorzugsweise beträgt der Abstand zwischen dem Gelenk des Wendebocks und der darüber angeordneten Abstützfläche ca. 2 - 3 m.In an advantageous embodiment of the securing device, this has above the foundation a jacked up on several supports and struts platform or platform on. The platform serves, for example, as a work platform for fitters, who make the alignment of the rotor in the vertical. In particular, it is advantageous if the support surface is provided at the height of the platform. The one or more support surfaces may then be connected to the platform via the fittings or the hydraulic cylinder. Preferably, the distance between the joint of the turning block and the supporting surface arranged above about 2 - 3 m.

Die Erfindung wird anhand einer Zeichnung erläutert. Es zeigen schematisch und in nicht maßstäblicher Weise:

- FIG 1

- die Montagevorrichtung zum Zusammensetzen und Zerlegen eines Rotors mit parallel zur Horizontalebene (waagerecht) angeordnetem Rotor,

- FIG 2

- die Montagevorrichtung gemäß

FIG 1 mit senkrecht aufgestelltem Rotor, - FIG 3

- die Draufsicht auf die Sicherungsvorrichtung bei geöffneter Aufnahme und

- FIG 4

- die Draufsicht auf die Sicherungsvorrichtung mit eingelegtem Rotor.

- FIG. 1

- the assembly device for assembling and disassembling a rotor with a rotor arranged parallel to the horizontal plane (horizontal),

- FIG. 2

- the mounting device according to

FIG. 1 with vertical rotor, - FIG. 3

- the top view of the securing device with open recording and

- FIG. 4

- the top view of the safety device with inserted rotor.

In den Figuren sind identische Bauteile mit gleichen Bezugszeichen versehen.In the figures, identical components are provided with the same reference numerals.

In

Zum Verspannen der Rotorscheiben 21 ist am verdichterseitigen Ende 33 des Rotors 13 eine vordere Hohlwelle 22 auf den Zuganker 15 aufgeschraubt. Turbinenseitig ist eine Schraubenmutter 24 vorgesehen.To clamp the rotor disks 21, a front

Um den modularen Rotor 13 der Gasturbine in seine Einzelteile zu zerlegen, ist neben den beiden Lagerböcken 11 eine Montagevorrichtung 23 vorgesehen, welche rotorendseitig angeordnet ist. Die Montagevorrichtung 23 umfasst einen Wendebock 27, der auf einem Fundament 29 befestigt ist. Der Wendebock 27 ist zu den beiden Lagerböcken 11 fluchtend aufgestellt und weist dabei an seiner Spitze ein Gelenk 31 auf, welches mit dem verdichterseitigen Ende 33 des Rotors 13 verbunden ist. Der Rotor 13 ist dabei um eine zur Horizontalebene 47 parallele Drehachse des Gelenks 31 drehbar. Ferner umfasst das Gelenk 31 eine wälzgelagerte Aufnahme für einen um eine senkrechte Achse 35 drehbaren Drehteller 37. Auf der senkrechten Achse 35 liegt außerdem der Rotorabstützpunkt.In order to disassemble the

Am turbinenseitigen Ende 39 des Rotors 13 ist eine Anhängemutter 41 montiert, an der mittels eines Schäkels das Seil eines Krans angeschlagen werden kann.At the turbine-

Die Montagevorrichtung 23 umfasst des Weiteren eine als Gerüst 43 ausgebildete Sicherungsvorrichtung 45, welche vom Wendebock 27 getrennt im Fundament 29 verankert ist.The mounting

Das Gerüst 43 umfasst eine auf vier senkrechten Stützen 64 aufgebockte Plattform 49 oder Arbeitsbühne. Zur Versteifung des Gerüsts 43 sind an jeder Seitenkante des Gerüsts 43 weitere sich quer zu den Stützen 64 erstreckende Streben 65 vorgesehen, die die fundamentseitigen Enden der Stützen 64 mit der Plattform 49 zusätzlich verbinden.The framework 43 comprises a

Damit der Rotor 13 in das Gerüst 43 und in die Sicherungsvorrichtung 45 eingeschwenkt werden kann, kann ein Teil der Plattform 49 und die darunter angeordneten Streben 65 aus dem Schwenkbereich des Rotors 13 herausbewegt werden. Die Plattform 49 und die Sicherungsvorrichtung 45 weisen dann eine geöffnete Aufnahme auf (vgl.

Durch das Anheben des turbinenseitigen Endes 39 des Rotors 13 mit dem Kran wird dieser aus den beiden Lagerböcken 11 gehoben, wobei das verdichterseitige Ende des Rotors 13 sich um die Drehachse des Gelenks 31 dreht. Bei geöffneter Aufnahme kann dann der Rotor 13 aus seiner horizontalen Lage (

Die gesamte Gewichtskraft des bei stationären Gasturbinen vergleichsweise schweren Rotors 13 lastet dann auf dem Wendebock 27, wohingegen das Gerüst 43 das Umkippen des Rotors 13 mit vergleichsweise geringen Kräften verhindern kann. Die geringste Kraft ist erforderlich, wenn der Rotor 13 lotrecht ausgerichtet ist und die Symmetrieachse 46 des Rotors 13 mit der Achse 35 des Drehtellers 37 übereinstimmt.The entire weight of the stationary in stationary gas turbine comparatively

Aufgrund des vergleichsweise großen Abstands zwischen Gelenk 31 und der seitlichen Abstützung des Rotors 13 auf Höhe der Plattform 49 kann eine besonders zuverlässige und zudem auch erdbebensichere seitliche Abstützung des Rotors 13 angegeben werden. Erdbebensicher heißt in diesem Umfang, dass die bei vergleichsweise schwachen Erdbeben mit einer vergleichsweise geringen Stärke auftretenden Beschleunigungskräfte auf den Rotor 13 in der Größenordnung von ca. ½ g (1g = einfache Erdbeschleunigung) von der Sicherungsvorrichtung 45 aufgefangen und über die Plattform 49 und die Streben 65 ins Fundament 29 abgeleitet werden können.Due to the comparatively large distance between joint 31 and the lateral support of the

Die Draufsicht auf die Plattform 49 der Sicherungsvorrichtung 45 zeigen die

Der Ring 53 liegt in einer Ebene parallel zur Horizontalebene 47, also parallel zum Fundament 29, und kann mittels einer ihn tragenden Hilfsvorrichtung innerhalb dieser Ebene zur lotrechten Ausrichtung des Rotors 13 verlagert werden. Die Hilfsvorrichtung umfasst beispielsweise mehrere an der Plattform 49 befestigte Verschraubungen 63. Jede dieser Verschraubung 63 weist eine Schraubenachse 67 auf, die ebenfalls in der Ebene parallel zur Horizontalebene 47 liegt. Die Verschraubungen 63 sind bei geschlossenem Ring 53 strahlenförmig angeordnet, so dass sich deren Schraubenachsen 67 in einem virtuellen Mittelpunkt 66 treffen. Anstelle der Verschraubungen 63 kann auch jeweils eine Hydraulikanordnung mit bewegbaren Kolbenstange vorgesehen sein, um den Ring 53 seinerseits seitlich abzustützen und dabei den Rotor 13 (oder auch Zuganker 15) gegenüber dem Wendebock 27 derart auszurichten, dass von dieser von einer annähernd senkrechten Ausrichtung in eine lotrechte Ausrichtung verlagert werden kann.The ring 53 lies in a plane parallel to the

Anstelle der Verschraubung oder anstelle von Hydraulikzylindern kann auch der Ring 53 in einem zweifach geschachtelten Excenter gelagert sein, so dass die Öffnung 51 gegenüber der Achse 35 des Wendebocks 27 beliebig ausrichtbar ist.Instead of screwing or instead of hydraulic cylinders and the ring 53 may be mounted in a double-nested eccentric, so that the

Auch der Ring 53 ist insgesamt nur optional. Es ist beispielsweise auch möglich, dass die seitliche Abstützung des Rotors 13 unmittelbar von den Verschraubungen 63 oder unmittelbar von den Kolbenstangen der Hydraulikzylinder erfolgt. Die Abstützflächen 61 wären dann an den nach innen ragenden freien Enden 69 der Verschraubungen 63 oder den nach innen ragenden freien Enden der Kolbenstangen der Hydraulikzylindern angeordnet, welche dann unmittelbar an die Mantelfläche des Rotors 13 anlegbar wären.Also, the ring 53 is only optional. For example, it is also possible for the lateral support of the

Damit der Rotor 13 beim Anheben seines turbinenseitigen Endes 39 in die Öffnung 51 eingeschwenkt werden kann, ist der Ring 53 und die Plattform 49 zuvor zu öffnen. Hierzu ist vorgesehen, dass das zweite Segment 57 des Rings 53 um die Drehachse 59 gemäß dem Pfeil 60 von einer geschlossenen Position in eine offene Position (dargestellt) schwenkbar ist. In gleicher Art und Weise sind die in der

Insgesamt kann durch die konstruktive Trennung von Wendebock und Sicherungsvorrichtung die letztgenannte größere, vom Rotor ausgehende Kräfte und Momente aufnehmen und ins Fundament weiterleiten als eine Sicherungsvorrichtung, welche unmittelbar am Wendebock angebracht ist. Größere Kräfte können beispielsweise bei vergleichsweise kleineren Erdbeben auftreten, so dass nun die erfindungsgemäße Vorrichtung Erdbebenanforderungen in einem gewissen Maße erfüllt. Außerdem kann das Gerüst auch als Arbeitsplattform dienen, so dass die Ausrichtung des Rotors in eine Lotrechte wesentlich einfacher von Monteuren ausgeführt werden kann.Overall, by the structural separation of turning block and safety device, the latter larger, outgoing from the rotor forces and moments and forward into the foundation as a backup device, which is mounted directly on the turning block. Larger forces can occur, for example, with comparatively smaller earthquakes, so that now the device according to the invention satisfies earthquake requirements to a certain extent. In addition, the scaffolding can also serve as a working platform, so that the alignment of the rotor can be performed in a perpendicular much easier by fitters.

Claims (10)

mit mindestens einer Abstützfläche (61), durch die ein zur Horizontalebene (47) quer aufgestellter Rotor (13) seitlich von der Sicherungsvorrichtung (45) abstützbar ist,

dadurch gekennzeichnet, dass

zum lotrechten Ausrichten des Rotors (13) die Abstützfläche (61) parallel zur Horizontalebene (47) verlagerbar ist.Safety device (45) for securing a transverse to a horizontal plane (47) erected rotor (13) of a turbomachine against tipping,

with at least one support surface (61), by which a rotor (13) arranged transversely to the horizontal plane (47) can be supported laterally by the securing device (45),

characterized in that

for vertical alignment of the rotor (13) the support surface (61) parallel to the horizontal plane (47) is displaceable.

bei der die Abstützfläche (61) an einem sich aus mindestens zwei Ringsegmenten (55, 57) zusammensetzenden Ring (53) angeordnet ist.Securing device (45) according to claim 1,

in which the support surface (61) is arranged on a ring (53) composed of at least two ring segments (55, 57).

bei der eines der beiden Ringsegmente (57) gegenüber dem anderen Ringsegment (55) schwenkbar befestigt ist.Securing device (45) according to claim 2,

in which one of the two ring segments (57) relative to the other ring segment (55) is pivotally mounted.

bei der mehrere Verschraubungen (63) oder mehrere Hydraulikzylinder vorgesehen sind,

welche sich jeweils parallel zur Horizontalebene (47) erstrecken und welche parallel zur Horizontalebene (47) bewegbare Elemente zur Verlagerung der Abstützfläche (61) aufweisen.Securing device (45) according to claim 1 to 3,

in which a plurality of screw connections (63) or several hydraulic cylinders are provided,

which each extend parallel to the horizontal plane (47) and which have parallel to the horizontal plane (47) movable elements for displacing the support surface (61).

bei der die Verschraubungen (63) oder Hydraulikzylinder strahlenartig um einen virtuellen Mittelpunkt (66) angeordnet sind.Securing device (45) according to claim 4,

in which the screw connections (63) or hydraulic cylinders are arranged in the manner of a beam around a virtual center (66).

die mindestens eine Excenterscheibe umfasst, in welcher die Abstützfläche (61) vorgesehen ist.Securing device (45) according to claim 1 to 3,

the at least one eccentric disc comprises, in which the support surface (61) is provided.

die auf einem Fundament (29) befestigbar ist und eine am Fundament (29) mittels mehrerer Stützen (64) und Streben (65) aufgebockte Plattform (49) aufweist.Securing device (45) according to one of claims 1 to 6,

which can be fastened on a foundation (29) and has a platform (49) jacked up on the foundation (29) by means of a plurality of supports (64) and struts (65).

bei der die Abstützfläche (61) auf der Höhe der Plattform vorgesehen ist.Safety device (45) according to claim 6,

in which the support surface (61) is provided at the height of the platform.

welche Rotorscheiben (21) von mindestens einem Zuganker (15) miteinander verspannt sind,

umfassend:

dass die Sicherungsvorrichtung (45) vom Wendebock (27) getrennt am Fundament (29) befestigbar ist.Mounting device (23) for assembling and disassembling a rotor (13) composed of rotor disks (21) of a turbomachine,

which rotor disks (21) are clamped together by at least one tie rod (15),

full:

that the securing device (45) from the turning block (27) separately on the foundation (29) can be fastened.

mit einer Sicherungsvorrichtung (45) nach einem der Ansprüche 1 bis 7.Mounting device (23) according to claim 8,

with a securing device (45) according to one of claims 1 to 7.

Priority Applications (12)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP20070007681 EP1983161A1 (en) | 2007-04-16 | 2007-04-16 | Safety device for protection of a rotor of a fluid flow engine installed at right angles to the horizontal plane against overturning and mounting device |

| JP2010503450A JP4937408B2 (en) | 2007-04-16 | 2008-04-03 | Assembly apparatus for assembling and disassembling a rotor in a fluid machine composed of a plurality of rotating disks |

| ES08735742T ES2365375T3 (en) | 2007-04-16 | 2008-04-03 | ASSEMBLY DEVICE FOR ASSEMBLY AND DISASSEMBLY OF A ROTOR FROM A TURBOMACHINE THAT IS COMPOSED BY ROTOR DISCS. |

| US12/595,556 US8667678B2 (en) | 2007-04-16 | 2008-04-03 | Assembly apparatus for assembling and dismantling a turbomachine rotor composed of rotor disks |

| PCT/EP2008/053993 WO2008125507A1 (en) | 2007-04-16 | 2008-04-03 | Assembly device for assembling and disassembling a rotor of a turbomachine consisting of rotor disks |

| US12/596,215 US9003656B2 (en) | 2007-04-16 | 2008-04-03 | Securing device for securing a turbomachine rotor set up transversely to a horizontal plane against tipping over and orientation method therefor |

| PCT/EP2008/053992 WO2008125506A1 (en) | 2007-04-16 | 2008-04-03 | Securing device for securing a rotor of a turbomachine counter to tilting, said rotor being arranged perpendicular to a horizontal plane and method for the alignment thereof |

| PL08735742T PL2134928T3 (en) | 2007-04-16 | 2008-04-03 | Assembly device for assembling and disassembling a rotor of a turbomachine consisting of rotor disks |

| AT08735742T ATE510998T1 (en) | 2007-04-16 | 2008-04-03 | ASSEMBLY DEVICE FOR ASSEMBLING AND DISASSEMBLY A ROTOR OF A FLOW MACHINE COMPOSED OF ROTOR DISKS |

| EP20080735742 EP2134928B1 (en) | 2007-04-16 | 2008-04-03 | Assembly device for assembling and disassembling a rotor of a turbomachine consisting of rotor disks |

| JP2010503449A JP4948644B2 (en) | 2007-04-16 | 2008-04-03 | Holding device for preventing overturning of rotor in fluid machine standing perpendicular to horizontal plane, and method for standing vertically therefor |

| EP08735741.4A EP2134927B1 (en) | 2007-04-16 | 2008-04-03 | Securing device for securing a rotor of a turbomachine counter to tilting, said rotor being arranged perpendicular to a horizontal plane and method for the alignment thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP20070007681 EP1983161A1 (en) | 2007-04-16 | 2007-04-16 | Safety device for protection of a rotor of a fluid flow engine installed at right angles to the horizontal plane against overturning and mounting device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP1983161A1 true EP1983161A1 (en) | 2008-10-22 |

Family

ID=38436746

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20070007681 Withdrawn EP1983161A1 (en) | 2007-04-16 | 2007-04-16 | Safety device for protection of a rotor of a fluid flow engine installed at right angles to the horizontal plane against overturning and mounting device |

| EP20080735742 Active EP2134928B1 (en) | 2007-04-16 | 2008-04-03 | Assembly device for assembling and disassembling a rotor of a turbomachine consisting of rotor disks |

| EP08735741.4A Not-in-force EP2134927B1 (en) | 2007-04-16 | 2008-04-03 | Securing device for securing a rotor of a turbomachine counter to tilting, said rotor being arranged perpendicular to a horizontal plane and method for the alignment thereof |

Family Applications After (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20080735742 Active EP2134928B1 (en) | 2007-04-16 | 2008-04-03 | Assembly device for assembling and disassembling a rotor of a turbomachine consisting of rotor disks |

| EP08735741.4A Not-in-force EP2134927B1 (en) | 2007-04-16 | 2008-04-03 | Securing device for securing a rotor of a turbomachine counter to tilting, said rotor being arranged perpendicular to a horizontal plane and method for the alignment thereof |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US9003656B2 (en) |

| EP (3) | EP1983161A1 (en) |

| JP (2) | JP4948644B2 (en) |

| AT (1) | ATE510998T1 (en) |

| ES (1) | ES2365375T3 (en) |

| PL (1) | PL2134928T3 (en) |

| WO (2) | WO2008125507A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3647538A1 (en) * | 2018-10-30 | 2020-05-06 | Siemens Aktiengesellschaft | Safety apparatus for containing an energy release from a rotor assembly |

| EP3647537A1 (en) * | 2018-10-30 | 2020-05-06 | Siemens Aktiengesellschaft | Safety apparatus and corresponding method for containing an energy release from a tension stud of a rotor assembly |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB201005351D0 (en) * | 2010-03-30 | 2010-05-12 | Rolls Royce Plc | Support frame |

| EP2570621A1 (en) * | 2011-09-15 | 2013-03-20 | Siemens Aktiengesellschaft | Device for pivoting a rotor of a fluid flow engine from a first position to a second position |

| EP2667493B1 (en) * | 2012-05-21 | 2019-11-20 | Siemens Gamesa Renewable Energy A/S | Method of vertically assembling a generator of a wind turbine |

| DE102014200760A1 (en) * | 2014-01-17 | 2015-07-23 | Siemens Aktiengesellschaft | Runners swivel system |

| KR101926288B1 (en) * | 2014-11-19 | 2018-12-06 | 미츠비시 히타치 파워 시스템즈 가부시키가이샤 | Maintenance method for gas turbine |

| KR101871061B1 (en) * | 2016-11-17 | 2018-06-25 | 두산중공업 주식회사 | Method for replacing the gas Turbine bearing and gas turbine |

| JP7274942B2 (en) * | 2019-05-31 | 2023-05-17 | 三菱重工業株式会社 | ROTOR ASSEMBLY METHOD, ROTOR DISC HOLDING JIG AND ROTOR STAND |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2325642A1 (en) * | 1972-05-24 | 1973-12-06 | Rolls Royce 1971 Ltd | GAS TURBINE SYSTEM |

| DE2426231A1 (en) * | 1974-05-29 | 1975-12-04 | Kraftwerk Union Ag | Stand for dismantling gas turbine rotor - ring member enclosing rotor permits rotor to tilt |

| WO2000017492A1 (en) * | 1998-09-24 | 2000-03-30 | Ramgen Power Systems, Inc. | Modular multi-part rail mounted engine assembly |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2930492A (en) * | 1957-07-23 | 1960-03-29 | Orenda Engines Ltd | Work stand and loading apparatus |

| DE2026254A1 (en) * | 1969-06-23 | 1971-01-07 | VEB Bergmann Borsig/Gorhtzer Ma schinenbau, χ 1000 Berlin Wilhelmsruh | Welding device with pivotal stand for fluid - flow engine armatures |

| JPS5072734A (en) | 1973-10-30 | 1975-06-16 | ||

| JPS51134107A (en) * | 1975-05-16 | 1976-11-20 | Matsushita Electric Ind Co Ltd | Recording stylus |

| DE3118073A1 (en) * | 1981-05-07 | 1982-11-25 | Hoechst Ag, 6000 Frankfurt | DIPHENYL ETHER AZO COMPOUNDS, METHOD FOR THE PRODUCTION THEREOF AND THEIR USE AS DYES |

| JPS6044267A (en) | 1983-08-20 | 1985-03-09 | Toyota Motor Corp | Method for enhancing attachment of metallization layer |

| JPS61161823A (en) * | 1985-01-10 | 1986-07-22 | Nec Corp | Input circuit |

| JPH0721261B2 (en) * | 1986-10-13 | 1995-03-08 | 三機工業株式会社 | Vertical vertical erecting jig |

| JPH0227071A (en) * | 1988-07-18 | 1990-01-29 | Sanki Eng Co Ltd | Pole vertical raise adjusting jig |

| JPH0572734A (en) | 1991-09-11 | 1993-03-26 | Mitsubishi Petrochem Co Ltd | Photosensitive resin composition |

| JPH0882117A (en) * | 1994-09-09 | 1996-03-26 | Masahito Kajii | Erectable pole device |

| JP2780736B2 (en) * | 1995-02-13 | 1998-07-30 | 山崎 勝己 | Pole support device |

| JPH11323962A (en) * | 1998-05-13 | 1999-11-26 | Kohan Kenzai Kk | Fitting accuracy adjusting tool and accurately fitting method using this fitting accuracy adjusting tool |

| JP2001234646A (en) * | 2000-02-24 | 2001-08-31 | Kyouyou:Kk | Steel tower and formation method thereof |

-

2007

- 2007-04-16 EP EP20070007681 patent/EP1983161A1/en not_active Withdrawn

-

2008

- 2008-04-03 US US12/596,215 patent/US9003656B2/en not_active Expired - Fee Related

- 2008-04-03 JP JP2010503449A patent/JP4948644B2/en not_active Expired - Fee Related

- 2008-04-03 WO PCT/EP2008/053993 patent/WO2008125507A1/en active Application Filing

- 2008-04-03 JP JP2010503450A patent/JP4937408B2/en not_active Expired - Fee Related

- 2008-04-03 AT AT08735742T patent/ATE510998T1/en active

- 2008-04-03 US US12/595,556 patent/US8667678B2/en not_active Expired - Fee Related

- 2008-04-03 WO PCT/EP2008/053992 patent/WO2008125506A1/en active Application Filing

- 2008-04-03 EP EP20080735742 patent/EP2134928B1/en active Active

- 2008-04-03 EP EP08735741.4A patent/EP2134927B1/en not_active Not-in-force

- 2008-04-03 PL PL08735742T patent/PL2134928T3/en unknown

- 2008-04-03 ES ES08735742T patent/ES2365375T3/en active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2325642A1 (en) * | 1972-05-24 | 1973-12-06 | Rolls Royce 1971 Ltd | GAS TURBINE SYSTEM |

| DE2426231A1 (en) * | 1974-05-29 | 1975-12-04 | Kraftwerk Union Ag | Stand for dismantling gas turbine rotor - ring member enclosing rotor permits rotor to tilt |

| WO2000017492A1 (en) * | 1998-09-24 | 2000-03-30 | Ramgen Power Systems, Inc. | Modular multi-part rail mounted engine assembly |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3647538A1 (en) * | 2018-10-30 | 2020-05-06 | Siemens Aktiengesellschaft | Safety apparatus for containing an energy release from a rotor assembly |

| EP3647537A1 (en) * | 2018-10-30 | 2020-05-06 | Siemens Aktiengesellschaft | Safety apparatus and corresponding method for containing an energy release from a tension stud of a rotor assembly |

| WO2020088811A1 (en) * | 2018-10-30 | 2020-05-07 | Siemens Aktiengesellschaft | Safety apparatus and corresponding method for containing an energy release from a tension stud of a rotor assembly |

| WO2020088809A1 (en) * | 2018-10-30 | 2020-05-07 | Siemens Aktiengesellschaft | Safety apparatus for containing an energy release from a rotor assembly |

| CN112955629A (en) * | 2018-10-30 | 2021-06-11 | 西门子能源环球有限责任两合公司 | Safety device for accommodating energy release from a rotor assembly |

| CN112955630A (en) * | 2018-10-30 | 2021-06-11 | 西门子能源环球有限责任两合公司 | Safety device for accommodating energy release from a tension stud of a rotor assembly and corresponding method |

| US11519301B2 (en) | 2018-10-30 | 2022-12-06 | Siemens Energy Global GmbH & Co. KG | Safety apparatus and corresponding method for containing an energy release from a tension stud of a rotor assembly |

| CN112955629B (en) * | 2018-10-30 | 2023-03-10 | 西门子能源环球有限责任两合公司 | Safety device for accommodating energy release from a rotor assembly |

| US11795835B2 (en) | 2018-10-30 | 2023-10-24 | Siemens Energy Global GmbH & Co. KG | Safety apparatus for containing an energy release from a rotor assembly |

Also Published As

| Publication number | Publication date |

|---|---|

| JP4948644B2 (en) | 2012-06-06 |

| EP2134927B1 (en) | 2017-03-08 |

| ES2365375T3 (en) | 2011-10-03 |

| US9003656B2 (en) | 2015-04-14 |

| JP2010523900A (en) | 2010-07-15 |

| US20100139064A1 (en) | 2010-06-10 |

| JP2010523901A (en) | 2010-07-15 |

| US8667678B2 (en) | 2014-03-11 |

| WO2008125507A1 (en) | 2008-10-23 |

| WO2008125506A1 (en) | 2008-10-23 |

| US20100107385A1 (en) | 2010-05-06 |

| PL2134928T3 (en) | 2011-10-31 |

| JP4937408B2 (en) | 2012-05-23 |

| EP2134928B1 (en) | 2011-05-25 |

| EP2134927A1 (en) | 2009-12-23 |

| ATE510998T1 (en) | 2011-06-15 |

| EP2134928A1 (en) | 2009-12-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2134927B1 (en) | Securing device for securing a rotor of a turbomachine counter to tilting, said rotor being arranged perpendicular to a horizontal plane and method for the alignment thereof | |

| EP2798163B1 (en) | Method for pulling and/or inserting a turbine bearing and device for performing the method | |

| EP1825141B1 (en) | Wind motor with a holding device for a rotor shaft | |

| EP2742213B1 (en) | Device for pivoting a rotor of a turbomachine from a first position into a second position | |

| DE102010062418B9 (en) | Method and device for rotating a robot blade bearing on wind turbines without the use of a mobile crane | |

| EP2278128A2 (en) | Gas turbine with exhaust casing and method for producing such a gas turbine | |

| WO2016078926A1 (en) | Gas turbine comprising a hoisting mechanism | |

| EP3538745B1 (en) | Method for assembly and disassembly of turbine components using a crane which is mounted to the turbine casing via an adapter, adapter and system for the method | |

| EP2177670A1 (en) | Superstructure for a movable work device | |

| DE202021106818U1 (en) | Mobile crane with a counterweight device | |

| WO2014154663A1 (en) | Cantilever slide for installing and removing a rotor block | |

| DE102013203793A1 (en) | Gondola frame and method for mounting and testing a nacelle for a wind turbine | |

| EP3051077A1 (en) | Mounting device for assembling or disassembling a gas turbine component in a gas turbine, in particular of a burner component in a burner system of a gas turbine | |

| EP0369938B1 (en) | Method and device for demolishing wallings | |

| EP3622164B1 (en) | Support system for a gas turbine and corresponding gas turbine | |

| EP1830006B1 (en) | Construction equipment and method for preparing said equipment for transportation | |

| EP3581794A1 (en) | Mounting system and method for mounting a wind turbine | |

| EP3663574A1 (en) | Transport device for a rotor hub of a wind turbine | |

| EP1342885B1 (en) | Thermal turbomaschine, especially axial gas turbine | |

| EP3438450B1 (en) | Platform to carry out maintenance operations on a wind turbine, method of assembling such a platform and wind turbine | |

| EP3562628A1 (en) | Method for assembly and/or disassembly, device for use in the method, burner adapter, transition adapter, arrangement and use of a robot | |

| CH702182A1 (en) | Gas turbine for power generation in combined cycle power plants, has supporting devices to absorb deformations of annular exhaust gas casing, where each supporting device exhibits pre-loaded spring support that acts in supporting direction | |

| DE102012009152B4 (en) | Inspection device for a crane slewing ring | |

| EP0013771A1 (en) | Maintenance platform | |

| DE9014748U1 (en) | Tiltable and erectable mast |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| AKX | Designation fees paid | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20090424 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |