EP1929894B1 - Überzug für Einlegesohlen in Schuhen - Google Patents

Überzug für Einlegesohlen in Schuhen Download PDFInfo

- Publication number

- EP1929894B1 EP1929894B1 EP07022718A EP07022718A EP1929894B1 EP 1929894 B1 EP1929894 B1 EP 1929894B1 EP 07022718 A EP07022718 A EP 07022718A EP 07022718 A EP07022718 A EP 07022718A EP 1929894 B1 EP1929894 B1 EP 1929894B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- shoe

- insoles

- threads

- fabric

- insole

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43B—CHARACTERISTIC FEATURES OF FOOTWEAR; PARTS OF FOOTWEAR

- A43B17/00—Insoles for insertion, e.g. footbeds or inlays, for attachment to the shoe after the upper has been joined

- A43B17/10—Insoles for insertion, e.g. footbeds or inlays, for attachment to the shoe after the upper has been joined specially adapted for sweaty feet; waterproof

- A43B17/102—Moisture absorbing socks; Moisture dissipating socks

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43B—CHARACTERISTIC FEATURES OF FOOTWEAR; PARTS OF FOOTWEAR

- A43B1/00—Footwear characterised by the material

- A43B1/0045—Footwear characterised by the material made at least partially of deodorant means

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43B—CHARACTERISTIC FEATURES OF FOOTWEAR; PARTS OF FOOTWEAR

- A43B1/00—Footwear characterised by the material

- A43B1/009—Footwear characterised by the material made at least partially of washable material

Definitions

- insoles are used to keep cold acting from the floor to the shoe sole cold off the foot.

- the known insoles are made of various materials, such as leather, plastic, cork o. The like ..

- the insoles can also be made of combinations of different materials. It is also known to provide insoles on one or both sides with layers of different materials. For example, it is known to ward off cold, apply an aluminum layer on the underside of the insole, on the other hand, a layer of textiles on the top of the insole.

- insoles which are provided for example with a perforation, to evoke improved ventilation within the shoe.

- charcoal insoles to improve shoe hygiene.

- insoles made of composite materials which contain, for example, surface-active or odor-absorbing agents or consist of bactericides or PH buffers, which bring about an improvement in shoe hygiene.

- the use of the insoles leads to satisfactory results.

- weak points in the use of the known insoles is that they are not universally applicable due to their shape and size.

- the insoles lose their effectiveness over their useful life, so that the climatic and hygienic conditions in the shoe deteriorate despite the use of insoles.

- the aforementioned problems occur in all application areas of shoes. However, they are particularly in applications of shoes in the foreground, in which different users use the same shoes, as is the case for example when renting ski boots, ice skates or bowling shoes. Here is not to ensure with the known insoles that at any time a perfect shoe hygiene in passing the shoes to a new user is present.

- the hygienic problems In addition, especially in sports in which the shoes are used without wearing socks, as is the case for example with athletes.

- the object of the invention is to produce a simple and at the same time very effective improvement of the climatic properties in the shoe. According to the invention, this object is solved by the features of patent claim 1.

- the invention provides a cover for insoles in shoes, which contributes to a significant improvement of the climate in shoes. Due to the tubular and elastic design of the coating, this adapts optimally to the shape of the insole. It is therefore possible to use the coating even with shoes that require an extremely high accuracy of fit, such as athletics sports shoes.

- the air duct used contributes to improving the climate in the shoe. It allows air to circulate in the shoe, allowing air to flow through the climate channels under the sole of the foot.

- the coating also has the advantage that it is easy to pull over the respective insole. After use of the shoe, the cover can be removed from the insole and washed in a conventional manner. As a result, the hygiene in the shoe is significantly increased. In addition, due to the material in relation to washable insoles, the drying time is significantly reduced, so that, for example, a washed in the evening coat the next morning is available again. As a result, there is a significant improvement in terms of ease of use relative to insoles having climate-improving or hygiene-improving properties in terms of their washability.

- the cover 1 chosen as an embodiment serves for slipping over an insole 2 of a shoe, not shown.

- the cover 1 consists of an elastic fabric 11 and has the shape of a closed-end hose. As a result, an opening 3 is formed.

- the opening 3 is surrounded by a band 4, which is also elastic in the embodiment.

- the selection of the materials used for the coating 1 can be essentially arbitrary.

- the most important requirement for the material of the fabric 11 or the yarn from which the fabric 11 is formed is its ability to stretch. This ensures that the cover 1 snuggles well on the insole 2 and wrinkling when wearing shoes with insole and cover is avoided.

- a friction reducing yarn such as Dynema or PTFE, can be used to make the fabric 11.

- the risk of skin irritation and blistering is significantly reduced.

- the fabric 11 of the coating 1 consists of a microfiber yarn, which is preferably a polymer fiber.

- the use of polyamide, aramid or acrylic fibers is possible.

- the risk of foot diseases, such as fungal infections, can be reduced by using antibacterial or antifungicidal yarns.

- Yarns made of silver or copper or yarns coated with silver or copper are particularly suitable for this purpose.

- the opening 3 has a diameter which is smaller than the narrowest point of the insole 2. This has the effect that the opening 3 exerts a pulling force on the fabric 11, regardless of their arrangement in the slipped-over state, so that the tension of the coating 1, which is already present due to its elastic formation, is reinforced.

- the opening 3 in the state in which it is slipped over in the region of the heel is arranged on the side facing the bottom - underside - of the insole 1. This position is particularly advantageous, since there is an impairment of the comfort is excluded in any case. It is also possible to design the cover 1 differently, so that the opening 3 is arranged in other areas of the insole 2. However, it is important to ensure that, for example, the rolling over the ball of the foot is not affected.

- the surrounding the opening 3 band 4 is formed in the embodiment in the manner of a cuff. It is relatively wide and therefore has a high clamping force. At the same time, the band 4 is made very thin in order to avoid impairment of wearing comfort.

- a functional surface 5 is provided on the upper side of the coating 1.

- the functional surface 5 can be designed differently and serves to improve the wearing comfort or the properties of the coating 1.

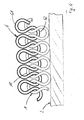

- the functional surface 5 has loop-shaped arranged threads 6, which extend over the entire upper side.

- the functional surface 5 also only partially be provided with the threads 6. For example, the area of the toes can be left out.

- the threads 6 form a "crimped" surface.

- This training can also be referred to as "loops”.

- the processing takes place, for example, by edges, as a result of which the threads 6 curl.

- the crimped shape of the threads 6 produces a relatively dense surface when woven with the tissue on the side facing the skin. This has the consequence that about 80% of the sole of the foot is in contact with the threads 6.

- the multitude of small loops work like microscopic rasps and can thus remove dead skin cells without attacking the living skin cells. In this way the bacteria on the foot is deprived of the breeding ground. The removed dead skin cells fall between the loops and therefore no longer come into contact with the foot. When washing the coating 1, they are removed without residue from the functional surface.

- the threads 6 in the exemplary embodiment are silver threads which have a core 61 made of polyamide surrounded by a layer 62 of silver ( FIG. 4 ).

- the core 61 is substantially inelastic and interwoven with the yarn from which the fabric is made.

- the coating of the threads 6 is preferably carried out galvanically.

- the layer 62 may also consist of copper, gold, polytetrafluoroethylene or the like in a modification of the embodiment. With the help of the different design of the layer 62 different effects can be achieved. For example, an antifungal effect can also be achieved with the aid of copper.

- a layer of polytetrafluoroethylene causes a reduction in the friction of the coating.

- the layer 62 is completely closed, which is why the threads 6 can not absorb moisture, for example in the form of sweat. Rather, the sweat is forwarded in the direction of the tissue.

- the fabric or yarn from which the fabric is made, therefore, has climatic properties. Therefore, it is able to absorb moisture and dirt. As a result, an almost closed, dry surface is created on the top of the cover 1, which gives an extremely comfortable wearing. At the same time, the fabric prevents penetration of the sweat up to the insole. As a result, on the one hand a protection of the insole caused; On the other hand, the insole is prevented by moisture absorbed contributes to a deterioration of the climate and hygiene in the shoe.

- At least one air conditioning duct 7 is provided in the functional surface 5 of the cover 1.

- the climate channel 7 contributes to an improvement of the climate in the shoe. It allows air to circulate in the shoe, allowing air to flow through the climate channels under the sole of the foot. As a result, a very good ventilation of the sole of the foot is achieved. Due to the movement of the foot movements in the shoe itself, which cause a pumping effect, with the help of air duct 7 spent or moist air can also be sucked under the foot.

- three air conditioning channels 7 are provided. Through the air ducts 7, the loop-shaped design of the functional surface 5 is interrupted.

- the air ducts 7 can be formed on the one hand by a simple interruption of the (high-pile) loops; but they can also be formed from climate-regulating net knit fabric. Corresponds to the thickness of the net knit fabric substantially the thickness of the functional surface 5, resulting in a continuous surface. As a result, the wearing comfort is positively influenced.

- the air conditioning ducts 7 may also be arranged radially. By this arrangement, wide area of the functional surface 5 are achieved by the air conditioning ducts 7, so that a removal of moisture from the entire performance area is possible.

- the width and the length of the air ducts 7 are usually freely selectable.

- the location and number of air conditioning channels 7 is variable. By increasing the lengths or widths of the air conditioning ducts 7 or increasing the number of air conditioning ducts 7, an increase in the conveyable air is possible.

- slip-resistant surfaces On the underside can be provided in a modification of the embodiment slip-resistant surfaces. These come in slipped-over state of the cover 1 with the shoe into contact and thus prevent slippage of the insole 2 with cover 1 in the shoe.

Landscapes

- Footwear And Its Accessory, Manufacturing Method And Apparatuses (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL07022718T PL1929894T3 (pl) | 2006-12-05 | 2007-11-23 | Osłona dla wkładek do butów |

| SI200730689T SI1929894T1 (sl) | 2006-12-05 | 2007-11-23 | Prevleka za vloĺ˝ke v äśevljih |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE202006018486U DE202006018486U1 (de) | 2006-12-05 | 2006-12-05 | Überzug für Einlegesohlen in Schuhen |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1929894A1 EP1929894A1 (de) | 2008-06-11 |

| EP1929894B1 true EP1929894B1 (de) | 2011-05-18 |

Family

ID=37853275

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07022718A Active EP1929894B1 (de) | 2006-12-05 | 2007-11-23 | Überzug für Einlegesohlen in Schuhen |

Country Status (8)

| Country | Link |

|---|---|

| EP (1) | EP1929894B1 (enExample) |

| JP (1) | JP3139574U (enExample) |

| AT (1) | ATE509540T1 (enExample) |

| DE (1) | DE202006018486U1 (enExample) |

| DK (1) | DK1929894T3 (enExample) |

| ES (1) | ES2366401T3 (enExample) |

| PL (1) | PL1929894T3 (enExample) |

| SI (1) | SI1929894T1 (enExample) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202007005259U1 (de) * | 2007-04-10 | 2007-06-28 | X-Technology Swiss Gmbh | Bekleidungsstück |

| EP2342984A1 (de) * | 2010-01-11 | 2011-07-13 | Masai Marketing & Trading AG | Sohleneinsatz für Gehgerät |

| PE20210015A1 (es) * | 2020-10-26 | 2021-01-05 | Armofa S A C | Dispositivo antimicrobiano y desinfectante de calzado |

| CN119977174B (zh) * | 2025-04-11 | 2025-07-22 | 鄂尔多斯市农牧技术推广中心 | 一种盐碱地水产养殖尾水循环处理系统和方法 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003037126A1 (en) | 2001-10-31 | 2003-05-08 | Saikyosya Co., Ltd. | Shoe insole |

| US20040261290A1 (en) * | 2003-06-27 | 2004-12-30 | Sasos, Ltd. | Sandal socks |

| US20060059712A1 (en) | 2004-08-13 | 2006-03-23 | Arnold Asham | Hygienic sandal |

| BE1016243A6 (fr) * | 2004-10-18 | 2006-06-06 | Bodart Luc | Dispositif hygienique pour sandales et son mode de fixation. |

-

2006

- 2006-12-05 DE DE202006018486U patent/DE202006018486U1/de not_active Expired - Lifetime

-

2007

- 2007-11-23 DK DK07022718.6T patent/DK1929894T3/da active

- 2007-11-23 EP EP07022718A patent/EP1929894B1/de active Active

- 2007-11-23 AT AT07022718T patent/ATE509540T1/de active

- 2007-11-23 SI SI200730689T patent/SI1929894T1/sl unknown

- 2007-11-23 ES ES07022718T patent/ES2366401T3/es active Active

- 2007-11-23 PL PL07022718T patent/PL1929894T3/pl unknown

- 2007-12-05 JP JP2007009359U patent/JP3139574U/ja not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP1929894A1 (de) | 2008-06-11 |

| SI1929894T1 (sl) | 2011-09-30 |

| PL1929894T3 (pl) | 2012-01-31 |

| ATE509540T1 (de) | 2011-06-15 |

| ES2366401T3 (es) | 2011-10-19 |

| DE202006018486U1 (de) | 2007-03-01 |

| DK1929894T3 (da) | 2011-09-12 |

| JP3139574U (ja) | 2008-02-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1476033B1 (de) | Element für Bekleidungsstücke sowie Verfahren zur Entfeuchtung von Hautbereichen | |

| EP1585397B1 (de) | Socke | |

| DE102016207387B4 (de) | Socke | |

| DE69302191T2 (de) | Schuheinlegsohlen | |

| WO2004068976A2 (de) | Socke | |

| EP1701626B1 (de) | Socke | |

| EP1364088B1 (de) | Textile fläche | |

| DE202009005651U1 (de) | Bekleidungsstück | |

| EP1929894B1 (de) | Überzug für Einlegesohlen in Schuhen | |

| WO2012065929A1 (de) | Kleidungsstück | |

| EP3697246A1 (de) | Tanzschuh, sohle-kappe-einheit, oberschuh und set bestehend aus einer sohle oder einer sohle-kappe-einheit und einem oberschuh | |

| DE2255628A1 (de) | Schuhueberzug | |

| WO2003013289A2 (de) | Bekleidungsstück | |

| EP1796490B1 (de) | Socke | |

| EP1893044B1 (de) | Socke | |

| DE202006001380U1 (de) | Kombinationsbekleidung zur Klimaregulierung | |

| DE3737302C2 (enExample) | ||

| DE202009010997U1 (de) | Polster zur Verbesserung des Tragekomforts von Bekleidungsstücken sowie Bekleidungsstück | |

| EP3932236B1 (de) | Skispringer-handschuh | |

| DE2059585B2 (de) | Schutzbekleidung für Schuhe oder Füße | |

| DE102005027100A1 (de) | Socke | |

| DE102005016659A1 (de) | Flexiformfüssling | |

| DE202006012701U1 (de) | Kleidungsstück | |

| DE10328607A1 (de) | Socke oder Strumpf mit Reliefstruktur im Auftrittsbereich | |

| DE942207C (de) | Schutzkleidung mit einem UEberzug aus plastischem Material |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17P | Request for examination filed |

Effective date: 20081111 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AXX | Extension fees paid |

Extension state: HR Payment date: 20081111 Extension state: BA Payment date: 20081111 Extension state: AL Payment date: 20081111 Extension state: MK Payment date: 20081111 Extension state: RS Payment date: 20081111 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502007007234 Country of ref document: DE Effective date: 20110630 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: RIEDERER HASLER & PARTNER PATENTANWAELTE AG |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2366401 Country of ref document: ES Kind code of ref document: T3 Effective date: 20111019 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110919 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110518 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110819 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110518 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110518 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110518 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110518 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110518 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20120221 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502007007234 Country of ref document: DE Effective date: 20120221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110518 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110818 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110518 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502007007234 Country of ref document: DE Representative=s name: TARVENKORN & WICKORD PATENTANWAELTE PARTG MBB, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502007007234 Country of ref document: DE Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: MC Payment date: 20171114 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IS Payment date: 20171019 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190531 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MM4D Effective date: 20191123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191123 Ref country code: LT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191123 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20211119 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20211118 Year of fee payment: 15 Ref country code: DK Payment date: 20211122 Year of fee payment: 15 Ref country code: GB Payment date: 20211119 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SI Payment date: 20211111 Year of fee payment: 15 Ref country code: BE Payment date: 20211118 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20211119 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20220121 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20221130 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20221123 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20221130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221124 Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221124 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221123 |

|

| REG | Reference to a national code |

Ref country code: SI Ref legal event code: KO00 Effective date: 20230712 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221123 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221130 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20231120 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20240102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221124 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221124 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20231120 Year of fee payment: 17 Ref country code: IT Payment date: 20231124 Year of fee payment: 17 Ref country code: FR Payment date: 20231120 Year of fee payment: 17 Ref country code: DE Payment date: 20231121 Year of fee payment: 17 Ref country code: CH Payment date: 20231201 Year of fee payment: 17 Ref country code: AT Payment date: 20231121 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502007007234 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20231123 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20241201 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 509540 Country of ref document: AT Kind code of ref document: T Effective date: 20241123 Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20250603 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241130 |