EP1736615B1 - Herstellungsverfahren eines Polymerschwimmbeckens - Google Patents

Herstellungsverfahren eines Polymerschwimmbeckens Download PDFInfo

- Publication number

- EP1736615B1 EP1736615B1 EP06356066.8A EP06356066A EP1736615B1 EP 1736615 B1 EP1736615 B1 EP 1736615B1 EP 06356066 A EP06356066 A EP 06356066A EP 1736615 B1 EP1736615 B1 EP 1736615B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- elements

- pool

- assembly

- assembled

- corner

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 238000000034 method Methods 0.000 title claims description 18

- 230000009182 swimming Effects 0.000 title description 13

- 229920000642 polymer Polymers 0.000 title description 7

- 238000010276 construction Methods 0.000 title 1

- 239000011347 resin Substances 0.000 claims description 13

- 229920005989 resin Polymers 0.000 claims description 13

- 239000012783 reinforcing fiber Substances 0.000 claims description 12

- 238000003856 thermoforming Methods 0.000 claims description 10

- 239000000463 material Substances 0.000 claims description 9

- 238000004519 manufacturing process Methods 0.000 claims description 7

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 claims description 3

- 238000005728 strengthening Methods 0.000 claims description 3

- 229920000058 polyacrylate Polymers 0.000 claims 1

- 239000000835 fiber Substances 0.000 description 12

- 239000004925 Acrylic resin Substances 0.000 description 4

- 229920000178 Acrylic resin Polymers 0.000 description 4

- 238000004026 adhesive bonding Methods 0.000 description 4

- 230000002787 reinforcement Effects 0.000 description 4

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 4

- 239000003973 paint Substances 0.000 description 3

- 230000001681 protective effect Effects 0.000 description 3

- 230000003014 reinforcing effect Effects 0.000 description 3

- 230000000295 complement effect Effects 0.000 description 2

- 238000000151 deposition Methods 0.000 description 2

- 238000011065 in-situ storage Methods 0.000 description 2

- 230000007774 longterm Effects 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 239000004848 polyfunctional curative Substances 0.000 description 2

- 238000007493 shaping process Methods 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 239000004793 Polystyrene Substances 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 238000002144 chemical decomposition reaction Methods 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 238000006731 degradation reaction Methods 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 239000003365 glass fiber Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 229920005594 polymer fiber Polymers 0.000 description 1

- 238000006116 polymerization reaction Methods 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04H—BUILDINGS OR LIKE STRUCTURES FOR PARTICULAR PURPOSES; SWIMMING OR SPLASH BATHS OR POOLS; MASTS; FENCING; TENTS OR CANOPIES, IN GENERAL

- E04H4/00—Swimming or splash baths or pools

- E04H4/0018—Easily movable or transportable swimming pools

- E04H4/0043—Easily movable or transportable swimming pools mainly made of panels

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04H—BUILDINGS OR LIKE STRUCTURES FOR PARTICULAR PURPOSES; SWIMMING OR SPLASH BATHS OR POOLS; MASTS; FENCING; TENTS OR CANOPIES, IN GENERAL

- E04H4/00—Swimming or splash baths or pools

- E04H4/0018—Easily movable or transportable swimming pools

- E04H4/0031—Easily movable or transportable swimming pools with shell type elements

Definitions

- the invention relates to a method of manufacturing a swimming pool, in particular a polymer pool, and to a swimming pool made by such a method.

- One-piece pools are known, of various sizes and shapes.

- a gel coat is spray-applied onto a shape or a shaper. Then, by projection or in sheets, reinforcing fibers are deposited on the gel coat. These reinforcing fibers are embedded in a resin in the presence of a hardener. These fibers make it possible to strengthen and maintain the geometry of the pool thus stiffened.

- glass fiber or polymer such as polyester are used as reinforcing fibers.

- Such pools can be stiffened by mechanical reinforcements, such as struts arranged on their outer face. These pools, have, more or less long term, an alteration of their walls. It is the appearance, on the inner side of the pool, of spots and / or blackish blisters. This phenomenon is known as the "osmosis of the gel coat". It occurs following prolonged contact of this resin with water, especially chlorinated or treated water used in swimming pools. This is a chemical degradation of the gel coat which no longer serves as a watertight barrier. This osmosis causes a passage of water in the layers of reinforcing fibers, which generates the appearance of traces of moisture and blisters. We know, to remedy this phenomenon, protective paints applied on a gel coat.

- FR-A-2 729 422 describes a method of manufacturing a swimming pool having the features of the preamble of claim 1 and describes a swimming pool having the features of the preamble of claim 6. The realization of such pools is long and not easy, which induces a manufacturing cost therefore. In addition, the installation of a sealing film is necessary.

- the invention intends to remedy more particularly by proposing a method of manufacturing a pool that is easy to implement, avoiding any risk of osmosis and preserving the watertightness and the quality of the walls of the swimming pool. .

- the invention relates to a method of manufacturing a swimming pool according to claim 1.

- thermoformable material By realizing the different elements of the pool in a thermoformable material, the phenomenon of osmosis of the gel coat is avoided, while having a process that is easy to implement because of the variety of shapes and dimensions possible for a pool made in from these unit wall elements.

- the fact of making several elements corresponding to at least two types of elements allows a great modularity when designing a swimming pool.

- the invention also relates to a swimming pool made according to claim 6.

- a wall element as shown in Figures 1 to 3 is made from a plate or sheet of a thermoformable material P.

- the material is a polymer or a mixture of polymers based on acrylic resin such as ABS.

- the thermoformable material is, for example, PVC or impact polystyrene.

- Such flat plates P are easy to manufacture and exist in thicknesses generally between 1 and 15 millimeters with a width close to 2.60 meters.

- the shaping of the wall elements from an acrylic resin-based polymer plate is effected by thermoforming, as illustrated in FIG. figure 10 for the element shown in figure 3 .

- This technique known per se, consists of heating a plate P and applying it to the frame of a negative mold M, in a sealed manner. By suction, by evacuating between the mold M and the plate P, is deformed the plate P which bears against the inner wall of the mold M by matching the shapes of the latter. Thus, the plate P deforms without losing its mechanical properties and certain dimensional characteristics, especially its thickness. After cooling, an acrylic resin wall element having the desired shape is obtained.

- This technique makes it possible, in series, to produce several wall elements such as those illustrated in FIGS. Figures 1 to 3 .

- This element is used in particular for making a bottom element of the pool 2.

- At least two bottom wall elements of the pool are assembled so as to obtain a pool width of 3 to 5 meters. Alternatively, for pools of width less than 3 meters, only one element 1 is used.

- bottom elements are adapted to cooperate with bottom elements 1 as illustrated in FIG. figure 1 to make long-term funds.

- the wall element 3 shown in FIG. figure 2 is a sidewall element of a pool.

- This lateral element 3 comprises a peripheral zone forming an upper rim 4 facing the outside of the pool.

- This upper outer rim 4 has preferably a U-shaped section, which improves the rigidity of the upper edge and the establishment of a curb surrounding the pool.

- a peripheral rim 5, made on the edge opposite that provided with the flange 4, is directed towards the inside of the pool.

- This lower rim is a foot support 5 ground. During the assembly of the different wall elements, the foot 5 participates in the bottom of the pool 2.

- Element 6, shown in figure 3 constitutes a corner element of the pool and has two walls 6a, 6b connected by a rounded area 6c constituting a corner of the pool 2.

- These corner elements 6 comprise, like the elements 3, upper flanges 4 and lower 5.

- Such a rim 4, alternatively, can be added, for example, by gluing, welding or screwing, once the assembly of the elements 3, 6 carried out, preferably before strengthening the pool.

- walls can be made in free or non-rectilinear form.

- an upwardly directed flange is formed on at least one edge of a bottom member 1. This flange is during assembly, a lower portion of a wall element 3 or 6. The latter are then without foot 5.

- thermoforming molds corresponding to the elements or modules 1, 3, 6, all shapes and sizes of pool of commonly encountered sizes, for example 7 m long by 3.6 m wide, 8 m, are produced. long by 3.8m wide, 9m long by 4m wide or 10m long by 4.2m wide. It should be noted that larger sizes are achievable, as long as the pool can be easily transported by land, rail, sea or air.

- thermoforming molds corresponding to the elements 3 and 6 are used, the bottom element 1 being made of a plate of thermoformable material, without shaping of the latter.

- thermoforming molds corresponding to elements 1 and 6 illustrated in FIGS. Figures 1 and 3 to make a rectangular pool 2 of common dimensions about 12 meters long and 5 meters wide.

- the elements 6 are then devoid of upper rim 4 and lower 5, the rim 4 can be added after assembly.

- an additional step is performed after the first step of thermoforming the elements.

- the reinforcing fibers 8 are placed on one side of the elements.

- reinforcing fibers 8 are deposited, in particular glass or polymer fibers such as polyester, "loose" or woven into sheets 20 on the outer face of the elements 1, 3, 6 as shown in FIG. figure 10 .

- the number of sheets 20 or the amount of bulk fibers 8 required is deposited by forming layers or strata until the desired reinforcement of the element is obtained.

- the fibers 8 or the sheets 20 are held together by means of a resin 80 impregnating the fibers 8 or the sheets 20 of fibers.

- This resin 80 is associated, in use, with a hardener which ensures rapid polymerization of the resin 80 thus reinforced by the fibers 8 or the sheets 20.

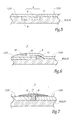

- the actual assembly of the elements is done, according to a first example illustrated in Figures 5 and 6 , by overlapping the edges of the adjacent elements. In this case, during the thermoforming step a), the edges are configured so as to overlap. This assembly is done before the step of depositing the fibers 8 or the reinforcing sheets 20.

- an element 1, 3, 6 has a recess D of one of its edges B sufficient for an edge B 'complementary to another element 1, 3, 6 is positioned on it.

- the elements are assembled, for example by gluing or welding, so that their two internal faces are coplanar.

- the reinforcement by the fibers 8 or the sheets 20 and the resin 80 is then carried out.

- Resin 80 is suitable to fix in a strong and durable manner on a bottom element 1 or wall element 3, 6.

- the edges B, B ' are overlapped without the elements 1, 3, 6 having their coplanar internal faces at the assembly zone Z.

- the elements are glued or welded.

- a seal 10 is arranged on either side of the assembly zone Z. This seal 10 also makes it possible to stiffen the assembly zone and to avoid the appearance of angular and unsightly zones at the level of the internal side of the pool.

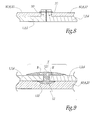

- FIGS. Figures 7 to 9 the identical edges B, B 'of two adjacent elements 1, 3, 6 are abutted as shown in FIGS. Figures 7 to 9 .

- a T-section seal 11 covers the entire assembly area Z. This seal 11 can be glued. It also improves the appearance of the internal surface of the pool.

- the figure 8 illustrates another example of an assembly.

- the edges 30 of two adjacent elements 1, 3, 6 are configured in L and secured for example by screwing, gluing, bolting or riveting.

- the edges 30 are oriented towards the outside of the pool 2, which makes it possible to obtain a smooth and regular internal face.

- the fibers 8 or the reinforcing sheets 20 are deposited on the outer face of the elements 1, 3, 6 where the actual assembly takes place.

- the tightness of the assembly can be improved by the insertion of a seal, not shown, between the edges 30 thus assembled.

- This type of assembly is particularly suitable for in situ mounting.

- the resin 80 armed with fibers 8 or sheets 20 covers the joined edges 30. In this case, the assembly must be done in the factory.

- the figure 9 illustrates a preferred mode of assembly of the elements.

- the seal 12 is generally configured in H with a leg 120 substantially shorter than the other leg 121. This configuration allows a more effective maintenance of the seal in position and an optimum seal compared to the illustrated assemblies. figures 7 and 8 .

- the edges B, B 'of the adjacent elements 1, 3, 6 are inserted into the housings defined on either side of the body of the gasket 12 by the legs 120, 121.

- the leg 120 is asymmetrical relative to the body of the seal 12. It is shorter on one side than the other.

- a housing with an edge B or B 'defined by the legs 120, 121 has sides of different lengths and the other housing of the other edge B' or B has flanks of the same length.

- a pool 2 as illustrated in the figure 4 , just assemble, as partially represented in the figure 10 four elements of angle 6 and two bottom elements 1.

- the elements 6 are free of rim 4.

- a side wall element 3 is inserted on one of the short sides of the pool 3.

- this pool 2 is equipped with a staircase 7 also thermoformed in a plate based on acrylic resin.

- thermoforming the wall members after the first step of thermoforming the wall members, these are stored for future use. In the case of subsequent use, the final assembly of the pool is done either in the factory or in situ.

- the assembly takes place at the factory.

- the deposition of the fibers 8 or reinforcing sheets 20 and the resin 80 is performed on the elements in the assembly position on a shaper or a form.

- a shape or conformation is used, constituting a template G in negative of the pool 2.

- the side wall elements 3, 6 and bottom 1 are positioned. If necessary, other elements are positioned. such as a staircase 7. In this positioning, it is necessary to put the face of the element intended to be in contact with the water as shown in FIG. figure 10 , that is to say in contact with the shaper, to avoid mounting "upside down".

- the fibers are covered by a protective outer layer, for example, paint.

- longitudinal and / or vertical mechanical reinforcements such as struts, are arranged on the outer face of the elements.

- Passages for ducts or ducts allowing, for example, the use of filtration and / or lighting devices may be provided in the wall elements.

- wall elements may be made to form, for example, round, oval or complex shaped pools.

- the wall elements can be colored or tinted in the mass, advantageously before thermoforming.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Blow-Moulding Or Thermoforming Of Plastics Or The Like (AREA)

- Separation Using Semi-Permeable Membranes (AREA)

Claims (6)

- Herstellungsverfahren für Pools in folgenden Etappen mit:- a) Realisierung aus thermoformbarem Material (P) für mehrere Seitenwände nach Wahl eines Seitenteils (3), Eckteils (6) oder Bodenteils (1) des besagten Pools (2),- b) Montage der beschriebenen thermoformbaren Wandteile (1, 3, 6) zur Aufstellung eines Pools (2),Mit den Merkmalen in Etappe b) zur Montage mit Überlappung der Ränder (B, B') beider angrenzender Teile (1, 3, 6) und den Zusatzetappen- c) Verstärkung der Seitenwand- (3), Eck- (6) und/oder Bodenteile(1) nach Montage mit Harzfaser (80) als Stütze (8) oder Folien (20) als Stützfasern (8) mit Anbringung auf den gekennzeichneten Montageteilen (1, 3, 6).

- Verfahren gemäß Anspruch 1 mit dem Merkmal der Etappe a), für mindestens einen Seitenwand- (3), Eck- (6) oder Bodenteil (1) durch Thermoverformung einer Acrylpolymerplatte oder auf Acrylgrundlage, z. B. ABS.

- Verfahren gemäß gemäß einem der vorigen Ansprüche mit Merkmalen der Etappe b), zur Montage mindestens einer Dichtung (10, 11, 12) in der Montagezone (Z) angrenzender Teile (1, 3, 6).

- Verfahren gemäß Anspruch 1 mit dem Merkmal der Verbindungen eines Rands (B) mit einem Element (1, 3, 6) und einer Trennung (D), sodass bei der Montage mit einem anderen Element (1, 3, 6) durch Überlappung beider Ränder (B, B') ihre Innenseiten gegengleich flach liegen (Abb. 5).

- Verfahren gemäß einem der vorigen Ansprüche mit Merkmalen der Etappe a) zur Herstellung eines Rands mit Bildung des Stützfußes (5) am Boden für bestimmte Teile (3, 6).

- Poolaufbau durch Montage mehrerer Wandteile aus thermoformbarem Material (P) entsprechend mindestens zweier Montageteilen nach Wahl aus einem Seitenwand- (3), Eck- (6) oder Bodenteil (1) des beschriebenen Pools (2) mit den Merkmalen der Teile (1, 3, 6) und Montage durch Überlappung der Ränder (B, B') beider aneinanderliegenden Teile (1, 3, 6) sowie Seitenwandteilen (3), Eck- (6) und/oder Bodenmontage (1) mit Harz- (80) und Faserverstärkung zur Robustheit (8) oder Folien (20) zur Verstärkung (8) mit Auflage auf den Aussenflächen der beschriebenen Montageteile (1, 3, 6).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL06356066T PL1736615T3 (pl) | 2005-06-20 | 2006-06-12 | Sposób wytwarzania polimerowego basenu pływackiego |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0506219A FR2887274B1 (fr) | 2005-06-20 | 2005-06-20 | Procede de fabrication d'une piscine en polymere |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1736615A2 EP1736615A2 (de) | 2006-12-27 |

| EP1736615A3 EP1736615A3 (de) | 2014-08-06 |

| EP1736615B1 true EP1736615B1 (de) | 2016-11-02 |

Family

ID=35708912

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06356066.8A Not-in-force EP1736615B1 (de) | 2005-06-20 | 2006-06-12 | Herstellungsverfahren eines Polymerschwimmbeckens |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1736615B1 (de) |

| ES (1) | ES2612262T3 (de) |

| FR (1) | FR2887274B1 (de) |

| PL (1) | PL1736615T3 (de) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2080855B1 (de) * | 2008-01-17 | 2011-05-25 | Polytherm Kunstoff- und Metalltechnik GmbH | Schwimmbecken |

| ITBO20110659A1 (it) * | 2011-11-18 | 2013-05-19 | Heinz Pecher | Piscina perfezionata, in particolare per ambiente esterno |

| CN102943575B (zh) * | 2012-11-01 | 2014-06-25 | 佛山市高明粤华卫生洁具有限公司 | 一种移动式整体泳池及其生产工艺 |

| FR3025546B1 (fr) * | 2014-09-04 | 2018-06-15 | Pascal Gonichon | Procede de fabrication d'une coque de piscine de forme parallelepipedique a partir d'elements en materiau thermoformable |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4048773A (en) * | 1973-12-27 | 1977-09-20 | Laven Merrill L | Above-ground pool walls, panels therefor, and panel-manufacturing methods |

| US3971075A (en) * | 1974-05-08 | 1976-07-27 | Heinbaugh Kenneth D | Swimming pool structure |

| FR2672629B1 (fr) * | 1991-02-12 | 1996-09-20 | Somethy Sa | Bac demontable a goulotte de debordement. |

| FR2716406B1 (fr) * | 1994-02-24 | 1996-07-05 | Desjoyaux Piscines | Procédé de fabrication par thermoformage d'une pièce, notamment d'un escalier, pour piscine et l'installation de mise en Óoeuvre. |

| FR2729422B1 (fr) * | 1995-01-17 | 1997-04-18 | Gonichon Pascal | Element de paroi prefabrique pour piscine |

| FR2732389A1 (fr) * | 1995-03-28 | 1996-10-04 | Piscines Desjoyaux Sa | Escalier thermoforme pour bassins de piscines notamment |

-

2005

- 2005-06-20 FR FR0506219A patent/FR2887274B1/fr not_active Expired - Lifetime

-

2006

- 2006-06-12 ES ES06356066.8T patent/ES2612262T3/es active Active

- 2006-06-12 PL PL06356066T patent/PL1736615T3/pl unknown

- 2006-06-12 EP EP06356066.8A patent/EP1736615B1/de not_active Not-in-force

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| FR2887274B1 (fr) | 2009-01-23 |

| EP1736615A3 (de) | 2014-08-06 |

| ES2612262T3 (es) | 2017-05-16 |

| PL1736615T3 (pl) | 2017-04-28 |

| FR2887274A1 (fr) | 2006-12-22 |

| EP1736615A2 (de) | 2006-12-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2872409B1 (de) | Kastenförmige verpackung aus zwei materialien zum verpacken eines produktes, und herstellungsverfahren | |

| FR2542363A1 (fr) | Garniture pour montage d'un vitrage de securite dans une baie notamment d'un pare-brise pour vehicule automobile | |

| EP1736615B1 (de) | Herstellungsverfahren eines Polymerschwimmbeckens | |

| WO2012076811A1 (fr) | Systeme de construction modulaire et demontable | |

| EP0799952B1 (de) | Vorrichtung zum Zusammenbau vorgefertigter Paneelen für eine Schwimmbadwand und dadurch hergestellte Schwimmbadwand | |

| EP3932822B1 (de) | Kunststoffverpackung mit rahmen aus karton oder anderem biobasierten material ohne verklebung | |

| WO2010008260A1 (fr) | Bassin, en particulier de piscine, forme d'une pluralite de modules | |

| EP2671665A1 (de) | Schutzelement für ein Fahrzeug, Fahrzeug versehen mit einem solchen Element und Verfahren zum Herstellen | |

| EP2894278B1 (de) | Vorrichtung zur Herstellung eines Schwimmbeckens | |

| FR2726796A1 (fr) | Receptacle etanche pour haut-parleur dans un vehicule | |

| FR2934295A1 (fr) | Procede de realisation d'un logement de reception d'une extremite de volet roulant immerge et coque de piscine formant un tel logement | |

| FR2990650A1 (fr) | Pare-brise hybride allege pour vehicule formant une bulle panoramique. | |

| BE1017285A3 (fr) | Entrevous isolant pour plancher a poutrelles et plancher obtenu. | |

| FR2574459A1 (fr) | Caveau etanche | |

| BE1029090B1 (fr) | Module de construction pour piscine, piscine associée et procédé de réalisation d'une piscine | |

| FR2707321A1 (fr) | Procédé de construction de piscine. | |

| WO2012019959A1 (fr) | Dispositif de coffrage pour piscine en beton arme et son procede de montage | |

| EP4091917B1 (de) | Karosseriepaneel eines kraftfahrzeugs | |

| FR2492435A1 (fr) | Panneau prefabrique pour bassins, procede de fabrication et procede de mise en place | |

| EP1705314A2 (de) | Unterstand mit einer Tragestruktur aus Profilelementen | |

| FR2913444A1 (fr) | Procede et outillage pour le moulage d'une piscine et piscine obtenue | |

| EP4086405A1 (de) | Stützbasis, insbesondere für rauchabzugsanlage | |

| FR2932514A1 (fr) | Bassin, tel que bassin de piscine. | |

| FR3025546A1 (fr) | Procede de fabrication d'une coque de piscine de forme parallelepipedique a partir d'elements en materiau thermoformable | |

| FR2974379A1 (fr) | Dispositif de coffrage perdu pour realiser des ouvrages de genie civil en beton arme. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK YU |

|

| 17P | Request for examination filed |

Effective date: 20070613 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E04H 4/00 20060101AFI20140702BHEP |

|

| 17Q | First examination report despatched |

Effective date: 20140730 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AXX | Extension fees paid |

Extension state: BA Extension state: AL Extension state: RS Extension state: HR Extension state: MK |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160629 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 842027 Country of ref document: AT Kind code of ref document: T Effective date: 20161115 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602006050743 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20161102 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170203 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2612262 Country of ref document: ES Kind code of ref document: T3 Effective date: 20170516 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170302 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170302 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20170620 Year of fee payment: 12 Ref country code: DE Payment date: 20170621 Year of fee payment: 12 Ref country code: GB Payment date: 20170620 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602006050743 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170202 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NO Payment date: 20170725 Year of fee payment: 10 Ref country code: LU Payment date: 20170620 Year of fee payment: 12 Ref country code: BE Payment date: 20170620 Year of fee payment: 12 Ref country code: SE Payment date: 20170620 Year of fee payment: 12 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20170803 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170612 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602006050743 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180613 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 842027 Country of ref document: AT Kind code of ref document: T Effective date: 20180612 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180612 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180612 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180612 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180630 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190101 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180612 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20060612 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20190531 Year of fee payment: 14 Ref country code: IT Payment date: 20190624 Year of fee payment: 14 Ref country code: CZ Payment date: 20190611 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: RO Payment date: 20190528 Year of fee payment: 14 Ref country code: FR Payment date: 20190527 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161102 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20190719 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: UEP Ref document number: 842027 Country of ref document: AT Kind code of ref document: T Effective date: 20161102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200612 Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200612 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200612 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20211103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200613 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200612 |