EP1635019B2 - Fitting assembly for a window, a door or the like - Google Patents

Fitting assembly for a window, a door or the like Download PDFInfo

- Publication number

- EP1635019B2 EP1635019B2 EP05017157.8A EP05017157A EP1635019B2 EP 1635019 B2 EP1635019 B2 EP 1635019B2 EP 05017157 A EP05017157 A EP 05017157A EP 1635019 B2 EP1635019 B2 EP 1635019B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- push rod

- guide

- rod element

- fitting assembly

- assembly according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000006073 displacement reaction Methods 0.000 claims description 13

- 230000005540 biological transmission Effects 0.000 claims 1

- 230000000717 retained effect Effects 0.000 claims 1

- 210000001331 nose Anatomy 0.000 description 15

- 230000000712 assembly Effects 0.000 description 8

- 238000000429 assembly Methods 0.000 description 8

- 238000009434 installation Methods 0.000 description 4

- 238000003780 insertion Methods 0.000 description 3

- 230000037431 insertion Effects 0.000 description 3

- 238000007789 sealing Methods 0.000 description 3

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05C—BOLTS OR FASTENING DEVICES FOR WINGS, SPECIALLY FOR DOORS OR WINDOWS

- E05C9/00—Arrangements of simultaneously actuated bolts or other securing devices at well-separated positions on the same wing

- E05C9/24—Means for transmitting movements between vertical and horizontal sliding bars, rods or cables for the fastening of wings, e.g. corner guides

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05C—BOLTS OR FASTENING DEVICES FOR WINGS, SPECIALLY FOR DOORS OR WINDOWS

- E05C9/00—Arrangements of simultaneously actuated bolts or other securing devices at well-separated positions on the same wing

- E05C9/20—Coupling means for sliding bars, rods, or cables

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05D—HINGES OR SUSPENSION DEVICES FOR DOORS, WINDOWS OR WINGS

- E05D15/00—Suspension arrangements for wings

- E05D15/06—Suspension arrangements for wings for wings sliding horizontally more or less in their own plane

- E05D15/0621—Details, e.g. suspension or supporting guides

- E05D15/066—Details, e.g. suspension or supporting guides for wings supported at the bottom

- E05D15/0665—Details, e.g. suspension or supporting guides for wings supported at the bottom on wheels with fixed axis

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05D—HINGES OR SUSPENSION DEVICES FOR DOORS, WINDOWS OR WINGS

- E05D15/00—Suspension arrangements for wings

- E05D15/06—Suspension arrangements for wings for wings sliding horizontally more or less in their own plane

- E05D15/0621—Details, e.g. suspension or supporting guides

- E05D15/066—Details, e.g. suspension or supporting guides for wings supported at the bottom

- E05D15/0691—Top guides

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2900/00—Application of doors, windows, wings or fittings thereof

- E05Y2900/10—Application of doors, windows, wings or fittings thereof for buildings or parts thereof

- E05Y2900/13—Type of wing

- E05Y2900/132—Doors

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2900/00—Application of doors, windows, wings or fittings thereof

- E05Y2900/10—Application of doors, windows, wings or fittings thereof for buildings or parts thereof

- E05Y2900/13—Type of wing

- E05Y2900/148—Windows

Definitions

- the invention relates to a fitting arrangement of a window, a door or the like according to the preamble of claim 1.

- Fitting arrangements are often arranged at the fold side in the case of a window or a door or the like. As a result of such fitting arrangements, forces or movements introduced by a control element must generally be transferred to fitting parts along the fold of the window or the door.

- a fitting arrangement on a wing or a fixed enclosure of the window or the door, wherein a guide is fixedly arranged on the wing or the fixed enclosure and a push rod element is movable relative to this guide.

- the push rod element is guided in or on the guide.

- On the push rod element one or more fitting parts are arranged through which a certain function is performed.

- a plurality of fitting parts must be arranged on the push rod element and coupled with it in motion.

- Object of the present invention is to provide a fitting assembly that can be mounted with little use of tools.

- a fitting arrangement of the type mentioned in which both the push rod element and the nose of at least one leg portion of the legs are engaged behind.

- the fitting part does not have to be connected directly to the push rod element. It may sit relatively loosely in or on the push rod member during assembly or assembly of the fitting assembly.

- the fitting part can be inserted with its nose in the recess.

- the fitting is held in the assembled state by the guide on the push rod element.

- the fitting is simply placed for mounting on the push rod element, so that the nose protrudes into the recess and is inserted together with the push rod element in the guide. After insertion into the guide, the fitting is held by the legs of the guide. This makes a tool-free installation possible.

- the fitting part is arranged captive on the push rod element. Characterized in that the nose protrudes into the recess, the push rod member and the fitting part are also movement coupled.

- the cross-sectionally C-shaped guide may be formed as a C-profile.

- the cross-sectionally C-shaped guide is designed in several parts. In particular, it can be composed of two profiles which are U-shaped in cross-section. It is also conceivable to provide a fitting part as a guide which has at a distance from the groove bottom of the groove flanks protruding webs, which form the legs of the guide.

- the push rod member is typically between two end positions, i. movable in limits along the guide. It may therefore be sufficient not to form the legs completely along the guide, but to provide them only in those areas as leg sections in which the fitting parts are moved along the guide. In other words, this means that it must be ensured that the lugs are held in engagement with the recesses in all possible movements of the push rod element.

- the strength of the nose preferably corresponds approximately to the strength of the push rod element.

- the thickness of the nose and a rear engagement portion of the push rod member are tuned approximately to the groove-like recess of the cross-sectionally C-shaped guide.

- the push rod member and the fitting part can be arranged substantially free of play in the guide.

- the dimensions of the nose are adapted to the recess.

- the fitting part in the direction of movement of the push rod element i. in the axial direction, arranged without play.

- the lugs can be arranged accurately in the recesses.

- a cross slide guide element may be provided which is mountable together with the push rod element in the C-shaped guide.

- a cross slide guide element must be stationary, in particular stationary with respect to the guide. This means that the push rod element must be displaceable relative to the cross slide guide element.

- the cross slide guide element is arranged with a holding portion behind the push rod element, can be fastened to the guide and engages with at least one guide means for a transverse slide a passage opening of the push rod element.

- the cross slide guide element is arranged with a holding portion behind the push rod element. This means that in the assembled state, the holding portion between the push rod member and the C-shaped guide is arranged.

- the push rod element preferably has a slot through which the guide means projects. This ensures that the push rod element is movable relative to the cross slide guide element.

- a particularly simple assembly results when the cross slide guide element is clipped into the at least partially cross-sectionally C-shaped guide.

- the cross slide guide element can be introduced together with the push rod element and one or more fitting parts in the C-shaped guide. Subsequently, the cross slide guide element can be attached in a simple manner to the C-shaped guide, in which it is simply clipped into corresponding Klipsfactn. For this purpose, e.g. only a force on the cross slide guide element perpendicular to the extension of the guide necessary.

- the assembly is further simplified if the cross slide guide element has an alignment aid for alignment with respect to the push rod member during assembly of the fitting assembly.

- the alignment aid cooperates with a corresponding alignment aid of the push rod element and forms a displacement safety device in order to prevent unintentional axial displacement of the transverse slide guide element with respect to the push rod element during assembly.

- the anti-displacement prevents a displacement of the push rod member relative to the guide because of the fixed cross slide guide element.

- the alignment aids cooperate in such a way that they form a displacement safety device, the problem arises that after assembly the push rod element is immovable with respect to the transverse slide guide element.

- the anti-displacement device is destructible, in particular one of the alignment aids is designed to be sheared off.

- the alignment aid is stable enough to ensure the mutual alignment of the components during assembly. By a corresponding force entry, the anti-slip device can be solved. In a particularly simple manner, the anti-displacement device can be released when the alignment aid is removed.

- the alignment aid may be formed as a pin which projects into a trained as a recess alignment aid of the push rod member, and which is sheared by a movement of the push rod member.

- a transverse slide which is held on a sliding member designed as a longitudinal member and a control pin on the push rod element.

- the cross slide preferably has guide means, which are guided by corresponding guide means of the cross slide guide element.

- the cross slide is thereby displaced obliquely to the direction of movement of the push rod element.

- a control slot is formed in the cross slide or in the longitudinal slide, in which the control pin is guided. The control pin is fixed to the slider which has no control slot.

- the longitudinal slide may be a fitting part which has a nose which projects into a corresponding recess of the push rod element.

- sealing elements of a seal assembly can be arranged so that the fitting assembly for controlling the seal assembly can be used to selectively open a gap between the window or door and a fixed enclosure for air passage or to close against air passage.

- the cross slide and / or the longitudinal slide on an orientation aid can be formed asymmetrically depending on the application.

- a mark can be provided, which indicates to the fitter how to properly install the longitudinal slide or the cross slide.

- the fitting arrangement can be used particularly easily in sliding doors.

- the carriage may be provided at the bottom end of the window or the door and the slider at the top.

- the carriage or the slider is screwed or clipped to the guide.

- the fitting arrangement can largely be assembled without tools.

- the carriage or slider is bolted to the guide, the use of tools in assembly of the fitting assembly is minimized.

- the slider and the carriage are each secured only with a screw.

- a corner deflection is provided, which is connected to the push rod element.

- the fitting arrangement is used in a sliding door which has a controllable sealing arrangement in the horizontally extending fold area, a movement introduced on a control element often has to be transferred to the fitting arrangement for controlling the seal arrangement, the operating element being attached, for example, to a vertical bar of the door. or window sash is arranged. A movement introduced there can be transmitted in a particularly simple manner via a corner drive to a fitting arrangement arranged in or on a horizontal spar of the door or window sash.

- a plurality of assemblies are provided, wherein at least one assembly has an at least partially cross-sectionally C-shaped guide and a push rod member and the push rod element is coupled in motion with a push rod element of an adjacent module.

- the C-shaped guide does not have to extend along the entire width of the window or door. It is sufficient to provide a guide at the places where fitting parts are necessary.

- Assemblies can be assembled for different purposes and locations, with different assemblies can use the same or similar components.

- end assemblies may be provided in the corner regions of the window or the door and for bridging larger distances between the end assemblies may be provided intermediate modules, wherein the push rod elements of the assemblies are coupled in motion via connecting elements.

- the illustrated assembly 1 has a push rod element 2, which recesses 3, 4 contains.

- the push rod element 2 has passage openings 5, 6 formed as elongated holes.

- a transverse slide guide element 7 is pushed through the passage opening 6 with a first of two guide means 8, 9.

- the cross slide guide element 7 is aligned with respect to the push rod element 2 by inserting a detachable alignment aid 10 from behind into an alignment aid 11 of the push rod element 2 designed as a passage opening.

- a holding portion 12 of the cross slide guide element 7 is behind or under the push rod element 2.

- a nose 14 is inserted into the recess 4 of the push rod element 2.

- the assembled fitting part 13 is coupled for movement with the push rod element 2.

- the fitting part 20 also has a nose 21, the dimensions of which are adapted to the recess 3.

- the cross slide 15 has a notch trained orientation aid 25, which ensures the correct installation of the cross slide 15. This is advantageous in particular in the case of asymmetrical control slot 17.

- the cross slide guide element 7 can be fastened by clipping into the guide 28.

- clip portions 34, 35 are provided on the holding element 12, which clip into the associated clip receptacles of the guide 28 by corresponding pressure. If now the push rod element 2 is acted upon in the axial direction 36 with a force and thereby moved, the alignment aid 10 is sheared off. As a result, a relative movement of the push rod element 2 to the cross slide guide element 7 is possible.

- the assembly 1 is intended to be used in an upper end region of a sliding door. Therefore, a slider 38 is still mounted.

- the slider 38 should be arranged stationary with respect to the guide 28. Furthermore, he should not hinder the axial movement of the push rod element 2. Therefore, the trained as a slot 5 passage opening is provided, through which the slider 38 can be inserted with a mounting portion 39.

- the slider 38 is fastened in the exemplary embodiment via a screw connection 40.

- anti-rotation means which are designed as pins 41, 42, are provided, which protrude into corresponding receptacles of the guide 28.

- the push rod element 2 with a push rod element of an adjacent module be movably coupled by attaching a connector to adjacent connectors of the two assemblies.

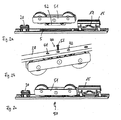

- FIGS. 2a to 2c Mounting steps for producing an end assembly of a fitting assembly are shown.

- the assembly 50 is intended for use in the lower end region of a sliding door. Components that correspond to components of the assembly 1 are designated by the same reference numerals. Since the assembly 50 is to be used at the lower end of a sliding door, the slider must be replaced by a carriage 51.

- the carriage 51 in turn has a mounting portion 52 which projects through the passage opening 5 and can be screwed from behind by means of a screw 40 with the guide 28.

- a single screw 53 is sufficient, since a rotation of the carriage 51 is excluded.

- There protrude cones 41, 42 through corresponding openings of the guide 28. Through them, a rotation lock is realized. Since the assembly 50 is an end assembly, a single connector 20 component is sufficient for motion coupling with an adjacent assembly.

- the control slot 17 is formed differently than in the cross slide 15 of the assembly 1. This is related to the operation of each driven by the cross slide 15 seal assembly.

- FIGS. 3a to 3h the assembly of a designed as a center assembly of a fitting assembly assembly 60 is shown.

- the push rod element 2 has two recesses 3, 3a for lugs 21, 21a of components 20, 20a designed as connectors. Since the module 60 acts as a center module, a push rod element of an adjacent module must be coupled to the push rod element 2 on both sides in each case. Therefore, two components 20, 20a are provided.

- the adjacent assembly may be another center assembly or an end or corner assembly.

- the cross slide guide element 7 Before attaching the control unit, consisting of component 13, cross slide 15 and control pin 16, the cross slide guide element 7 is arranged from the rear of the push rod element 2, wherein the first and second guide means 8, 9 pass through the openings formed as slots 6, 6a.

- the alignment aid 10 engages in the alignment 11, so that when applying the control unit, the nose 14 automatically enters the recess 4 when the guide means 18, 19 are inserted into the guide means 8, 9.

- the entire still loosely assembled arrangement consisting of push rod element 2, components 20, 20a, control unit and cross slide guide element 7 is inserted together in a cross-sectionally C-shaped guide 28, whereby the components 20, 20a and 13 are held captive on the push rod 2.

- the cross slide guide element 7 is clipped to the guide 28.

- the cross slide guide element 7 is held immovably on the guide 28.

- the cross slide guide element 7 and the push rod element 2 are immovable relative to one another via the alignment aids 10, 11 which act as a displacement safeguard.

- the position of the push rod element 2 is fixed. It can not move unintentionally and the components 20, 20a, 13 can not "fall out” because the push rod element 2 can not slip out of the guide 28. Only when the assemblies 60 are mounted, for example, in a fitting part of a sash, the components 20, 20a are connected via a rigid connecting element with an adjacent assembly 60.

- the displacement protection ensures that when connecting adjacent components 20, 20a of adjacent subassemblies 60, the guide means 8, 9 are arranged centrally in the passage openings 6, 6a. Only when all adjacent formed as a connector components 20, 20a are motion-coupled, the anti-displacement device is destroyed.

- FIGS. 4a to 4h the assembly of a designed as a corner assembly assembly 70, which can be arranged in the lower corner of a sliding door, is shown.

- the push rod element 2 is coupled for movement with a corner drive 71.

- a movement of the push rod member 72, which can be driven via a control handle is transmitted by a flexible push rod member 73 to the push rod member 2, wherein a deflection of the movement takes place from a vertical to a horizontal movement.

- the components 20, 13 and the cross slide guide element 7 are arranged on the push rod element 2. Subsequently, the entire assembly is inserted into a guide 28 ( Fig. 4c ).

- a longitudinal slide 75 is fastened to a connecting element 74 of the corner drive 71. Since it is not easy to attach a cross slide guide element 7 in the corner region of the corner drive 71, as in the Fig. 4e shown, a guide member 76 disposed in the corner. This guide element 76 engages, as in the Fig. 4f can be seen, in a slot 77 of the cross slide 78 and holds it immobile in the folding longitudinal direction 79.

- the cross slide 78 is placed on the longitudinal slide 75 and held on this via a control pin, which passes through a through hole 80.

- the push rod element 2 has a passage opening 5 for receiving the attachment portion of a carriage 51. This is fastened via a screw 40 to the guide 28.

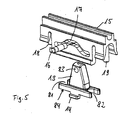

- FIG. 5 an exploded view of a control device is shown.

- Trained as a longitudinal slide member 13 has a nose 14.

- Laterally U-shaped recesses 81, 82 are provided, the make it possible to approach with the component 13 as close as possible to the guide means 18, 19 of the cross slide 15.

- the guide means 18, 19 are designed as pins, which can engage in corresponding formed as sleeves guide means of the cross slide guide element 7.

- the component 13 has a control pin receptacle 83 into which the control pin 16 can be inserted.

- the control pin 16 also passes through a control slot 17 in the cross slide 15. In axially fixed cross slide 15, therefore, a transverse movement of the cross slide 15 is generated by a longitudinal movement of the component 13.

- sealing elements of a seal assembly can be attached.

- the longitudinal slide 13 has a bearing surface 84 with which it can rest on the push rod element 2.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Window Of Vehicle (AREA)

- Power-Operated Mechanisms For Wings (AREA)

- Securing Of Glass Panes Or The Like (AREA)

- Connection Of Plates (AREA)

Abstract

Description

Die Erfindung betrifft eine Beschlaganordnung eines Fensters, einer Tür oder dergleichen nach dem Oberbegriff des Anspruchs 1.The invention relates to a fitting arrangement of a window, a door or the like according to the preamble of claim 1.

Das Dokument

Beschlaganordnungen sind häufig falzseitig bei einem Fenster oder einer Tür oder dergleichen angeordnet. Durch solche Beschlaganordnungen müssen in der Regel durch ein Bedienelement eingeleitete Kräfte oder Bewegungen auf Beschlagteile entlang des Falzes des Fenster oder der Türe übertragen werden. So ist es bekannt, eine Beschlaganordnung an einem Flügel oder einer festen Einfassung des Fensters oder der Türe zu montieren, wobei eine Führung fest an dem Flügel oder der festen Einfassung angeordnet ist und ein Schubstangenelement relativ zu dieser Führung beweglich ist. Das Schubstangenelement ist in oder an der Führung geführt. An dem Schubstangenelement sind ein oder mehrere Beschlagteile angeordnet, durch die eine bestimmte Funktion ausgeführt wird. Je nach Funktion müssen mehrere Beschlagteile an dem Schubstangenelement angeordnet werden und mit diesem bewegungsgekoppelt werden. Hierzu ist es beispielsweise bekannt, Beschlagteile an dem Schubstangenelement anzuschrauben. Dies ist mit einem erheblichen Montageaufwand verbunden.Fitting arrangements are often arranged at the fold side in the case of a window or a door or the like. As a result of such fitting arrangements, forces or movements introduced by a control element must generally be transferred to fitting parts along the fold of the window or the door. Thus, it is known to mount a fitting arrangement on a wing or a fixed enclosure of the window or the door, wherein a guide is fixedly arranged on the wing or the fixed enclosure and a push rod element is movable relative to this guide. The push rod element is guided in or on the guide. On the push rod element one or more fitting parts are arranged through which a certain function is performed. Depending on the function, a plurality of fitting parts must be arranged on the push rod element and coupled with it in motion. For this purpose, it is known, for example, to screw fitting parts on the push rod element. This is associated with a considerable installation effort.

Aufgabe der vorliegenden Erfindung ist es, eine Beschlaganordnung zu schaffen, die mit geringem Werkzeugeinsatz montiert werden kann.Object of the present invention is to provide a fitting assembly that can be mounted with little use of tools.

Gelöst wird diese Aufgabe durch eine Beschlaganordnung der eingangs genannten Art, bei der sowohl das Schubstangenelement als auch die Nase von zumindest einem Schenkelabschnitt der Schenkel hintergriffen sind. Dies bedeutet, dass das Beschlagteil nicht unmittelbar mit dem Schubstangenelement verbunden werden muss. Es kann während der Montage bzw. dem Zusammenbau der Beschlaganordnung relativ lose in oder an dem Schubstangenelement sitzen. Insbesondere kann das Beschlagteil mit seiner Nase in die Ausnehmung eingesteckt werden. Das Beschlagteil wird im montierten Zustand durch die Führung an dem Schubstangenelement gehalten. Das Beschlagteil wird zur Montage einfach auf das Schubstangenelement aufgesetzt, so dass die Nase in die Ausnehmung ragt und zusammen mit dem Schubstangenelement in die Führung eingeführt wird. Nach dem Einführen in die Führung wird das Beschlagteil durch die Schenkel der Führung, gehalten. Dadurch ist eine werkzeugfreie Montage möglich. Das Beschlagteil ist unverlierbar an dem Schubstangenelement angeordnet. Dadurch, dass die Nase in die Ausnehmung ragt, sind das Schubstangenelement und das Beschlagteil auch bewegungsgekoppelt.This object is achieved by a fitting arrangement of the type mentioned, in which both the push rod element and the nose of at least one leg portion of the legs are engaged behind. This means that the fitting part does not have to be connected directly to the push rod element. It may sit relatively loosely in or on the push rod member during assembly or assembly of the fitting assembly. In particular, the fitting part can be inserted with its nose in the recess. The fitting is held in the assembled state by the guide on the push rod element. The fitting is simply placed for mounting on the push rod element, so that the nose protrudes into the recess and is inserted together with the push rod element in the guide. After insertion into the guide, the fitting is held by the legs of the guide. This makes a tool-free installation possible. The fitting part is arranged captive on the push rod element. Characterized in that the nose protrudes into the recess, the push rod member and the fitting part are also movement coupled.

Die im Querschnitt C-förmige Führung kann als C-Profil ausgebildet sein. Alternativ ist es denkbar, dass die im Querschnitt C-förmige Führung mehrteilig ausgebildet ist. Insbesondere kann sie aus zwei im Querschnitt U-förmigen Profilen zusammengesetzt sein. Es ist weiterhin denkbar, als Führung eine Beschlagteilnut vorzusehen, die im Abstand vom Nutgrund von den Nutflanken hervorstehende Stege aufweist, die die Schenkel der Führung bilden.The cross-sectionally C-shaped guide may be formed as a C-profile. Alternatively, it is conceivable that the cross-sectionally C-shaped guide is designed in several parts. In particular, it can be composed of two profiles which are U-shaped in cross-section. It is also conceivable to provide a fitting part as a guide which has at a distance from the groove bottom of the groove flanks protruding webs, which form the legs of the guide.

Das Schubstangenelement ist in der Regel zwischen zwei Endpositionen, d.h. in Grenzen entlang der Führung beweglich. Es kann daher ausreichend sein, die Schenkel nicht vollständig entlang der Führung auszubilden, sondern sie nur in denjenigen Bereichen als Schenkelabschnitte vorzusehen, in denen die Beschlagteile entlang der Führung bewegt werden. Mit anderen Worten bedeutet dies, dass sichergestellt sein muss, dass die Nasen bei allen möglichen Bewegungen des Schubstangenelements in Eingriff mit den Ausnehmungen gehalten werden.The push rod member is typically between two end positions, i. movable in limits along the guide. It may therefore be sufficient not to form the legs completely along the guide, but to provide them only in those areas as leg sections in which the fitting parts are moved along the guide. In other words, this means that it must be ensured that the lugs are held in engagement with the recesses in all possible movements of the push rod element.

Vorzugsweise entspricht die Stärke der Nase etwa der Stärke des Schubstangenelements. Insbesondere sind die Dicke der Nase und eines Hintergreifabschnitts des Schubstangenelements etwa auf die nutartige Ausnehmung der im Querschnitt C-förmigen Führung abgestimmt. Somit können das Schubstangenelement und das Beschlagteil im Wesentlichen spielfrei in der Führung angeordnet werden.The strength of the nose preferably corresponds approximately to the strength of the push rod element. In particular, the thickness of the nose and a rear engagement portion of the push rod member are tuned approximately to the groove-like recess of the cross-sectionally C-shaped guide. Thus, the push rod member and the fitting part can be arranged substantially free of play in the guide.

Bei der bevorzugten Ausgestaltung der Erfindung ist vorgesehen, dass die Ausmaße der Nase auf die Ausnehmung angepasst sind. Dadurch ist das Beschlagteil in Bewegungsrichtung des Schubstangenelements, d.h. in axialer Richtung,spielfrei angeordnet. Es können unterschiedlich dimensionierte Ausnehmungen für unterschiedliche Nasen unterschiedlicher Beschlagteile vorgesehen sein. Dadurch kann sichergestellt werden, dass ein bestimmtes Beschlagteil nur an der richtigen Stelle des Schubstangenelements angeordnet werden kann. Dadurch wird der Zusammenbau der Beschlaganordnung erleichtert. Insbesondere können die Nasen passgenau in den Ausnehmungen angeordnet sein.In the preferred embodiment of the invention it is provided that the dimensions of the nose are adapted to the recess. As a result, the fitting part in the direction of movement of the push rod element, i. in the axial direction, arranged without play. It can be provided differently sized recesses for different noses different fittings. This can ensure that a certain fitting part can be arranged only at the right place of the push rod element. As a result, the assembly of the fitting arrangement is facilitated. In particular, the lugs can be arranged accurately in the recesses.

Bei einer besonders bevorzugten Ausführungsform kann ein Querschieberführungselement vorgesehen sein, das gemeinsam mit dem Schubstangenelement in der C-förmigen Führung montierbar ist.In a particularly preferred embodiment, a cross slide guide element may be provided which is mountable together with the push rod element in the C-shaped guide.

Ein Querschieberführungselement muss in der Regel ortsfest, insbesondere ortsfest gegenüber der Führung, angeordnet sein. Dies bedeutet, dass das Schubstangenelement relativ zum Querschieberführungselement verschiebbar sein muss. Das Querschieberführungselement und das Schubstangenelement getrennt voneinander in oder an der Führung zu montieren, erweist sich als schwierig. Die Montage kann daher vereinfacht werden, wenn das Querschieberführungselement und das Schubstangenelement gemeinsam montiert werden können, da das Querschieberführungselement bereits vor der endgültigen Montage bezüglich des Schubstangenelements richtig angeordnet werden kann.As a rule, a cross slide guide element must be stationary, in particular stationary with respect to the guide. This means that the push rod element must be displaceable relative to the cross slide guide element. The cross slide guide element and the push rod element separately mounted in or on the guide, proves to be difficult. The assembly can therefore be simplified if the cross slide guide element and the push rod element can be mounted together, since the cross slide guide element can be arranged properly prior to final assembly with respect to the push rod member.

Bei einer Weiterbildung kann vorgesehen sein, dass das Querschieberführungselement mit einem Halteabschnitt hinter dem Schubstangenelement angeordnet ist, an der Führung befestigbar ist und mit zumindest einem Führungsmittel für einen Querschieber eine Durchgangsöffnung des Schubstangenelements durchgreift. Insbesondere bei dieser Weiterbildung wird klar, dass es vorteilhaft ist, das Querschieberführungselement gemeinsam mit dem Schubstangenelement zu montieren. Das Querschieberführungselement ist mit einem Halteabschnitt hinter dem Schubstangenelement angeordnet. Dies bedeutet, dass im montierten Zustand der Halteabschnitt zwischen dem Schubstangenelement und der C-förmigen Führung angeordnet ist. Das Schubstangenelement weist vorzugsweise ein Langloch auf, durch das das Führungsmittel ragt. Somit ist sichergestellt, dass das Schubstangenelement relativ zum Querschieberführungselement beweglich ist.In a further development can be provided that the cross slide guide element is arranged with a holding portion behind the push rod element, can be fastened to the guide and engages with at least one guide means for a transverse slide a passage opening of the push rod element. In particular, in this development, it is clear that it is advantageous to mount the cross slide guide element together with the push rod element. The cross slide guide element is arranged with a holding portion behind the push rod element. This means that in the assembled state, the holding portion between the push rod member and the C-shaped guide is arranged. The push rod element preferably has a slot through which the guide means projects. This ensures that the push rod element is movable relative to the cross slide guide element.

Eine besonders einfache Montage ergibt sich, wenn das Querschieberführungselement in die zumindest abschnittsweise im Querschnitt C-förmige Führung eingeklipst ist. Dies bedeutet, dass das Querschieberführungselement zusammen mit dem Schubstangenelement und einem oder mehreren Beschlagteilen in die C-förmige Führung eingeführt werden kann. Anschließend kann das Querschieberführungselement auf einfache Art und Weise an der C-förmigen Führung befestigt werden, in dem es dort einfach in entsprechender Klipsaufnahmen eingeklipst wird. Dazu ist z.B. lediglich ein Krafteintrag auf das Querschieberführungselement senkrecht zur Erstreckung der Führung notwendig.A particularly simple assembly results when the cross slide guide element is clipped into the at least partially cross-sectionally C-shaped guide. This means that the cross slide guide element can be introduced together with the push rod element and one or more fitting parts in the C-shaped guide. Subsequently, the cross slide guide element can be attached in a simple manner to the C-shaped guide, in which it is simply clipped into corresponding Klipsaufnahmen. For this purpose, e.g. only a force on the cross slide guide element perpendicular to the extension of the guide necessary.

Die Montage wird weiterhin vereinfacht, wenn das Querschieberführungselement eine Ausrichthilfe zur Ausrichtung bezüglich dem Schubstangenelement während der Montage der Beschlaganordnung aufweist.The assembly is further simplified if the cross slide guide element has an alignment aid for alignment with respect to the push rod member during assembly of the fitting assembly.

Bei einer vorteilhaften Ausgestaltung kann vorgesehen sein, dass die Ausrichthilfe mit einer entsprechenden Ausrichthilfe des Schubstangenelements zusammenwirkt und eine Verschiebesicherung bildet, um ein ungewolltes axiales Verschieben des Querschieberführungselements bezüglich des Schubstangenelements bei der Montage zu verhindern. Bei der Montage der zusammengebauten Baugruppe, beispielsweise an einem Flügel eines Fensters, verhindert die Verschiebesicherung wegen des ortsfesten Querschieberführungselements ein Verschieben des Schubstangenelements relativ zu Führung.In an advantageous embodiment, it can be provided that the alignment aid cooperates with a corresponding alignment aid of the push rod element and forms a displacement safety device in order to prevent unintentional axial displacement of the transverse slide guide element with respect to the push rod element during assembly. When assembling the assembled assembly, for example, on a wing of a window, the anti-displacement prevents a displacement of the push rod member relative to the guide because of the fixed cross slide guide element.

Wenn die Ausrichthilfen so zusammenwirken, dass sie eine Verschiebesicherung bilden, stellt sich das Problem, dass nach erfolgter Montage das Schubstangenelement bezüglich des Querschieberführungselements unbeweglich ist. Für die ordnungsgemäße Funktion der Beschlaganordnung ist es jedoch notwendig, dass eine Relativbewegung der beiden Bautelemente zueinander möglich ist. Deshalb ist es vorteilhaft, wenn die Verschiebesicherung zerstörbar ist, insbesondere eine der Ausrichthilfen abscherbar ausgebildet ist. Die Ausrichthilfe ist dabei stabil genug, die gegenseitige Ausrichtung der Bauteile während der Montage sicherzustellen. Durch einen entsprechenden Krafteintrag kann die Verschiebesicherung gelöst werden. Auf besonders einfache Art und Weise lässt sich die Verschiebesicherung lösen, wenn die Ausrichthilfe entfernt wird. Dazu kann sie beispielsweise abscherbar oder mit einer Sollbruchstelle ausgestaltet sein. Beispielsweise kann die Ausrichthilfe als Zapfen ausgebildet sein, der in eine als Ausnehmung ausgebildete Ausrichthilfe des Schubstangenelements ragt, und der durch eine Bewegung des Schubstangenelements abgeschert wird.If the alignment aids cooperate in such a way that they form a displacement safety device, the problem arises that after assembly the push rod element is immovable with respect to the transverse slide guide element. However, for the proper functioning of the fitting arrangement, it is necessary that a relative movement of the two building elements to each other is possible. Therefore, it is advantageous if the anti-displacement device is destructible, in particular one of the alignment aids is designed to be sheared off. The alignment aid is stable enough to ensure the mutual alignment of the components during assembly. By a corresponding force entry, the anti-slip device can be solved. In a particularly simple manner, the anti-displacement device can be released when the alignment aid is removed. For this purpose, it can be designed, for example, as shear-offable or with a predetermined breaking point. For example, the alignment aid may be formed as a pin which projects into a trained as a recess alignment aid of the push rod member, and which is sheared by a movement of the push rod member.

Besonders bevorzugt ist es, wenn ein Querschieber vorgesehen ist, der über ein als Längsschieber ausgebildetes Bauteil und einen Steuerzapfen an dem Schubstangenelement gehalten ist. Dabei weist der Querschieber vorzugsweise Führungsmittel auf, die durch entsprechende Führungsmittel des Querschieberführungselements geführt sind. Der Querschieber ist dadurch schräg zur Bewegungsrichtung des Schubstangenelements verschiebbar. Durch den Quer- und Längsschieber lässt sich eine Längsbewegung der Schubstange in eine Querbewegung des Querschiebers umsetzen. Dazu ist in dem Querschieber oder in dem Längsschieber ein Steuerschlitz ausgebildet, in dem der Steuerzapfen geführt ist. Der Steuerzapfen ist an demjenigen Schieber, der keinen Steuerschlitz aufweist, fest angeordnet. Über den Steuerzapfen sind der Längs- und Querschieber miteinander verbunden bzw. aneinander gehalten, so dass es ausreichend ist, den Längsschieber unverlierbar an dem Schubstangenelement anzuordnen. Insbesondere kann der Längsschieber ein Beschlagteil sein, das eine Nase aufweist, die in eine entsprechende Ausnehmung des Schubstangenelements ragt. An dem Querschieber können Dichtungselemente einer Dichtungsanordnung angeordnet werden, so dass die Beschlaganordnung zur Steuerung der Dichtungsanordnung eingesetzt werden kann, um gezielt einen Spalt zwischen Fenster- oder Türflügel und einer festen Einfassung für Luftdurchtritt zu öffnen oder gegen Luftdurchtritt zu verschließen.It is particularly preferred if a transverse slide is provided, which is held on a sliding member designed as a longitudinal member and a control pin on the push rod element. In this case, the cross slide preferably has guide means, which are guided by corresponding guide means of the cross slide guide element. The cross slide is thereby displaced obliquely to the direction of movement of the push rod element. Through the transverse and longitudinal slide can be a longitudinal movement of the push rod in a transverse movement of the cross slide implement. For this purpose, a control slot is formed in the cross slide or in the longitudinal slide, in which the control pin is guided. The control pin is fixed to the slider which has no control slot. About the control pins of the longitudinal and transverse slides are connected or held together, so that it is sufficient to arrange the longitudinal slide captive on the push rod element. In particular, the longitudinal slide may be a fitting part which has a nose which projects into a corresponding recess of the push rod element. At the cross slide sealing elements of a seal assembly can be arranged so that the fitting assembly for controlling the seal assembly can be used to selectively open a gap between the window or door and a fixed enclosure for air passage or to close against air passage.

Vorteilhafterweise weisen der Querschieber und/oder der Längsschieber eine Orientierungshilfe auf. Der Steuerschlitz in dem Querschieber oder dem Längsschieber kann je nach Anwendungsfall unsymmetrisch ausgebildet sein. Um den seitenrichtigen Einbau sicherzustellen, kann eine Markierung vorgesehen sein, die dem Monteur anzeigt, wie der Längsschieber bzw. der Querschieber richtigerweise einzubauen ist.Advantageously, the cross slide and / or the longitudinal slide on an orientation aid. The control slot in the cross slide or the longitudinal slide can be formed asymmetrically depending on the application. In order to ensure the correct installation, a mark can be provided, which indicates to the fitter how to properly install the longitudinal slide or the cross slide.

Wenn an der zumindest abschnittsweise im Querschnitt C-förmigen Führung wenigstens ein Gleiter oder ein Laufwagen befestigt sind, kann die Beschlaganordnung besonders einfach bei Schiebetüren eingesetzt werden. Dabei kann der Laufwagen am bodenseitigen Ende des Fensters oder der Türe vorgesehen sein und der Gleiter am oberen Ende.If at least a slider or a carriage are fastened to the at least partially cross-sectionally C-shaped guide, the fitting arrangement can be used particularly easily in sliding doors. In this case, the carriage may be provided at the bottom end of the window or the door and the slider at the top.

Es bestehen mehrere Möglichkeiten, den Laufwagen oder den Gleiter zu befestigen. Besonders vorteilhaft ist es, wenn der Laufwagen oder der Gleiter mit der Führung verschraubt oder verklipst sind. Bei einer Verklipsung kann die Beschlaganordnung weitestgehend ohne Werkzeug zusammengebaut werden. Jedoch selbst, wenn der Laufwagen oder der Gleiter mit der Führung verschraubt sind, ist der Einsatz von Werkzeug bei der Montage der Beschlaganordnung minimiert. Insbesondere kann vorgesehen sein, dass der Gleiter und der Laufwagen jeweils nur mit einer Schraube befestigt sind.There are several ways to attach the carriage or the slider. It is particularly advantageous if the carriage or the slider is screwed or clipped to the guide. When verklipsung the fitting arrangement can largely be assembled without tools. However, even when the carriage or slider is bolted to the guide, the use of tools in assembly of the fitting assembly is minimized. In particular, it can be provided that the slider and the carriage are each secured only with a screw.

Besonders bevorzugt ist es, wenn eine Eckumlenkung vorgesehen ist, die mit dem Schubstangenelement verbunden ist. Insbesondere, wenn die Beschlaganordnung bei einer Schiebetüre eingesetzt wird, die eine steuerbare Dichtungsanordnung im horizontal verlaufenden Falzbereich aufweist, muss häufig eine an einem Bedienelement eingebrachte Bewegung auf die Beschlaganordnung zur Steuerung der Dichtungsanordnung übertragen werden, wobei das Bedienelement beispielsweise an einem vertikalen Holm des Tür- oder Fensterflügels angeordnet ist. Eine dort eingebrachte Bewegung lässt sich besonders einfach über eine Eckumlenkung auf eine in oder an einem horizontalen Holm des Tür- oder Fensterflügels angeordnete Beschlaganordnung übertragen.It is particularly preferred if a corner deflection is provided, which is connected to the push rod element. In particular, if the fitting arrangement is used in a sliding door which has a controllable sealing arrangement in the horizontally extending fold area, a movement introduced on a control element often has to be transferred to the fitting arrangement for controlling the seal arrangement, the operating element being attached, for example, to a vertical bar of the door. or window sash is arranged. A movement introduced there can be transmitted in a particularly simple manner via a corner drive to a fitting arrangement arranged in or on a horizontal spar of the door or window sash.

Bei einer besonders vorteilhaften Ausführungsform der Erfindung sind mehrere Baugruppen vorgesehen, wobei mindestens eine Baugruppe eine zumindest abschnittsweise im Querschnitt C-förmige Führung und ein Schubstangenelement aufweist und das Schubstangenelement mit einem Schubstangenelement einer benachbarten Baugruppe bewegungsgekoppelt ist. Durch diese Maßnahme kann eine Materialersparnis erzielt werden. Beispielsweise muss die C-förmige Führung sich nicht entlang der gesamten Fenster- oder Türbreite erstrecken. Es ist ausreichend, eine Führung an den Stellen vorzusehen, wo Beschlagteile notwendig sind. Es können Baugruppen für unterschiedliche Einsatzzwecke und Einsatzorte zusammengebaut werden, wobei verschiedene Baugruppen gleiche oder ähnliche Bauteile verwenden können. Insbesondere können in den Eckbereichen des Fensters oder der Türe Endbaugruppen vorgesehen sein und zur Überbrückung größerer Strecken zwischen den Endbaugruppen können Mittelbaugruppen vorgesehen sein, wobei die Schubstangenelemente der Baugruppen über Verbindungselemente bewegungsgekoppelt sind.In a particularly advantageous embodiment of the invention, a plurality of assemblies are provided, wherein at least one assembly has an at least partially cross-sectionally C-shaped guide and a push rod member and the push rod element is coupled in motion with a push rod element of an adjacent module. By this measure, a material savings can be achieved. For example, the C-shaped guide does not have to extend along the entire width of the window or door. It is sufficient to provide a guide at the places where fitting parts are necessary. Assemblies can be assembled for different purposes and locations, with different assemblies can use the same or similar components. In particular, end assemblies may be provided in the corner regions of the window or the door and for bridging larger distances between the end assemblies may be provided intermediate modules, wherein the push rod elements of the assemblies are coupled in motion via connecting elements.

Die Erfindung wird nachfolgend anhand der Figuren der Zeichnung näher erläutert. Es zeigen:

- Fig. 1a

- eine perspektivische Ansicht eines Schubstangenelements und eines Querschieberführungselements einer Baugruppe einer Beschlaganordnung vor der Montage der Baugruppe;

- Fig. 1b

- einen Montageschritt bei der Herstellung der Beschlaganordnung, wobei das Querschieberführungselement an dem Schubstangenelement angeordnet ist;

- Fig. 1c

- die Beschlaganordnung mit an dem Schubstangenelement angeordnetem Verbinder und Querschieber;

- Fig. 1d

- eine Darstellung zur Verdeutlichung der Montage des Schubstangenelements zusammen mit weiteren Beschlagteilen in einer im Querschnitt C-förmigen Führung;

- Fig. 1e

- eine Darstellung zur Verdeutlichung der Montage eines Gleiters;

- Fig. 1f

- eine Draufsicht auf die Rückseite der im Querschnitt C-förmigen Führung zur Verdeutlichung der Montage des Gleiters;

- Fig. 1g

- die fertigmontierte Baugruppe der Beschlaganordnung;

- Fig. 2a

- eine Ansicht einer Baugruppe einer Beschlaganordnung zur Darstellung der Montage eines Laufwagens;

- Fig. 2b

- eine perspektivische Draufsicht auf die Rückseite der Baugruppe zur Darstellung der Montage des Laufwagens;

- Fig. 2c

- eine Ausführungsform einer Baugruppe einer Beschlaganordnung;

- Fig. 3a

- ein Schubstangenelement und ein Querschieberführungselement einer Baugruppe einer Beschlaganordnung vor der Montage;

- Fig. 3b

- das auf das Querschieberführungselement aufgesetzte Schubstangenelement;

- Fig. 3c

- einen Querschieber und einen Längsschieber vor der Anordnung des Querschiebers an dem Querschieberführungselement;

- Fig. 3d

- den an dem Querschieberführungselement angeordneten Querschieber;

- Fig. 3e

- die Anordnung der

Fig. 3d mit zwei daran anzuordnenden Verbindern; - Fig. 3f

- die Anordnung der

Fig. 3d mit daran angeordneten Verbindern; - Fig. 3g

- eine Darstellung zur Verdeutlichung der Montage der Anordnung der

Fig. 3f in einer im Querschnitt C-förmigen Führung; - Fig. 3h

- eine fertigmontierte Mittenbaugruppe einer Beschlaganordnung;

- Fig. 4a

- eine Darstellung zur Verdeutlichung der Montage einer Eckbaugruppe einer Beschlaganordnung mit einer Eckumlenkung;

- Fig. 4b

- die Endbaugruppe der

Fig. 4a mit daran angeordnetem Querschieber und Verbinder; - Fig. 4c

- die Anordnung der

Fig. 4b mit einer im Querschnitt C-förmigen Führung; - Fig. 4d

- die Anordnung der

Fig. 4c mit an der Eckumlenkung angeordnetem Längsschieber; - Fig. 4e

- eine Detaildarstellung des Eckbereichs der Eckumlenkung;

- Fig. 4f

- eine Darstellung der Anordnung der

Fig. 4d mit an dem Längsschieber angebrachtem Querschieber; - Fig. 4g

- eine perspektivische Ansicht zur Darstellung der Verbindung eines Laufwagens;

- Fig. 4h

- eine Ansicht einer fertigmontierten Eckbaugruppe einer Beschlaganordnung;

- Fig. 5

- eine Explosionsdarstellung einer Steuereinheit bestehend aus Längsschieber, Querschieber und Steuerzapfen.

- Fig. 1a

- a perspective view of a push rod member and a cross slide guide element of an assembly of a fitting assembly prior to assembly of the assembly;

- Fig. 1b

- an assembly step in the manufacture of the fitting arrangement, wherein the cross slide guide element is arranged on the push rod element;

- Fig. 1c

- the fitting arrangement with arranged on the push rod element connector and cross slide;

- Fig. 1d

- a representation to illustrate the mounting of the push rod element together with other fitting parts in a cross-sectionally C-shaped guide;

- Fig. 1e

- a representation to illustrate the assembly of a slider;

- Fig. 1f

- a plan view of the back of the cross-sectionally C-shaped guide to illustrate the assembly of the slider;

- Fig. 1g

- the finished assembly of the fitting assembly;

- Fig. 2a

- a view of an assembly of a fitting assembly for illustrating the assembly of a carriage;

- Fig. 2b

- a top perspective view of the back of the assembly to illustrate the assembly of the carriage;

- Fig. 2c

- an embodiment of an assembly of a fitting assembly;

- Fig. 3a

- a push rod member and a cross slide guide member of an assembly of a fitting assembly prior to assembly;

- Fig. 3b

- the push rod element mounted on the cross slide guide element;

- Fig. 3c

- a cross slide and a longitudinal slide before the arrangement of the cross slide on the cross slide guide element;

- Fig. 3d

- the arranged on the cross slide guide element cross slide;

- Fig. 3e

- the arrangement of

Fig. 3d with two connectors to be placed thereon; - Fig. 3f

- the arrangement of

Fig. 3d with connectors arranged thereon; - Fig. 3g

- a representation to illustrate the assembly of the arrangement of

Fig. 3f in a cross-sectionally C-shaped guide; - Fig. 3h

- a finished center assembly of a fitting assembly;

- Fig. 4a

- a representation to illustrate the assembly of a corner assembly of a fitting assembly with a corner drive;

- Fig. 4b

- the end module of

Fig. 4a with cross slide and connector arranged thereon; - Fig. 4c

- the arrangement of

Fig. 4b with a cross-sectionally C-shaped guide; - Fig. 4d

- the arrangement of

Fig. 4c with arranged at the corner guide longitudinal slide; - Fig. 4e

- a detailed representation of the corner of the corner deflection;

- Fig. 4f

- a representation of the arrangement of

Fig. 4d with attached to the longitudinal slide cross slide; - Fig. 4g

- a perspective view illustrating the connection of a carriage;

- Fig. 4h

- a view of a finished corner assembly of a fitting assembly;

- Fig. 5

- an exploded view of a control unit consisting of longitudinal slide, cross slide and control pin.

Anhand der

In der

An dem Beschlagteil 13 ist ein Querschieber 15 über einen Steuerzapfen 16, der in einem Steuerschlitz 17 des Querschiebers 15 geführt ist, gehalten. Beim Aufsetzen des Beschlagteils 13 gelangen als Zapfen ausgebildete Führungsmittel 18, 19 in die als Führungshülsen ausgebildeten Führungsmittel 8, 9. Da das Querschieberführungselement 7 über die Ausrichthilfen 10, 11 bereits richtig zum Schubstangenelement 2 ausgerichtet ist, kommen die Nase 14 und die Führungsmittel 18, 19 bei der Montage ohne weiteres in Eingriff mit der Ausnehmung 4 und den Führungsmitteln 8, 9.At the fitting 13 is a

Weiterhin wird ein als Verbinder ausgebildetes Beschlagteil 20 aufgesetzt. Das Beschlagteil 20 weist ebenfalls eine Nase 21 auf, deren Ausmaße auf die Ausnehmung 3 angepasst sind.Furthermore, designed as a connector

Der Querschieber 15 weist eine als Kerbe ausgebildete Orientierungshilfe 25 auf, die den korrekten Einbau des Querschiebers 15 sicherstellt. Dies ist insbesondere bei unsymmetrischem Steuerschlitz 17 vorteilhaft.The

Aus der

Nach der Einführung in die Führung 28 kann das Querschieberführungselement 7 durch Einklipsen in die Führung 28 befestigt werden. Dafür sind am Halteelement 12 Klipsabschnitte 34, 35 vorgesehen, die durch entsprechenden Druck in zugeordnete Klipsaufnahmen der Führung 28 einrasten. Wird nun das Schubstangenelement 2 in axialer Richtung 36 mit einer Kraft beaufschlagt und dadurch bewegt, wird die Ausrichthilfe 10 abgeschert. Dadurch ist eine Relativbewegung des Schubstangenelements 2 zum Querschieberführungselement 7 möglich.After insertion into the

Die Baugruppe 1 soll in einem oberen Endbereich einer Schiebetüre eingesetzt werden. Deshalb wird noch ein Gleiter 38 montiert. Der Gleiter 38 soll bezüglich der Führung 28 ortsfest angeordnet sein. Weiterhin soll er die axiale Bewegung des Schubstangenelements 2 nicht behindern. Deshalb ist die als Langloch 5 ausgebildete Durchgangsöffnung vorgesehen, durch die der Gleiter 38 mit einem Befestigungsabschnitt 39 hindurchgesteckt werden kann. Rückseitig ist der Gleiter 38 im Ausführungsbeispiel über eine Schraubverbindung 40 befestigt. Um ein Verdrehen des Gleiters 38 zu verhindern, sind Drehsicherungsmittel, die als Zapfen 41, 42 ausgebildet sind, vorgesehen, die in entsprechende Aufnahmen der Führung 28 hineinragen. Über den Verbinder 20 kann das Schubstangenelement 2 mit einem Schubstangenelement einer benachbarten Baugruppe bewegungsgekoppelt werden, indem ein Verbindungselement an benachbarten Verbindern der beiden Baugruppen befestigt wird.The assembly 1 is intended to be used in an upper end region of a sliding door. Therefore, a

In den

In den

Nach dem Einführen der Anordnung wird das Querschieberführungselement 7 mit der Führung 28 verklipst. Dadurch ist das Querschieberführungselement 7 unverschieblich an der Führung 28 gehalten. In diesem Zustand sind das Querschieberführungselement 7 und das Schubstangenelement 2 über die als Verschiebesicherung wirkenden Ausrichthilfen 10, 11 zueinander unbeweglich. Dies bedeutet, dass die Position des Schubstangenelementes 2 festgelegt ist. Es kann sich nicht ungewollt verstellen und die Bauteile 20, 20a, 13 können nicht "herausfallen", da das Schubstangenelement 2 nicht aus der Führung 28 rutschen kann. Erst, wenn die Baugruppen 60 beispielsweise in einer Beschlagteilnut eines Flügelrahmens montiert ist, werden die Bauteile 20, 20a über ein starres Verbindungselement mit einer benachbarten Baugruppe 60 verbunden. Durch die Verschiebesicherung wird sichergestellt, dass beim Verbinden benachbarter Bauteile 20, 20a benachbarter Baugruppen 60 die Führungsmittel 8, 9 mittig in den Durchgangsöffnungen 6, 6a angeordnet sind. Erst, wenn alle benachbarten als Verbinder ausgebildete Bauteile 20, 20a bewegungsgekoppelt sind, wird die Verschiebesicherung zerstört.After insertion of the arrangement, the cross slide guide element 7 is clipped to the

In den

In der

Claims (15)

- Fitting assembly of a window, a door or the like, having a guide (28), which is formed with a C-shaped cross-section at least in portions and which comprises side pieces (29, 30) projecting from the groove flanks at a spacing from the guide bottom (33), having a push rod element (2), which is guided by the guide (28) and at least one fitting part (13, 20, 20a), which is coupled in terms of movement to the push rod element (2), wherein the push rod element (2) comprises at least one recess (3, 4) and the fitting part (13, 20, 20a) comprises at least one projection (14, 21, 21a) projecting into the recess (3, 4), and wherein the fitting part (13, 20, 20a) is coupled in terms of movement to the push rod element (2) via the projection (14, 21, 21a) and the recess (3, 4), characterised in that at least one side piece portion of the side pieces (29, 30) engage(s) behind both the push rod element (2) and the projection (14, 21, 21a).

- Fitting assembly according to Claim 1, characterised in that the thickness of the projection (14, 21, 21a) corresponds approximately to the thickness of the push rod element (2).

- Fitting assembly according to Claim 1 or 2, characterised in that the dimensions of the projection (14, 21, 21a) are adapted to the recess (3, 4).

- Fitting assembly according to any one of the preceding Claims, characterised in that a cross slide guide element (7) is provided which, together with the push rod element (2), can be assembled in the guide (28) with a C-shaped cross-section at least in portions.

- Fitting assembly according to Claim 4, characterised in that the cross slide guide element (7) is disposed with a retaining portion (12) behind the push rod element (2), can be fastened to the guide (28) and reaches with at least one guide means (8, 9) for a cross slide (15) through a through-opening (6, 6a) of the push rod element (2).

- Fitting assembly according to Claim 4 or 5, characterised in that the cross slide guide element (7) is clipped into the guide (28) with a C-shaped cross-section at least in portions.

- Fitting assembly according to any one of the preceding Claims, characterised in that the cross slide guide element (7) comprises an alignment aid (10) for the purpose of alignment relative to the push rod element (2) during assembly of the fitting assembly.

- Fitting assembly according to Claim 7, characterised in that the alignment aid (10) interacts with a corresponding alignment aid (11) of the push rod element (2) and forms a displacement lock in order to prevent an axial displacement of the cross slide guide element (7) relative to the push rod element during assembly.

- Fitting assembly according to Claim 8, characterised in that the displacement lock is destructible, with one of the alignment aids (10, 11) in particular being formed such that it can be sheared off.

- Fitting assembly according to any one of the preceding Claims, characterised in that a cross slide (15) is provided which is retained at the push rod element (2) via a component (13) formed as a longitudinal slide and a control pin (16).

- Fitting assembly according to Claim 10, characterised in that the cross slide (15) and/or the longitudinal slide (13) comprise(s) an orientation aid (25).

- Fitting assembly according to any one of the preceding Claims, characterised in that a slider (38) or a carriage (51) is fastened to the guide (28) with a C-shaped cross-section at least in portions.

- Fitting assembly according to Claim 12, characterised in that the carriage (51) or the slider (38) is fastened, in particular screwed or clipped, to the guide (28).

- Fitting assembly according to any one of the preceding Claims, characterised in that at least one corner transmission (71) is provided which is connected to the push rod element (2).

- Fitting assembly according to any one of the preceding Claims, characterised in that a plurality of sub-units (1, 50, 60, 70) are provided, wherein at least one sub-unit comprises a guide (28) with a C-shaped cross-section at least in portions and a push rod element (2), and the push rod element (2) is coupled in terms of movement to a push rod element (2) of an adjacent sub-unit (1, 50, 60, 70).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL05017157T PL1635019T5 (en) | 2004-09-11 | 2005-08-06 | Fitting assembly for a window, a door or the like |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102004043942A DE102004043942A1 (en) | 2004-09-11 | 2004-09-11 | Fitting arrangement for a window, a door or the like |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP1635019A2 EP1635019A2 (en) | 2006-03-15 |

| EP1635019A3 EP1635019A3 (en) | 2006-04-12 |

| EP1635019B1 EP1635019B1 (en) | 2007-10-17 |

| EP1635019B2 true EP1635019B2 (en) | 2013-10-23 |

Family

ID=35482598

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05017157.8A Active EP1635019B2 (en) | 2004-09-11 | 2005-08-06 | Fitting assembly for a window, a door or the like |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1635019B2 (en) |

| AT (1) | ATE376112T1 (en) |

| DE (2) | DE102004043942A1 (en) |

| PL (1) | PL1635019T5 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11866968B2 (en) * | 2019-09-17 | 2024-01-09 | Truth Hardware Corporation | Tie bar and guide for casement window |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2217458C2 (en) † | 1971-04-15 | 1982-06-03 | Manfred 4972 Löhne Mühle | Fitting for windows, doors or the like. with a holder for operating rails |

| DE29920094U1 (en) † | 1999-11-15 | 2000-02-10 | Siegenia-Frank Kg, 57074 Siegen | Fitting of an at least fixable, but preferably also movable wing of a window or a door |

| EP1002919B1 (en) † | 1998-11-20 | 2002-11-27 | Siegenia-Frank Kg | Espagnolette for windows, doors or the like |

| EP1219768B1 (en) † | 2000-12-13 | 2004-04-28 | Euroinvest S.r.L. | Mechanical junction assembly for perimetrical locking device of wings of burglarproof doors and windows made of metallic profiles |

| EP1447505A2 (en) † | 2001-01-29 | 2004-08-18 | van Parys, Remi Emiel | Fitting for a window |

| DE10345758A1 (en) † | 2003-10-01 | 2005-04-21 | Wicona Bausysteme Gmbh | Method for fitting cover plate over control bar in door or window frame with fasteners set through slots in bar and secured without creating swarf |

| EP1491706B1 (en) † | 2003-06-27 | 2006-11-02 | SAVIO S.p.A. | Transmission rod for accessories for windows and doors |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH437727A (en) * | 1964-10-21 | 1967-06-15 | Gretsch Unitas Gmbh | Sash frame with a longitudinally movable rail in at least one frame strip |

| AT373342B (en) * | 1974-05-30 | 1984-01-10 | Winkhaus Fa August | FASTENING ANGLE OF A PUSHBAR CORNER DRIVE |

| DE2426030C2 (en) * | 1974-05-30 | 1986-09-11 | Winkhaus, August, 4404 Telgte | Opening device for a tilt and turn window |

| DE3525705A1 (en) * | 1985-07-18 | 1987-01-22 | Winkhaus Fa August | PAIRING LOCKING ELEMENTS ON A WINDOW OF A DOOR OR THE LIKE |

| FR2747150B1 (en) * | 1996-04-04 | 1998-08-07 | Ferco Int Usine Ferrures | CREMONE OR CREMONE-LOCK, ESPECIALLY OF THE MULTIPOINT TYPE |

| DE59912748D1 (en) * | 1998-03-25 | 2005-12-15 | Siegenia Aubi Kg | Hardware for windows or doors |

-

2004

- 2004-09-11 DE DE102004043942A patent/DE102004043942A1/en not_active Withdrawn

-

2005

- 2005-08-06 PL PL05017157T patent/PL1635019T5/en unknown

- 2005-08-06 AT AT05017157T patent/ATE376112T1/en active

- 2005-08-06 EP EP05017157.8A patent/EP1635019B2/en active Active

- 2005-08-06 DE DE502005001709T patent/DE502005001709D1/en active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2217458C2 (en) † | 1971-04-15 | 1982-06-03 | Manfred 4972 Löhne Mühle | Fitting for windows, doors or the like. with a holder for operating rails |

| EP1002919B1 (en) † | 1998-11-20 | 2002-11-27 | Siegenia-Frank Kg | Espagnolette for windows, doors or the like |

| DE29920094U1 (en) † | 1999-11-15 | 2000-02-10 | Siegenia-Frank Kg, 57074 Siegen | Fitting of an at least fixable, but preferably also movable wing of a window or a door |

| EP1219768B1 (en) † | 2000-12-13 | 2004-04-28 | Euroinvest S.r.L. | Mechanical junction assembly for perimetrical locking device of wings of burglarproof doors and windows made of metallic profiles |

| EP1447505A2 (en) † | 2001-01-29 | 2004-08-18 | van Parys, Remi Emiel | Fitting for a window |

| EP1491706B1 (en) † | 2003-06-27 | 2006-11-02 | SAVIO S.p.A. | Transmission rod for accessories for windows and doors |

| DE10345758A1 (en) † | 2003-10-01 | 2005-04-21 | Wicona Bausysteme Gmbh | Method for fitting cover plate over control bar in door or window frame with fasteners set through slots in bar and secured without creating swarf |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1635019A3 (en) | 2006-04-12 |

| PL1635019T3 (en) | 2008-03-31 |

| DE502005001709D1 (en) | 2007-11-29 |

| DE102004043942A1 (en) | 2006-03-30 |

| PL1635019T5 (en) | 2014-03-31 |

| ATE376112T1 (en) | 2007-11-15 |

| EP1635019A2 (en) | 2006-03-15 |

| EP1635019B1 (en) | 2007-10-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3165703A2 (en) | Lowerable seal device | |

| DE2313690A1 (en) | DRIVE ROD FITTINGS FOR WINDOWS, DOORS OR DGL | |

| EP0582258B1 (en) | Fastening device | |

| EP3266969B1 (en) | Corner deflection of a fitting for a wing of a window or a door | |

| EP0843064B1 (en) | Fitting for a window | |

| EP1635019B2 (en) | Fitting assembly for a window, a door or the like | |

| DE202008004032U1 (en) | Window or door | |

| EP1264954B1 (en) | Locking device | |

| EP1746235B1 (en) | Fitting assembly | |

| EP2754803B1 (en) | Espagnolette fitting for a window or door and driving rod for such an espagnolette fitting | |

| EP3535824B1 (en) | Busbar holder and corresponding assembly | |

| EP4146888A1 (en) | Hinge assembly with common actuation | |

| DE3225049C2 (en) | Espagnolette lock | |

| DE19859546A1 (en) | Slide rod fixing and guide element for window rods is resilient with detent elements on outside to lock in window socket | |

| EP0833028B1 (en) | Sliding guide end stop for window or door stay | |

| EP3599335B1 (en) | Lowerable seal, in particular for sliding doors | |

| EP2317047A2 (en) | Fitting device | |

| EP1580370B1 (en) | Fitting assembly | |

| WO2015074933A1 (en) | Holding device for a housing and method for mounting the housing using the holding device | |

| EP1626150B1 (en) | Sealing arrangement | |

| EP4074931B1 (en) | Fitting with a locking hook which can be locked by longitudinal sliding | |

| EP1580371B1 (en) | Fitting assembly | |

| DE102021125772B4 (en) | Spacer, guide rail for a venetian blind or venetian blind and venetian blind and blind and method therefor | |

| DE2461228A1 (en) | Window locking mechanism actuator rod - is connected to corner connectors by detachable connection involving pins and holes | |

| DE102004043973B3 (en) | Method for connecting assemblies of a fitting arrangement in a fitting part of a door or window sash |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK YU |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK YU |

|

| 17P | Request for examination filed |

Effective date: 20060810 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502005001709 Country of ref document: DE Date of ref document: 20071129 Kind code of ref document: P |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080128 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080117 |

|

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080317 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080117 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071017 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071017 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080217 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071017 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071017 |

|

| 26 | Opposition filed |

Opponent name: SIEGENIA-AUBI KG Effective date: 20080711 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071017 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071017 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071017 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20080828 Year of fee payment: 4 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: SIEGENIA-AUBI KG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071017 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080118 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20080725 Year of fee payment: 4 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071017 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20080908 Year of fee payment: 4 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071017 |

|