EP1982943A3 - Spooling device for a workstation of a textile machine for creating cross-wound spools - Google Patents

Spooling device for a workstation of a textile machine for creating cross-wound spools Download PDFInfo

- Publication number

- EP1982943A3 EP1982943A3 EP08006782A EP08006782A EP1982943A3 EP 1982943 A3 EP1982943 A3 EP 1982943A3 EP 08006782 A EP08006782 A EP 08006782A EP 08006782 A EP08006782 A EP 08006782A EP 1982943 A3 EP1982943 A3 EP 1982943A3

- Authority

- EP

- European Patent Office

- Prior art keywords

- cross

- wound

- workstation

- coil

- textile machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H54/00—Winding, coiling, or depositing filamentary material

- B65H54/02—Winding and traversing material on to reels, bobbins, tubes, or like package cores or formers

- B65H54/40—Arrangements for rotating packages

- B65H54/54—Arrangements for supporting cores or formers at winding stations; Securing cores or formers to driving members

- B65H54/553—Both-ends supporting arrangements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H75/00—Storing webs, tapes, or filamentary material, e.g. on reels

- B65H75/02—Cores, formers, supports, or holders for coiled, wound, or folded material, e.g. reels, spindles, bobbins, cop tubes, cans, mandrels or chucks

- B65H75/18—Constructional details

- B65H75/185—End caps, plugs or adapters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/30—Handled filamentary material

- B65H2701/31—Textiles threads or artificial strands of filaments

Landscapes

- Winding Filamentary Materials (AREA)

Abstract

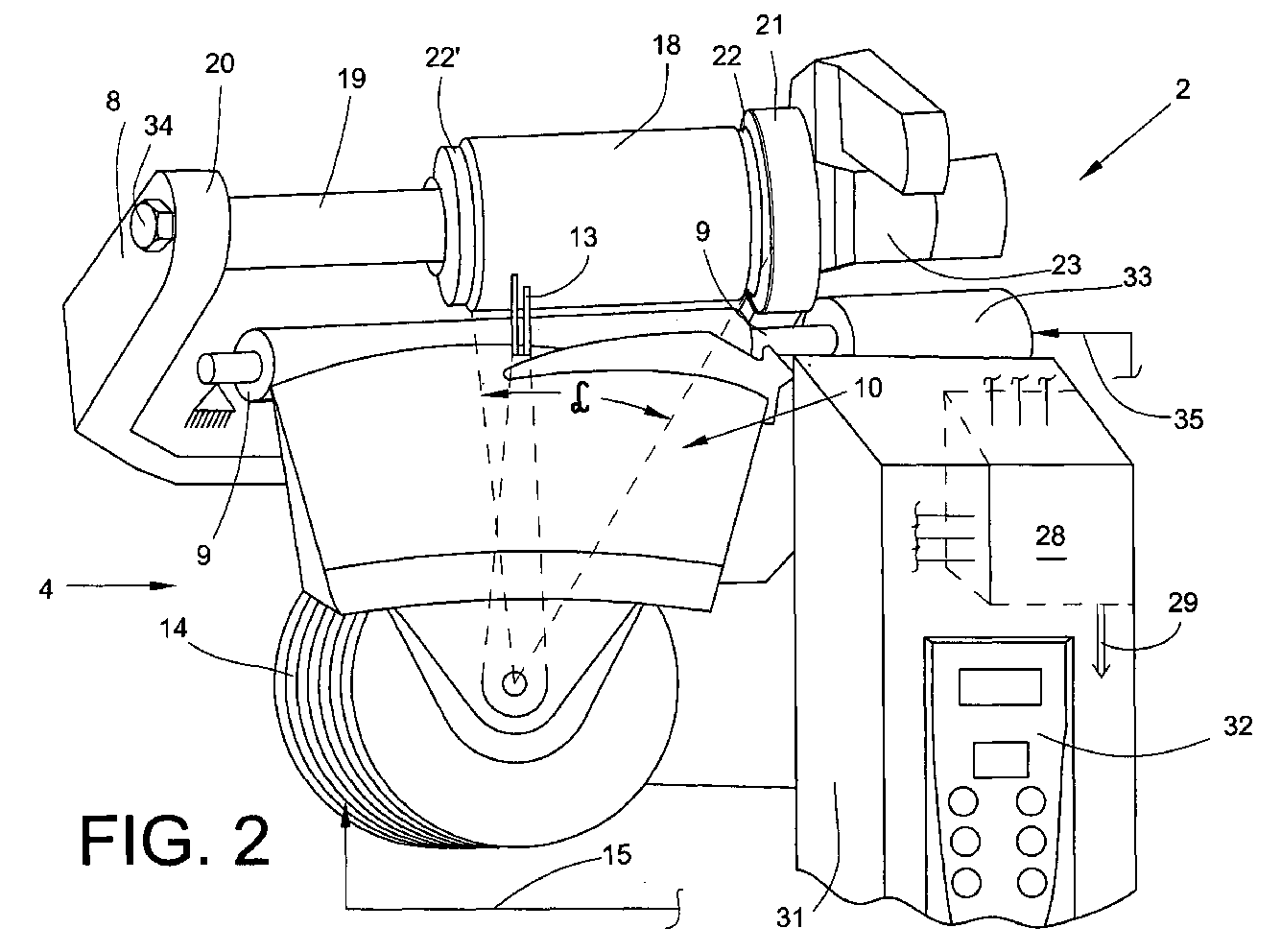

Die Erfindung betrifft eine Spulvorrichtung (4) für eine Arbeitsstelle (2) einer Kreuzspulen herstellenden Textilmaschine (1), mit einem Spulenrahmen (8) zum Haltern einer rotierbar gelagerten Kreuzspulenhülse (18), einer Einrichtung (9, 33) zum Rotieren der Kreuzspulenhülse (18) bzw. einer Kreuzspule (5) sowie einer separat antreibbaren Fadenchangiereinrichtung (10) zum Traversieren eines auf die Kreuzspule (5) auflaufenden Fadens (16), die so ausgebildet ist, dass wahlweise der Changierhub veränderbar ist und dadurch unterschiedliche Kreuzspulenformate herstellbar sind.The invention relates to a winding device (4) for a workstation (2) of a textile machine (1) producing cross-wound bobbins, comprising a creel (8) for supporting a rotatably mounted cheese package (18), means (9, 33) for rotating the cheese package ( 18) or a cross-wound bobbin (5) and a separately drivable Fadenchangiereinrichtung (10) for traversing the cross-wound bobbin (5) running thread (16) which is designed so that either the traverse stroke is variable and thereby different cross-coil formats can be produced.

Erfindungsgemäß ist vorgesehen, dass die Spulvorrichtung (4) einen Spulenrahmen (8) aufweist, der durch Bestückung mit Adaptern (19) unterschiedlicher Länge auf einfache Weise so modifizierbar ist, dass Kreuzspulenhülsen (18) unterschiedlicher Breite und unterschiedlichen Hülsenformats zwischen den Spulenrahmenarmen (20, 21) des Spulenrahmens (8) fixierbar sind. According to the invention, it is provided that the winding device (4) has a coil frame (8) which can be easily modified by equipping with adapters (19) of different lengths such that cross-wound coil sleeves (18) of different width and different sleeve format are arranged between the coil frame arms (20, FIG. 21) of the coil frame (8) are fixable.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102007018660A DE102007018660A1 (en) | 2007-04-20 | 2007-04-20 | Winding device for a job of a cheese-producing textile machine |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| DE102007018660 Previously-Filed-Application | 2007-04-20 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1982943A2 EP1982943A2 (en) | 2008-10-22 |

| EP1982943A3 true EP1982943A3 (en) | 2009-11-04 |

| EP1982943B1 EP1982943B1 (en) | 2011-06-08 |

Family

ID=39493231

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20080006782 Active EP1982943B1 (en) | 2007-04-20 | 2008-04-03 | Spooling device for a workstation of a textile machine for creating cross-wound spools |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1982943B1 (en) |

| DE (1) | DE102007018660A1 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102021129226A1 (en) | 2021-11-10 | 2023-05-11 | Saurer Spinning Solutions Gmbh & Co. Kg | Thread guiding device for a winding device |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| LU42729A1 (en) * | 1962-11-22 | 1964-05-22 | ||

| DE7217902U (en) * | 1972-08-03 | Palitex Project Co Gmbh | Bobbin holder | |

| DE9016205U1 (en) * | 1990-11-29 | 1991-02-14 | FAG Kugelfischer Georg Schäfer KGaA, 8720 Schweinfurt | Spool holder for high-speed textile spindles |

| JPH0428878U (en) * | 1990-06-29 | 1992-03-09 | ||

| JPH08104470A (en) * | 1994-10-05 | 1996-04-23 | Abansu Techno Kk | Bobbin |

| EP0712802A2 (en) * | 1995-08-16 | 1996-05-22 | TEMCO TEXTILMASCHINENKOMPONENTEN GmbH & Co. KG | Support for yarn bobbins rotating at high speed in textile machines and associated bobbin adapter |

| JPH0986794A (en) * | 1995-09-22 | 1997-03-31 | Hitachi Cable Ltd | Bobbin mounting structure |

| DE19908093A1 (en) * | 1999-02-25 | 2000-08-31 | Schlafhorst & Co W | Bobbin drive at a cross wound bobbin winding frame has an integrated pneumatic brake unit to move the stator housing with a brake lining against a braking surface on the rear of the bobbin holder plate |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1351934A (en) * | 1969-12-02 | 1974-05-01 | Ronfred Eng Co Ltd | Tube adapter for use with textile yarn processing machines |

| DE3628735A1 (en) | 1986-08-23 | 1988-02-25 | Hacoba Textilmaschinen | Thread-guide device for winding machines |

| US5305962A (en) | 1991-06-19 | 1994-04-26 | Murata Kikai Kabushiki Kaisha | Yarn winding apparatus and method |

| GB9510825D0 (en) * | 1995-05-23 | 1995-07-19 | Rieter Scragg Ltd | Package support device |

| DE19858548A1 (en) | 1998-12-18 | 2000-06-21 | Schlafhorst & Co W | Electromechanical drive for the reciprocating yarn guide for winding cross wound bobbins has a structured air gap with magnetic field lines through it acting on a coil at the yarn guide |

| EP1126058A3 (en) | 2000-02-17 | 2002-11-27 | Schärer Schweiter Mettler AG | Device for driving rotating components in an open-end spinning machine |

-

2007

- 2007-04-20 DE DE102007018660A patent/DE102007018660A1/en not_active Withdrawn

-

2008

- 2008-04-03 EP EP20080006782 patent/EP1982943B1/en active Active

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7217902U (en) * | 1972-08-03 | Palitex Project Co Gmbh | Bobbin holder | |

| LU42729A1 (en) * | 1962-11-22 | 1964-05-22 | ||

| JPH0428878U (en) * | 1990-06-29 | 1992-03-09 | ||

| DE9016205U1 (en) * | 1990-11-29 | 1991-02-14 | FAG Kugelfischer Georg Schäfer KGaA, 8720 Schweinfurt | Spool holder for high-speed textile spindles |

| JPH08104470A (en) * | 1994-10-05 | 1996-04-23 | Abansu Techno Kk | Bobbin |

| EP0712802A2 (en) * | 1995-08-16 | 1996-05-22 | TEMCO TEXTILMASCHINENKOMPONENTEN GmbH & Co. KG | Support for yarn bobbins rotating at high speed in textile machines and associated bobbin adapter |

| JPH0986794A (en) * | 1995-09-22 | 1997-03-31 | Hitachi Cable Ltd | Bobbin mounting structure |

| DE19908093A1 (en) * | 1999-02-25 | 2000-08-31 | Schlafhorst & Co W | Bobbin drive at a cross wound bobbin winding frame has an integrated pneumatic brake unit to move the stator housing with a brake lining against a braking surface on the rear of the bobbin holder plate |

Also Published As

| Publication number | Publication date |

|---|---|

| DE102007018660A1 (en) | 2008-10-23 |

| EP1982943B1 (en) | 2011-06-08 |

| EP1982943A2 (en) | 2008-10-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2261158A3 (en) | Spooling machine with a changing device and method for operating the same | |

| EP2444347A3 (en) | Workstation of a textile machine for creating cross-wound spools | |

| DE102012004910A1 (en) | Method for optimizing the winding speed of a work station of an automatic winder | |

| DE102007023490A1 (en) | Method and device for operating a winding device of a cross-wound producing textile machine | |

| DE102017114707A1 (en) | Thread splicer for pneumatically connecting thread ends | |

| DE102011111033A1 (en) | Thread splicing device for cross coil-producing textile machine with pneumatic loadable splicing prism in textile industry, has actuators for lower thread clamp and cutting device and upper thread clamp and cutting device | |

| EP2801544A1 (en) | Method and device for operating a workstation of a textile machine for creating cross-wound spools | |

| EP2388224A3 (en) | Operating unit | |

| EP2279976B1 (en) | Method for operating workplaces on a textile machine for creating cross-wound spools | |

| DE102007058857A1 (en) | Method for operating a winding head of a textile machine producing cross coils comprises a ball limiter which is raised in the direction of the starting position before the complete thread is removed from the spinning cop | |

| DE10342266B4 (en) | Method for producing a cross-wound bobbin | |

| DE102015016664A1 (en) | yarn splicing | |

| EP1982943A3 (en) | Spooling device for a workstation of a textile machine for creating cross-wound spools | |

| EP1971545B1 (en) | Thread splicing apparatus for a textile machine producing cross-wound bobbins | |

| EP1928773B1 (en) | Method for threading in a thread | |

| DE102004051880A1 (en) | Optimizing yarn take-off in automatic cross-winding machine, to reduce tensile force on yarn and minimize damage, using positioning device for vertically adjustable yarn guide above take-off bobbin | |

| EP2060524B1 (en) | Crosswound textile bobbin and apparatus to manufacture such a bobbin | |

| EP2036847A3 (en) | Method and device for positioning a finger yarn guide of a textile machine for creating cross-wound spools | |

| DE102014014998A1 (en) | Winding station with an alignment device for a spinning cop | |

| DE102009033377A1 (en) | Method and apparatus for operating a workstation of a textile machine producing cross-wound bobbins | |

| DE102006044646A1 (en) | Operating site for a textile machine producing cross-wound bobbins comprises a toothed segment pivoting on a driven shaft and arranged on a lever unit | |

| EP1783082B1 (en) | Method for rewinding dye bobbins to cross-wound bobbins | |

| EP2468669B1 (en) | Method for manufacturing a dye bobbin | |

| DE102016123451A1 (en) | yarn splicing | |

| DE102016001115A1 (en) | Working place of a winding machine producing textile machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| 17P | Request for examination filed |

Effective date: 20100504 |

|

| AKX | Designation fees paid |

Designated state(s): CH DE IT LI TR |

|

| 17Q | First examination report despatched |

Effective date: 20100629 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B65H 54/553 20060101AFI20110110BHEP Ipc: B65H 75/18 20060101ALI20110110BHEP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE IT LI TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502008003762 Country of ref document: DE Effective date: 20110721 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20120309 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502008003762 Country of ref document: DE Effective date: 20120309 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502008003762 Country of ref document: DE Owner name: SAURER GERMANY GMBH & CO. KG, DE Free format text: FORMER OWNER: OERLIKON TEXTILE GMBH & CO. KG, 42897 REMSCHEID, DE Effective date: 20130918 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: SCHMAUDER AND PARTNER AG PATENT- UND MARKENANW, CH Ref country code: CH Ref legal event code: PUE Owner name: SAURER GERMANY GMBH AND CO. KG, DE Free format text: FORMER OWNER: OERLIKON TEXTILE GMBH AND CO. KG, DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCOW Free format text: NEW ADDRESS: LEVERKUSER STRASSE 65, 42897 REMSCHEID (DE) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20150506 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502008003762 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161101 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230519 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20250325 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250424 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20250501 Year of fee payment: 18 |