EP1961663B1 - Mobile Verpackungsmaschine für kleine Gegenstände - Google Patents

Mobile Verpackungsmaschine für kleine Gegenstände Download PDFInfo

- Publication number

- EP1961663B1 EP1961663B1 EP08405058A EP08405058A EP1961663B1 EP 1961663 B1 EP1961663 B1 EP 1961663B1 EP 08405058 A EP08405058 A EP 08405058A EP 08405058 A EP08405058 A EP 08405058A EP 1961663 B1 EP1961663 B1 EP 1961663B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- machine according

- packaging material

- packaging

- products

- product

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 238000004806 packaging method and process Methods 0.000 title claims description 21

- 238000001035 drying Methods 0.000 claims abstract description 8

- 238000000926 separation method Methods 0.000 claims abstract description 8

- 239000005022 packaging material Substances 0.000 claims description 25

- 238000010438 heat treatment Methods 0.000 claims description 9

- 238000007599 discharging Methods 0.000 claims 1

- 239000000463 material Substances 0.000 abstract description 6

- 229920000298 Cellophane Polymers 0.000 abstract description 5

- 238000012856 packing Methods 0.000 abstract description 3

- 229920003023 plastic Polymers 0.000 description 3

- 235000009508 confectionery Nutrition 0.000 description 2

- 238000007649 pad printing Methods 0.000 description 2

- 230000001737 promoting effect Effects 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000001143 conditioned effect Effects 0.000 description 1

- 238000005034 decoration Methods 0.000 description 1

- 238000010981 drying operation Methods 0.000 description 1

- 239000005021 flexible packaging material Substances 0.000 description 1

- 235000013305 food Nutrition 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 235000012054 meals Nutrition 0.000 description 1

- 235000014594 pastries Nutrition 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B9/00—Enclosing successive articles, or quantities of material, e.g. liquids or semiliquids, in flat, folded, or tubular webs of flexible sheet material; Subdividing filled flexible tubes to form packages

- B65B9/06—Enclosing successive articles, or quantities of material, in a longitudinally-folded web, or in a web folded into a tube about the articles or quantities of material placed upon it

- B65B9/073—Enclosing successive articles, or quantities of material, in a longitudinally-folded web, or in a web folded into a tube about the articles or quantities of material placed upon it the web having intermittent motion

Definitions

- the present invention relates to a mobile packaging machine for small individual objects, such as writing instruments, table cutlery, confectionery products or the like.

- the packaging of small objects such as pens, plastic cutlery or objects of decoration or utilities, including elongated objects, in cellophane packaging for example, is usually done either manually or automatically by robotic facilities expensive and cumbersome complexes such as those described in particular in patents US 5,423,162 A , US 3,564,809 A , US 4,862,679 A and the European publication EP 0 055 133 A .

- the market demand corresponds more to units of small size, mobile and flexible in terms of their use, which are easy to use and whose maintenance is simple and economical.

- One of the applications is, for example, the placing in a cellophane wrapper of a set of plastic table cutlery for airplanes. It is advantageous to be able to place the machine near the site of use of packaged products, that is to say in the area of the airport where meals are prepared for departing planes.

- Another application may be to package food portions, such as pastries or confectionery products, or promotional items.

- the present invention proposes to overcome the disadvantages of the known systems and to respond to the new market demand by producing a packaging machine, in particular for the semi-automatic or automatic packaging of pens or other small objects, which may be installed in a small room and moved according to the needs of the user or intended applications.

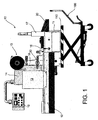

- the packaging machine as defined in the preamble and characterized in that it comprises a frame, integral with a mobile lift truck, extended by a supply arm of products to be packaged, on which is mounted a heating-drying unit, a device for supplying packaging material in the form of a continuous strip, a device for packaging and guiding products covered with tube-shaped packaging material, a unit separating the package containing an individual conditioned object and a discharge member of the packaged product to a storage bin.

- the machine further comprises a control unit provided with a mobile control keyboard.

- said supply arm of products to be packaged comprises a guide channel which constitutes a linear gutter in which the products respectively pushed by lugs integral with a conveyor belt circulate, these cleats exerting a thrust on the products for the products. bring to said packaging material.

- said packaging material is stored as a continuous web on a rotating drum of the supply device and is unwound by passing on and between pairs of rollers before being conveyed by an element of guiding substantially inclined at 45 °, to the packaging and guiding device arranged to perform the folding and the longitudinal junction of the edges of the strip of packaging material.

- the packaging and guiding device comprises two pairs of horizontal disks, respectively driven by toothed pinions, which ensure both the driving of the products and the joining of the longitudinal edges of the strip of folded packaging material covering the product.

- These horizontal disks can be heating disks.

- the separation unit is advantageously arranged to perform simultaneously a bonding by welding between the two juxtaposed packing material surfaces and a cross section in this connection to separate the packaged products from each other.

- this separation unit preferably comprises two transverse heating elements, sliding, of inverted U-shaped cross-section, which cooperate to weld transversely the packaging material between each product that it contains, and a knife, vertically movable through an actuator, which slides in the upper heating element.

- Said actuator of the knife may be a cylinder or a motor element.

- the packaging machine 10 is disposed on the plate 110 of a forklift truck 100.

- This representation illustrates both the small size and the mobility of the machine 10.

- the forklift truck 100 can either move the machine 10 to the machine. bring to a site of use, either to support the machine during its use.

- the function of this machine is to cover the object with a flexible packaging material, which may be paper or the like, a cellophane film or a strip of synthetic material such as for example a heat-shrinkable plastic material.

- the machine 10 comprises a frame 11 extended by a supply arm 12 of products to be packaged, on which is mounted a heating-drying unit 13, a supply device 15 of packaging material 30, a packaging device and guiding 16 products covered with the packaging material, a separation unit 17 of the package containing an individual packaged product, and a storage bin 20 of the packaged product.

- a control keyboard 19, or a touch screen, is connected by a movable arm to this control unit 14.

- the packaging material 30, for example a cellophane web is stored as a continuous web on a rotating drum 151 of the supply device 15. It is unrolled and passed over and between pairs of rolls. drive 152 and 153 before being conveyed, via a guide member 154 having substantially a 45 ° inclination and disposed at the output of the feed arm 12, to the packaging and guiding device 16 .

- the feed arm 12 illustrated in more detail by the figure 3 , on which are deposited the products to be packaged, is provided with a longitudinal guide channel 121 which constitutes a linear gutter in which the products circulate, respectively pushed by tabs 122 integral with a conveyor belt 123, these cleats exerting a thrust on the products to bring them to a sheet of packaging material.

- the heating-drying unit 13 is arranged on the supply arm 12 above the longitudinal channel 121 and is used when the products to be packaged are provided with an inscription or a mark and that, therefore, they have been presented in advance to a pad printing machine (not shown), or by any other known ink printing machine, for affixing said registration or mark.

- the purpose of this heating-drying unit 13 is to ensure the drying of the inscription affixed to the product by the pad printing machine.

- this unit 13 advantageously contains at least one infrared radiation ramp 131 and / or the if necessary a fan or other means of drying. If no ink marking is performed beforehand, the drying operation becomes unnecessary.

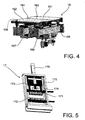

- the packaging and guiding device16 provides the folding and the longitudinal junction of the edges of the band of the packaging material 30 to produce a pouch in which the product is finally packaged.

- this device 16 comprises two horizontal plates 161 and 162 separated by a slot 163 whose inlet 164, disposed on the arrival side of the packaging material 30, has a flared V shape arranged to allow the introduction of said packaging material, the product to be packaged brought by the supply arm 12 is covered, by folding under said product.

- Two pairs of rotating horizontal disks 165 and 166 disposed under said trays 161 and 162, drive the product covered with said material along this slot while sealing, by heating or compression, the two longitudinal edges of the folded material under the trays 161 and 162 to form a tube in which the product is located.

- These disks 165 and 166 are rotated respectively by toothed pinions 167 and 168 coupled to respective drive motors.

- This unit 17 which closes the transverse edges of the package and separates the products, is of the guillotine type and comprises two transverse heating elements 171 and 172, of inverted U-shaped cross-section, which cooperate with each other. sliding along rods 173, for transversely welding the tube of packaging material between each product contained therein.

- a knife 174 vertically movable through an actuator 175, which may be a cylinder or other motor element, slides in the upper heating element 171 and simultaneously separates the products in the middle of the weld.

- the packaged and separated products are finally discharged into the storage tank 20 by an evacuation ramp 201.

- the machine according to the invention as configured allows to be available and mobile in any environment for automatic or semi-automatic packaging of small objects, for example promotional items such as pens.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

- Basic Packing Technique (AREA)

Claims (11)

- Mobile Verpackungsmaschine (10) für einzelne Gegenstände mit kleinen Abmessungen, wie beispielsweise Schreibgeräte, Tafelbesteck, Süßwaren oder Ähnliches,

dadurch gekennzeichnet, dass sie einen fest mit einem beweglichen Hubwagen (100) verbundenen Pfosten (11) aufweist, der durch einen Zufuhrarm (12) zur Zufuhr von abzupackenden Produkte verlängert ist, auf dem eine Heiz-Trockeneinheit (13), eine Versorgungseinrichtung (15) zur Versorgung mit Verpackungsmaterial (30) in Form eines Endlos-bandes, eine Verpackungs- und Führungsvorrichtung (16) für mit dem Verpackungsmaterial bedeckte Produkte in Rohrform, eine Trenneinheit (17) für die Verpackung, die ein einzelnes konditioniertes Objekt enthält, und ein Auswurfelement (201) zum Auswurf des verpackten Produktes in einen Lagerbehälter (20) angebracht ist. - Maschine nach Anspruch 1,

dadurch gekennzeichnet, dass sie eine Steuerungszentrale (14) aufweist, die mit einer beweglichen Steuerungstastatur (19) versehen ist. - Maschine nach Anspruch 1,

dadurch gekennzeichnet, dass der Zufuhrarm (12) einen Führungskanal (121) aufweist, der eine lineare Ablaufrinne darstellt, worin die Produkte umlaufen, die jeweils von fest mit einem Transportband (123) verbundenen Ansätzen (122) geschoben werden, wobei die Ansätze eine Schubkraft auf die Produkte ausüben, um sie zu dem Verpackungsmaterial (30) zu bringen. - Maschine nach Anspruch 1,

dadurch gekennzeichnet, dass das Verpackungsmaterial (30) in Form eines Endlos-bandes auf einer Drehtrommel (151) der Versorgungseinrichtung (15) gelagert ist. - Maschine nach Anspruch 4,

dadurch gekennzeichnet, dass das Verpackungsmaterial (30) abgerollt wird, indem es über und zwischen Rollenpaaren (152, 153) läuft, bevor es durch ein Führungselement (154), das praktisch um 45° geneigt ist, in Richtung der Verpackungs- und Führungsvorrichtung (16) befördert wird, die angeordnet ist, um das Falten und Zusammenfügen der Ränder des Bandes von Verpackungsmaterial (30) in Längsrichtung zu bewirken. - Maschine nach Anspruch 5,

dadurch gekennzeichnet, dass die Verpackungs- und Führungsvorrichtung (16) zwei Paare von Horizontalscheiben (165, 166) aufweist, die jeweils durch Zahnritzel (167, 168) angetrieben werden, die gleichzeitig den Antrieb der Produkte und das Zusammenfügen der Längsränder des gefalteten Bandes von Verpackungsmaterial (30) sicherstellen, welches das Produkt bedeckt. - Maschine nach Anspruch 6,

dadurch gekennzeichnet, dass die Horizontalscheiben (165, 166) beheizbare Scheiben sind. - Maschine nach Anspruch 1,

dadurch gekennzeichnet, dass die Trenneinheit (17) angeordnet ist, um gleichzeitig eine Verbindung durch eine Schweißung zwischen den zwei nebeneinander positionierten Oberflächen des Verpackungsmaterials, und einen Transversalschnitt in dieser Verbindung zu bewirken, um die verpackten Produkte voneinander zu trennen. - Maschine nach Anspruch 8,

dadurch gekennzeichnet, dass die Trenneinheit (17) zwei transversale gleitende Heizelemente (171, 172) in Form eines umgedrehten U, die zusammenwirken, um das Verpackungsmaterial (30) transversal zwischen jedem Produkt zu schweißen, das es enthält, und ein Messer (174) aufweist, das mittels eines Stellgliedes (175) vertikal bewegbar ist, das in dem oberen Heizelement (171) gleitet. - Maschine nach Anspruch 9,

dadurch gekennzeichnet, dass das Stellglied (175) ein Zylinder ist. - Maschine nach Anspruch 9,

dadurch gekennzeichnet, dass das Stellglied (175) ein Antriebselement ist.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH00316/07A CH702570B1 (fr) | 2007-02-26 | 2007-02-26 | Machine de conditionnement mobile d'objets de petites dimensions. |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1961663A1 EP1961663A1 (de) | 2008-08-27 |

| EP1961663B1 true EP1961663B1 (de) | 2011-12-21 |

Family

ID=38521755

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08405058A Not-in-force EP1961663B1 (de) | 2007-02-26 | 2008-02-25 | Mobile Verpackungsmaschine für kleine Gegenstände |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1961663B1 (de) |

| AT (1) | ATE538036T1 (de) |

| CH (1) | CH702570B1 (de) |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3564809A (en) * | 1968-10-08 | 1971-02-23 | James G Keramas | Automatic heat seal packaging machine and method |

| US4430845A (en) * | 1980-12-24 | 1984-02-14 | Doboy Packaging Machinery Inc. | Folder for polyfilm |

| JPH0257508A (ja) * | 1988-08-11 | 1990-02-27 | Hanagata:Kk | 半折フィルムによる物品包装装置 |

| US5423162A (en) * | 1994-11-03 | 1995-06-13 | Chiu; Shao-Yi | Automatic packing and sealing machine |

-

2007

- 2007-02-26 CH CH00316/07A patent/CH702570B1/fr not_active IP Right Cessation

-

2008

- 2008-02-25 AT AT08405058T patent/ATE538036T1/de active

- 2008-02-25 EP EP08405058A patent/EP1961663B1/de not_active Not-in-force

Also Published As

| Publication number | Publication date |

|---|---|

| ATE538036T1 (de) | 2012-01-15 |

| EP1961663A1 (de) | 2008-08-27 |

| CH702570B1 (fr) | 2011-07-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2735354C2 (ru) | Этикетировочное устройство | |

| FR2586662A1 (fr) | Table de transport a vide pour l'entrainement de matiere en feuille | |

| FR2615166A1 (fr) | Procede de conditionnement d'un produit et dispositif pour la mise en oeuvre de ce procede | |

| EP1415919A1 (de) | Verfahren und Vorrichtung zum Befüllen von Verpackungsschalen mit einem Nahrungsmittel | |

| EP2616242B1 (de) | Vorrichtung zur streifenführung für eine folienprägevorrichtung | |

| EP2511188B1 (de) | Maschine und Verfahren zum Verpacken von länglichen Lebensmittelprodukten in Beutel, und entsprechender Verpackungsbeutel | |

| EP1961663B1 (de) | Mobile Verpackungsmaschine für kleine Gegenstände | |

| AU2008246848A1 (en) | Bag making and packaging machine | |

| JP7144440B2 (ja) | 包装体に追加要素を貼着するための貼着デバイス、貼着装置、および方法 | |

| CH639343A5 (fr) | Emballage scelle pour produits a etaler ainsi que procede et appareil pour sa fabrication. | |

| BE1024021B1 (fr) | Trancheuse de denrees | |

| FR2462348A1 (fr) | Agencement pour le traitement de materiau sous forme de bande ou de feuille | |

| KR102037856B1 (ko) | 브리또 포장장치 | |

| EP1525146B1 (de) | Vorrichtung zum vorbereiten von materialbahnen wie auf thermoformanlagen erzeugten fangleisten | |

| JPH06171606A (ja) | フィルム包装方法及びその装置 | |

| FR2754240A1 (fr) | Dispositif d'application de bandes de dechirement | |

| KR101244146B1 (ko) | 커피스틱 포장 장치 | |

| EP1873079A1 (de) | Deckel für eine Palette | |

| WO2000043268A1 (fr) | Procede et installation permettant la realisation et le remplissage en continu de recipients souples | |

| JP2001294209A (ja) | 封緘機 | |

| JP2019089569A (ja) | 粘着テープ切断装置および封緘製品の製造方法 | |

| TWI719397B (zh) | 三面封(背封)包裝機 | |

| WO2010021029A1 (ja) | 包装袋製造装置および包装袋製造方法 | |

| FR2461647A1 (fr) | Procede et appareil pour former un recipient pour liquides | |

| FR2649670A1 (fr) | Nouvel emballage autocollant en carton ondule ou compact et machine pour le fabriquer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| 17P | Request for examination filed |

Effective date: 20090210 |

|

| R17P | Request for examination filed (corrected) |

Effective date: 20090209 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 538036 Country of ref document: AT Kind code of ref document: T Effective date: 20120115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602008012146 Country of ref document: DE Effective date: 20120301 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20111221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120321 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20111221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120322 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120321 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120421 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 |

|

| BERE | Be: lapsed |

Owner name: PCL S.A. Effective date: 20120228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120423 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 538036 Country of ref document: AT Kind code of ref document: T Effective date: 20111221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120229 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20121031 |

|

| 26N | No opposition filed |

Effective date: 20120924 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120321 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602008012146 Country of ref document: DE Effective date: 20120901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120229 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120321 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120901 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120225 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080225 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20160823 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170228 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170228 |