EP1736615B1 - Construction process for a polymer swimming pool - Google Patents

Construction process for a polymer swimming pool Download PDFInfo

- Publication number

- EP1736615B1 EP1736615B1 EP06356066.8A EP06356066A EP1736615B1 EP 1736615 B1 EP1736615 B1 EP 1736615B1 EP 06356066 A EP06356066 A EP 06356066A EP 1736615 B1 EP1736615 B1 EP 1736615B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- elements

- pool

- assembly

- assembled

- corner

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04H—BUILDINGS OR LIKE STRUCTURES FOR PARTICULAR PURPOSES; SWIMMING OR SPLASH BATHS OR POOLS; MASTS; FENCING; TENTS OR CANOPIES, IN GENERAL

- E04H4/00—Swimming or splash baths or pools

- E04H4/0018—Easily movable or transportable swimming pools

- E04H4/0043—Easily movable or transportable swimming pools mainly made of panels

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04H—BUILDINGS OR LIKE STRUCTURES FOR PARTICULAR PURPOSES; SWIMMING OR SPLASH BATHS OR POOLS; MASTS; FENCING; TENTS OR CANOPIES, IN GENERAL

- E04H4/00—Swimming or splash baths or pools

- E04H4/0018—Easily movable or transportable swimming pools

- E04H4/0031—Easily movable or transportable swimming pools with shell type elements

Definitions

- the invention relates to a method of manufacturing a swimming pool, in particular a polymer pool, and to a swimming pool made by such a method.

- One-piece pools are known, of various sizes and shapes.

- a gel coat is spray-applied onto a shape or a shaper. Then, by projection or in sheets, reinforcing fibers are deposited on the gel coat. These reinforcing fibers are embedded in a resin in the presence of a hardener. These fibers make it possible to strengthen and maintain the geometry of the pool thus stiffened.

- glass fiber or polymer such as polyester are used as reinforcing fibers.

- Such pools can be stiffened by mechanical reinforcements, such as struts arranged on their outer face. These pools, have, more or less long term, an alteration of their walls. It is the appearance, on the inner side of the pool, of spots and / or blackish blisters. This phenomenon is known as the "osmosis of the gel coat". It occurs following prolonged contact of this resin with water, especially chlorinated or treated water used in swimming pools. This is a chemical degradation of the gel coat which no longer serves as a watertight barrier. This osmosis causes a passage of water in the layers of reinforcing fibers, which generates the appearance of traces of moisture and blisters. We know, to remedy this phenomenon, protective paints applied on a gel coat.

- FR-A-2 729 422 describes a method of manufacturing a swimming pool having the features of the preamble of claim 1 and describes a swimming pool having the features of the preamble of claim 6. The realization of such pools is long and not easy, which induces a manufacturing cost therefore. In addition, the installation of a sealing film is necessary.

- the invention intends to remedy more particularly by proposing a method of manufacturing a pool that is easy to implement, avoiding any risk of osmosis and preserving the watertightness and the quality of the walls of the swimming pool. .

- the invention relates to a method of manufacturing a swimming pool according to claim 1.

- thermoformable material By realizing the different elements of the pool in a thermoformable material, the phenomenon of osmosis of the gel coat is avoided, while having a process that is easy to implement because of the variety of shapes and dimensions possible for a pool made in from these unit wall elements.

- the fact of making several elements corresponding to at least two types of elements allows a great modularity when designing a swimming pool.

- the invention also relates to a swimming pool made according to claim 6.

- a wall element as shown in Figures 1 to 3 is made from a plate or sheet of a thermoformable material P.

- the material is a polymer or a mixture of polymers based on acrylic resin such as ABS.

- the thermoformable material is, for example, PVC or impact polystyrene.

- Such flat plates P are easy to manufacture and exist in thicknesses generally between 1 and 15 millimeters with a width close to 2.60 meters.

- the shaping of the wall elements from an acrylic resin-based polymer plate is effected by thermoforming, as illustrated in FIG. figure 10 for the element shown in figure 3 .

- This technique known per se, consists of heating a plate P and applying it to the frame of a negative mold M, in a sealed manner. By suction, by evacuating between the mold M and the plate P, is deformed the plate P which bears against the inner wall of the mold M by matching the shapes of the latter. Thus, the plate P deforms without losing its mechanical properties and certain dimensional characteristics, especially its thickness. After cooling, an acrylic resin wall element having the desired shape is obtained.

- This technique makes it possible, in series, to produce several wall elements such as those illustrated in FIGS. Figures 1 to 3 .

- This element is used in particular for making a bottom element of the pool 2.

- At least two bottom wall elements of the pool are assembled so as to obtain a pool width of 3 to 5 meters. Alternatively, for pools of width less than 3 meters, only one element 1 is used.

- bottom elements are adapted to cooperate with bottom elements 1 as illustrated in FIG. figure 1 to make long-term funds.

- the wall element 3 shown in FIG. figure 2 is a sidewall element of a pool.

- This lateral element 3 comprises a peripheral zone forming an upper rim 4 facing the outside of the pool.

- This upper outer rim 4 has preferably a U-shaped section, which improves the rigidity of the upper edge and the establishment of a curb surrounding the pool.

- a peripheral rim 5, made on the edge opposite that provided with the flange 4, is directed towards the inside of the pool.

- This lower rim is a foot support 5 ground. During the assembly of the different wall elements, the foot 5 participates in the bottom of the pool 2.

- Element 6, shown in figure 3 constitutes a corner element of the pool and has two walls 6a, 6b connected by a rounded area 6c constituting a corner of the pool 2.

- These corner elements 6 comprise, like the elements 3, upper flanges 4 and lower 5.

- Such a rim 4, alternatively, can be added, for example, by gluing, welding or screwing, once the assembly of the elements 3, 6 carried out, preferably before strengthening the pool.

- walls can be made in free or non-rectilinear form.

- an upwardly directed flange is formed on at least one edge of a bottom member 1. This flange is during assembly, a lower portion of a wall element 3 or 6. The latter are then without foot 5.

- thermoforming molds corresponding to the elements or modules 1, 3, 6, all shapes and sizes of pool of commonly encountered sizes, for example 7 m long by 3.6 m wide, 8 m, are produced. long by 3.8m wide, 9m long by 4m wide or 10m long by 4.2m wide. It should be noted that larger sizes are achievable, as long as the pool can be easily transported by land, rail, sea or air.

- thermoforming molds corresponding to the elements 3 and 6 are used, the bottom element 1 being made of a plate of thermoformable material, without shaping of the latter.

- thermoforming molds corresponding to elements 1 and 6 illustrated in FIGS. Figures 1 and 3 to make a rectangular pool 2 of common dimensions about 12 meters long and 5 meters wide.

- the elements 6 are then devoid of upper rim 4 and lower 5, the rim 4 can be added after assembly.

- an additional step is performed after the first step of thermoforming the elements.

- the reinforcing fibers 8 are placed on one side of the elements.

- reinforcing fibers 8 are deposited, in particular glass or polymer fibers such as polyester, "loose" or woven into sheets 20 on the outer face of the elements 1, 3, 6 as shown in FIG. figure 10 .

- the number of sheets 20 or the amount of bulk fibers 8 required is deposited by forming layers or strata until the desired reinforcement of the element is obtained.

- the fibers 8 or the sheets 20 are held together by means of a resin 80 impregnating the fibers 8 or the sheets 20 of fibers.

- This resin 80 is associated, in use, with a hardener which ensures rapid polymerization of the resin 80 thus reinforced by the fibers 8 or the sheets 20.

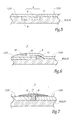

- the actual assembly of the elements is done, according to a first example illustrated in Figures 5 and 6 , by overlapping the edges of the adjacent elements. In this case, during the thermoforming step a), the edges are configured so as to overlap. This assembly is done before the step of depositing the fibers 8 or the reinforcing sheets 20.

- an element 1, 3, 6 has a recess D of one of its edges B sufficient for an edge B 'complementary to another element 1, 3, 6 is positioned on it.

- the elements are assembled, for example by gluing or welding, so that their two internal faces are coplanar.

- the reinforcement by the fibers 8 or the sheets 20 and the resin 80 is then carried out.

- Resin 80 is suitable to fix in a strong and durable manner on a bottom element 1 or wall element 3, 6.

- the edges B, B ' are overlapped without the elements 1, 3, 6 having their coplanar internal faces at the assembly zone Z.

- the elements are glued or welded.

- a seal 10 is arranged on either side of the assembly zone Z. This seal 10 also makes it possible to stiffen the assembly zone and to avoid the appearance of angular and unsightly zones at the level of the internal side of the pool.

- FIGS. Figures 7 to 9 the identical edges B, B 'of two adjacent elements 1, 3, 6 are abutted as shown in FIGS. Figures 7 to 9 .

- a T-section seal 11 covers the entire assembly area Z. This seal 11 can be glued. It also improves the appearance of the internal surface of the pool.

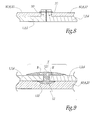

- the figure 8 illustrates another example of an assembly.

- the edges 30 of two adjacent elements 1, 3, 6 are configured in L and secured for example by screwing, gluing, bolting or riveting.

- the edges 30 are oriented towards the outside of the pool 2, which makes it possible to obtain a smooth and regular internal face.

- the fibers 8 or the reinforcing sheets 20 are deposited on the outer face of the elements 1, 3, 6 where the actual assembly takes place.

- the tightness of the assembly can be improved by the insertion of a seal, not shown, between the edges 30 thus assembled.

- This type of assembly is particularly suitable for in situ mounting.

- the resin 80 armed with fibers 8 or sheets 20 covers the joined edges 30. In this case, the assembly must be done in the factory.

- the figure 9 illustrates a preferred mode of assembly of the elements.

- the seal 12 is generally configured in H with a leg 120 substantially shorter than the other leg 121. This configuration allows a more effective maintenance of the seal in position and an optimum seal compared to the illustrated assemblies. figures 7 and 8 .

- the edges B, B 'of the adjacent elements 1, 3, 6 are inserted into the housings defined on either side of the body of the gasket 12 by the legs 120, 121.

- the leg 120 is asymmetrical relative to the body of the seal 12. It is shorter on one side than the other.

- a housing with an edge B or B 'defined by the legs 120, 121 has sides of different lengths and the other housing of the other edge B' or B has flanks of the same length.

- a pool 2 as illustrated in the figure 4 , just assemble, as partially represented in the figure 10 four elements of angle 6 and two bottom elements 1.

- the elements 6 are free of rim 4.

- a side wall element 3 is inserted on one of the short sides of the pool 3.

- this pool 2 is equipped with a staircase 7 also thermoformed in a plate based on acrylic resin.

- thermoforming the wall members after the first step of thermoforming the wall members, these are stored for future use. In the case of subsequent use, the final assembly of the pool is done either in the factory or in situ.

- the assembly takes place at the factory.

- the deposition of the fibers 8 or reinforcing sheets 20 and the resin 80 is performed on the elements in the assembly position on a shaper or a form.

- a shape or conformation is used, constituting a template G in negative of the pool 2.

- the side wall elements 3, 6 and bottom 1 are positioned. If necessary, other elements are positioned. such as a staircase 7. In this positioning, it is necessary to put the face of the element intended to be in contact with the water as shown in FIG. figure 10 , that is to say in contact with the shaper, to avoid mounting "upside down".

- the fibers are covered by a protective outer layer, for example, paint.

- longitudinal and / or vertical mechanical reinforcements such as struts, are arranged on the outer face of the elements.

- Passages for ducts or ducts allowing, for example, the use of filtration and / or lighting devices may be provided in the wall elements.

- wall elements may be made to form, for example, round, oval or complex shaped pools.

- the wall elements can be colored or tinted in the mass, advantageously before thermoforming.

Description

L'invention a trait à un procédé de fabrication d'une piscine, en particulier une piscine en polymère, ainsi qu'à une piscine réalisée par un tel procédé.The invention relates to a method of manufacturing a swimming pool, in particular a polymer pool, and to a swimming pool made by such a method.

On connaît des piscines monobloc, de dimensions et formes variées.One-piece pools are known, of various sizes and shapes.

Selon un procédé connu, on dépose par projection un gel coat sur une forme ou un conformateur. Puis on dépose, par projection ou en feuilles, des fibres de renfort sur le gel coat. Ces fibres de renfort sont noyées dans une résine, en présence d'un durcisseur. Ces fibres permettent de renforcer et de maintenir la géométrie de la piscine ainsi rigidifiée. En général, on utilise comme fibres de renfort des fibres de verre ou de polymère tel que le polyester. Une fois la résine polymérisée, il suffit de retirer l'ensemble du conformateur pour obtenir une piscine monobloc correspondant, en négatif, au conformateur. L'extérieur de la piscine est ainsi formé des fibres de renfort disposées en strates, plus ou moins ordonnées, et noyées dans une résine durcie. L'intérieur, lisse et brillant, est réalisé par le gel coat. De telles piscines peuvent être rigidifiées par des renforts mécaniques, telles que des jambes de force disposées sur leur face extérieure. Ces piscines, présentent, à plus ou moins longue échéance, une altération de leurs parois. Il s'agit d'apparition, sur la face intérieure de la piscine, de taches et/ou de cloques noirâtres. Ce phénomène est connu sous le terme « d'osmose du gel coat ». Il se produit suite au contact prolongé de cette résine avec l'eau, notamment l'eau chlorée ou traitée utilisée dans les piscines. Il s'agit d'une dégradation chimique du gel coat qui n'assure plus son rôle de barrière étanche. Cette osmose provoque un passage d'eau dans les strates de fibres de renfort, ce qui génère l'apparition de traces d'humidité et de cloques. On connaît, pour remédier à ce phénomène, des peintures de protection appliquées sur un gel coat. Ces peintures de protection, dites « de qualité marine », sont délicates à mettre en oeuvre, onéreuse et la surface revêtue de gel coat doit être repeinte régulièrement, sans grande efficacité. On connait également des piscines où, entre les strates de fibres de renfort et le gel coat, on intercale une couche d'un matériau isolant permettant de préserver l'étanchéité de la piscine. Néanmoins ce procédé ne permet pas d'éviter la dégradation du gel coat lui-même.According to a known method, a gel coat is spray-applied onto a shape or a shaper. Then, by projection or in sheets, reinforcing fibers are deposited on the gel coat. These reinforcing fibers are embedded in a resin in the presence of a hardener. These fibers make it possible to strengthen and maintain the geometry of the pool thus stiffened. In general, glass fiber or polymer such as polyester are used as reinforcing fibers. Once the polymerized resin, simply remove the entire shaper to obtain a corresponding monobloc pool, negative, the shaper. The outside of the pool is thus formed reinforcing fibers arranged in layers, more or less ordered, and embedded in a cured resin. The interior, smooth and shiny, is made by the gel coat. Such pools can be stiffened by mechanical reinforcements, such as struts arranged on their outer face. These pools, have, more or less long term, an alteration of their walls. It is the appearance, on the inner side of the pool, of spots and / or blackish blisters. This phenomenon is known as the "osmosis of the gel coat". It occurs following prolonged contact of this resin with water, especially chlorinated or treated water used in swimming pools. This is a chemical degradation of the gel coat which no longer serves as a watertight barrier. This osmosis causes a passage of water in the layers of reinforcing fibers, which generates the appearance of traces of moisture and blisters. We know, to remedy this phenomenon, protective paints applied on a gel coat. These protective paints, called "marine grade", are difficult to implement, expensive and the surface coated with gel coat must be repainted regularly, without great efficiency. Swimming pools are also known where, between the layers of reinforcing fibers and the gel coat, a layer of insulating material is interposed making it possible to preserve the tightness of the pool. However, this method does not prevent degradation of the gel coat itself.

On connait par

C'est à ces inconvénients qu'entend plus particulièrement remédier l'invention en proposant un procédé de fabrication d'une piscine facile à mettre en oeuvre, évitant tout risque d'osmose et préservant l'étanchéité et la qualité des parois de la piscine.It is these drawbacks that the invention intends to remedy more particularly by proposing a method of manufacturing a pool that is easy to implement, avoiding any risk of osmosis and preserving the watertightness and the quality of the walls of the swimming pool. .

A cet effet, l'invention a pour objet un procédé de fabrication d'une piscine selon la revendication 1.For this purpose, the invention relates to a method of manufacturing a swimming pool according to claim 1.

En réalisant les différents éléments de la piscine dans un matériau thermoformable, on évite le phénomène d'osmose du gel coat, tout en ayant un procédé aisé à mettre en oeuvre du fait de la variété de formes et de dimensions possibles pour une piscine réalisée à partir de ces éléments de paroi unitaires. Le fait de réaliser plusieurs éléments correspondant à au moins deux types d'éléments permet une grande modularité lors de la conception d'une piscine.By realizing the different elements of the pool in a thermoformable material, the phenomenon of osmosis of the gel coat is avoided, while having a process that is easy to implement because of the variety of shapes and dimensions possible for a pool made in from these unit wall elements. The fact of making several elements corresponding to at least two types of elements allows a great modularity when designing a swimming pool.

Selon des aspects avantageux mais non obligatoires de l'invention, le procédé peut incorporer une ou plusieurs des caractéristiques suivantes :

- Lors de l'étape a), on réalise au moins un élément de paroi latérale, d'angle ou de fond par thermoformage d'une plaque de polymère acrylique ou à base d'acrylique tel l'ABS.

- Lors de l'étape b), on positionne au moins un joint d'étanchéité sur la zone d'assemblage de deux éléments adjacents.

- Un bord d'un élément comprend un décrochement de manière à ce que lors de l'assemblage avec un autre élément par chevauchement des bords, les faces internes des éléments soient coplanaires.

- Lors de l'étape b), l'assemblage est effectué par aboutage des bords de deux éléments adjacents. Avantageusement, les bords sont configurés en L et assemblés par vissage, rivetage ou collage.

- Lors de l'étape a), on réalise un rebord formant un pied d'appui au sol de certains éléments.

- During step a), at least one side wall, corner or bottom element is made by thermoforming an acrylic or acrylic-based polymer plate such as ABS.

- During step b), at least one seal is positioned on the assembly zone of two adjacent elements.

- An edge of an element includes a recess so that when assembled with another element by overlapping edges, the inner faces of the elements are coplanar.

- In step b), the assembly is performed by butting the edges of two adjacent elements. Advantageously, the edges are configured in L and assembled by screwing, riveting or gluing.

- During step a), a rim is formed forming a support foot on the ground of certain elements.

L'invention concerne également une piscine réalisée selon la revendication 6.The invention also relates to a swimming pool made according to

L'invention sera mieux comprise et d'autres avantages de celle-ci apparaîtront plus clairement à la lecture des dessins dans lesquels :

- la

figure 1 est une vue en perspective d'un élément de paroi de fond d'une piscine réalisée selon le procédé conforme à l'invention, - la

figure 2 est une vue en perspective d'un élément de paroi latérale, - la

figure 3 est une vue en perspective d'un élément d'angle, - la

figure 4 est une représentation schématique d'une piscine réalisée à partir d'éléments de paroi tels que ceux représentés auxfigures 1, 2 et 3 , les éléments étant représentés non joints et dépourvus de rebord, un élément n'étant pas en place pour plus de lisibilité, - les

figures 5 à 9 sont des coupes schématiques, à plus grande échelle, de zones d'assemblage de deux éléments de paroi adjacents, les modes d'assemblage représentés auxfigures 7 à 9 ne faisant pas partie de l'invention, et - la

figure 10 est un schéma simplifié décrivant les étapes du procédé.

- the

figure 1 is a perspective view of a bottom wall element of a swimming pool made according to the process according to the invention, - the

figure 2 is a perspective view of a side wall element, - the

figure 3 is a perspective view of a corner element, - the

figure 4 is a schematic representation of a pool made from wall elements such as those shown inFigures 1, 2 and 3 , the elements being shown not joined and without flange, an element not being in place for more legibility, - the

Figures 5 to 9 are schematic sections, on a larger scale, of assembly zones of two adjacent wall elements, the assembly modes represented in FIGS.Figures 7 to 9 not forming part of the invention, and - the

figure 10 is a simplified diagram describing the steps of the process.

Un élément de paroi tel que représenté aux

La mise en forme des éléments de paroi à partir d'une plaque de polymère à base de résine acrylique s'effectue par thermoformage, comme illustré à la

Un premier élément 1, plan avec deux angles arrondis, est représenté à la

D'autres types d'éléments de fond, non représentés, sont adapés pour coopérer avec des éléments 1 de fond tels qu'illustré à la

L'élément de paroi 3 représenté à la

L'élément 6, représenté à la

Dans un autre mode de réalisation non illustré, un rebord orienté vers le haut est réalisé sur au moins un bord d'un élément de fond 1. Ce rebord constitue, lors de l'assemblage, une portion inférieure d'un élément de paroi 3 ou 6. Ces derniers sont alors dépourvus de pied 5.In another embodiment not illustrated, an upwardly directed flange is formed on at least one edge of a bottom member 1. This flange is during assembly, a lower portion of a

Ainsi, avantageusement à partir de trois moules de thermoformage correspondant aux éléments ou modules 1, 3, 6, on réalise toutes formes et dimensions de piscine de tailles couramment rencontrées, par exemple 7 m de long par 3,6 m de large, 8 m de long par 3,8 m de large, 9 m de long par 4 m de large ou 10 m de long par 4,2 m de large. Il est à noter que des tailles supérieures sont réalisables, pour autant que la piscine peut être aisément transportée par un véhicule terrestre, ferroviaire, maritime ou aérien.Thus, advantageously from three thermoforming molds corresponding to the elements or

Dans un mode de réalisation non illustré, deux moules de thermoformage correspondant aux éléments 3 et 6 sont utilisés, l'élément de fond 1 étant réalisé dans une plaque de matériau thermoformable, sans mise en forme de cette dernière.In a non-illustrated embodiment, two thermoforming molds corresponding to the

En variante, il est possible avec seulement deux moules de thermoformage correspondant aux éléments 1 et 6 illustrés aux

Lorsque les éléments de paroi ont une épaisseur faible et/ou lorsque la piscine envisagée est de grandes dimensions et/ou pour préserver la géométrie de la piscine, il est nécessaire de renforcer les éléments 1, 3, 6 avant l'assemblage de la piscine.When the wall elements have a small thickness and / or when the proposed pool is large and / or to preserve the geometry of the pool, it is necessary to strengthen the

Pour renforcer les éléments, on effectue une étape supplémentaire après la première étape de thermoformage des éléments. Lors de cette étape, on dispose des fibres de renfort 8 sur une face des éléments. Pour cela, on dépose des fibres de renfort 8, notamment des fibres de verre ou de polymère tel le polyester, en « vrac » ou tissées en feuilles 20 sur la face extérieure des éléments 1, 3, 6 comme représenté à la

L'assemblage proprement dit des éléments se fait, selon un premier exemple illustré aux

En particulier, comme illustré à la

Selon un autre mode d'assemblage illustré à la

Dans d'autres modes d'assemblage, qui ne font pas partie de l'invention, les bords B, B', identiques, de deux éléments 1, 3, 6 adjacents sont aboutés comme représenté aux

La

La

Le joint 12 est globalement configuré en H avec une jambe 120 sensiblement plus courte que l'autre jambe 121. Cette configuration permet un maintien plus efficace du joint en position et une étanchéité optimale par rapport aux assemblages illustrés

En variante non illustrée, la jambe 120 est disymétrique par rapport au corps du joint 12. Elle est plus courte d'un coté que de l'autre. Ainsi un logement d'un bord B ou B' défini par les jambes 120, 121 a des flancs de différentes longueurs et l'autre logement de l'autre bord B' ou B a des flancs de même longueur. Ainsi on peut aisément insérer successivement les bords B, B' des éléments adjacents dans leurs logements respectifs.In a variant not shown, the

D'autres modes d'assemblage, notamment par encliquetage de bords de formes complémentaires peuvent être envisagés.Other methods of assembly, in particular by snapping edges of complementary shapes can be envisaged.

Pour obtenir une piscine 2 telle qu'illustrée à la

Dans certains modes de réalisation, après la première étape de thermoformage des éléments de paroi, ceux-ci sont stockés en vu d'une utilisation ultérieure. Dans le cas d'une utilisation ultérieure, l'assemblage final de la piscine se fait soit en usine, soit in situ.In some embodiments, after the first step of thermoforming the wall members, these are stored for future use. In the case of subsequent use, the final assembly of the pool is done either in the factory or in situ.

Si la piscine est livrée prêt à poser, l'assemblage a lieu en usine. De manière avantageuse, le dépôt des fibres 8 ou des feuilles 20 de renfort et de la résine 80 est réalisé sur les éléments en position d'assemblage sur un conformateur ou une forme.If the pool is delivered ready to install, the assembly takes place at the factory. Advantageously, the deposition of the

On utilise une forme ou conformateur, constituant un gabarit G en négatif de la piscine 2. Sur ce conformateur G, on positionne les éléments de paroi latérale 3, d'angle 6 et de fond 1. Si nécessaire, on positionne d'autres éléments tels qu'un escalier 7. Lors de ce positionnement, il convient de mettre la face de l'élément destinée à être au contact de l'eau comme représenté à la

Une fois les éléments en position sur la forme G on effectue le renforcement proprement dit des éléments comme décrit précédemment. L'étanchéité de la piscine est obtenue et/ou améliorée par l'utilisation d'un liner. Ce procédé permet de raccorder des éléments de paroi à d'autres éléments thermoformés, de préférence dans un même matériau, tels qu'un escalier.Once the elements in position on the shape G is carried out the actual strengthening of the elements as described above. The tightness of the pool is obtained and / or improved by the use of a liner. This method makes it possible to connect wall elements to other thermoformed elements, preferably in the same material, such as a staircase.

Dans certaines configurations, les fibres sont recouvertes par une couche extérieure protectrice, par exemple, de peinture.In some configurations, the fibers are covered by a protective outer layer, for example, paint.

Si nécessaire, des renforts mécaniques longitudinaux et/ou verticaux tels des jambes de force, sont disposés sur la face externe des éléments.If necessary, longitudinal and / or vertical mechanical reinforcements such as struts, are arranged on the outer face of the elements.

Des passages pour des conduites ou des gaines permettant par exemple la mise en oeuvre d'appareils de filtration et/ou d'éclairage peuvent être prévus dans les éléments de paroi.Passages for ducts or ducts allowing, for example, the use of filtration and / or lighting devices may be provided in the wall elements.

D'autres formes d'éléments de paroi peuvent être réalisées pour former par exemple des piscines rondes, ovales ou de forme complexe.Other forms of wall elements may be made to form, for example, round, oval or complex shaped pools.

Les éléments de paroi peuvent être colorés ou teintés dans la masse, avantageusement avant le thermoformage.The wall elements can be colored or tinted in the mass, advantageously before thermoforming.

Claims (6)

- A method for manufacturing a pool comprising steps consisting in:- a) performing, in a thermoformable material (P), several wall elements corresponding to at least two different elements chosen among one side wall element (3), one corner element (6) or one bottom element (1) of said pool (2),- b) assembling said thermoformed wall elements (1, 3, 6) necessary to form a pool (2),characterized in that, during step b), the assembly is performed by the overlapping of the edges (B, B') of two adjacent elements (1, 3, 6) and in that it comprises an additional step consisting in- c) strengthening the side wall (3), corner (6) and/or bottom (1) elements assembled by resin (80) reinforced with reinforcing fibers (8) or with reinforcing fibers (8) sheets (20), deposited on the outer face of said assembled elements (1, 3, 6).

- The method according to claim 1, characterized in that, during step a), at least one side wall (3), corner (6) or bottom (1) element is performed by thermoforming of an acrylic polymer plate or an acrylic-based plate such as ABS.

- The method according any of the preceding claims, characterized in that, during step b), at least one seal (10, 11, 12) is positioned on the assembly zone (Z) of two adjacent elements (1, 3, 6).

- The method according to claim 1, characterized in that one edge (B) of an element (1, 3, 6) comprises a recess (D) so as, during the assembly with another element (1 , 3, 6) by overlapping of said edges (B, B'), their inner faces are coplanar (Figure 5).

- The method according any of the preceding claims, characterized in that, during step a), a rim forming a ground support leg (5) of some elements (3, 6), is performed.

- A pool formed by assembling several wall elements made of a thermoformable material (P) corresponding to at least two different assembled elements chosen among one side wall element (3), one corner element (6) or one bottom element (1) of said pool (2), characterized in that the elements (1 , 3, 6) are assembled by overlapping edges (B, B') of two adjacent elements (1, 3, 6) and in that the assembled side wall (3), corner (6) and/or bottom (1) elements are strengthened with resin (80) reinforced with reinforcing fibers (8) or with reinforcing fibers (8) sheets (20), deposited on the outer face of said assembled elements (1, 3, 6).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL06356066T PL1736615T3 (en) | 2005-06-20 | 2006-06-12 | Construction process for a polymer swimming pool |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0506219A FR2887274B1 (en) | 2005-06-20 | 2005-06-20 | PROCESS FOR PRODUCING A POLYMER POOL |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1736615A2 EP1736615A2 (en) | 2006-12-27 |

| EP1736615A3 EP1736615A3 (en) | 2014-08-06 |

| EP1736615B1 true EP1736615B1 (en) | 2016-11-02 |

Family

ID=35708912

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06356066.8A Not-in-force EP1736615B1 (en) | 2005-06-20 | 2006-06-12 | Construction process for a polymer swimming pool |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1736615B1 (en) |

| ES (1) | ES2612262T3 (en) |

| FR (1) | FR2887274B1 (en) |

| PL (1) | PL1736615T3 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ATE510981T1 (en) * | 2008-01-17 | 2011-06-15 | Polytherm Kunstoff Und Metalltechnik Gmbh | SWIMMING POOL |

| ITBO20110659A1 (en) * | 2011-11-18 | 2013-05-19 | Heinz Pecher | PERFECTED POOL, IN PARTICULAR FOR EXTERNAL ENVIRONMENT |

| CN102943575B (en) * | 2012-11-01 | 2014-06-25 | 佛山市高明粤华卫生洁具有限公司 | Movable type integral swimming pool and production process thereof |

| FR3025546B1 (en) * | 2014-09-04 | 2018-06-15 | Pascal Gonichon | PROCESS FOR MANUFACTURING A PARALLELEPIPEDIC SHAPE OF SWIMMING POOL FROM THERMOFORMABLE MATERIAL ELEMENTS |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4048773A (en) * | 1973-12-27 | 1977-09-20 | Laven Merrill L | Above-ground pool walls, panels therefor, and panel-manufacturing methods |

| US3971075A (en) * | 1974-05-08 | 1976-07-27 | Heinbaugh Kenneth D | Swimming pool structure |

| FR2672629B1 (en) * | 1991-02-12 | 1996-09-20 | Somethy Sa | REMOVABLE CONTAINER WITH OVERFLOW CHANNEL. |

| FR2716406B1 (en) * | 1994-02-24 | 1996-07-05 | Desjoyaux Piscines | Method of manufacturing by thermoforming a room, in particular a staircase, for a swimming pool and the installation for its implementation. |

| FR2729422B1 (en) * | 1995-01-17 | 1997-04-18 | Gonichon Pascal | PREFABRICATED POOL WALL ELEMENT |

| FR2732389A1 (en) * | 1995-03-28 | 1996-10-04 | Piscines Desjoyaux Sa | Thermally-moulded steps, esp. for swimming pool |

-

2005

- 2005-06-20 FR FR0506219A patent/FR2887274B1/en active Active

-

2006

- 2006-06-12 PL PL06356066T patent/PL1736615T3/en unknown

- 2006-06-12 EP EP06356066.8A patent/EP1736615B1/en not_active Not-in-force

- 2006-06-12 ES ES06356066.8T patent/ES2612262T3/en active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| FR2887274B1 (en) | 2009-01-23 |

| FR2887274A1 (en) | 2006-12-22 |

| EP1736615A2 (en) | 2006-12-27 |

| EP1736615A3 (en) | 2014-08-06 |

| PL1736615T3 (en) | 2017-04-28 |

| ES2612262T3 (en) | 2017-05-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1736615B1 (en) | Construction process for a polymer swimming pool | |

| FR2542363A1 (en) | TRIM FOR MOUNTING A SECURITY GLAZING IN A BAY, IN PARTICULAR A WINDSHIELD FOR A MOTOR VEHICLE | |

| EP0382649A1 (en) | Boarding for the realisation of swimming pools in particular, and method of manufacturing same | |

| EP2872409A1 (en) | Package of the two-material box type for packaging a product | |

| WO2012076811A1 (en) | Modular and dismantleable construction system | |

| EP2894278B1 (en) | Device for manufacturing a swimming pool | |

| EP0799952A1 (en) | Method for assembling prefabricated panels for swimmingpool-walls and swimmingpool-wall obtained by this method | |

| EP2671665A1 (en) | Protective structure for vehicle, vehicle comprising such a structure and method for producing | |

| FR2990650A1 (en) | ALLEGED HYBRID WINDSCREEN FOR A VEHICLE FORMING A PANORAMIC BUBBLE. | |

| FR2934295A1 (en) | Immersed rolling blind's end receiving housing realizing method for wall of synthetic material shell of swimming-pool, involves applying reinforcement fibers and resin on hollow relief element, and demolding shell | |

| FR2726796A1 (en) | SEALED RECEPTACLE FOR SPEAKER IN A VEHICLE | |

| FR3041672B1 (en) | PLASTIC SWIMMING POOL HULL WITH REINFORCING ELEMENTS | |

| EP1705314A2 (en) | Shelter with support structure made from profiled elements | |

| EP0065914A1 (en) | Profiles for insulating cross-shaped screen coverings | |

| WO2012019959A1 (en) | Formwork system for reinforced-concrete swimming pool and method for mounting same | |

| BE1029090B1 (en) | Construction module for swimming pool, associated swimming pool and method of making a swimming pool | |

| FR2707321A1 (en) | Method for constructing a pool | |

| BE1017285A3 (en) | INSULATING CARRIER FOR FLOOR FLOORS AND FLOOR OBTAINED. | |

| FR2492435A1 (en) | Panel for constructing swimming pools etc. - contains a recess into which a corrugated sheet is secured | |

| FR2732384A1 (en) | Shuttering panel for building wall | |

| EP4086405A1 (en) | Support base, in particular for smoke vent | |

| FR2932514A1 (en) | Swimming pool, has shell that is formed by set of modules that are assembled with each other by connection unit e.g. screw or nut system, and T shaped packing seal that is interposed between adjacent modules | |

| FR2974379A1 (en) | Formwork device for use in construction of reinforced concrete wall for e.g. swimming pool, has identical lower, intermediate and upper modules whose plates are made to contact with each other by peripheral edges of corresponding plates | |

| FR3025546A1 (en) | PROCESS FOR MANUFACTURING A PARALLELEPIPEDIC SHAPE OF SWIMMING POOL FROM THERMOFORMABLE MATERIAL ELEMENTS | |

| FR2612829A1 (en) | Container which includes at least one layer of fibre-reinforced polyester, and method for manufacturing it |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK YU |

|

| 17P | Request for examination filed |

Effective date: 20070613 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E04H 4/00 20060101AFI20140702BHEP |

|

| 17Q | First examination report despatched |

Effective date: 20140730 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AXX | Extension fees paid |

Extension state: BA Extension state: AL Extension state: RS Extension state: HR Extension state: MK |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160629 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 842027 Country of ref document: AT Kind code of ref document: T Effective date: 20161115 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602006050743 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20161102 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170203 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2612262 Country of ref document: ES Kind code of ref document: T3 Effective date: 20170516 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170302 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170302 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20170620 Year of fee payment: 12 Ref country code: DE Payment date: 20170621 Year of fee payment: 12 Ref country code: GB Payment date: 20170620 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602006050743 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170202 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NO Payment date: 20170725 Year of fee payment: 10 Ref country code: LU Payment date: 20170620 Year of fee payment: 12 Ref country code: BE Payment date: 20170620 Year of fee payment: 12 Ref country code: SE Payment date: 20170620 Year of fee payment: 12 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20170803 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170612 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602006050743 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180613 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 842027 Country of ref document: AT Kind code of ref document: T Effective date: 20180612 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180612 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180612 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180612 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180630 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190101 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180612 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20060612 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20190531 Year of fee payment: 14 Ref country code: IT Payment date: 20190624 Year of fee payment: 14 Ref country code: CZ Payment date: 20190611 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: RO Payment date: 20190528 Year of fee payment: 14 Ref country code: FR Payment date: 20190527 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161102 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20190719 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: UEP Ref document number: 842027 Country of ref document: AT Kind code of ref document: T Effective date: 20161102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200612 Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200612 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200612 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20211103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200613 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200612 |